Bismuth ferrite-based piezoelectric ceramic material with high depolarization temperature and high piezoelectric property, and preparation method thereof

A technology of depolarization temperature and bismuth ferrite, which is applied in the field of functional ceramics, can solve the problems of not being able to meet the requirements of high depolarization temperature and high-voltage electrical performance at the same time, achieve broad industrial application prospects, low preparation cost, and a preparation method simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The preparation method of the above-mentioned bismuth ferrite-based piezoelectric ceramic material comprises the following steps:

[0038] 1) Bi with a purity greater than 99% 2 o 3 , Fe 2 o 3 , PbO, BaCO 3 、TiO 2 It is used as the raw material of bismuth ferrite-based piezoelectric ceramic material and mixed according to the stoichiometric ratio, then mixed with absolute ethanol and zirconia balls and subjected to a ball mill for 10-14 hours, and after drying, the dried powder is obtained;

[0039] 2) Put the dried powder in a muffle furnace, and pre-burn it at 750°C for more than 5 hours (preferably 5 hours), to obtain the pre-fired powder;

[0040] 3) Combine the calcined powder with MnO 2 , anhydrous ethanol and zirconia balls are mixed and subjected to secondary ball milling for 12 hours. After the material is discharged and dried, it is mixed with 5wt% polyvinyl alcohol solution (PVA) to granulate. After sieving, it is pressed under a molding pressure of 7MP...

