High-electrostriction sodium-bismuth-titanate-base lead-free piezoelectric material and preparation method thereof

A sodium bismuth titanate-based, electrostrained technology, applied in the field of functional ceramics, can solve problems such as narrow operating temperature range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

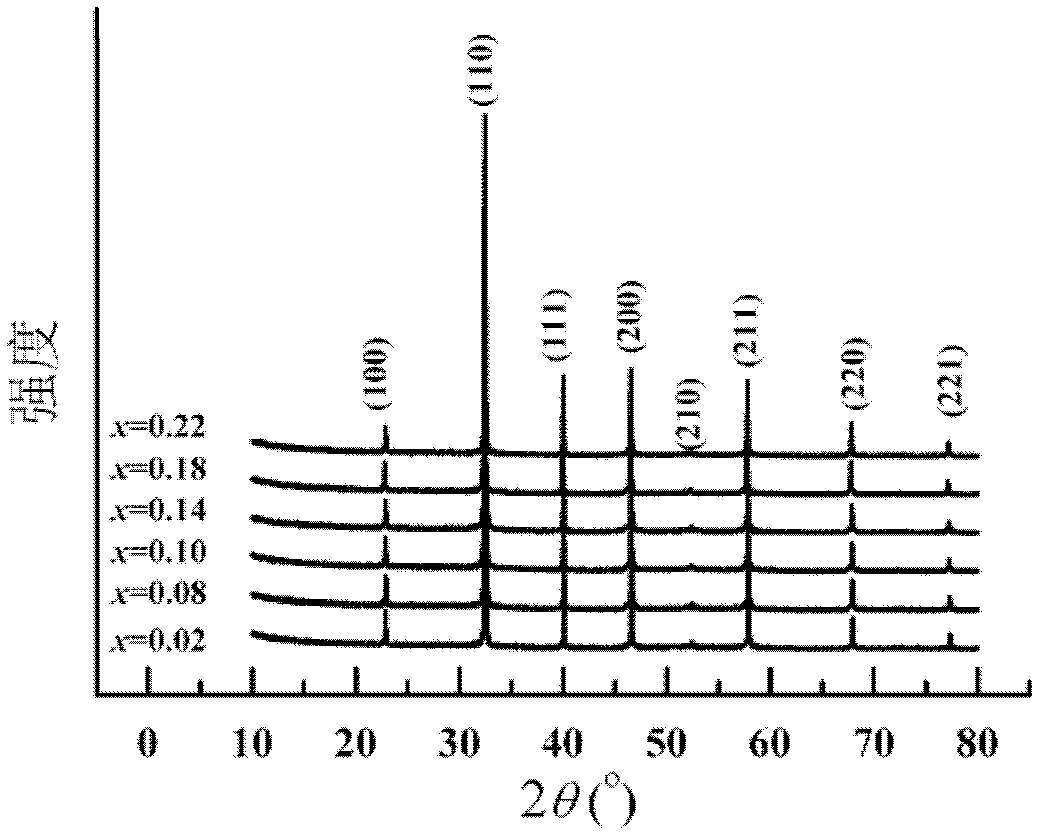

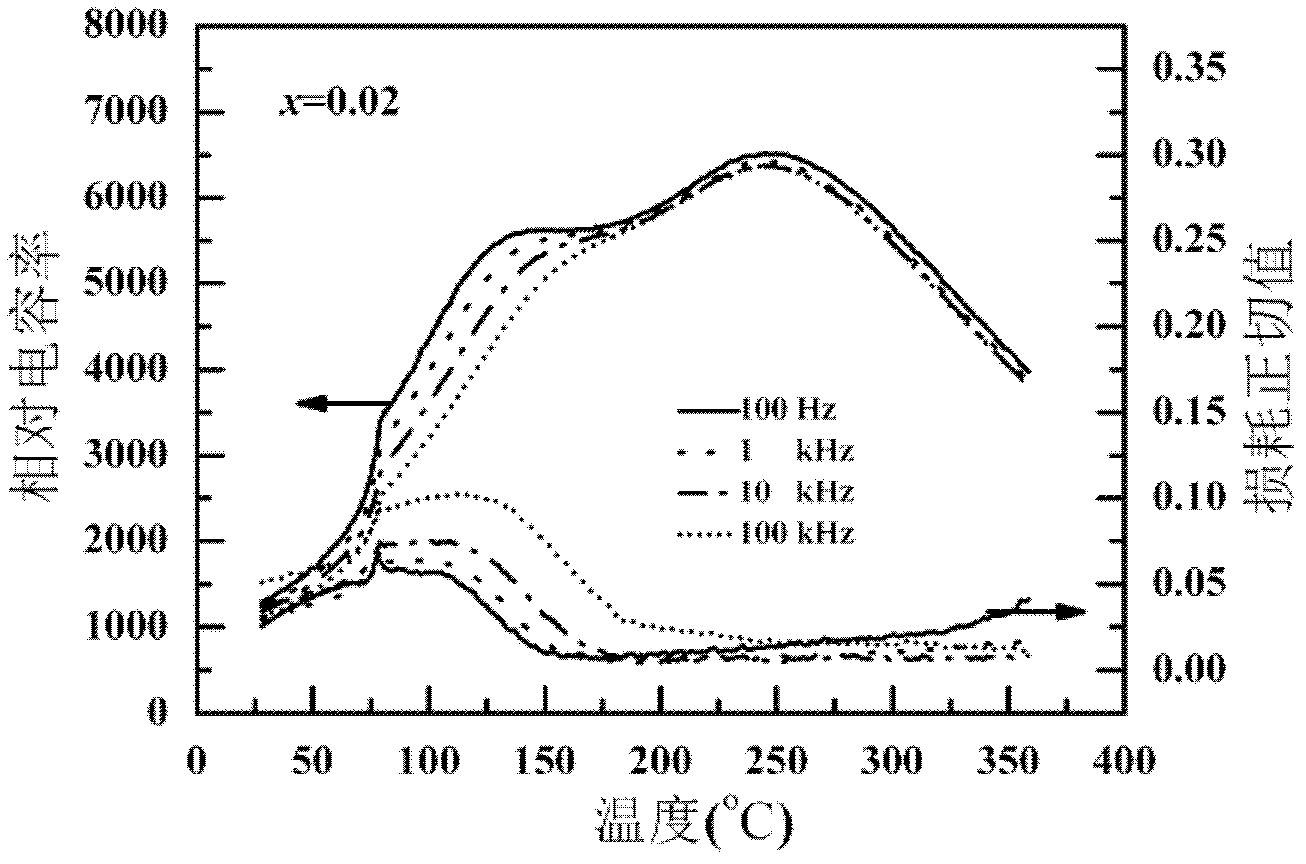

[0027] Use high purity Bi 2 o 3 , Na 2 CO 3 , BaCO 3 ,TiO 2 and SrCO 3 As raw material, according to the chemical formula 0.915Bi 0.5 Na 0.5 TiO 3 -0.065BaTiO 3 -0.02SrTiO 3 carry out ingredients;

[0028] Use absolute ethanol as the medium, use a planetary mill to wet grind for 6 hours, dry at 90°C to obtain a dry powder, pre-burn the dried raw material in air at 850°C for 2 hours, and grind to obtain a solid solution raw material;

[0029] Use anhydrous ethanol as the medium to carry out secondary wet grinding for 6 hours, and obtain finely ground raw materials after drying, and use dry pressing method for molding;

[0030] Sinter the molded piece in air at 1200°C for 2 hours to obtain a dense BNBST ceramic piece.

