Sodium bismuth titanate-barium titanate-potassium bismuth titanate lead-free piezoelectric texture ceramic and preparation method thereof

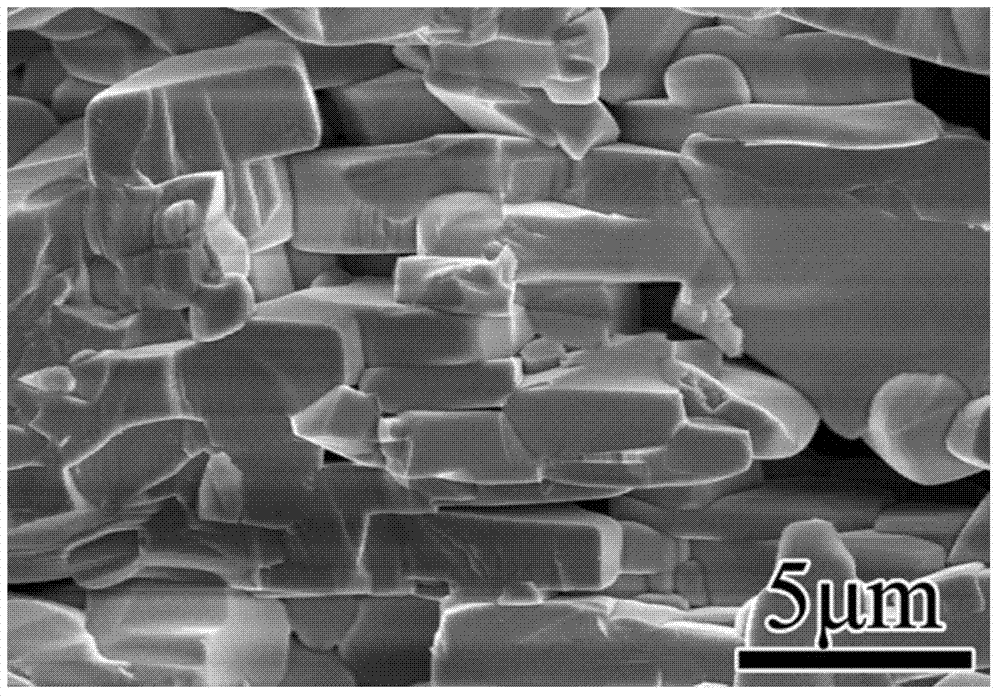

A bismuth sodium titanate-barium titanate and lead-free piezoelectric technology, which is applied in the field of lead-free piezoelectric materials, can solve the problems of easy uneven composition, difficult directional arrangement of templates, and high piezoelectric coefficient, achieving excellent performance, Good grain orientation effect and high texture effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

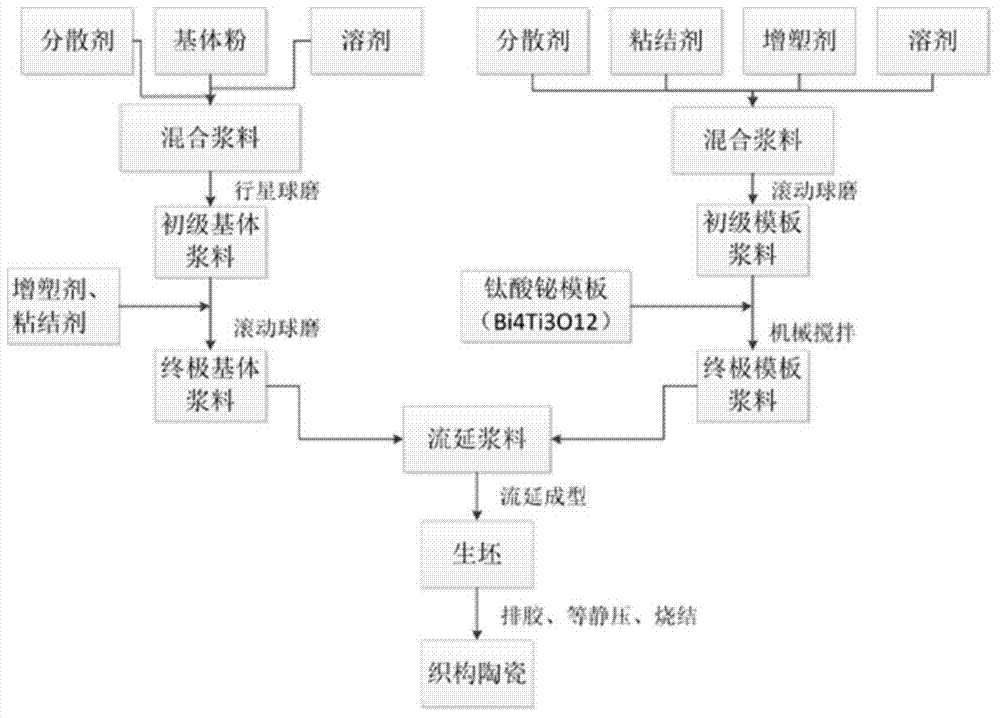

[0038] A preparation method of sodium bismuth titanate-barium titanate-bismuth titanate potassium lead-free piezoelectric textured ceramics, the steps are as follows:

[0039] 1) Preparation of Bi 4 Ti 3 o 12 Template: Preparation of Bi by molten salt method 4 Ti 3 o 12 Flaky powder template, boiled and washed with hot deionized water;

