Lead-less piezoelectric sodium bismuth titanate-bariumtitanate ceramic and its prepn process

A lead-free piezoelectric, sodium bismuth titanate technology, applied in the direction of piezoelectric/electrostrictive/magnetostrictive devices, circuits, electrical components, etc., can solve the difficult to obtain anisotropic morphology, texture process Complicated, inconsistent material properties, etc., to achieve the effect of simple printing process, low cost, high density and degree of orientation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

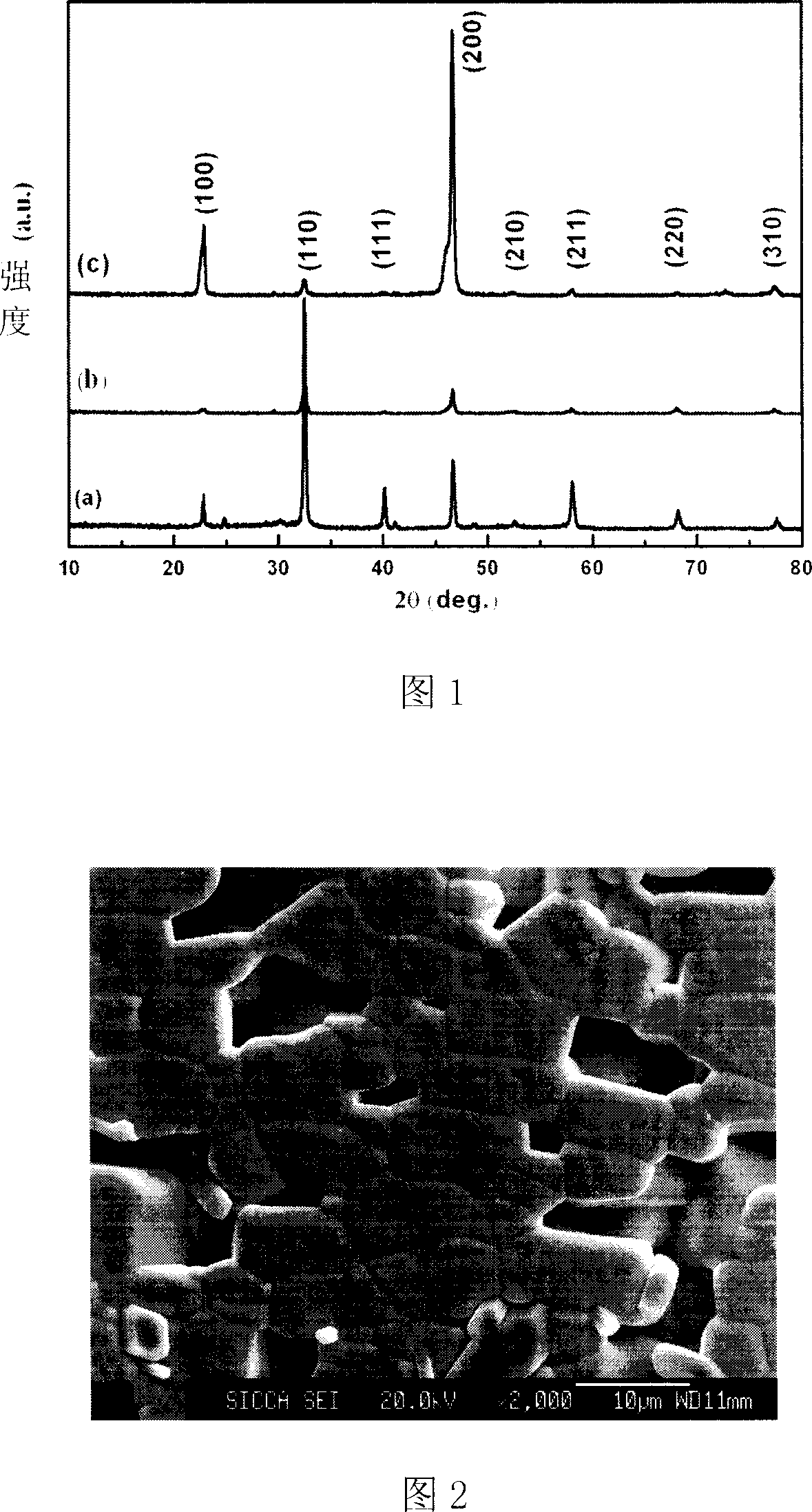

Embodiment 1

[0026] (1) Slurry preparation Dissolve 5.90 g of ethyl cellulose in 130.82 g of terpineol, heat and stir at 80°C until the ethyl cellulose is completely dissolved to form a transparent solution. Weigh 7.02g Na 2 CO 3 , 3.33g BaCO 3 , 10.32g Bi 2 o 3 and 17.21g nano-TiO 2 , added to the above solution, ball milled for 2 hours and mixed evenly. Then 25.80g of flaky Bi synthesized by molten salt method 4 Ti 3 o 12 Add in the slurry and continue ball milling for 15 minutes.

[0027] (2) Screen printing Screen-print the prepared slurry on a polyester film, put it in an oven at 100°C for drying, and repeat the above steps about 30 times until a ceramic film of 0.15 mm is formed.

