High-piezoelectric-property and high-stability anti-reduction potassium-sodium niobate-based leadless piezoelectric ceramic and preparation method thereof

A potassium sodium niobate-based, lead-free piezoelectric technology, applied in the field of lead-free piezoelectric ceramic materials, can solve problems such as disadvantage, high price, and lower device cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

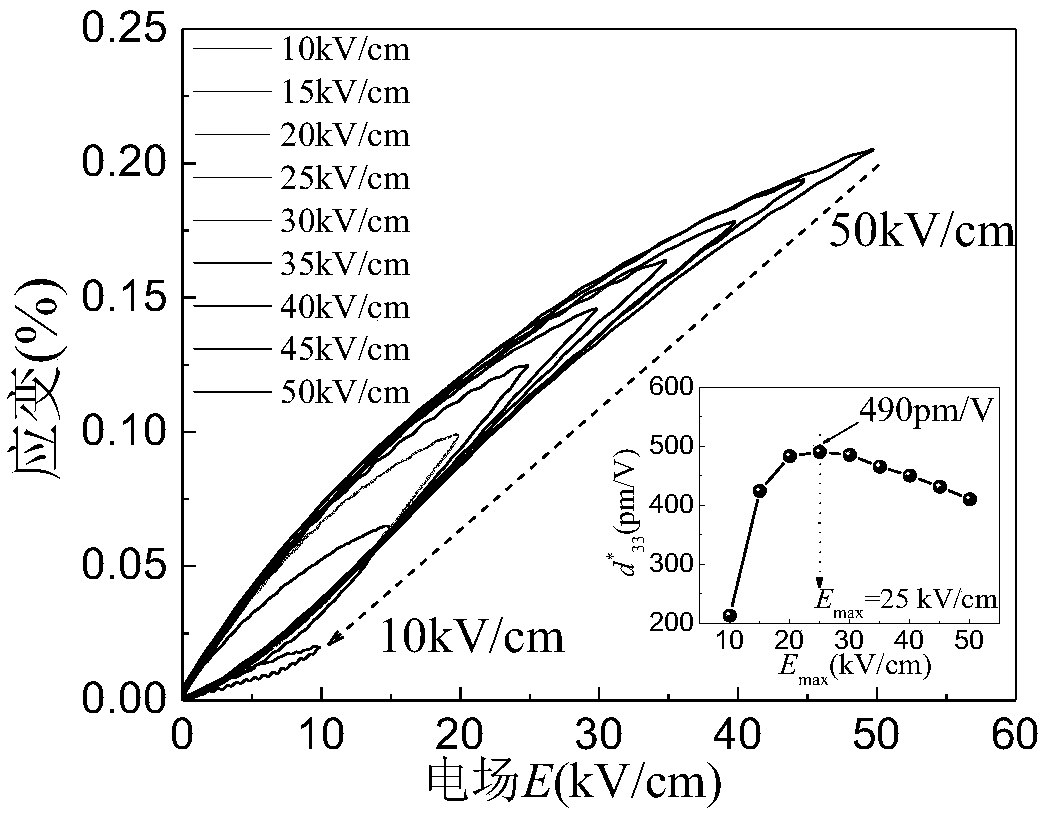

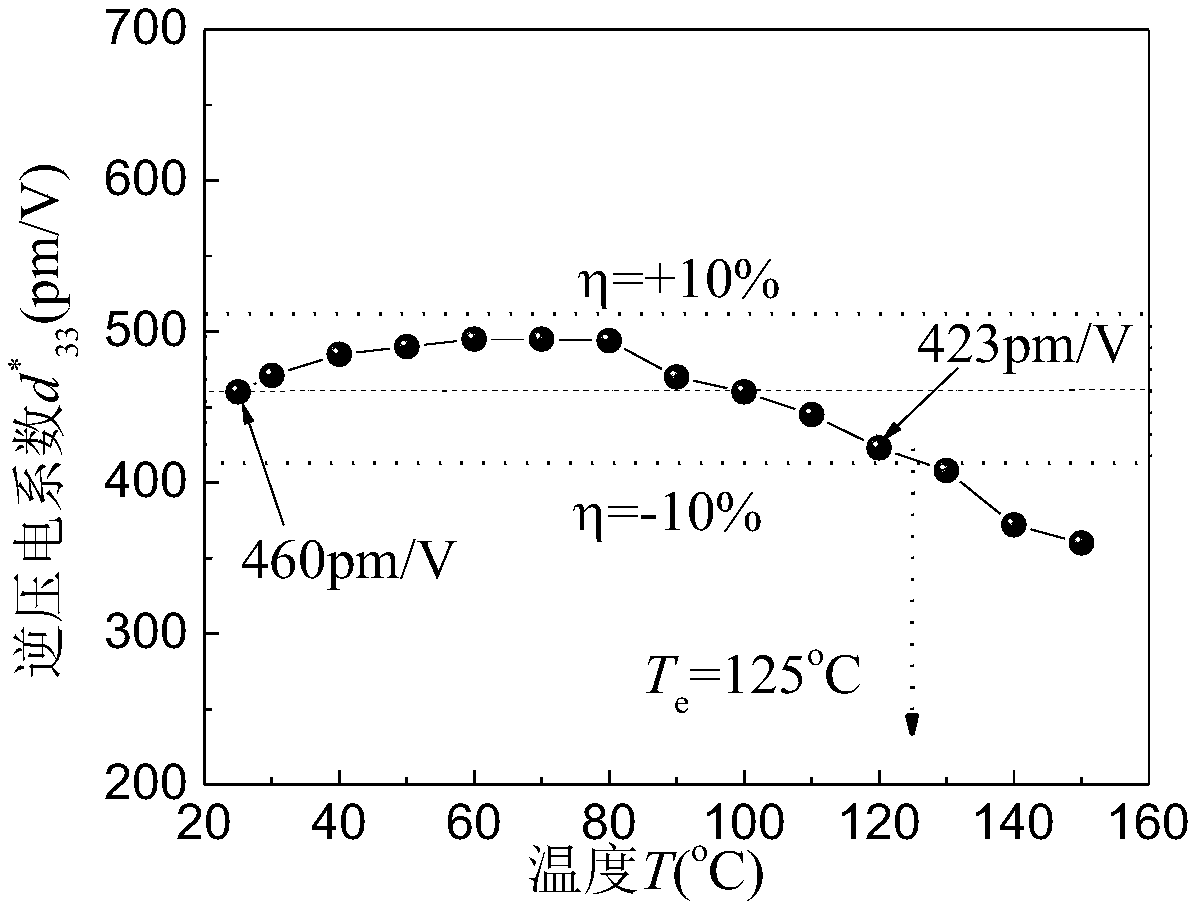

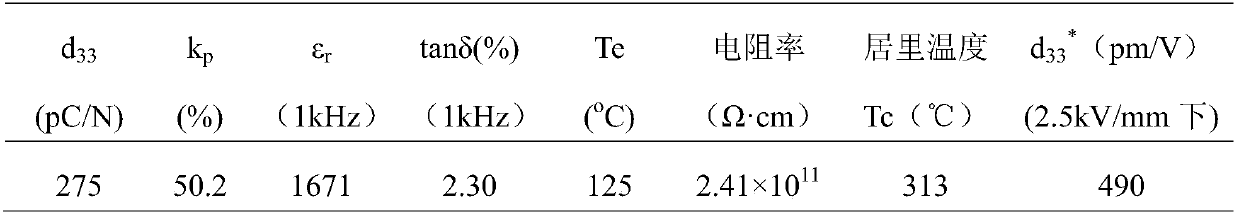

[0065] Example 1. Preparation of Potassium Sodium Niobate-Based Lead-Free Piezoelectric Ceramics

[0066] The composition expression of potassium sodium niobate-based lead-free piezoelectric ceramics in this embodiment is as follows:

[0067] 0.99[0.96K 0.5 Na 0.5 Nb 0.98 Ta 0.02 o 3 -0.04Bi 0.5 (Na 0.82 K 0.18 ) 0.5 ZrO 3 ]-0.01CaZrO 3 +0.3%MnCO 3 ; Prepared according to the following steps:

[0068] (1) Wet grinding, drying and firing:

[0069] To analyze pure Na 2 CO 3 、K 2 CO 3 , Nb 2 o 5 , ZrO 2 、 Bi 2 o 3 、 Ta 2 o 5 , CaCO 3 and MnCO 3 As the raw material, mix according to the above chemical formula, use absolute ethanol (about 150mL, that is, 14 times the mass of the powder) as the medium for planetary ball milling for 24 hours (300 rpm), and dry (temperature 80°C, time is 4h) and then calcined at 850°C for 5 hours;

[0070] (2) Secondary ball milling, granulation, compression molding, debinding and sintering:

[0071] The ceramic material ob...

Embodiment 2

[0077] Example 2, preparation of potassium sodium niobate based lead-free piezoelectric ceramics

