Preparation method of low-loss high-energy-density sodium bismuth titanate based ceramic

A high energy storage density, sodium bismuth titanate-based technology, applied in the field of dielectric energy storage materials, can solve the problems of low energy storage density and excessive loss, and achieve the effects of improving energy storage density and energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

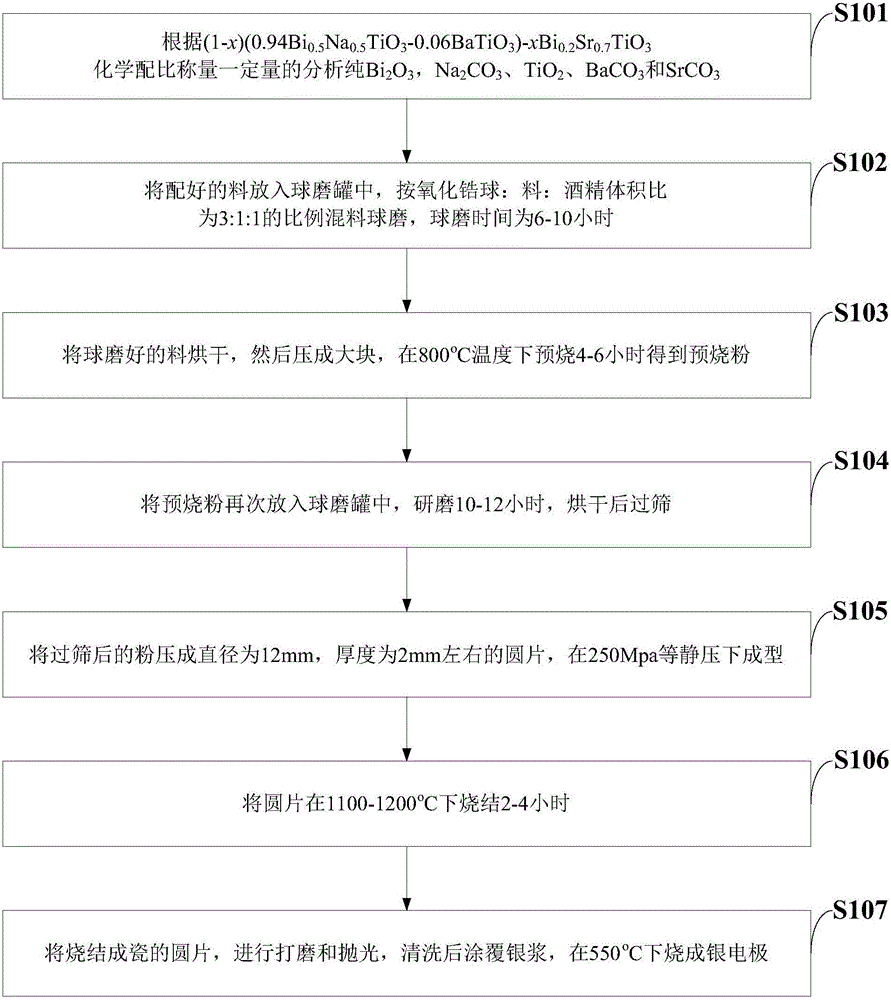

[0033] Such as figure 1 As shown, the method for preparing sodium bismuth titanate-based ceramics with low loss and high energy storage density in the embodiment of the present invention includes the following steps:

[0034] S101: According to (1-x)(0.94Bi 0.5 Na 0.5 TiO 3 -0.06BaTiO 3 )-xBi 0.2 Sr 0.7 TiO 3 Chemical proportioning weighing a certain amount of analytical pure Bi 2 O 3 , Na 2 CO 3 , TiO 2 , BaCO 3 And SrCO 3 ;

[0035] S102: Put the prepared materials into a ball mill tank, and mix the materials according to the ratio of zirconia ball: material: alcohol volume ratio of 3:1:1, and the milling time is 6-10 hours;

[0036] S103: Dry the ball-milled material, then press it into large pieces, and pre-fire at 800°C for 4-6 hours to obtain pre-fired powder;

[0037] S104: Put the pre-burned powder into the ball milling tank again, grind for 10-12 hours, dry and sieve;

[0038] S105: Press the sieved powder into a disc with a diameter of 12mm and a thickness of about 2mm, and fo...

