Ultraviolet fluorescence up-conversion material and preparation method and application thereof

A conversion material and fluorescence technology, applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve the problems of weak luminescence, low up-conversion efficiency, and restrictions on the practical application of rare-earth-doped up-conversion materials, and achieve cheap raw materials and simple synthesis methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

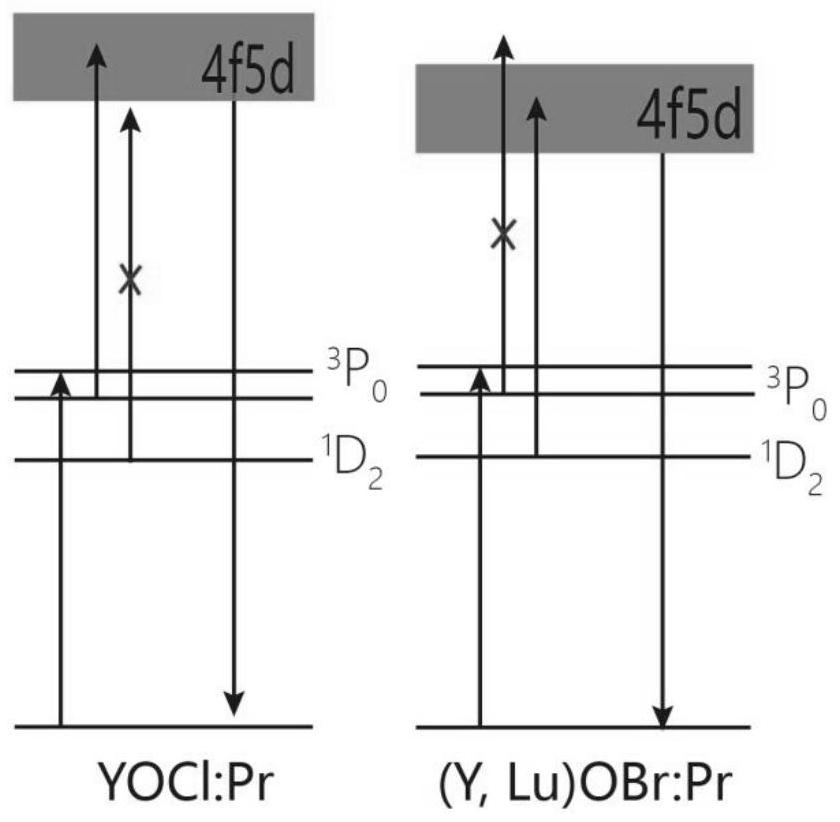

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] 0.2g Y 2 o 3 with 0.25g NH 4 Cl mixed and ground evenly, add 0.01g Li 2 CO 3 Continue grinding and mixing with 0.05g KCl, then add 0.0029g Pr 2 o 3 Continue to grind and mix evenly to obtain mixed powder. Mix the powder in 95%Ar-5%H 2 In a reducing atmosphere, the temperature was raised from room temperature to 200°C at a rate of 5°C / min for 1 hour, the temperature was raised to 500°C at a rate of 5°C / min for 1 hour, and the temperature was raised to 720°C for 1 hour at a rate of 5°C / min. UV Fluorescence Upconversion Material YOCl:Pr 3+ .

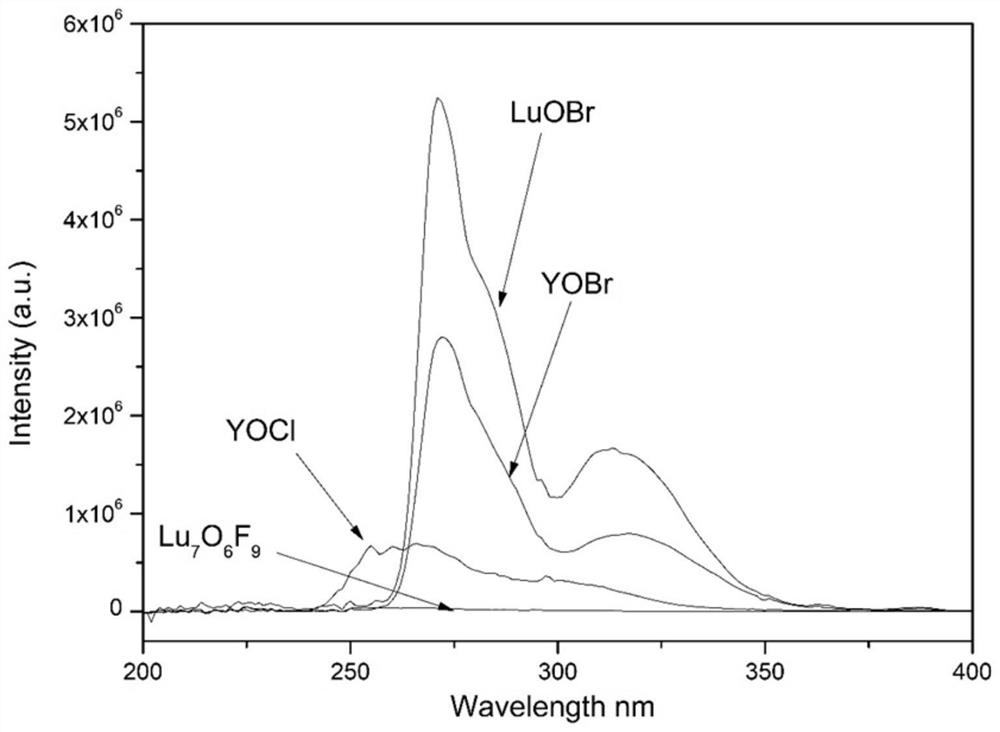

[0051] The ultraviolet fluorescent up-conversion material YOCl:Pr that this embodiment prepares 3+ The upconversion luminescence under the excitation of 450nm wavelength is as follows figure 2 shown.

