Potassium-sodium niobate based oxide up-conversion luminescent material and preparation method thereof

A potassium-sodium niobate-based, luminescent material technology, applied in the direction of luminescent materials, chemical instruments and methods, to achieve the effect of broadening the application field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

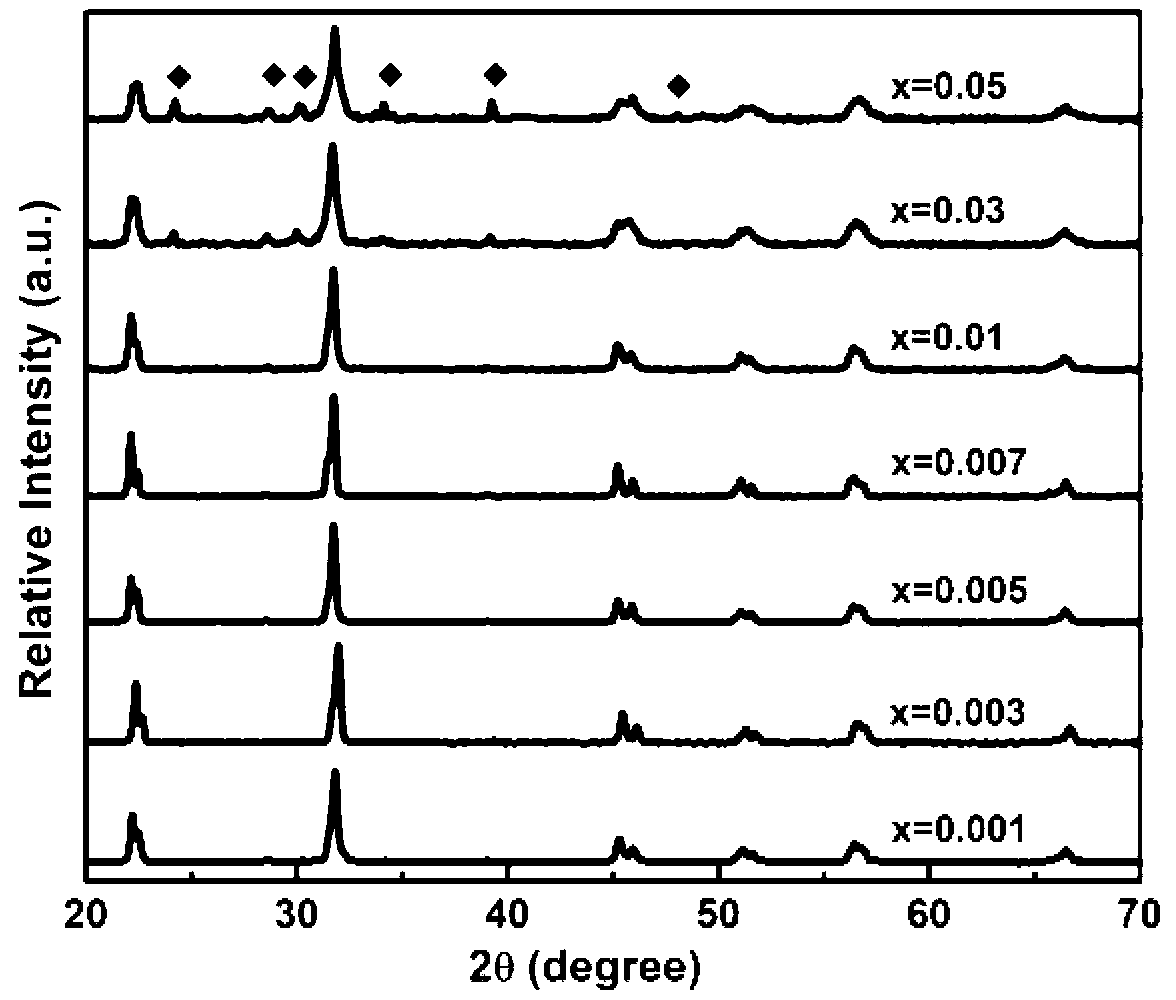

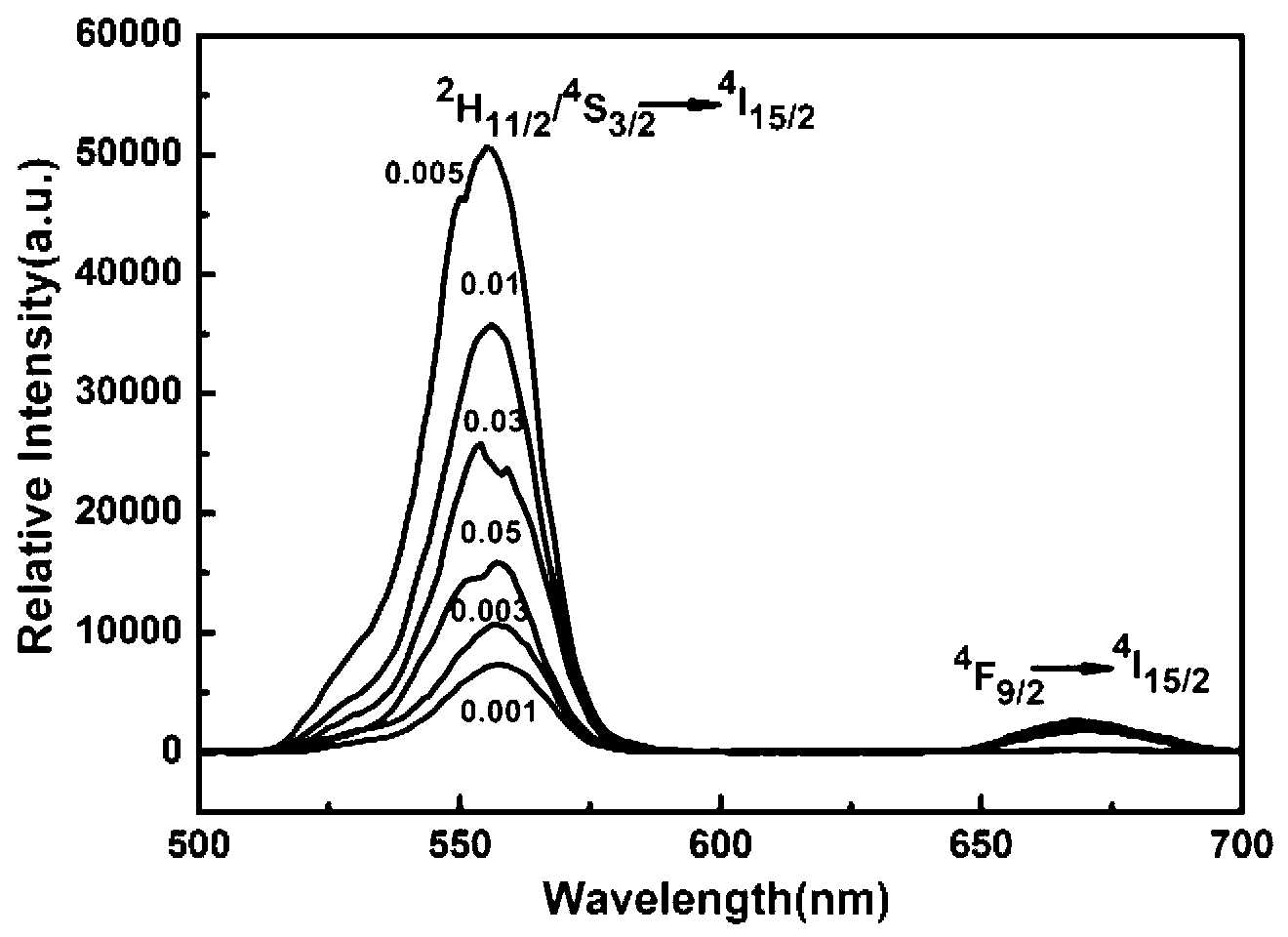

[0028] Preparation (Na 0.5 K 0.5 ) 1-x Er x NbO 3 Up-conversion luminescent material, where x=0.001, 0.003, 0.005, 0.007, 0.01, 0.03, 0.05.

[0029] Select raw material Na 2 CO 3 、K 2 CO 3 、Er 2 o 3 and Nb 2 o 5 , according to the formula (Na 0.5 K 0.5 ) 1-x Er x NbO 3 The stoichiometric ratios of the corresponding elements in the formula were weighed respectively, and the weighed raw materials were put into a ball mill jar, added with absolute ethanol and zirconia balls, milled on the ball mill for 24 hours, and dried with absolute ethanol to obtain a ball mill. . Pre-fire the ball abrasive in an alumina crucible, the pre-fire temperature is 880°C, the heating rate is 3°C / min, keep warm for 6 hours and cool naturally to get the pre-fired powder, grind the pre-fired powder and add anhydrous Ethanol and zirconia balls are ball-milled for 24 hours and dried, then sintered in the temperature range of 1100-1200°C, with a heating rate of 3°C / min, kept for 4 hours,...

Embodiment 2

[0035] Preparation (Na 0.5 K 0.5 ) 0.995-z Er 0.005 Yb z NbO 3 , where z=0.1, 0.2, 0.35.

