Bismuth sodium titanate-barium titanate base piezoelectric ceramic and its prepn process

A technology of barium titanate and electric ceramics, applied in the direction of piezoelectric/electrostrictive/magnetostrictive devices, circuits, electrical components, etc., can solve the problem of high conductivity in the ferroelectric phase region, narrow working temperature, and stable temperature of performance parameters In order to reduce the coercive field and resistivity, the chemical process is simple and easy, and the production cost is low.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

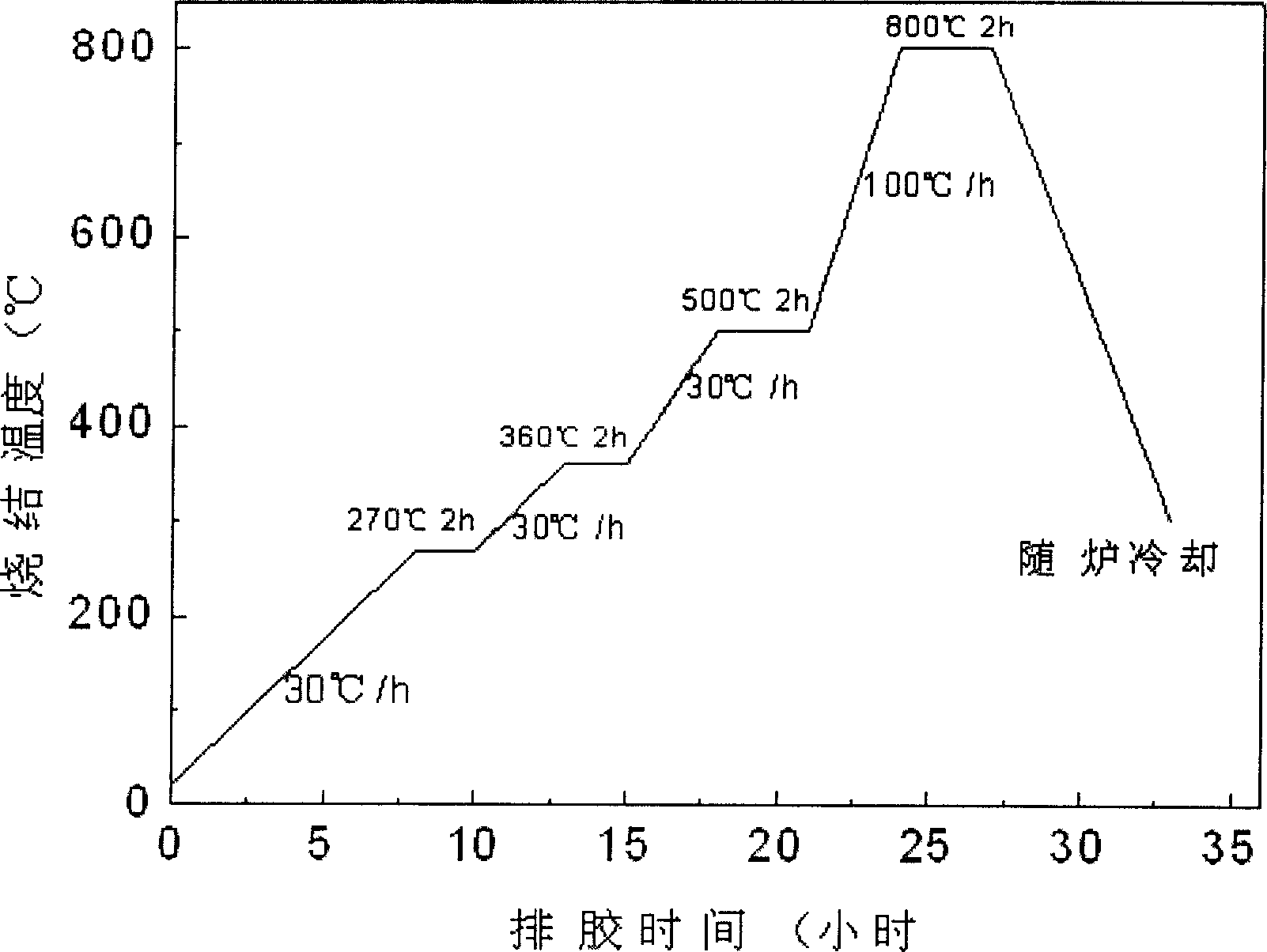

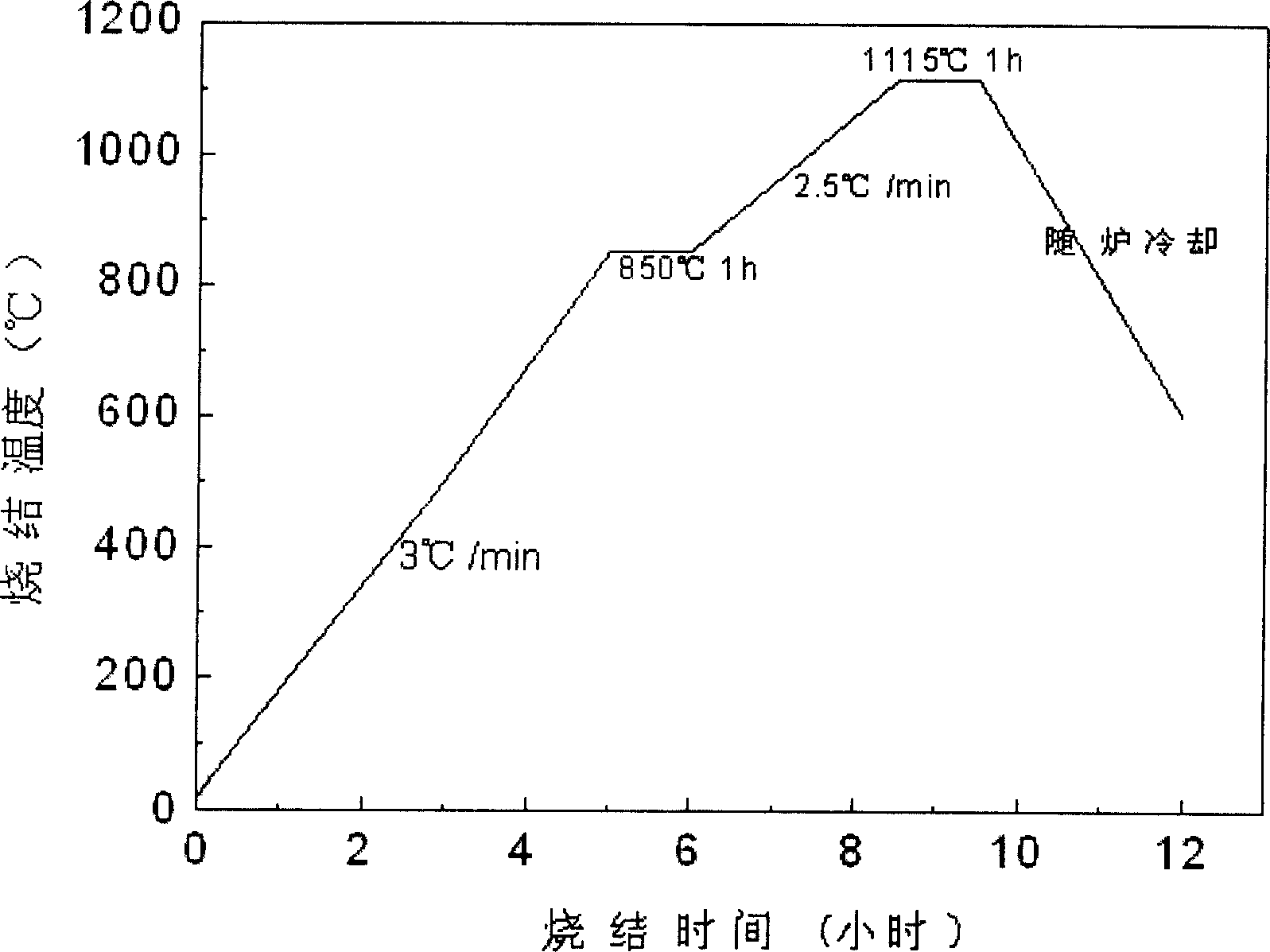

[0028] Embodiment 1, with the bismuth trioxide that analysis pure level content is 99.0%, the sodium carbonate that content is 99.8%, the barium carbonate that content is 99.0%, the titanium dioxide that content is 98%, the tin oxide that content is 99.5%, press The stoichiometric ratio is 0.96[(Na 0.5 Bi 0.5 )TiO 3 ]-0.04BaTiO 3 -0.2wt%SnO 2 Weigh ingredients. Put the prepared material into the vibrating mill hopper and mix according to the ratio of iron ball: material 3:1, and do not add other media during the mixing process. The vibration grinding time is 6 hours, the mixed material briquette is pre-fired at 800°C for 1 hour, the calcined material is taken out and crushed, and then sieved after vibration grinding for 6 hours; Repeated rolling on the rolling machine for 1 hour, the final shape is 12×12×0.5mm 3 Put square slices in an oven at 120°C for 10 hours to dry into plain slices, then put the dried plain slices into the furnace to remove glue, the heating rate is...

Embodiment 2

