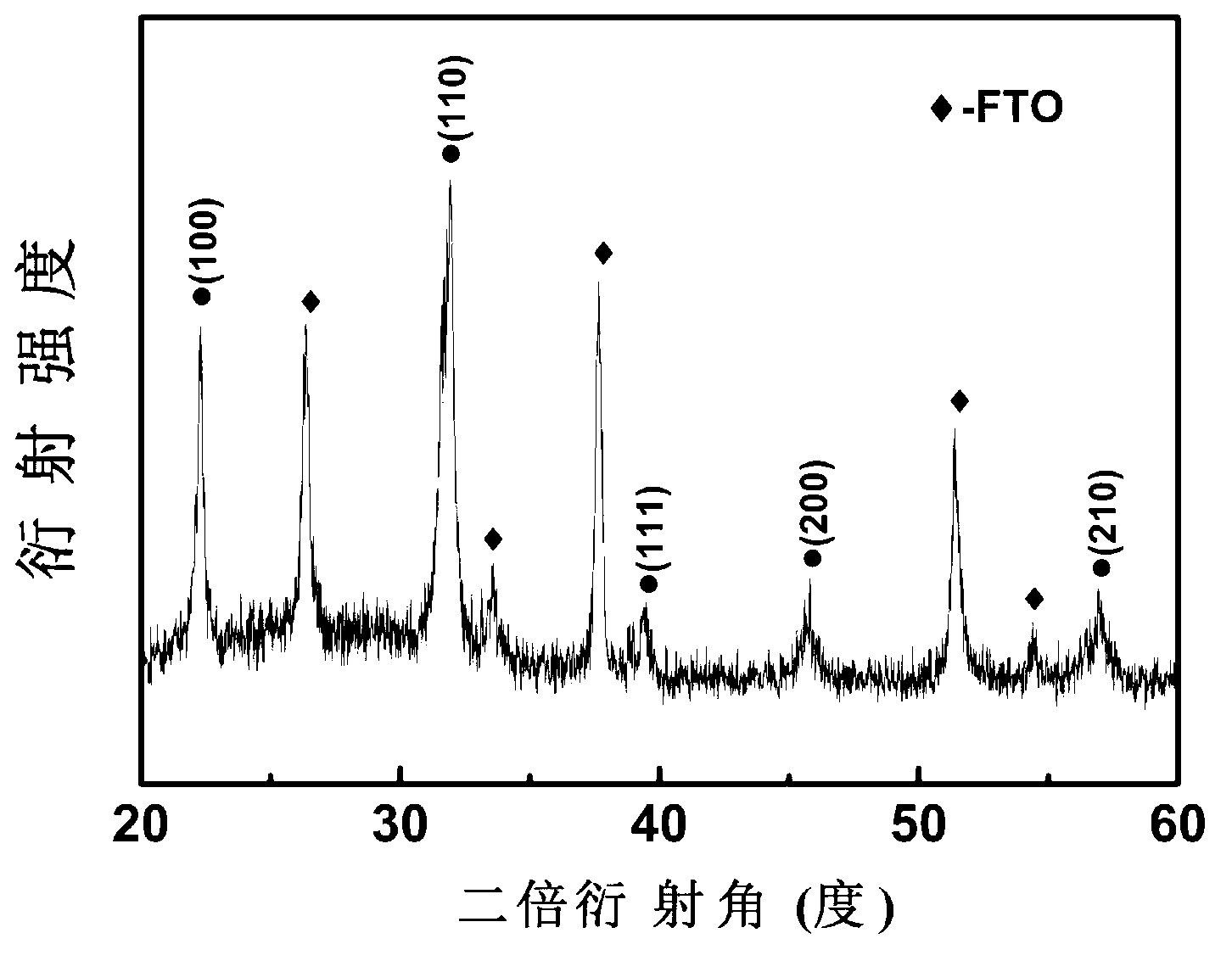

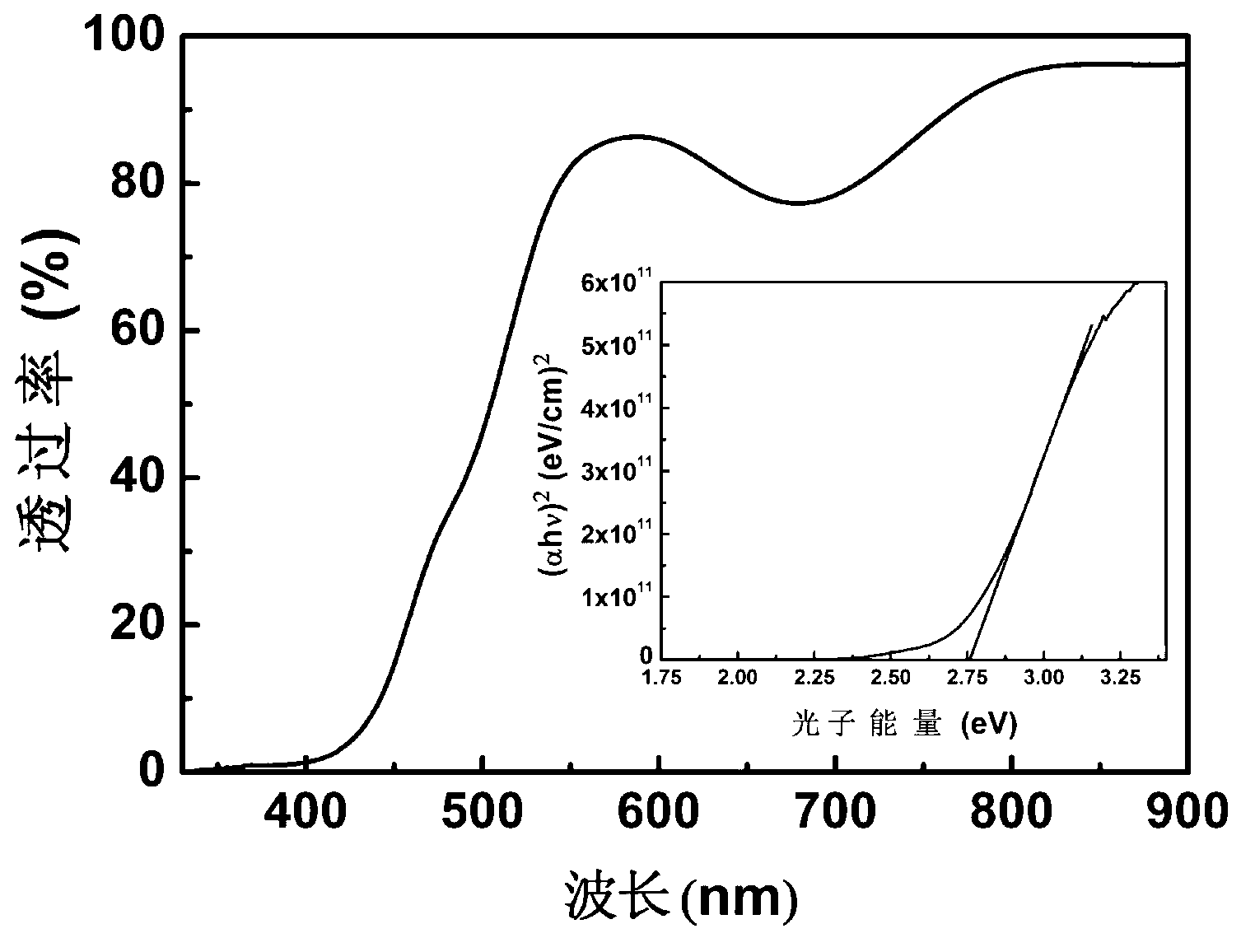

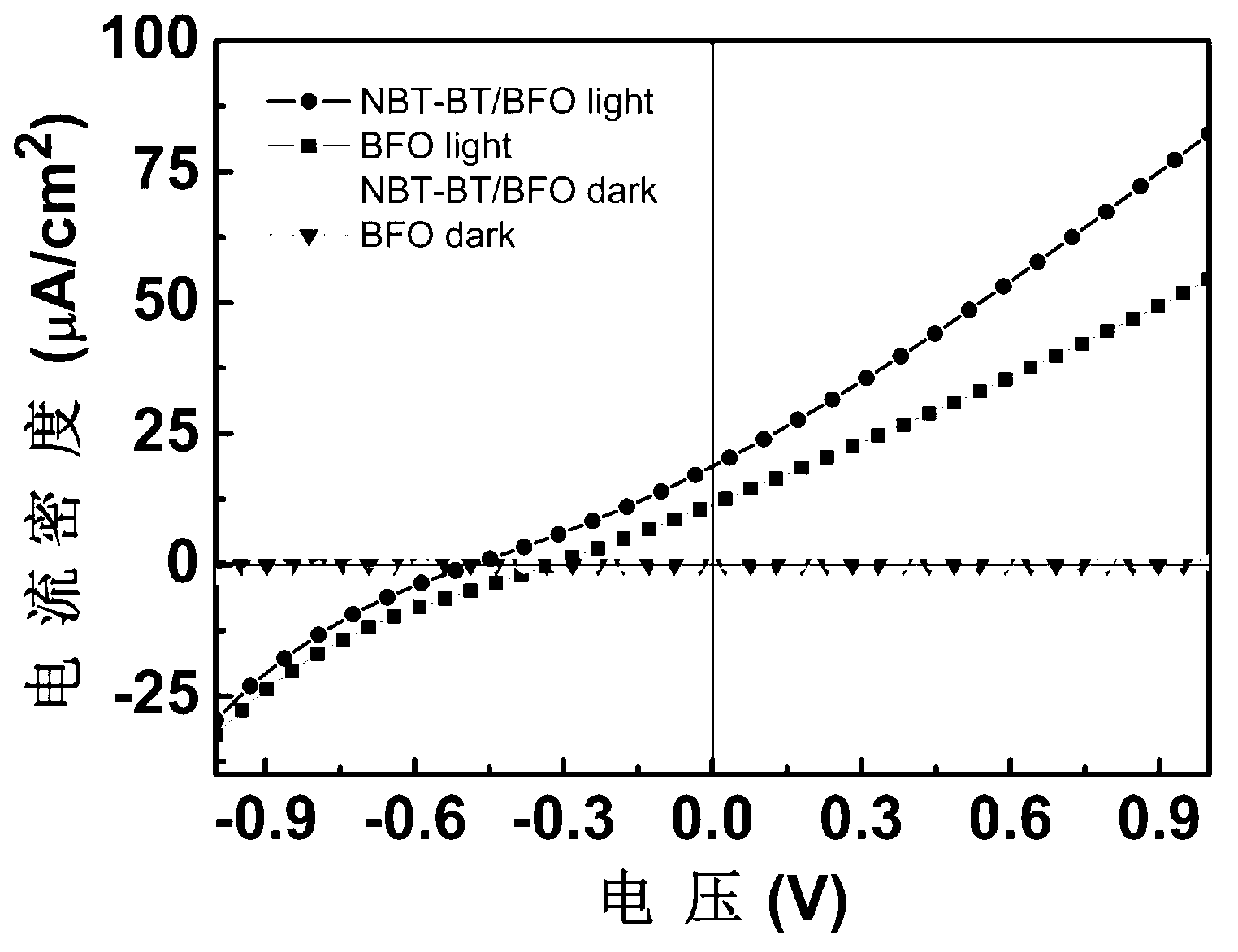

Preparation method of solar battery with bismuth ferrite/sodium bismuth titanate-barium titanate heterostructure ferroelectric film

A technology of solar cells and heterogeneous structures, applied in the manufacture of circuits, electrical components, and final products, to achieve superior photovoltaic performance, simple preparation methods, and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) Preparation of BFO precursor solution and NBT-BT precursor solution

[0036] BFO precursor solution preparation: Bi(NO 3 ) 3 ·5H 2 O and Fe(NO3 ) 3 9H 2 O is completely dissolved in ethylene glycol methyl ether at a molar ratio of 1:1 to obtain a reddish-brown clear and stable BFO precursor solution;

[0037] Preparation of NBT-BT precursor solution: using ethylene glycol methyl ether as solvent, Ti[OCH(CH 3 ) 2 ] 4 , Bi(NO 3 ) 3 ·5H 2 O, Ba(CH 3 COO) 2 and NaNO 3 As the solute, prepare the NBT-BT precursor solution in atomic proportion; dissolve Ti[OCH(CH 3 ) 2 ] 4 Mix it with acetylacetone evenly; after the above solutes are dissolved, add ethanolamine and 1 / 4 of the volume of the prepared solution under heating conditions at 70°C to obtain a stable NBT-BT precursor solution;

