Sodium bismuth titanate-system lead-free piezoelectric ceramic and preparation method thereof

A lead-free piezoelectric and sodium bismuth titanate technology, applied in the field of ceramic compositions, can solve the problems of strong coercive field, poor chemical stability, and low comprehensive piezoelectric performance, and achieve good piezoelectric performance and low production cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) Ingredients synthesis

[0038] According to 0.96 (Bi 0.5 Na 0.44-x K 0.06 Li x )TiO 3 -0.04BaTiO 3 , the stoichiometric ratio of x=0.005 takes raw material Bi 2 o 3 、K 2 CO 3 、Na 2 CO 3 、TiO 2 , Li 2 CO 3 , and Ba 2 CO 3 , mix evenly, put it into a ball mill jar, use absolute ethanol and zirconia balls as the ball mill medium, mill at a speed of 800 rpm for 5 hours, and then place the milled slurry in an oven for drying at 80°C ;

[0039] (2) pre-burning

[0040] Put the powder dried in step (1) into an alumina crucible, pre-fire it in a muffle furnace at 850°C, keep it warm for 5 hours, then cool it down to room temperature naturally, and then put the pre-fired powder in a ball mill Carry out secondary ball milling, that is, ball milling at a speed of 800 revolutions per minute for 5 hours to obtain ball milling slurry, and then place the slurry in an oven to dry at 80°C;

[0041] (3) Granulation

Embodiment 2

[0058] The stoichiometric ratio of the raw material composition of embodiment 2, x=0.025 wherein, other process conditions are identical with embodiment 1.

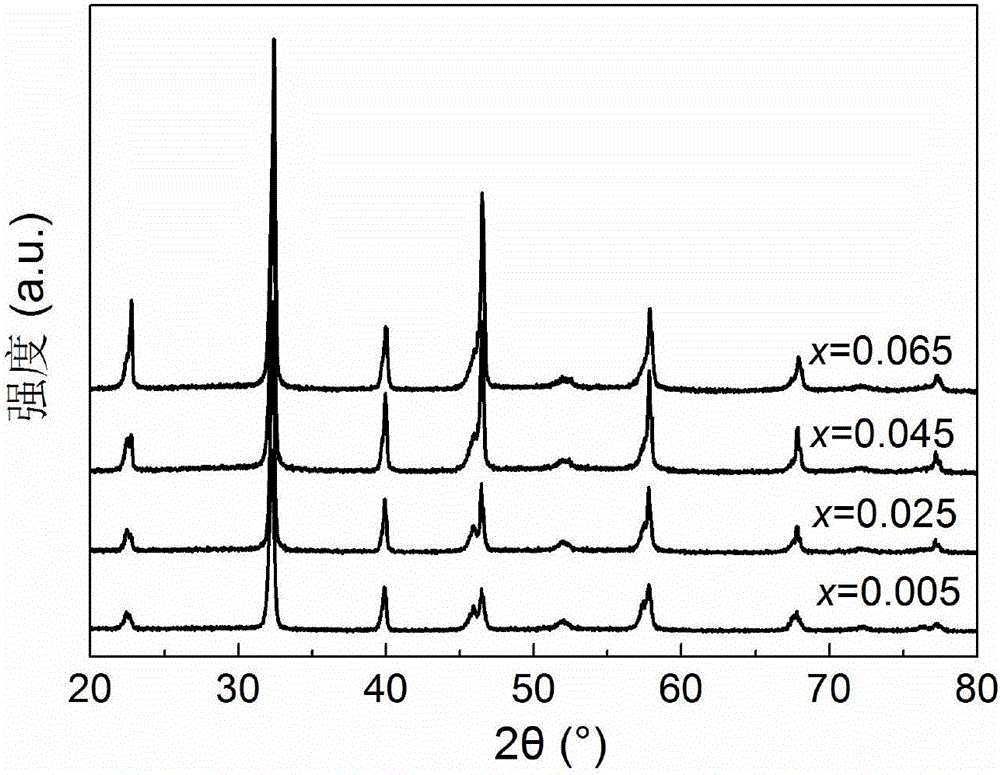

[0059] The piezoelectric ceramics prepared in this experiment were analyzed by XRD, which showed that the piezoelectric ceramics had a single perovskite structure.

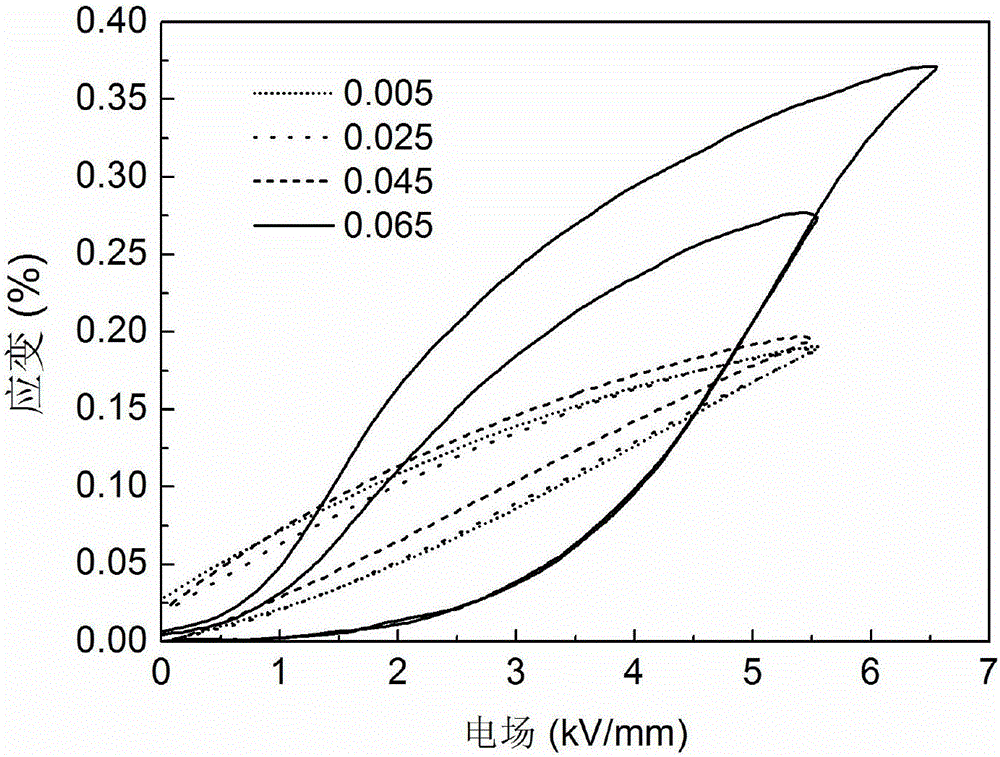

[0060] The detection performance is as follows:

[0061] d 33 (pC / N)ε r tanδ

[0062] 210 1207 0.030

Embodiment 3

[0064] The stoichiometric ratio of the raw material composition of embodiment 3, x=0.045 wherein, other process conditions are identical with embodiment 1.

[0065] The piezoelectric ceramics prepared in this experiment were analyzed by XRD, which showed that the piezoelectric ceramics had a single perovskite structure.

[0066] The detection performance is as follows:

[0067] d 33 (pC / N)ε r tanδ

[0068] 205 1347 0.043

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com