[0030] Embodiment 2, with the bismuth trioxide that analysis pure level content is 99.0%, the sodium carbonate that content is 99.8%, the barium carbonate that content is 99.0%, the titanium dioxide that content is 98%, the tin oxide that content is 99.5%, press The stoichiometric ratio is 0.94[(Na 0.5 Bi 0.5 )TiO 3 ]-0.06BaTiO 3 -0.2wt%SnO 2 Weigh ingredients. Put the prepared material into the vibrating mill hopper and mix according to the ratio of iron ball: material 3:1, and do not add other media during the mixing process. The time of vibration grinding is 8 hours, and the mixed material briquette is pre-fired at 840 ° C for 1.5 hours, the calcined material is taken out and crushed, and then sieved after vibration grinding for 8 hours; Repeated rolling on the film machine for 1.5 hours, the final shape is 12×12×0.5mm 3Put the square sheet in an oven at 120°C for 11 hours to dry it into a plain sheet, then put the dried plain sheet in the furnace to remove the glue, ...

Embodiment 3

[0031] Embodiment 3, with the bismuth trioxide that analysis pure level content is 99.0%, the sodium carbonate that content is 99.8%, the barium carbonate that content is 99.0%, the titanium dioxide that content is 98%, the tin oxide that content is 99.5%, press The stoichiometric ratio is 0.92[(Na 0.5 Bi 0.5 )TiO 3 ]-0.08BaTiO 3 -0.2wt%SnO 2 Weigh ingredients. Put the prepared material into the vibrating mill hopper and mix according to the ratio of iron ball: material 3:1, and do not add other media during the mixing process. The time of vibratory milling is 10 hours, the mixed material briquette is pre-fired at 850°C for 2 hours, the calcined material is taken out and crushed, and then sieved after vibrating milling for 10 hours; Repeated rolling on the film machine for 2 hours, the final shape is 12×12×0.5mm 3 Put the square sheet in an oven at 120°C for 12 hours to dry it into a plain sheet, then put the dried plain sheet into the furnace to remove the glue, the hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com