[0038] (2) Preparation of BFO / NBT-BT heterostructure ferroelectric thin film

[0039] Then thin films were prepared on the FTO substrate by the glue-spin method. The condi...

Embodiment 2

[0043] Prepare the required NBT-BT and BFO precursor solutions according to the aforementioned precursor solution preparation method. Then thin films were prepared on the FTO substrate by the glue-spin method. The condition of glue rejection is as follows: 10 seconds at 1000 rpm and 30 seconds at 3000 rpm. After spinning the glue, the substrate with the precursor wet film was first dried on a hot plate at 200°C for 3 minutes, then calcined at 350°C for 5 minutes, and finally in O 2 Sintering in a rapid annealing furnace under atmosphere for 5 minutes, wherein the annealing temperature of NBT-BT is 600°C, and the annealing temperature of BFO is 550°C. Two layers of NBT-BT films were deposited on the FTO substrate first, and then eight layers of BFO films were deposited on the NBT-BT films to obtain 2NBT-BT / 8BFO heterostructure ferroelectric films.

[0044] The prepared thin film was shielded by a mask with a hole of 0.5mm*1mm, and an Au upper electrode of 0.5mm*1mm was deposi...

Embodiment 3

[0046] Prepare the required NBT-BT and BFO precursor solutions according to the aforementioned precursor solution preparation method. Then thin films were prepared on the FTO substrate by the glue-spin method. The condition of glue rejection is as follows: 10 seconds at 1000 rpm and 30 seconds at 3000 rpm. After spinning the glue, the substrate with the precursor wet film was first dried on a hot plate at 200°C for 3 minutes, then calcined at 350°C for 5 minutes, and finally in O 2 Sintering in a rapid annealing furnace under atmosphere for 5 minutes, wherein the annealing temperature of NBT-BT is 600°C, and the annealing temperature of BFO is 550°C. First, 3 layers of NBT-BT films were deposited on the FTO substrate, and then 7 layers of BFO films were deposited on the NBT-BT films to obtain 3NBT-BT / 7BFO heterostructure ferroelectric films.

[0047] The prepared thin film was shielded by a mask with a hole of 0.5mm*1mm, and an Au upper electrode of 0.5mm*1mm was deposited o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com