Embodiment 2

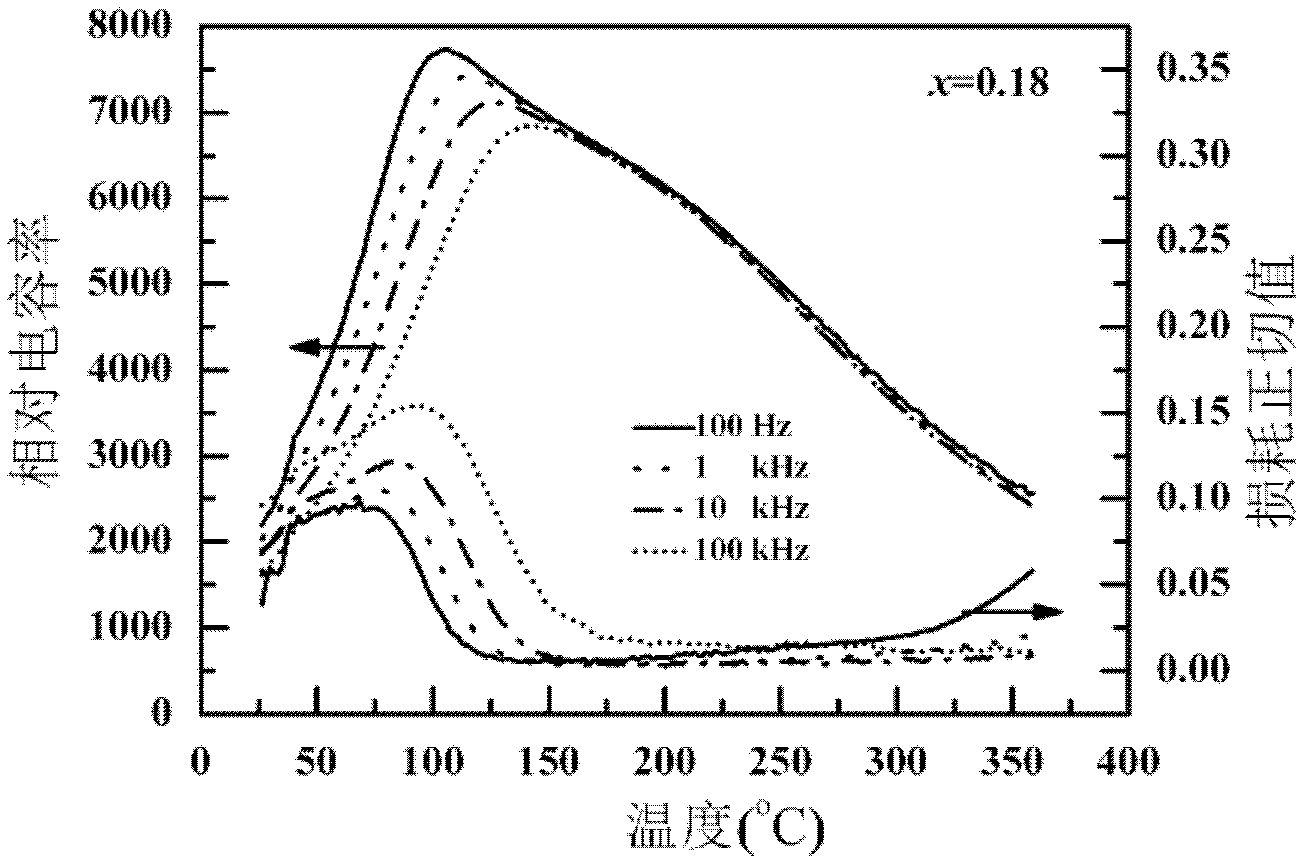

[0032] The steps of this embodiment are basically the same as those of Embodiment 1, the difference is that according to the chemical formula 0.855Bi 0.5 Na 0.5 TiO 3 -0.065BaTiO 3 -0.08SrTiO 3 Proceed to the ingredients.

Embodiment 3

[0034] The steps of this embodiment are basically the same as those of Embodiment 1, except that according to the chemical formula 0.835Bi 0.5 Na 0.5 TiO 3 -0.065BaTiO 3 -0.10SrTiO 3 Proceed to the ingredients.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Peak temperature | aaaaa | aaaaa |

| Remanent polarization | aaaaa | aaaaa |

| Coercive field | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com