[0078] The composition expression of potassium sodium niobate base lead-free piezoelectric ceramics in the present embodiment is as follows: 0.987[0.96K 0.5 Na 0.5 Nb 0.96 Ta 0.04 o 3 -0.04Bi 0.5 (Na 0.82 K 0.18 ) 0.5 ZrO 3 ]-0.013CaZrO 3 +0.4%MnO 2 Prepared according to the following steps:

[0079] To analyze pure Na 2 CO 3 、K 2 CO 3 , Nb 2 o 5 , ZrO 2 、 Bi 2 o 3 、 Ta 2 o 5 , CaCO 3 and MnO 2 Be raw material, carry out batching according to above-mentioned expression, all the other steps are with embodiment 1.

[0080] The experimental results are shown in Table 2.

[0081] Table 2 Example 2 Potassium sodium niobate-based lead-free piezoelectric ceramic properties

[0082]

[0083]

Embodiment 3

[0084] Example 3, preparation of potassium sodium niobate based lead-free piezoelectric ceramics

[0085] The composition expression of potassium sodium niobate base lead-free piezoelectric ceramics in the present embodiment is as follows: 0.985[0.96K 0.5 Na 0.5 Nb 0.99 Ta 0.01 o 3 -0.04Bi 0.5 (Na 0.82 K 0.18 ) 0.5 ZrO 3 ]-0.015CaZrO 3 +0.4% MnO, prepared according to the following steps:

[0086] To analyze pure Na 2 CO 3 、K 2 CO 3 , Nb 2 o 5 , ZrO 2 、 Bi 2 o 3 、 Ta 2 o 5 , CaCO 3 And MnO is raw material, carries out batching according to above-mentioned expression, all the other steps are with embodiment 1.

[0087] The experimental results are shown in Table 3.

[0088] Table 3 Example 3 Potassium sodium niobate-based lead-free piezoelectric ceramic properties

[0089]

PUM

| Property | Measurement | Unit |

|---|---|---|

| piezoelectric charge coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com