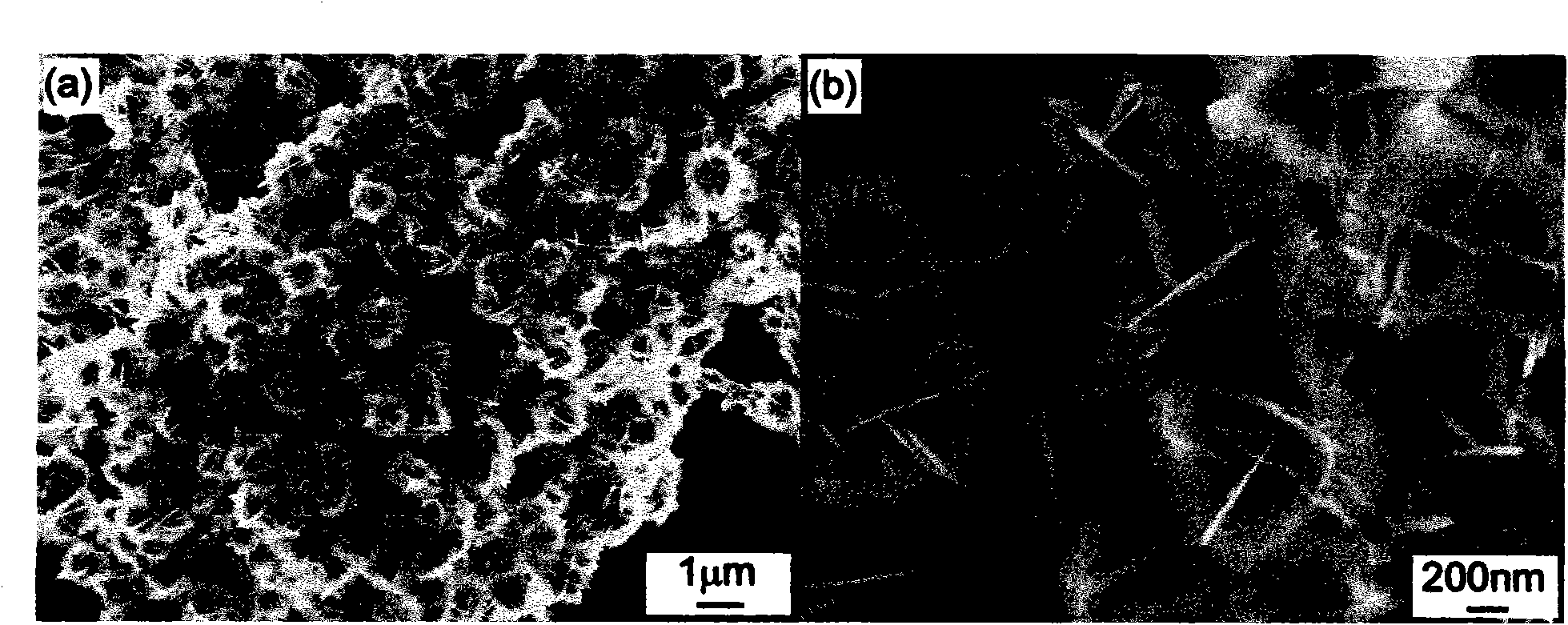

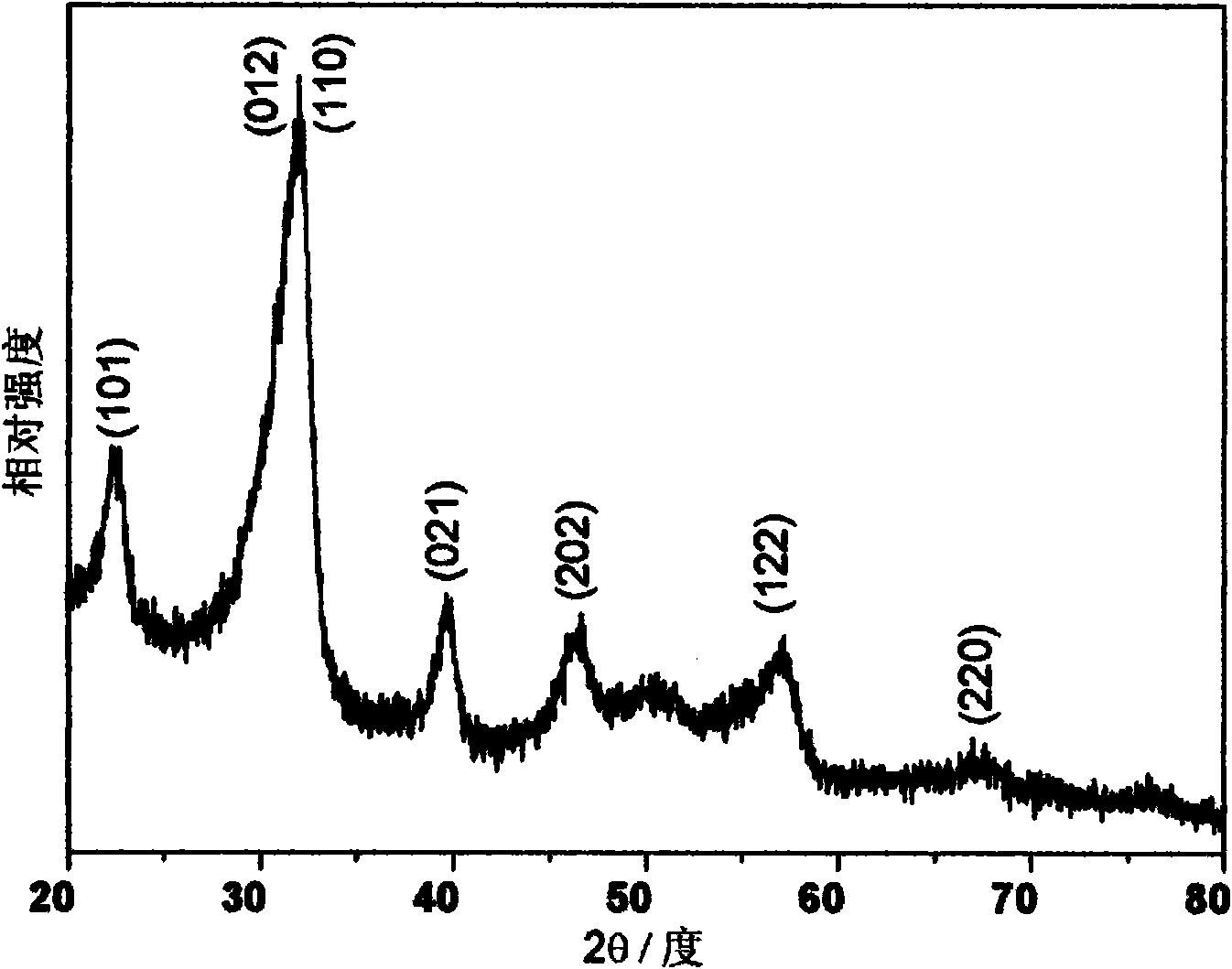

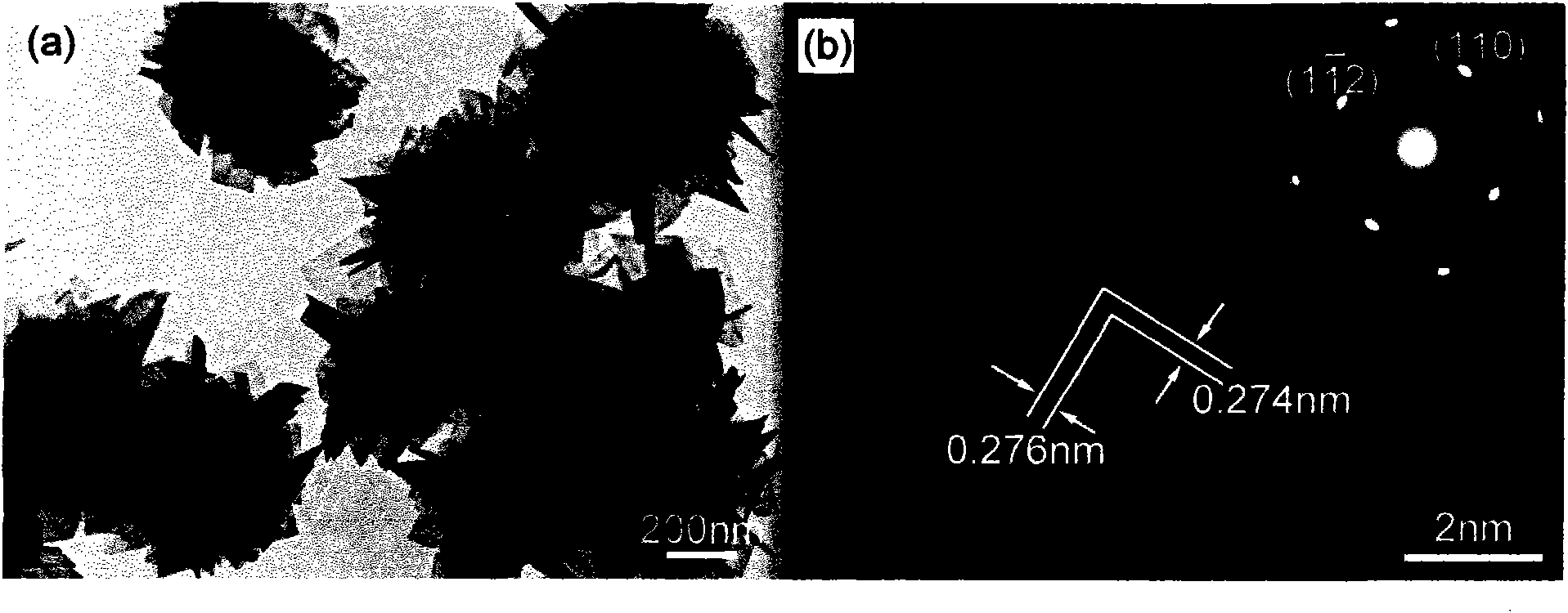

Bismuth sodium titanate nanometer flower and preparation method thereof

A technology of sodium bismuth titanate and nanoflowers, applied in chemical instruments and methods, titanium compounds, bismuth compounds, etc., can solve the problems of undisclosed production process parameters, unable to produce sodium bismuth titanate, not nanoflower structure, and the like, Achieve the effect of easy industrial production, good single crystallinity, and cheap raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020]The specific preparation steps are as follows: the first step, adding ammonia water to the citric acid aqueous solution with a concentration of 0.8M to adjust the pH to 4.5, then adding tetrabutyl titanate to it, and stirring it at 50° C. for 9 hours to obtain A clear solution; wherein, the aqueous citric acid solution is prepared by adding citric acid to water at a temperature of 60°C, and the molar ratio between tetrabutyl titanate and citric acid is 1:2.5. In the second step, the aqueous solution of bismuth nitrate pentahydrate is mixed with the clear solution, and stirred at 