[0036] Raw material selection Na 2 CO 3 、K 2 CO 3 、Er 2 o 3 , Yb 2 o 3 and Nb 2 o 5 , according to the formula (Na 0.5 K 0.5 ) 0.995 Er 0.005 Yb z NbO 3 Carry out element proportioning and weigh the selected raw materials, put the raw materials into a ball mill tank, add absolute ethanol and zirconia balls, mill on the ball mill for 24 hours, discharge and dry with absolute ethanol to obtain a ball mill. Pre-fire the ball abrasive in an alumina crucible, the pre-fire temperature is 880°C, the heating rate is 3°C / min, keep warm for 6 hours and cool naturally to get the pre-fired powder, grind the pre-fired powder and add anhydrous Ethanol and zirconia balls are ball-milled for 24 hours and dried, then sintered in the temperature range of 1100-1200°C, with a heating rate of 3°C / min, kept for 4 hours, cooled naturally and ground to obtain a powder, which is The up-conv...

Embodiment 3

[0039] Preparation (Na 0.5+δ K 0.5-y A y ) 1-x-z m x Yb z NbO 3 : φC, where φ=0.1, z=0.25, x=0.15, y=0.2; δ=0.1, M is Ho 3+ , A is Li, and C is Li.

[0040] Raw material selection Na 2 CO 3 、K 2 CO 3 、Ho 2 o 3 , Yb 2 o 3 , Nb 2 o 5 and Li 2 CO 3 , according to the formula (Na 0.6 K 0.3 Li 0.2 ) 0.6 Ho 0.15 Yb 0.25 NbO 3 : 0.1 Li to carry out the element ratio and weigh the selected raw materials, put into the ball mill tank after weighing the raw materials, add absolute ethanol and zirconia balls, ball mill on the ball mill for 24 hours, discharge and dry with absolute ethanol to obtain the ball mill. Pre-fire the ball abrasive in an alumina crucible, the pre-fire temperature is 880°C, the heating rate is 3°C / min, keep warm for 6 hours and cool naturally to get the pre-fired powder, grind the pre-fired powder and add anhydrous Ethanol and zirconia balls are ball-milled for 24 hours and dried, then sintered in the temperature range of 1100-1200°C, with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com