Embodiment 1

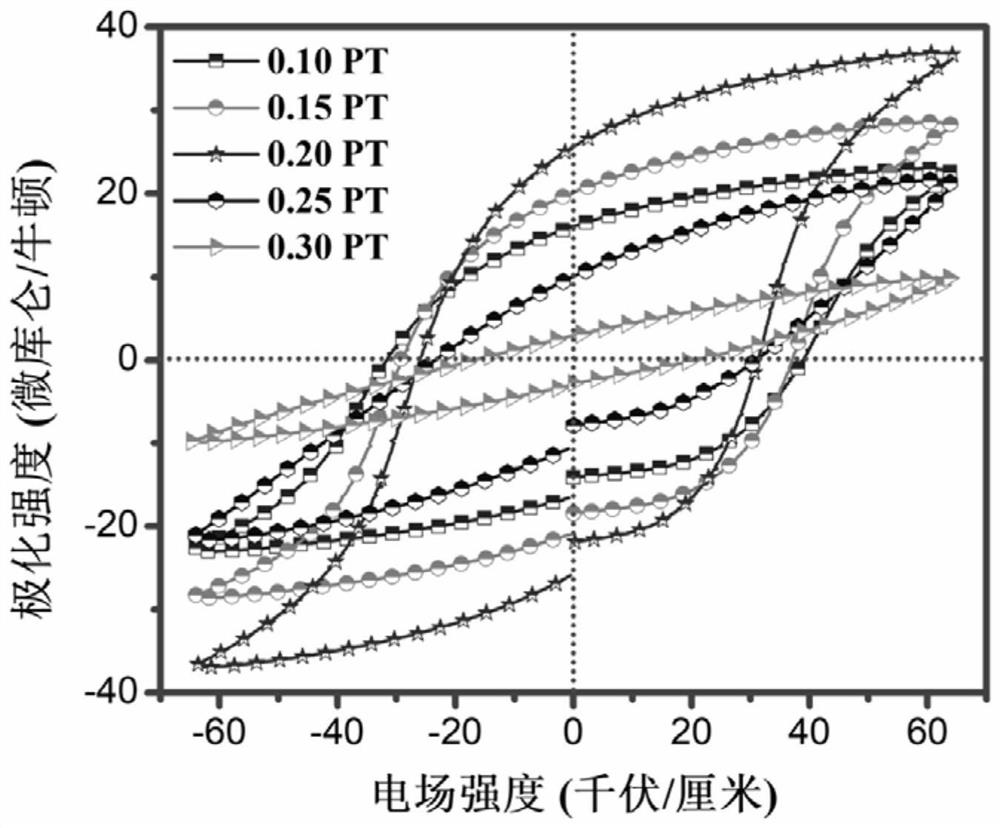

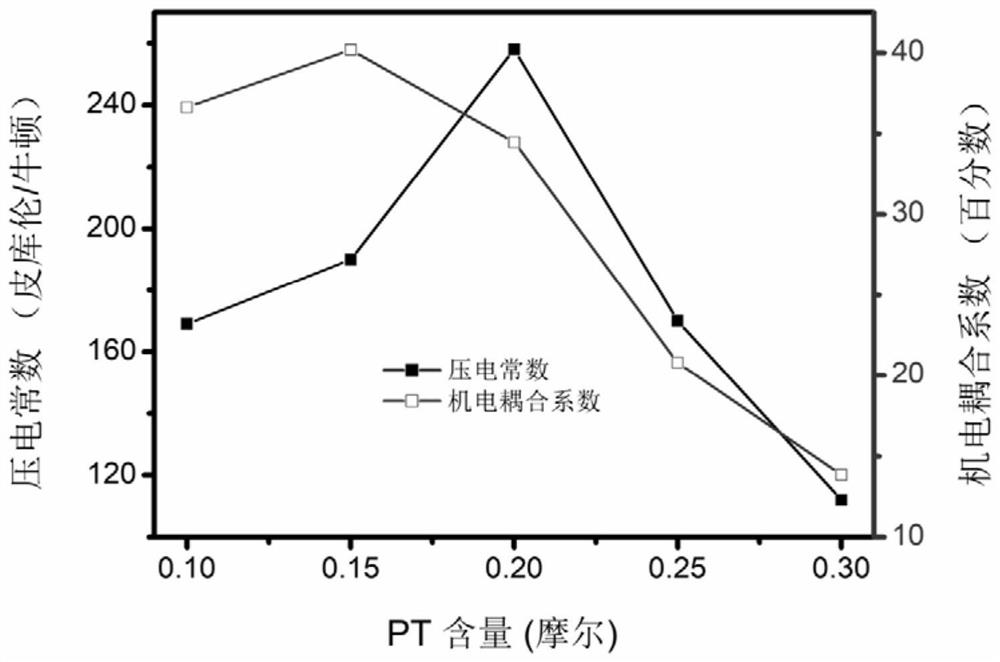

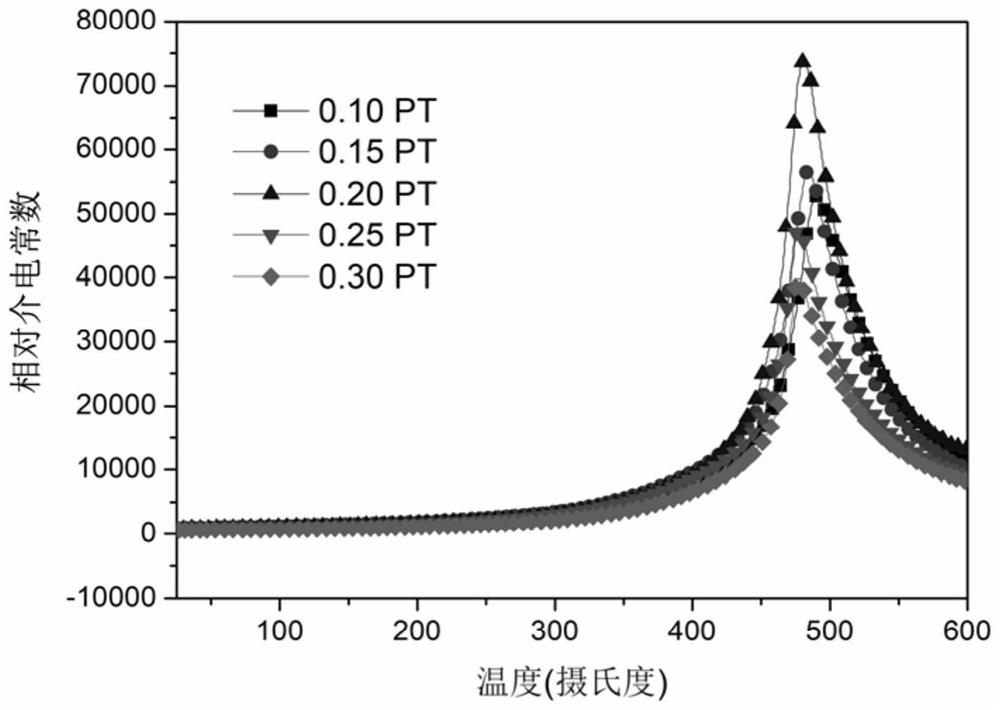

[0047] A bismuth ferrite-based piezoelectric ceramic material with high depolarization temperature and high piezoelectric performance, its general chemical formula is 0.90(0.725BiFeO 3 -0.275BaTiO 3 )-0.10PbTiO 3 +0.8mol%MnO 2 , its preparation method comprises the following steps:

[0048] 1) Bi with a purity greater than 99% 2 o 3 , Fe 2 o 3 , PbO, BaCO 3 、TiO 2 It is used as the raw material of bismuth ferrite-based piezoelectric ceramic material and mixed according to the stoichiometric ratio, then mixed with absolute ethanol and zirconia balls and subjected to a ball mill for 12 hours, and the dried powder is obtained after discharging and drying;

[0049] 2) Put the dried powder in a muffle furnace, and pre-burn it at 750°C for 5 hours to obtain the pre-fired powder;

[0050] 3) Mix the calcined powder with 0.8mol% MnO 2 , anhydrous ethanol and zirconia balls are mixed and subjected to secondary ball milling for 12 hours. After the material is discharged and dr...

Embodiment 2

[0057] A bismuth ferrite-based piezoelectric ceramic material with high depolarization temperature and high piezoelectric performance, whose general chemical formula is 0.85(0.725BiFeO 3 -0.275BaTiO 3 )-0.15PbTiO 3 +0.8mol%MnO 2 , its preparation method comprises the following steps:

[0058] 1) Bi with a purity greater than 99% 2 o 3 , Fe 2 o 3 , PbO, BaCO 3 、TiO 2 It is used as the raw material of bismuth ferrite-based piezoelectric ceramic material and mixed according to the stoichiometric ratio, then mixed with absolute ethanol and zirconia balls and subjected to a ball mill for 12 hours, and the dried powder is obtained after discharging and drying;

[0059] 2) Put the dried powder in a muffle furnace, and pre-burn it at 750°C for 5 hours to obtain the pre-fired powder;

[0060] 3) Mix the calcined powder with 0.8mol% MnO 2 , anhydrous ethanol and zirconia balls are mixed and subjected to secondary ball milling for 12 hours. After the material is discharged and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

| piezoelectric charge coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com