Brominated butyl rubber dielectric elastomer composite material and preparation method thereof

A technology of bromobutyl rubber and dielectric elastomer, which is applied in the field of bromobutyl rubber dielectric elastomer composite material and its preparation, can solve the problem of easy formation of conductive paths, lower percolation threshold and low electrical breakdown strength and other problems, to achieve the effects of excellent ductility, improved compatibility, and low air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

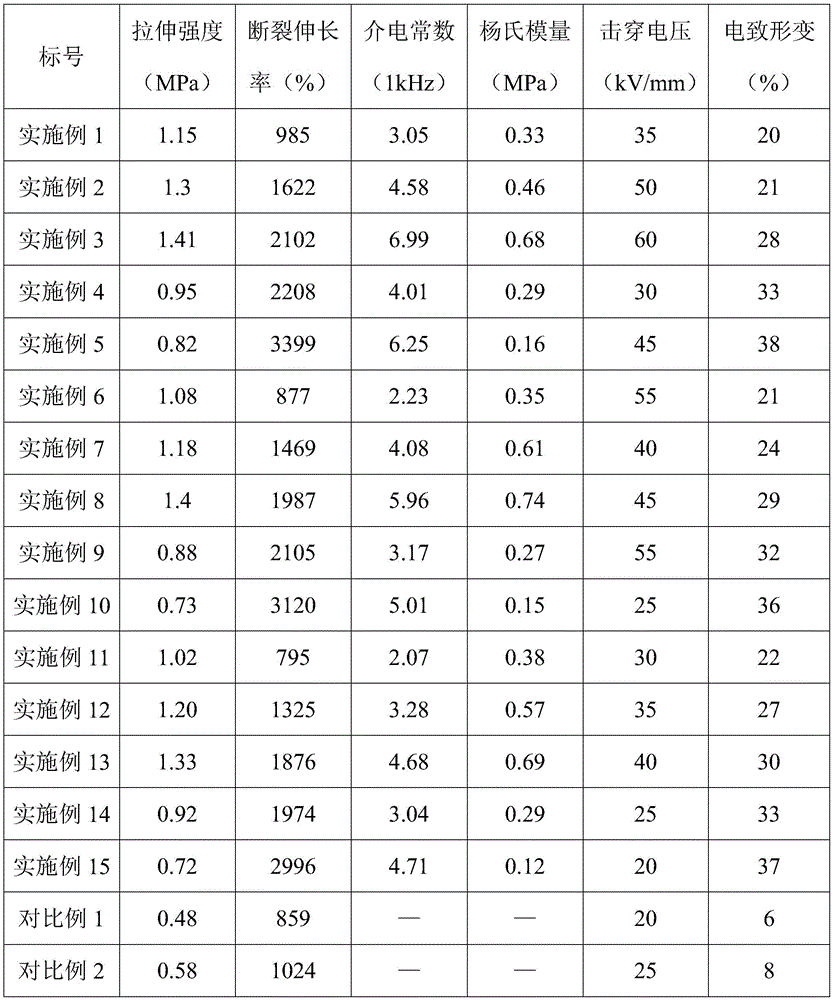

[0031] Embodiment 1: taking brominated butyl rubber as the matrix, adopting nano-barium titanate as the high dielectric ceramic filler, the specific operation steps are: (1) plasticizing 100 parts by mass of brominated butyl rubber at room temperature on an open mill , gradually add 10 parts by mass of nano-barium titanate with a particle size of 30nm, then gradually add 1 part by mass of calcium stearate and 5 parts by mass of zinc oxide cutter knives for mixing, make triangular bags, make it evenly mixed, and then gradually pour Add 10 parts by mass of tributyl phosphate (TBP), knead evenly, and release the tablet. (2) After the mixed rubber is parked for 7-16 hours, set the pressure on a flat vulcanizer at 15 MPa and vulcanize at 170° C. for 40 min to prepare a brominated butyl rubber dielectric elastomer composite. The test results are shown in Table 1.

Embodiment 2

[0032] Example 2: The preparation method is the same as in Example 1, except that the number of parts of barium titanate is 30 parts by mass. The test results are shown in Table 1.

Embodiment 3

[0033] Embodiment 3: The preparation method is the same as that of Embodiment 1, except that the number of parts of barium titanate is 50 parts by mass. The test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com