Sodium bismuth titanate based lead-free piezoelectric ceramic with high piezoelectric coefficient and method for preparing sodium bismuth titanate based lead-free piezoelectric ceramic

A technology based on lead-free piezoelectric and sodium bismuth titanate, applied in the manufacture/assembly of piezoelectric/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, circuits, etc. Coefficient and other issues, to achieve the effect of good piezoelectric performance, low production cost and good application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

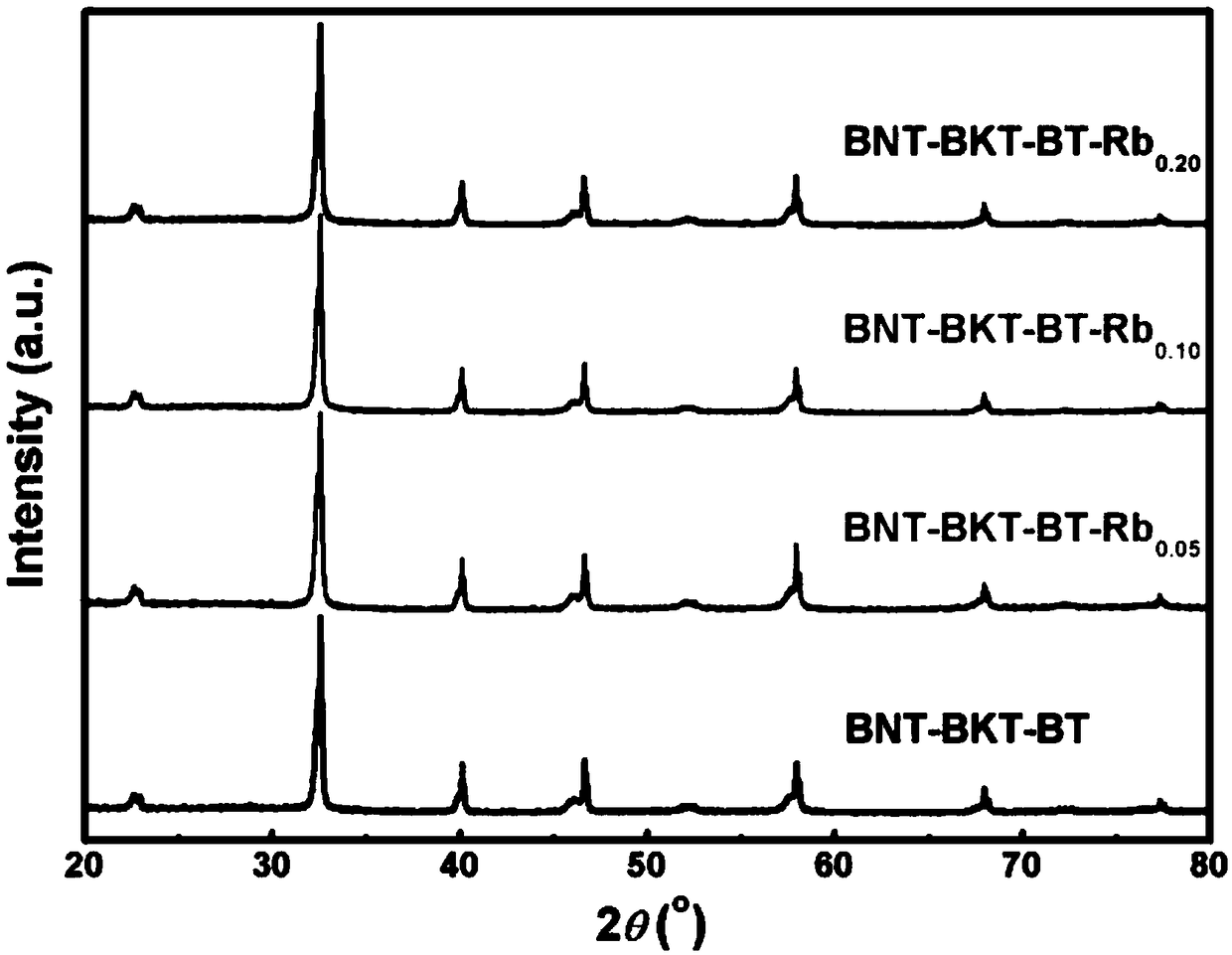

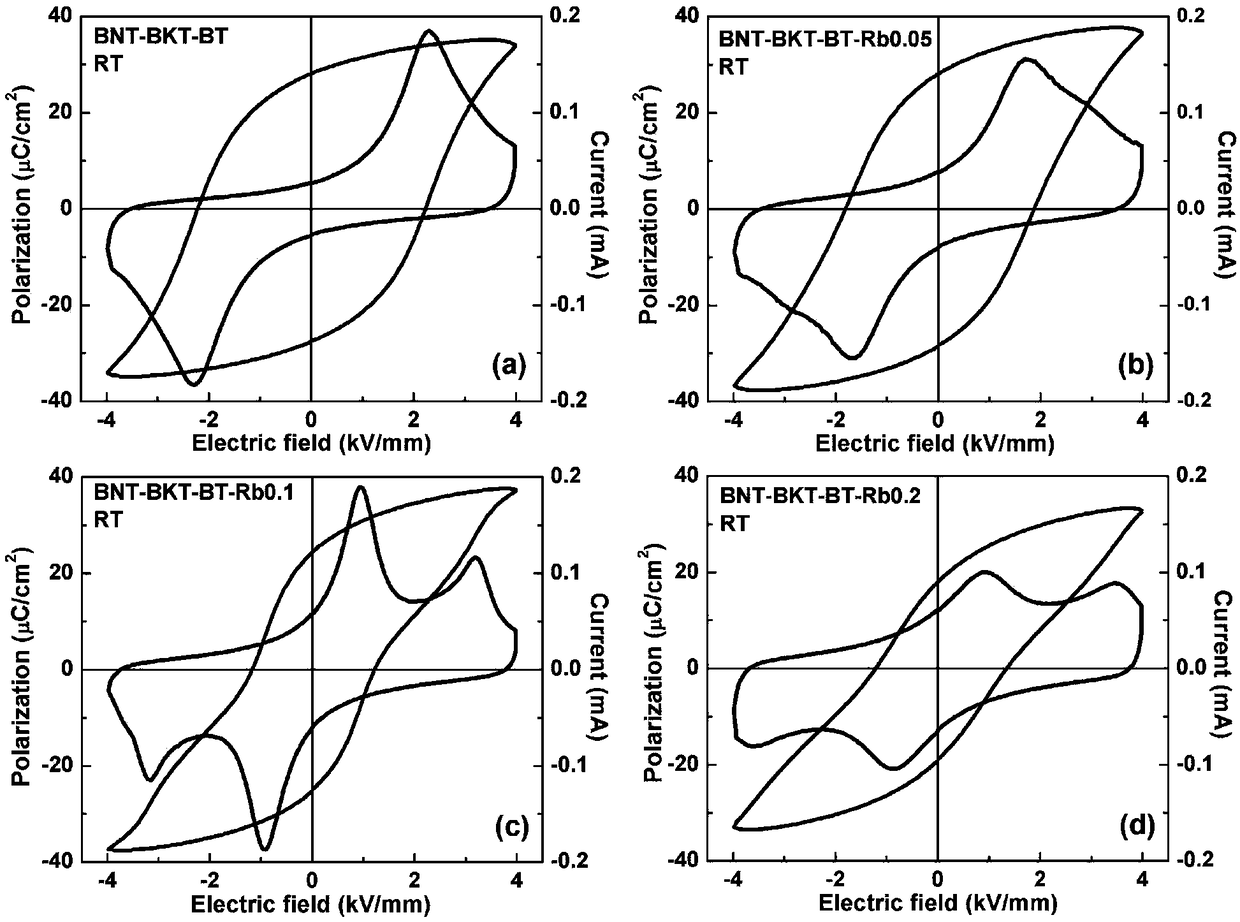

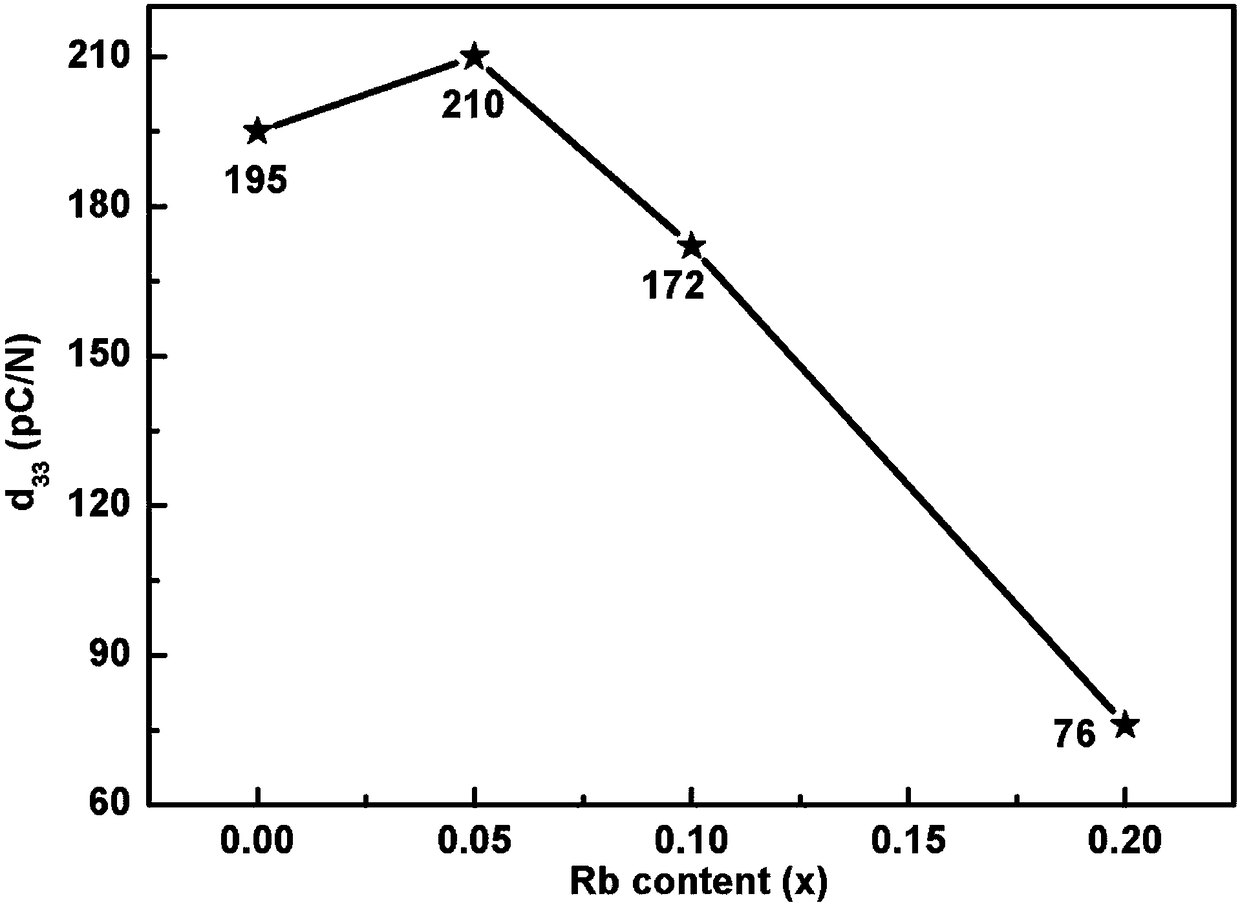

[0035] Example 1: Preparation of BNT-BKT-BT lead-free piezoelectric ceramics.

[0036] According to 0.85Bi 0.5 Na 0.5 TiO 3 -0.11Bi 0.5 K 0.5 TiO 3 -0.04BaTiO 3 The molar stoichiometric ratio of the raw material Bi was weighed 2 o 3 , Na 2 CO 3 , K 2 CO 3 , BaCO 3 and TiO 2 Mix evenly, put the prepared material into a nylon jar with absolute ethanol as the medium and zirconia balls as the balls for ball milling, and ball mill for 12 hours at a speed of 400r / min. Then the ball-milled slurry was dried at 80°C. The dried powder was passed through a 200-mesh sieve, placed