A kind of itaconate/isoprene copolymer type composite material and use as dielectric elastomer

A technology of itaconate and isoprene, applied in the field of composite materials, can solve the problems of reducing material flexibility and toughness, not conducive to improving material strain response and driving response, and high rigidity, so as to achieve the effect of high electrical deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

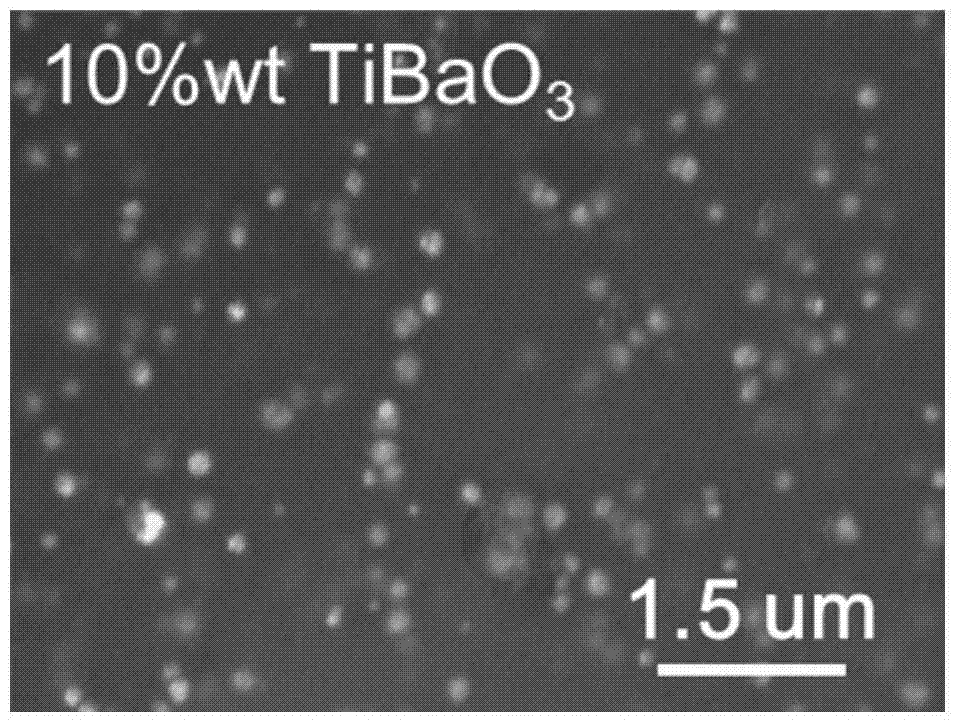

Image

Examples

Embodiment 1

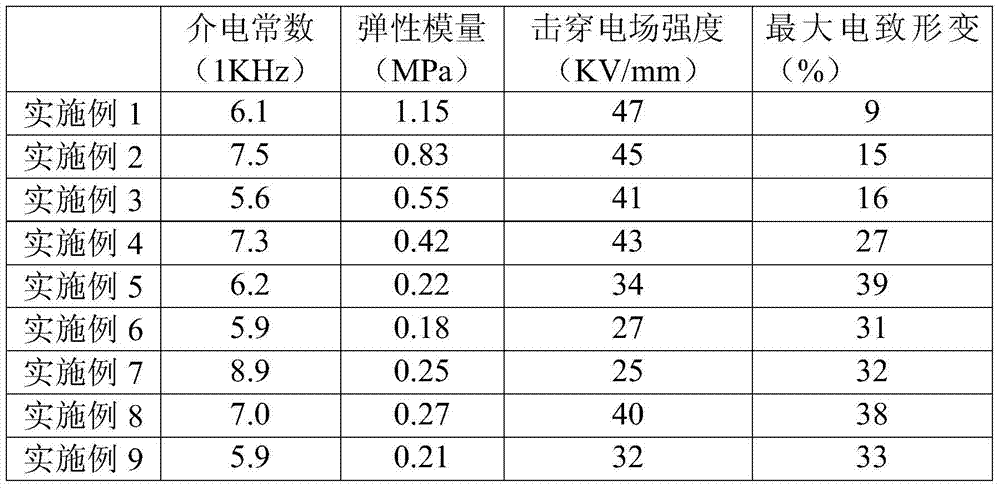

[0024] Example 1: Synthesis of dibutyl itaconate monomer from itaconic acid and butanol, and then prepare dibutyl itaconate / isoprene copolymerization by emulsion polymerization of dibutyl itaconate monomer and isoprene thing. Dibutyl itaconate and isoprene are fed in a mass ratio of 50:50, polymerized according to the method described in the patent "CN 102558578 B", the polymerized product is demulsified with 1% calcium chloride aqueous solution, and ethanol Washed repeatedly with deionized water and dried to constant weight. Get 100 parts by mass of itaconate di-n-ester / isoprene copolymer, masticate on an open mill, add 1 part by mass of sulfur, 4 parts by mass of zinc oxide, 0.5 parts by mass of stearic acid, 0.7 parts by mass of Parts of accelerator M, 1 mass part of accelerator CZ, mixed on the open mill. It is vulcanized on a 25-ton electric heating plate vulcanizing machine produced by Shanghai Machinery Manufacturing Plant, with a vulcanization temperature of 150°C an...

Embodiment 2

[0025] Example 2: The preparation method is the same as Example 1, except that the feed ratio of itaconate / isoprene copolymer is 80:20. The test results are shown in Table 1.

Embodiment 3

[0026] Example 3: Synthesis of dibutyl itaconate monomer from itaconic acid and butanol, and then prepare dibutyl itaconate / isoprene copolymerization by emulsion polymerization of dibutyl itaconate monomer and isoprene things. Dibutyl itaconate and isoprene are fed in a mass ratio of 50:50, polymerized according to the method described in the patent "CN 102558578 B", the polymerized product is demulsified with 1% calcium chloride aqueous solution, and ethanol Washed repeatedly with deionized water and dried to constant weight. Take 100 parts by mass of dibutyl itaconate / isoprene copolymer, masticate it on an open mill, add 5 parts by mass of DCP, and mix evenly on the open mill. It is vulcanized on a 25-ton electric heating plate vulcanizing machine produced by Shanghai Machinery Manufacturing Plant, with a vulcanization temperature of 165°C and a vulcanization time of 15 minutes. The dielectric constant and Young's modulus of the itaconate / isoprene copolymer dielectric elas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com