Sodium titanate nanowire/graphene composite negative electrode material, and preparation method thereof

A graphene composite and negative electrode material technology, which is applied in battery electrodes, electrical components, non-aqueous electrolyte storage batteries, etc., can solve the problem of poor sodium ion electrochemical performance of sodium titanate nanowires/graphene composite negative electrode materials, and sodium ion electrochemical performance. Poor performance, cumbersome process and other problems, to achieve the effect of good sodium storage performance, excellent shape, simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

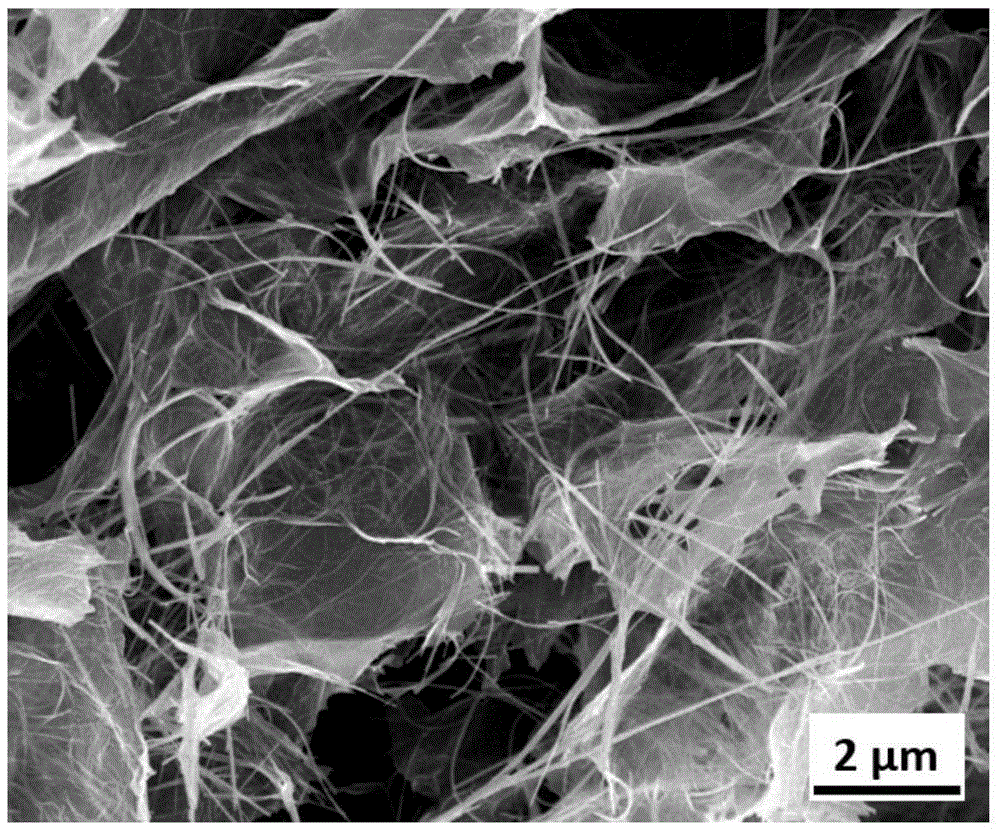

[0020] The embodiment of the present invention provides a method for preparing a sodium titanate nanowire / graphene composite negative electrode material, comprising the following steps:

[0021] S01. graphite oxide is dissolved in an organic solvent to obtain a graphene oxide solution;

[0022] S02. Add a titanium source in the graphene oxide solution, and after mixing, carry out the first solvothermal reaction to obtain a titanium dioxide / graphene composite;

[0023] S03. Add NaOH aqueous solution to the titanium dioxide / graphene composite, and carry out the second solvothermal reaction to obtain the crude product of sodium titanate nanowire / graphene;

[0024] S04. The sodium titanate nanowire / graphene crude product is washed with water until the pH value is neutral, and dried to obtain a sodium titanate nanowire / graphene composite negative electrode material.

[0025] Specifically, in the above step S01, the graphite oxide can be purchased from the market, or can be prepare...

