Lead-free piezoelectric knitting ceramic of titanic acid bismuth sodium-titanic acid bismuth potassium and its production

A potassium bismuth titanate, lead-free piezoelectric technology, applied in piezoelectric/electrostrictive/magnetostrictive devices, circuits, electrical components, etc., can solve problems such as environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

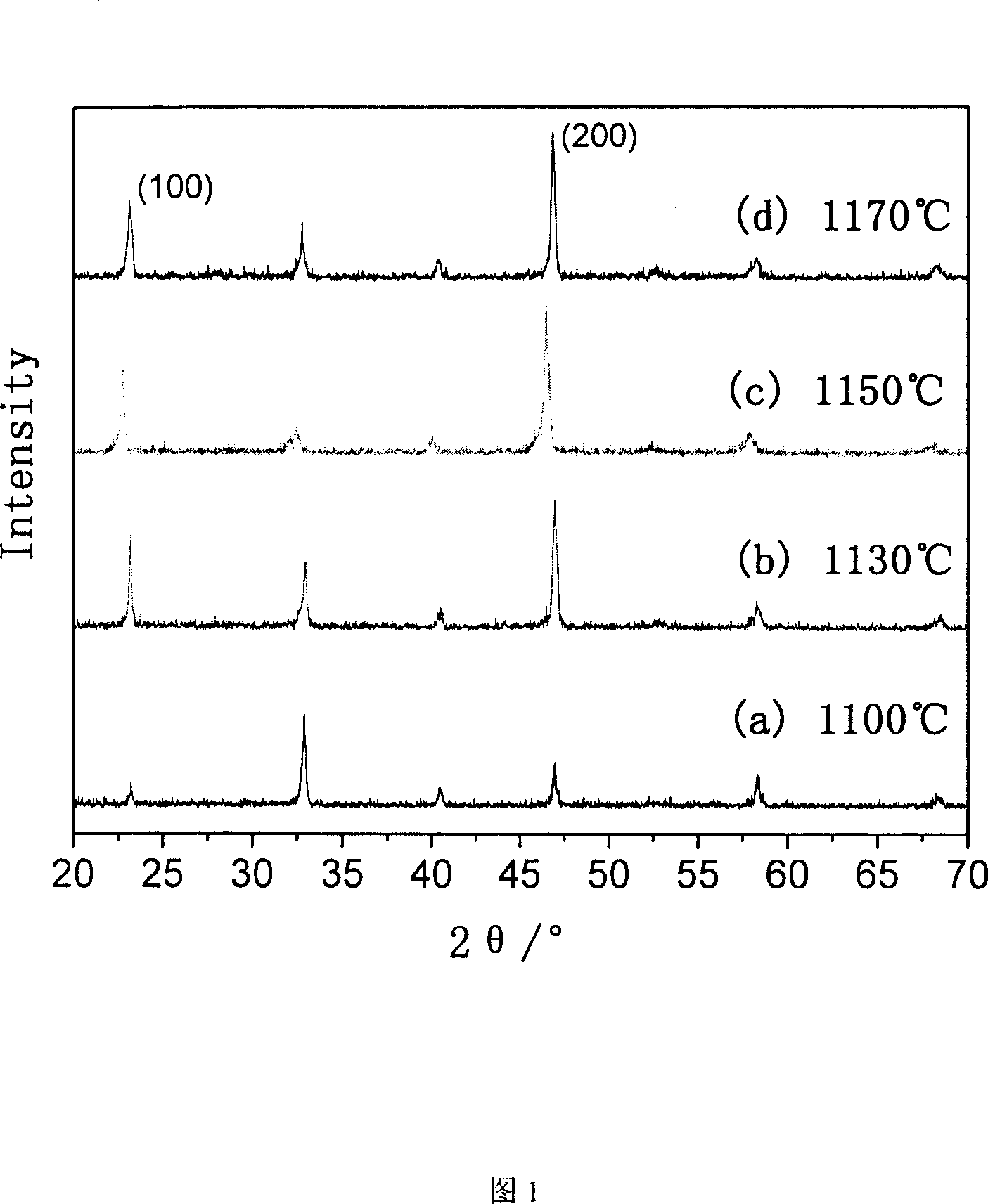

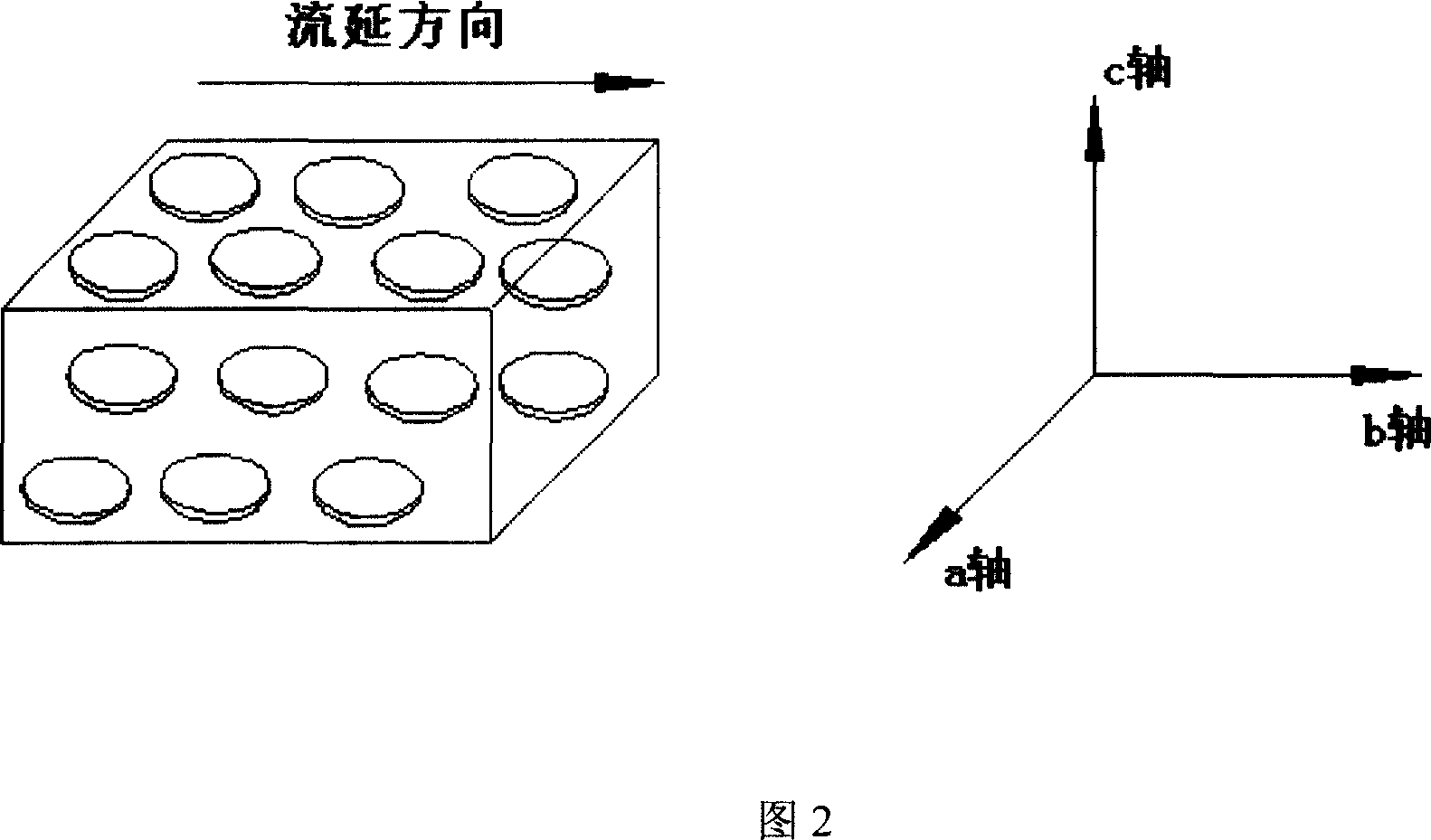

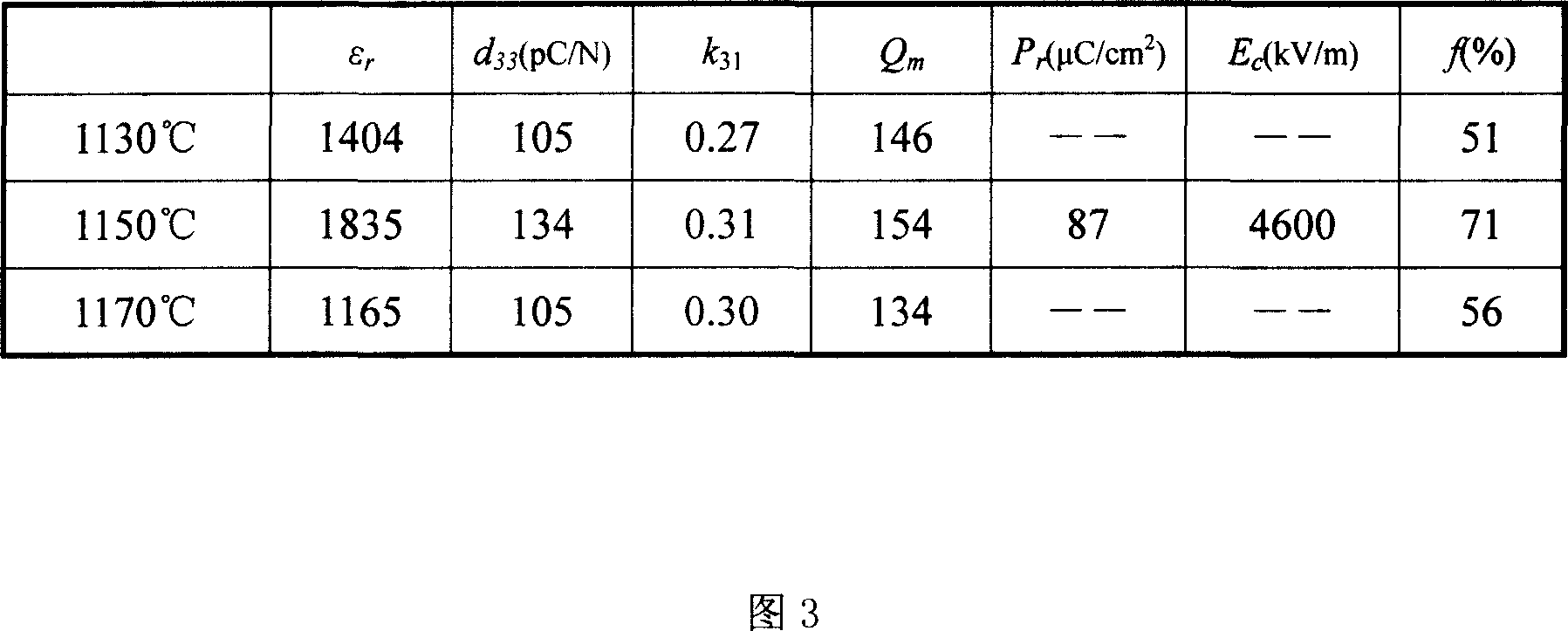

Embodiment 1

[0024] In this embodiment, the microcrystalline template bismuth titanate is mixed with the original powder, organic solvent and binder, wherein:

[0025] The microcrystalline template of textured ceramics is made of 3 parts of titanium dioxide, 2 parts of bismuth oxide, 15% by weight of sodium chloride and potassium chloride, wherein the molar ratio of sodium chloride and potassium chloride is 1:1. The raw powder includes 10% by weight of sodium carbonate, 2.5% by weight of potassium carbonate, 22% by weight of titanium dioxide and 24.5% by weight of bismuth oxide. The binder is 30% of the total weight of the powder, and the organic solvent is 50% of the total weight of the powder.

