Sheet bismuth sodium titanate mould plate grain and manufacture method thereof

A bismuth sodium titanate, flaky technology, which is applied in the field of flaky sodium bismuth titanate template grains and its preparation, can solve the problems such as difficult preparation of template grains, achieve strong orientation, simple preparation method, and low price Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1. Precursor synthesis: according to Bi 4 Ti 3 o 12 Calculate the reaction equation, accurately weigh Bi 2 o 3 (purity: 99.9%) 7.9621g, TiO 2 (purity: 99.8%) 2.0500g, NaCl (purity: 100%) 4.4053g and KCl (purity: 99%) 5.6634g, each raw material and ethanol 10ml, ZrO 2 After 40 g of balls were mixed and milled for 24 hours, they were transferred to a glass container for drying. After the dried raw material powder is sieved, it is filled with Al 2 o 3The crucible was covered, and synthesized in a high-temperature furnace at 1100°C for 0.5h, with a heating rate of 5°C / min.

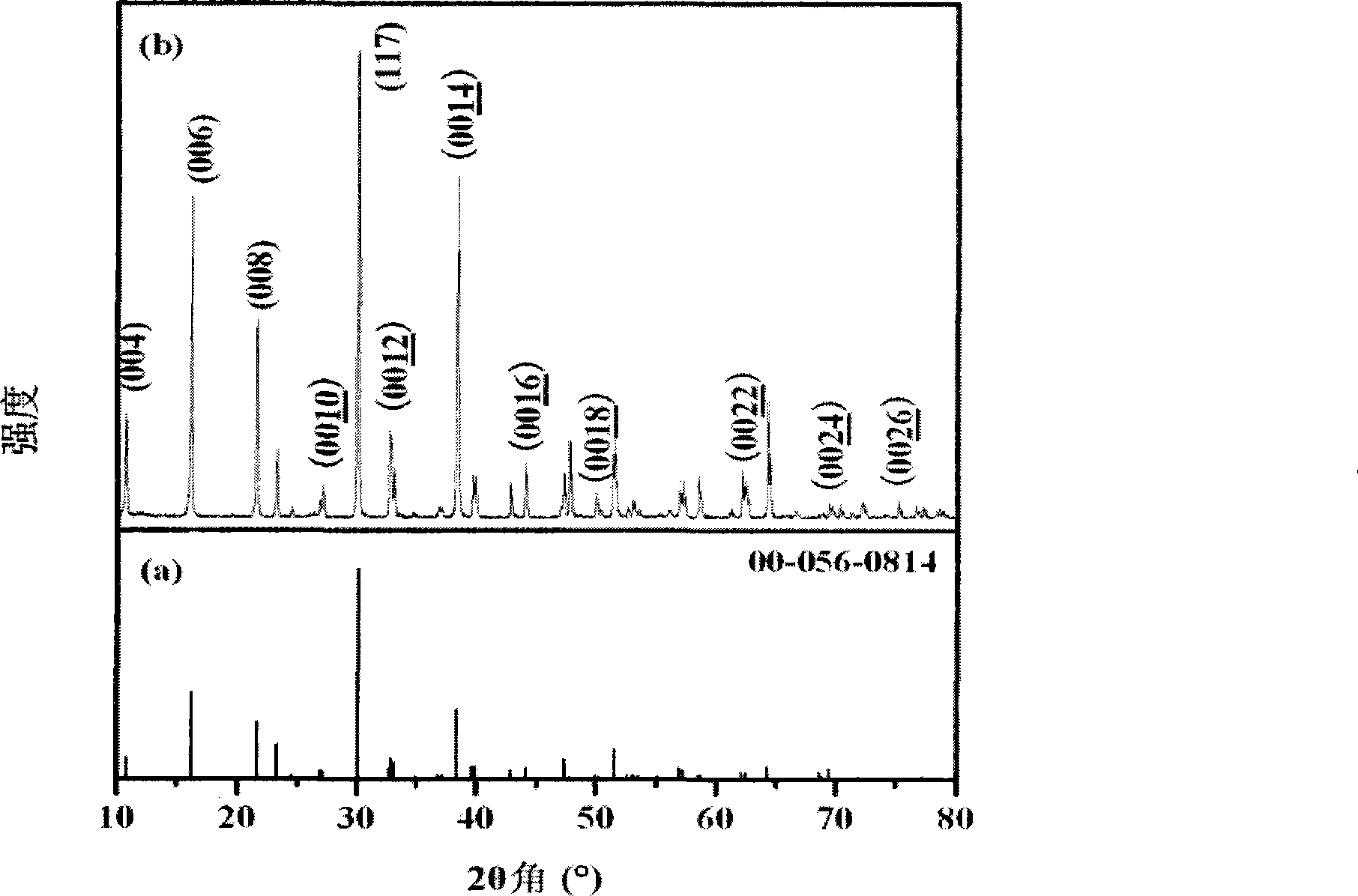

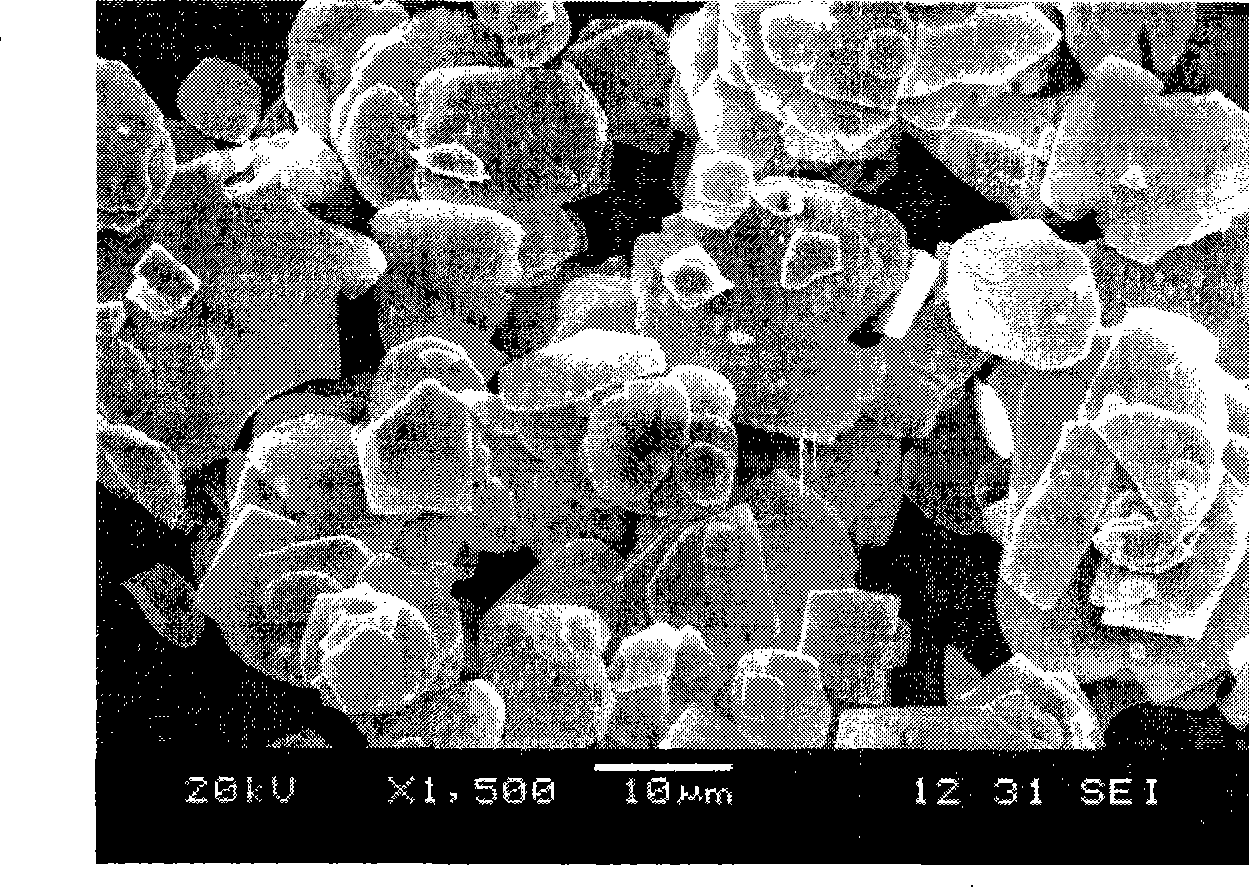

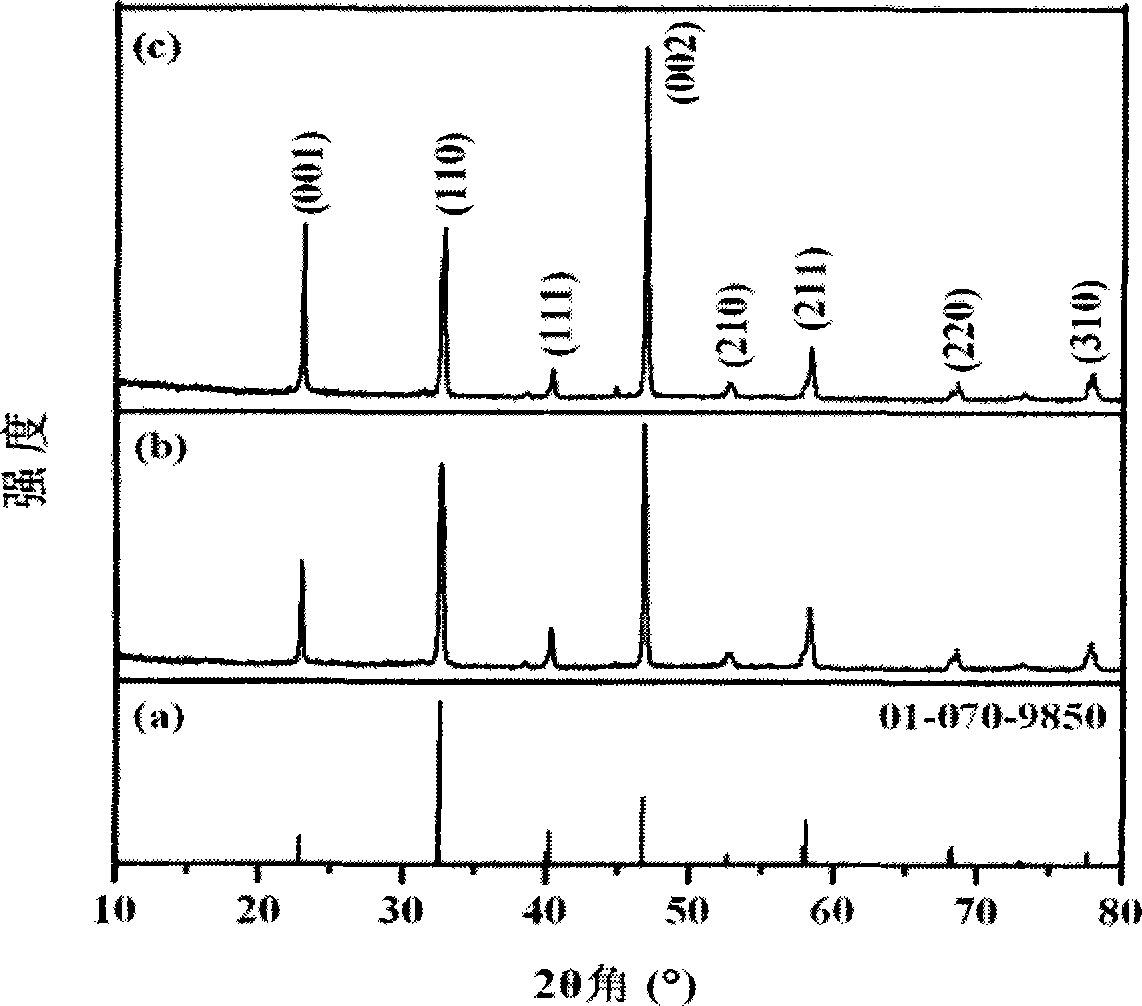

[0027] 2. Precursor filtration: the synthesized Bi 4 Ti 3 o 12 The precursor was pulverized, ultrasonically dispersed, and washed with deionized water 10 times to remove NaCl and KCl molten salts. figure 1 is the resulting Bi 4 Ti 3 o 12 It can be seen from the XRD pattern of the precursor that the intensity of the (001) diffraction peak is enhanced and has a strong orientation; the SEM ph...

Embodiment 2

[0031] 1. Precursor synthesis: according to Bi 4 Ti 3 o 12 The reaction equation calculation, accurate weighing Bi 2 o 3 (purity: 99.9%) 7.9621g, TiO 2 (purity: 99.8%) 2.0501g, NaCl (purity: 100%) 4.4055g and KCl (purity: 99%) 5.6635g, each raw material and ethanol 7ml, ZrO 2 After 40 g of balls were mixed and milled for 24 hours, they were transferred to a glass container for drying. After the dried raw material powder is sieved, it is filled with Al 2 o 3 The crucible was covered, and synthesized in a high-temperature furnace at 1100°C for 0.5h, with a heating rate of 5°C / min.

[0032] 2. Precursor filtration: the synthesized Bi 4 Ti 3 o 12 The precursor was pulverized, ultrasonically dispersed, and washed with deionized water 10 times to remove NaCl and KCl molten salts. The produced Bi 4 Ti 3 o 12 Precursor, its XRD pattern is as follows figure 1 As shown, it can be seen from the figure that the intensity of the (001) diffraction peak is enhanced and has a s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com