[0028] (3) Forming The obtained ceramic membrane was cut into square pieces of 12 mm×12 mm, the membrane piece was removed from the substrate, about 60 layers were stacked, and pressed into shape.

[0029] (4) Exhaust plastic sintering Put the above-mentioned ceramic green body into a heat treatm...

Embodiment 2

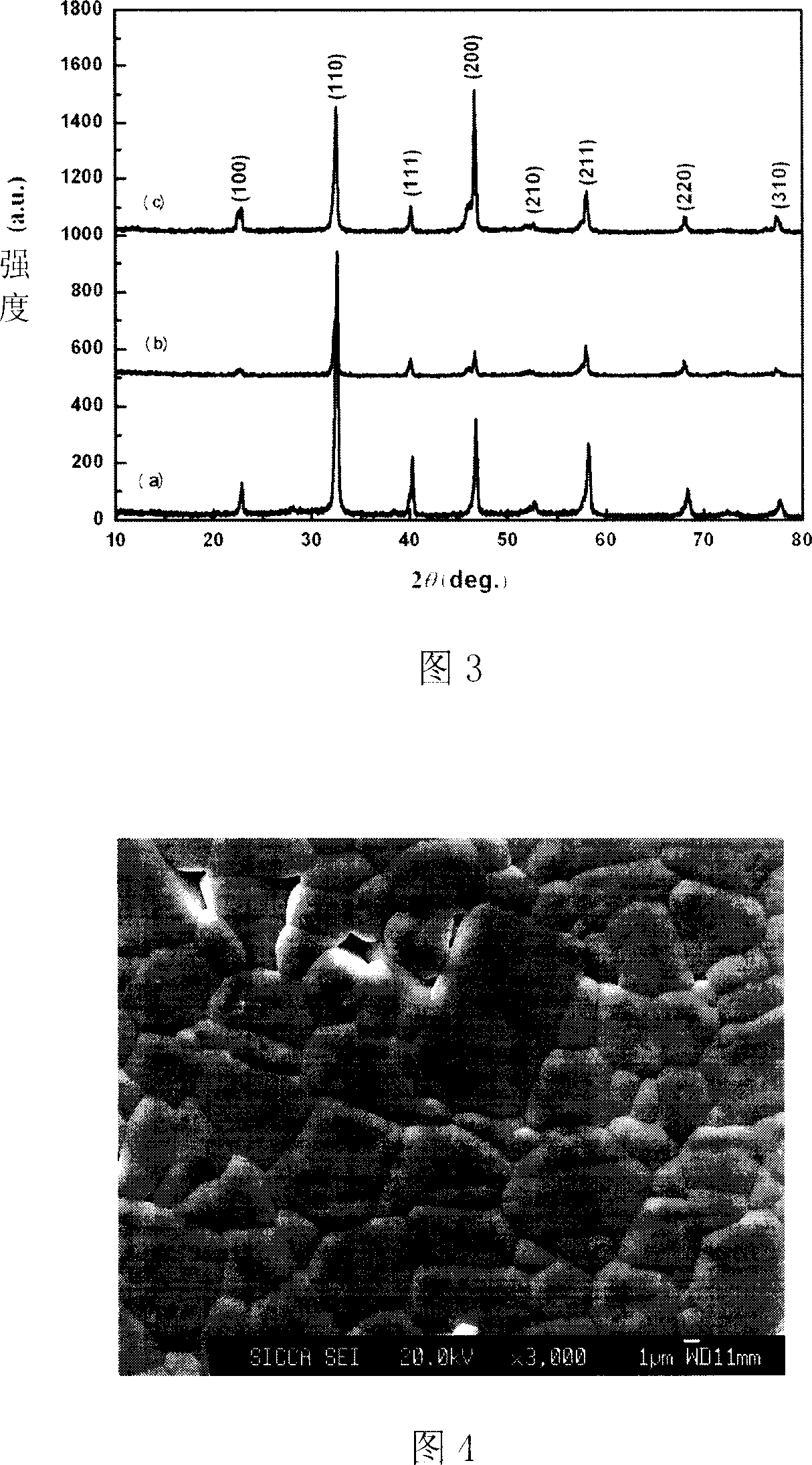

[0032] (1) Slurry preparation Dissolve 5.90 g of ethyl cellulose in 130.82 g of terpineol, heat and stir at 80°C until the ethyl cellulose is completely dissolved to form a transparent solution. Weigh 6.65g Na 2 CO 3 , 3.33g BaCO3 , 16.16g Bi 2 o 3 and 18.01g nano-TiO 2 , added to the above solution, ball milled for 2 hours and mixed evenly. Then 19.46g of Na synthesized by solid phase reaction method 0.5 Bi 4.5 Ti 4 o 15 Add in the slurry and continue ball milling for 15 minutes.

[0033] (2) Screen printing Screen-print the prepared slurry on a polyester film, put it in an oven at 100°C for drying, and repeat the above steps about 30 times until a ceramic film of 0.15 mm is formed.

[0034] (3) Forming The obtained ceramic membrane was cut into square pieces of 12 mm×12 mm, the membrane piece was removed from the substrate, about 60 layers were stacked, and pressed into shape.

[0035] (4) Exhaust plastic sintering Put the above-mentioned ceramic green body into a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Orientation degree | aaaaa | aaaaa |

| Orientation degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com