[0040] Bi 4 Ti 3 o 12 The preparation method of the template is as follows: analytically pure bismuth titanate (Bi 2 o 3 ) and titanium dioxide (TiO 2 ) After mixing the ingredients, add sodium sulfate (Na 2 CO 3 ) and potassium sulfate (K 2 CO 3 ); among them, Bi 2 o 3 、TiO 2 、Na 2 SO 4 and K 2 SO 4 The matching ratio is as follows: Bi 2 o 3 with TiO 2 The mass ratio of Na is 3.89:1; Na 2 SO 4 and K 2 SO 4 According to the eutectic point ratio, its mass ratio is 69.3:30.7; Na 2 SO 4 and K 2 SO 4 The sum of the mass (that is, the sulfate content) accounts for 30-50wt% of the total mass of the four powders; after...

Embodiment 1

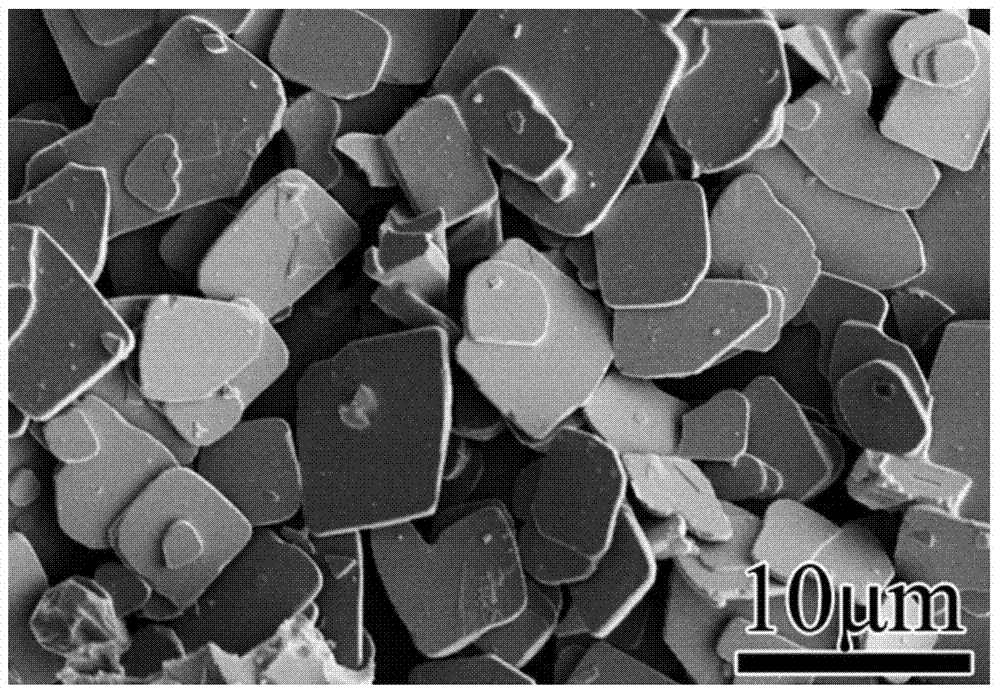

[0056] 1. Preparation of Bi 4 Ti 3 o 12 template

[0057] Weigh 19.888g of bismuth oxide powder, 5.112g of titanium dioxide powder, 17.324g of sodium sulfate, and 7.675g of potassium sulfate (the sulfate content accounts for 50wt% of the total mass of the powder). After the above powders were mixed, the planetary ball was milled for 6 hours at a speed of 1100 rpm. After ball milling, it is dried, ground and pre-fired. The pre-firing degree is to raise the temperature at a rate of 5 °C / min to 950 °C for 2 hours, and then slowly lower the temperature to 850 °C at a rate of 0.8 °C / min. After pre-firing, the powder is fired into a block and cooked with deionized water at 95°C until the block is completely pulverized. It was then washed 8 times with 60°C deionized water to remove residual sulfate. After drying, flake Bi 4 Ti 3 o 12 crystals. Its scanning electron microscope (SEM) image is as follows figure 2 shown.

[0058] 2. Prepare template slurry

[0059] Weigh 0....

Embodiment 2

[0068] 1. Preparation of bismuth titanate template

[0069] Weigh 19.888g of bismuth oxide powder, 5.112g of titanium dioxide powder, 7.422g of sodium sulfate, and 3.288g of potassium sulfate (the sulfate content accounts for 30wt% of the total mass of the powder). After the above powders were mixed, the planetary ball mill was carried out for 4 hours at a speed of 1100 rpm. After ball milling, it is dried, ground and pre-fired. The pre-firing degree is to raise the temperature at a rate of 3 °C / min to 950 °C for 2 hours, and then slowly lower the temperature to 850 °C at a rate of 0.2 °C / min. After pre-firing, the powder is fired into a block, which is cooked in deionized water at 95 °C until the block is completely pulverized. It was then washed 10 times with 60°C deionized water to remove residual sulfate. After drying, flake Bi 4 Ti 3 o 12 crystals.

[0070] 2. Preparation of Template Slurry

[0071] Weigh 18.815gBi 4 Ti 3 o 12 template, adding 82wt% ethanol-but...

PUM

| Property | Measurement | Unit |

|---|---|---|

| piezoelectric charge coefficient | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

| piezoelectric charge coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com