Embodiment 1

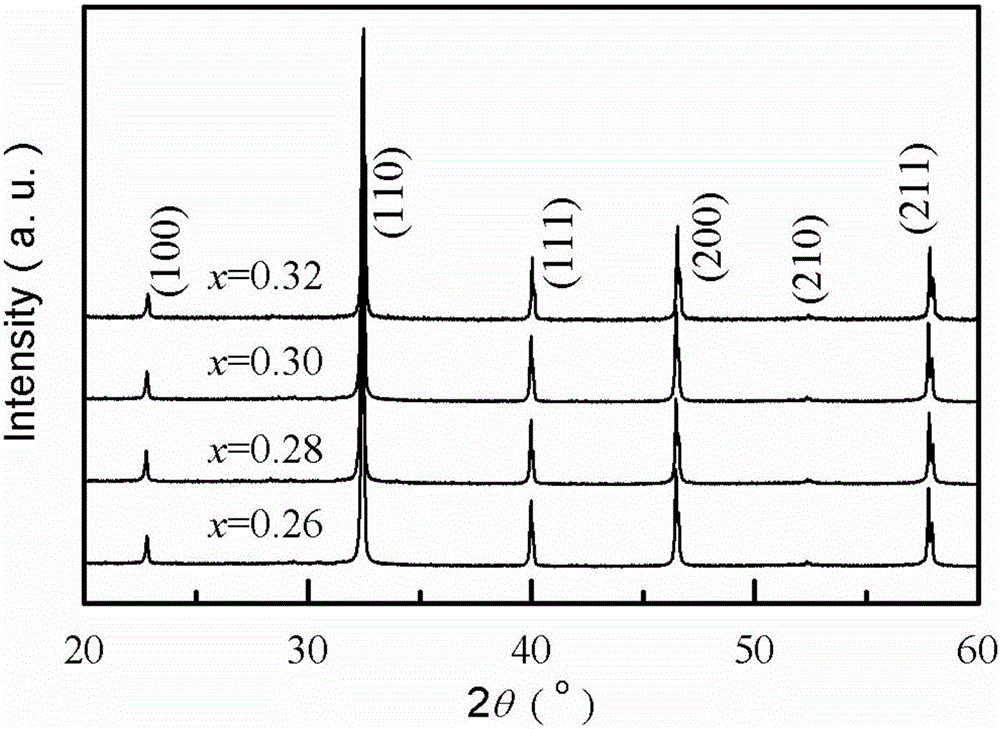

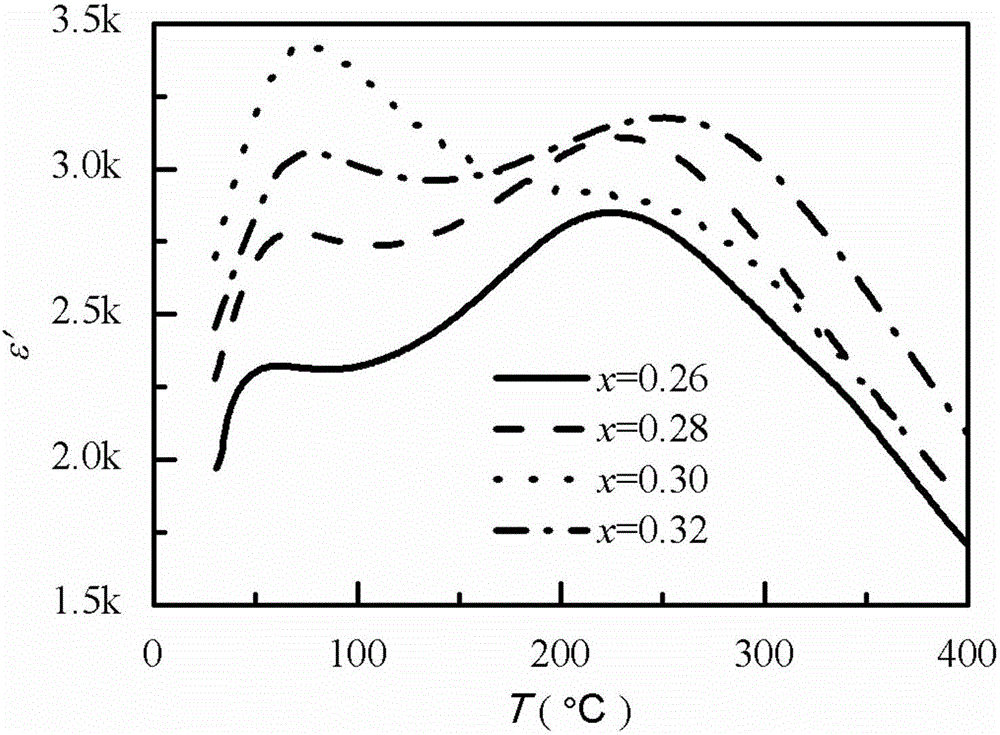

[0042] Example 1, 9.3145g of Bi was weighed according to the stoichiometric ratio 2 O 3 , 1.9608g of Na 2 CO 3 , 7.987g of TiO 2 , 0.8762g of BaCO 3 And 2.6869g of SrCO 3 , Put the weighed material into the ball mill tank, and mix the material with the ratio of zirconia ball: material: alcohol volume ratio of 3:1:1, and the ball milling time is 6-10 hours; after drying the ball milled material Press large pieces and pre-fire at 800°C for 4-6 hours. Take out the calcined material, grind it and ball-mill it again for 10-12 hours, dry and sieve; pre-press the sieved powder into a diameter of 12mm, A disc with a thickness of 2mm is molded under an isostatic pressure of 250MPa; the disc is kept at 1100-1200℃ for 2-4 hours; after sintering into porcelain, it is polished and then coated with silver paste. At 550℃, Keep the temperature for 30 minutes and burn the silver electrode. From figure 2 In the X-ray diffraction pattern of the BNT-based material, it can be seen that the prepare...

Embodiment 2

[0043] Example 2, Weigh 9.1887g of Bi according to the stoichiometric ratio 2 O 3 , 1.9078g of Na 2 CO 3 , 7.987g of TiO 2 , 0.8526g of BaCO 3 And 2.8936g of SrCO 3 , Put the weighed material into the ball mill tank, and mix the material with the ratio of zirconia ball: material: alcohol volume ratio of 3:1:1, and the ball milling time is 6-10 hours; after drying the ball milled material Press large pieces and pre-fire at 800°C for 4-6 hours. Take out the calcined material, grind it and ball-mill it again for 10-12 hours, dry and sieve; pre-press the sieved powder into a diameter of 12mm, A disc with a thickness of 2mm is molded under an isostatic pressure of 250MPa; the disc is kept at 1100-1200℃ for 2-4 hours; after sintering into porcelain, it is polished and then coated with silver paste. At 550℃, Keep the temperature for 30 minutes and burn the silver electrode. From figure 2 In the X-ray diffraction pattern of the BNT-based material, it can be seen that the prepared cera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| energy density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com