80° C. for 40 minutes to obtain a uniform, transparent and viscous mixed solution; wherein, the aqueous solution of bismuth nitrate pentahydrate is a mixture of The bismuth nitrate is added into water at a temperature of 90° C. and stirred for 25 minutes to prepare, and the molar ratio between the bismuth nitrate pentahydrate and the citric acid in the clear solution is 1:3.5. The sodium hydroxid...

Embodiment 2

[0022] The specific preparation steps are as follows: the first step, adding ammonia water to the citric acid aqueous solution with a concentration of 0.9M to adjust the pH to 5, then adding tetrabutyl titanate thereinto, and stirring it at 55° C. for 8 hours to obtain A clear solution; wherein, the citric acid aqueous solution is prepared by adding citric acid to water at a temperature of 63°C, and the molar ratio between tetrabutyl titanate and citric acid is 1:2.8. In the second step, first mix the aqueous bismuth nitrate pentahydrate solution with the clear solution, and stir it at 85°C for 38 minutes to obtain a uniform, transparent and viscous mixed solution; wherein, the aqueous solution of bismuth nitrate pentahydrate is a mixture of The bismuth nitrate was added into water at a temperature of 93° C. and stirred for 23 minutes to prepare, and the molar ratio between the bismuth nitrate pentahydrate and the citric acid in the clear solution was 1:3.3. The sodium hydroxi...

Embodiment 3

[0024] The specific preparation steps are as follows: the first step, adding ammonia water to the citric acid aqueous solution with a concentration of 1M to adjust the pH to 5.3, then adding tetrabutyl titanate to it, and stirring it at 60° C. for 7 hours to obtain clarification solution; wherein, the citric acid aqueous solution is prepared by adding citric acid to water at a temperature of 65°C, and the molar ratio between tetrabutyl titanate and citric acid is 1:3. In the second step, the aqueous bismuth nitrate pentahydrate solution is mixed with the clear solution, and stirred at 90° C. for 35 minutes to obtain a uniform, transparent and viscous mixed solution; wherein, the aqueous bismuth nitrate pentahydrate solution is a mixture of The bismuth nitrate is added into water at a temperature of 95° C. and stirred for 20 minutes to prepare, and the molar ratio between the bismuth nitrate pentahydrate and the citric acid in the clear solution is 1:3. The sodium hydroxide was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com