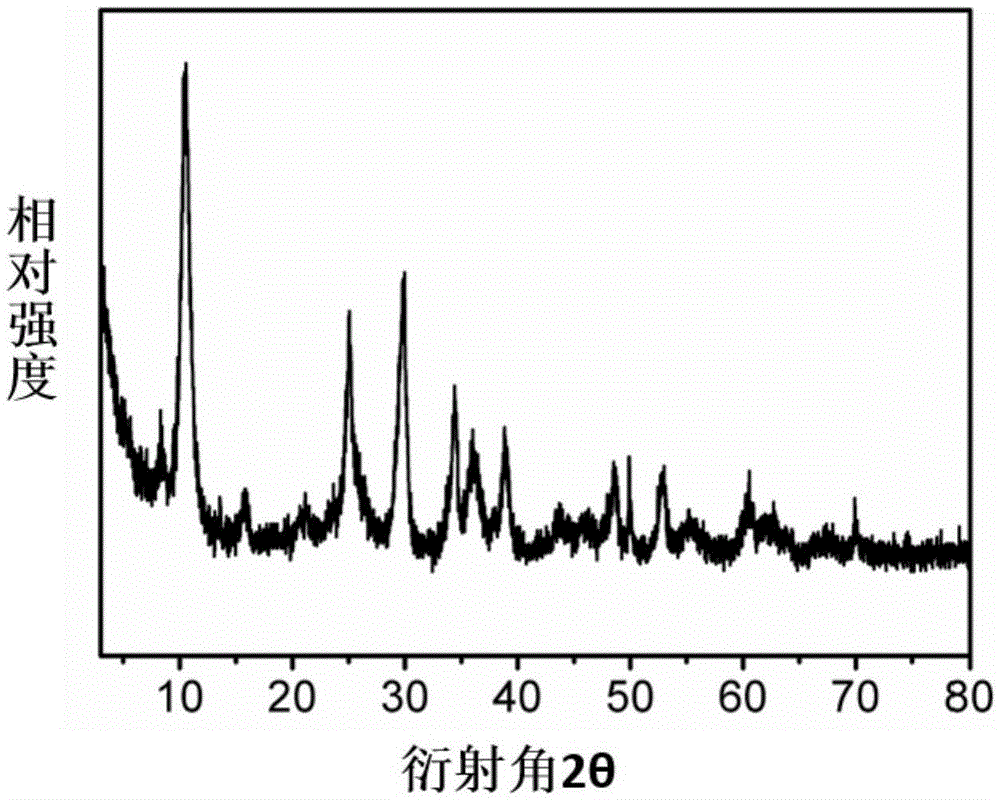

Embodiment 1

[0042] A preparation method of sodium titanate nanowire / graphene composite negative electrode material, comprising the following steps:

[0043] S11. Take 60mg of graphite oxide, add it to 30mL of absolute ethanol, conduct ultrasonic treatment at a constant temperature of 30°C for 30min, and continue stirring for 2h to obtain a graphene oxide ethanol solution;

[0044] S12. Add 0.3 mL of tetrabutyl titanate to the graphene oxide ethanol solution, stir and mix evenly, pour it into a hydrothermal reaction kettle, and perform a solvothermal reaction at 200° C. for 12 hours to obtain a titanium dioxide / graphene composite ;

[0045] S13. Wash the titanium dioxide / graphene composite with water and suction filter, put the filter residue into a hydrothermal reaction kettle, add an appropriate amount of 10mol / L NaOH aqueous solution 5mL, and conduct a hydrothermal reaction at 200°C for 12h to obtain sodium titanate nanowires / graphene crude product;

[0046] S14. The sodium titanate...

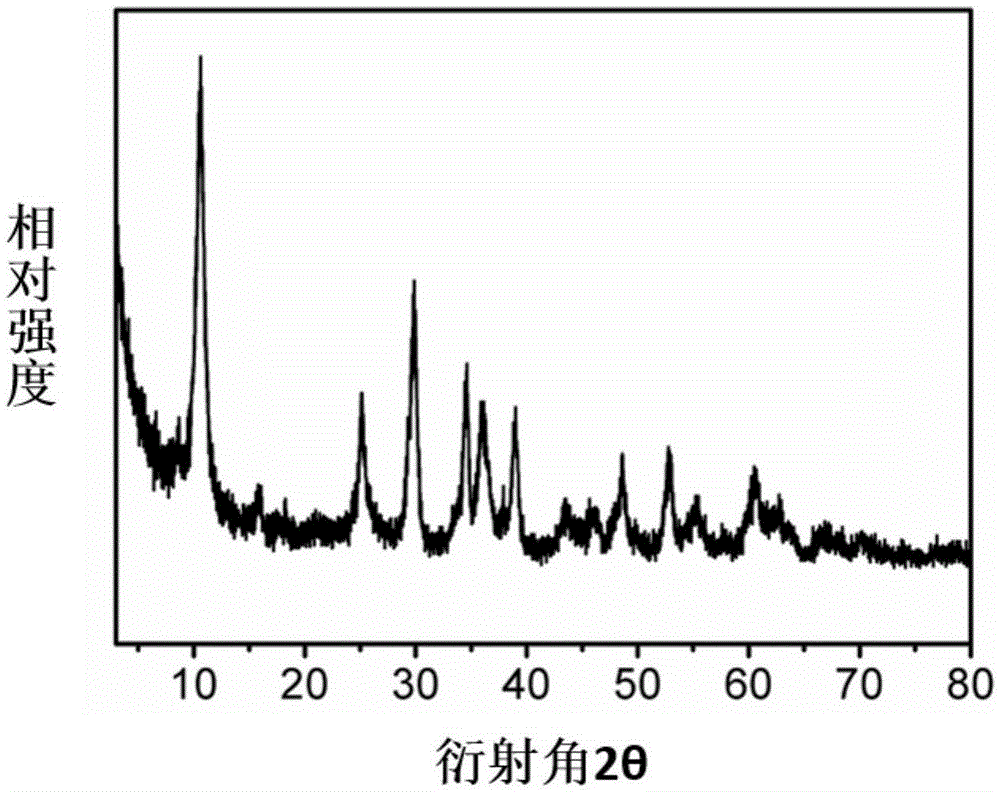

Embodiment 2

[0051] A preparation method of sodium titanate nanowire / graphene composite negative electrode material, comprising the following steps:

[0052] S21. Take 60mg of graphite oxide, add it to 30mL of absolute ethanol, conduct ultrasonic treatment at a constant temperature of 60°C for 10min, and continue stirring for 4h to obtain a graphene oxide ethanol solution;

[0053] S22. Add 0.5 mL of tetrabutyl titanate to the graphene oxide ethanol solution, stir and mix evenly, pour it into a hydrothermal reaction kettle, and perform a solvothermal reaction at 160° C. for 12 hours to obtain a titanium dioxide / graphene composite ;

[0054] S23. Wash the titanium dioxide / graphene composite with water and suction filter, put the filter residue into a hydrothermal reaction kettle, add an appropriate amount of 10mol / L NaOH aqueous solution 10mL, and conduct a hydrothermal reaction at 220°C for 24h to obtain sodium titanate nanowires / graphene crude product;

[0055]S24. The sodium titanate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com