[0026] In this embodiment, a lead-free piezoelectric textured ceramic is prepared by using a chemical method. Concrete preparation steps are:

[0027] The first step: preparation of microcrystalline template bismuth titanate

[0028] (1) After mixing analytically pure bismuth oxide and titaniu...

Embodiment 2

[0038] In this embodiment, the microcrystalline template bismuth titanate is mixed with the original powder, organic solvent and binder, wherein:

[0039] The microcrystalline template of textured ceramics is made of 3 parts of titanium dioxide, 2 parts of bismuth oxide, 15% by weight of sodium chloride and potassium chloride, wherein the molar ratio of sodium chloride and potassium chloride is 1:1. The raw powder includes 10% by weight of sodium carbonate, 2.5% by weight of potassium carbonate, 28.5% by weight of titanium dioxide and 24% by weight of bismuth oxide. The binder is 40% of the total weight of the powder. The organic solvent is 55% of the total weight of the powder.

[0040] In this embodiment, a lead-free piezoelectric textured ceramic is prepared by using a chemical method. Concrete preparation steps are:

[0041] The first step: preparation of microcrystalline template bismuth titanate

[0042] (1) After mixing analytically pure bismuth oxide and titanium d...

Embodiment 3

[0052] In this embodiment, the microcrystalline template bismuth titanate is mixed with the original powder, organic solvent and binder, wherein:

[0053] The microcrystalline template of textured ceramics is made of 3 parts of titanium dioxide, 2 parts of bismuth oxide, 15% by weight of sodium chloride and potassium chloride, wherein the molar ratio of sodium chloride and potassium chloride is 1:1. The raw powder includes 10% by weight of sodium carbonate, 2.5% by weight of potassium carbonate, 28.5% by weight of titanium dioxide and 29% by weight of bismuth oxide. The binder is 45% of the total weight of the powder. The organic solvent is 60% of the total weight of the powder.

[0054] In this embodiment, a lead-free piezoelectric textured ceramic is prepared by using a chemical method. The specific steps are:

[0055] The first step: preparation of microcrystalline template bismuth titanate

[0056] (1) After mixing analytically pure bismuth oxide and titanium dioxide, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com