in an alumina crucible, and pre-fired at 800°C for 3 hours to obtain a pre-fired powder. Then the calcined powder was ball milled at 400r / min for 24h, and then dried at 80°C. After sieving the above powder, add 1% of the total mass of calcined powder, add polyvinyl butyral (PVA), fully grind until the powder is granular, and obtain a powder with uniform particles, and hold the pressure for 5 minut...

Embodiment 2

[0037] Embodiment 2: Preparation of BNT-BKT-BT-Rb 0.05 Lead-free piezoelectric ceramics.

[0038]According to 0.85Bi 0.5 Na 0.5 TiO 3 -0.11Bi 0.5 K 0.45 Rb 0.05 TiO 3 -0.04BaTiO 3 The stoichiometric ratio of the raw material Bi is weighed 2 o 3 , Na 2 CO 3 ,K 2 CO 3 , BaCO 3 ,Rb 2 CO 3 and TiO 2 powder, put the prepared material into a nylon jar with absolute ethanol as the medium and zirconia balls as the balls for ball milling, and ball mill for 12 hours at a speed of 400r / min. Then the ball-milled slurry was dried at 75°C. The dried powder was passed through a 200-mesh sieve, placed in an alumina crucible, and pre-fired at 850°C for 3 hours to obtain a pre-fired powder. Then the calcined powder was ball milled at 400r / min for 24h, and then dried at 80°C. After sieving the above powder, add 0.8% of the total mass of calcined powder, add polyvinyl butyral (PVA), fully grind until the powder is granular, and obtain a powder with uniform particles, and hold ...

Embodiment 3

[0039] Embodiment 3: Preparation of BNT-BKT-BT-Rb 0.10 Lead-free piezoelectric ceramics.

[0040] According to 0.85Bi 0.5 Na 0.5 TiO 3 -0.11Bi 0.5 K 0.40 Rb 0.10 TiO 3 -0.04BaTiO 3 The stoichiometric ratio of the raw material Bi is weighed 2 o 3 , Na 2 CO 3 ,K 2 CO 3 , BaCO 3 ,Rb 2 CO 3 and TiO 2 powder, put the prepared material into a nylon jar with absolute ethanol as the medium and zirconia balls as the balls for ball milling, and ball mill for 12 hours at a speed of 400r / min. Then the ball-milled slurry was dried at 85°C. The dried powder was passed through a 200-mesh sieve, placed in an alumina crucible, and pre-fired at 850°C for 3 hours to obtain a pre-fired powder. Then the calcined powder was ball milled at 400r / min for 24h, and then dried at 85°C. After sieving the above powder, add 1% of the total mass of calcined powder, add polyvinyl butyral (PVA), fully grind until the powder is granular, and obtain a powder with uniform particles, and hold t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| piezoelectric charge coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com