Potassium-sodium niobate-based lead-free piezoelectric ceramic with gradient components and preparation method thereof

A potassium sodium niobate-based, lead-free piezoelectric technology, applied in the manufacture/assembly of piezoelectric/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, circuits, etc., can solve environmental and human problems. Health hazards, restrictions on the wide application of ceramics, poor temperature stability of piezoelectric and strain properties, etc., to meet environmental protection requirements, facilitate industrial production, and have good stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

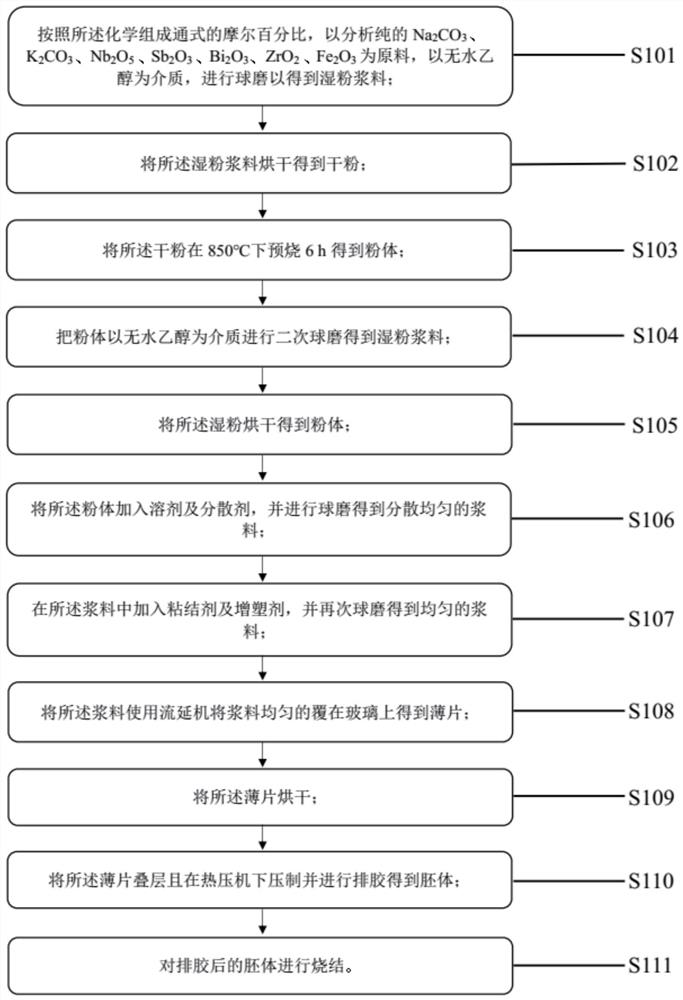

[0060] figure 1 It is a schematic flow chart of the casting preparation method of composition gradient potassium sodium niobate-based lead-free piezoelectric ceramics provided by the second embodiment of the present invention. Such as figure 1 As shown, the preparation method of the sodium potassium niobate-based lead-free piezoelectric ceramics comprises the following steps:

[0061] Step S101, according to the mole percentage in the chemical composition general formula of the above-mentioned first embodiment, to analyze pure Na 2 CO 3 、K 2 CO 3 , Nb 2 o 5 , Sb 2 o 3 、 Bi 2 o 3 , ZrO 2 , Fe 2 o 3 As a raw material, ball milling is carried out with anhydrous ethanol as a medium to obtain a wet powder slurry.

[0062] Specifically, the pure Na will be analyzed according to the molar percentage of the general chemical composition formula 2 CO 3 、K 2 CO 3 , Nb 2 o 5 , Sb 2 o 3 、 Bi 2 o 3 , ZrO 2 , Fe 2 o 3 As a raw material, using absolute ethanol as a ...

Embodiment 1

[0092] The chemical composition of the piezoelectric ceramic of embodiment 1 is:

[0093] 0.99K 0.48 Na 0.52 Nb 0.955 8b 0.045 o 3 -0.01Bi 0.5 Na 0.5 ZrO 3 -0.2mol%Fe 2 o 3 , x is 0.01.

[0094] The preparation method of the piezoelectric ceramic is as follows:

[0095] (1) Take by weighing analytically pure 2.7602g Na 2 CO 3 , 3.3170g K 2 CO 3 , 12.5718g Nb 2 o 5 , 0.6494gSb 2 o 3 , 0.1165g Bi 2 o 3 , 0.1245g ZrO 2 , 0.0323g Fe 2 o 3 As raw material, carry out batching.

[0096] (2) Use absolute ethanol as the medium for the weighed raw materials, planetary ball mill for 12 hours, and then dry to obtain a uniformly mixed dry powder, and then pre-calcine the obtained dry powder at 850° C. for 6 hours.

[0097] (3) The pre-burned powder is dried with anhydrous ethanol as a medium, and then ball-milled by a planetary ball mill for 12 hours to obtain a powder.

[0098] (4) Add the above-mentioned powder to absolute ethanol and triethanolamine and perform ...

Embodiment 2

[0100] The chemical composition of the piezoelectric ceramic of embodiment 2 is:

[0101] 0.98K 0.48 Na 0.52 Nb 0.955 Sb 0.045 o 3 -0.02Bi 0.5 Na 0.5 ZrO 3 -0.2mol%Fe 2 o 3 , that is, x is 0.02.

[0102] The preparation method of the piezoelectric ceramic is the same as that of Example 1, and the similarities will not be described again. The difference is that the quality of the raw materials is weighed and prepared according to the chemical formula in Example 2 to obtain dry flakes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| piezoelectric charge coefficient | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com