Method for preparing titanium dioxide nanowire

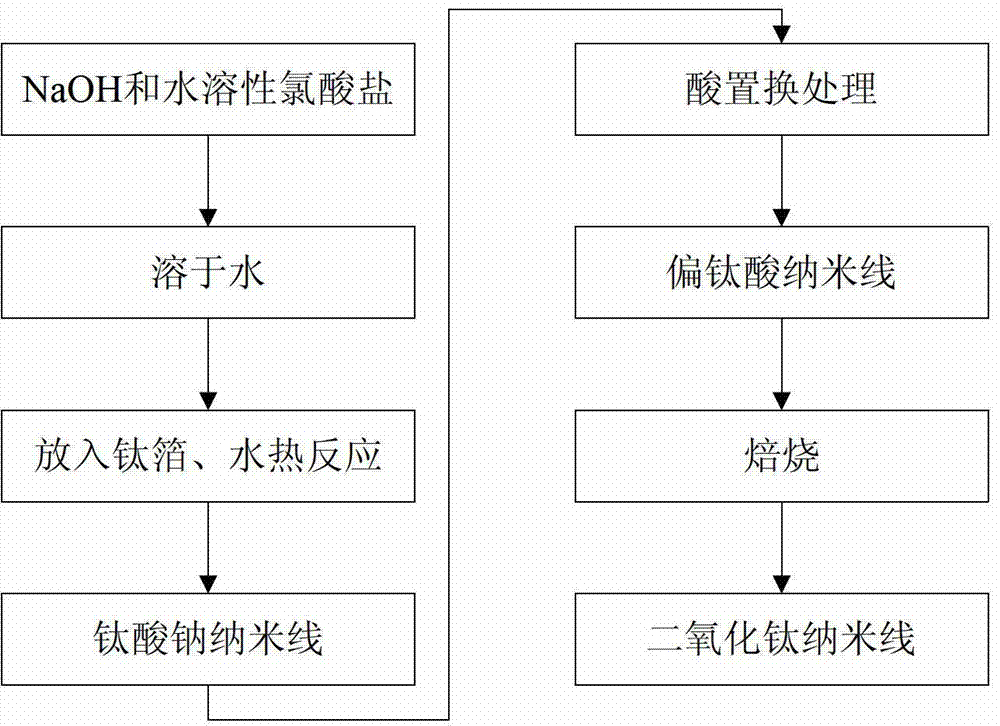

A titanium dioxide and nanowire technology, which is applied in the field of preparation of inorganic materials, can solve problems such as low yield, and achieve the effects of good crystallinity, large specific surface area and regular size arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

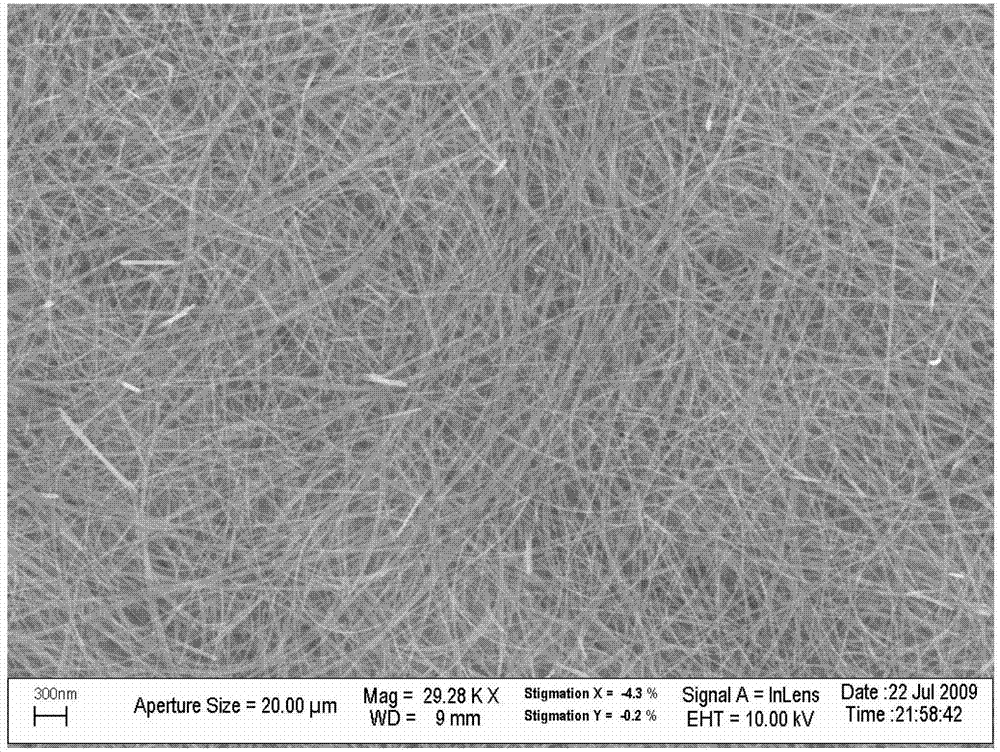

[0021] Add 60g NaOH and 6.5g NaCl to 500ml deionized water, stir until completely dissolved. Then the above solution was transferred to a polytetrafluoroethylene-lined hydrothermal kettle, added with a clean titanium foil, sealed, and hydrothermally reacted at 200°C for 48 hours. The hydrothermal reaction forms a layer of white sodium titanate on the surface of the titanium foil, and part of it is dispersed into the solution. The white matter of sodium titanate on the titanium foil was scraped off, filtered together with the sodium titanate in the solution, washed with deionized water, and dried at 110° C. to obtain sodium titanate nanowires. Immerse the titanate nanowires in 0.5M HCl solution for 10 hours, then filter, wash with deionized water, and dry at 105-130° C. to obtain the metatitanic acid nanowires. Calcining the metatitanic acid nanowires at 400° C. for 1 hour to obtain titanium dioxide nanowires. Electron microscope observation shows that its diameter is fine, w...

Embodiment 2

[0023] Add 120g NaOH and 3.0g NaCl to 1000ml deionized water, stir until completely dissolved. Then the above solution was transferred to a polytetrafluoroethylene-lined hydrothermal kettle, and a cleaned titanium foil was added, sealed, and hydrothermally reacted at 180° C. for 48 hours. The hydrothermal reaction forms a layer of white sodium titanate on the surface of the titanium foil, and part of it is dispersed into the solution. The white matter of sodium titanate on the titanium foil was scraped off, filtered together with the sodium titanate in the solution, washed with deionized water, and dried at 110° C. to obtain sodium titanate nanowires. Immerse the titanate nanowires in 0.5M HCl solution for 10 hours, then filter, wash with deionized water, and dry at 105-130° C. to obtain the metatitanic acid nanowires. Calcining the metatitanic acid nanowires at 400° C. for 1 hour to obtain titanium dioxide nanowires. Electron microscope observation shows that its diameter i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com