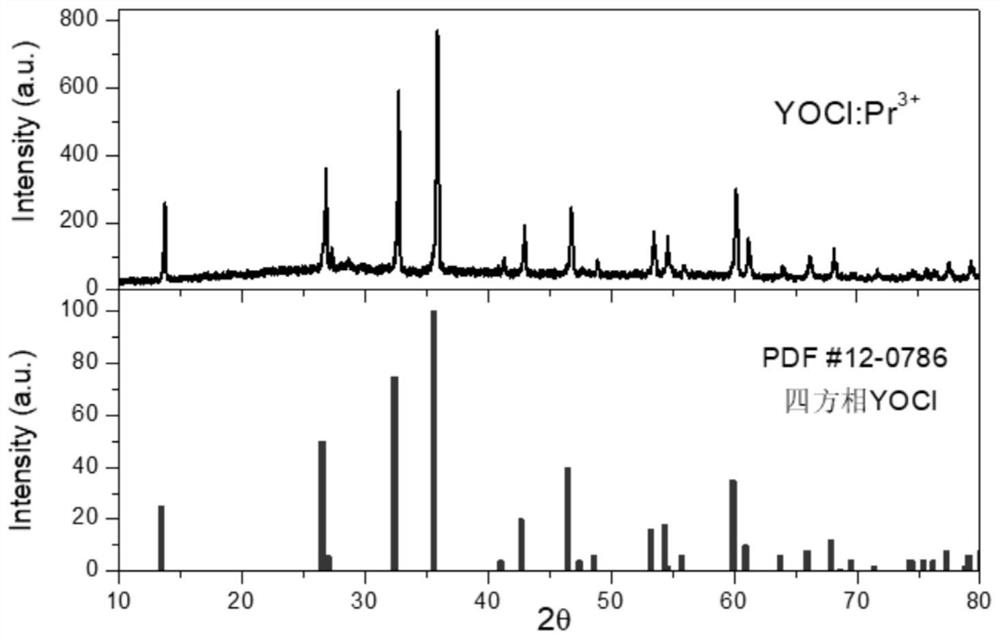

[0052] The ultraviolet fluorescent up-conversion material YOCl:Pr prepared in this embodiment 3+ The X-ray diffraction patterns and scanning electron microscope pictures are as follows image 3 , Figure 4 As shown, it c...

Embodiment 2

[0054] 0.2g Y 2 o 3 with 0.3g NH 4 Mix and grind Br evenly, add 0.008g Li 2 CO 3 Continue grinding and mixing with 0.05g KBr, then add 0.0029g Pr 2 o 3 Continue to grind and mix evenly to obtain mixed powder. Mix the powder in 95%Ar-5%H 2 In a reducing atmosphere, the temperature was raised from room temperature to 240°C at a rate of 10°C / min for 1 hour, the rate was raised to 380°C for 1 hour at a rate of 5°C / min, and the temperature was raised to 650°C for 1 hour at a rate of 5°C / min. Ultraviolet Fluorescence Upconversion Material YOBr:Pr 3+ .

[0055] The ultraviolet fluorescent up-conversion material YOBr that this embodiment prepares: Pr 3+ The upconversion luminescence under the excitation of 450nm wavelength is as follows figure 2 shown.

[0056] The ultraviolet fluorescent up-conversion material YOBr:Pr prepared in this embodiment 3+ The X-ray diffraction patterns and scanning electron microscope pictures are as follows Figure 5 , Image 6 As shown, it ...

Embodiment 3

[0058] 0.3g Lu 2 o 3 with 0.3g NH 4 Mix and grind Br evenly, add 0.008g Li 2 CO 3 Continue grinding and mixing with 0.05g KBr, then add 0.0024g Pr 2 o 3 Continue to grind and mix evenly to obtain mixed powder. Mix the powder in 95%Ar-5%H 2 In a reducing atmosphere, the temperature was raised from room temperature to 300°C at a rate of 10°C / min for 1 hour, the rate was raised to 500°C for 1 hour at a rate of 5°C / min, and the temperature was raised to 830°C for 1 hour at a rate of 5°C / min. UV Fluorescence Upconversion Material LuOBr:Pr 3+ .

[0059] The ultraviolet fluorescent up-conversion material LuOBr that this embodiment prepares: Pr 3+ The upconversion luminescence under the excitation of 450nm wavelength is as follows figure 2 shown.

[0060] The ultraviolet fluorescent up-conversion material LuOBr that this embodiment prepares: Pr 3+ The X-ray diffraction pattern of Figure 7 shown by Figure 7 It can be seen that the ultraviolet fluorescent up-conversion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com