Method for producing nano-wire array film of titanium dioxide

A technology of nanowire array and titanium dioxide, which is applied in the direction of titanium dioxide, titanium oxide/hydroxide, metal material coating technology, etc., to achieve the effect of low cost, firm combination and ideal crystallization

Inactive Publication Date: 2010-11-10

ZHEJIANG UNIV

View PDF0 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, there is no simple method for preparing titania nanowire array films without adding templates and catalysts.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Login to View More

Abstract

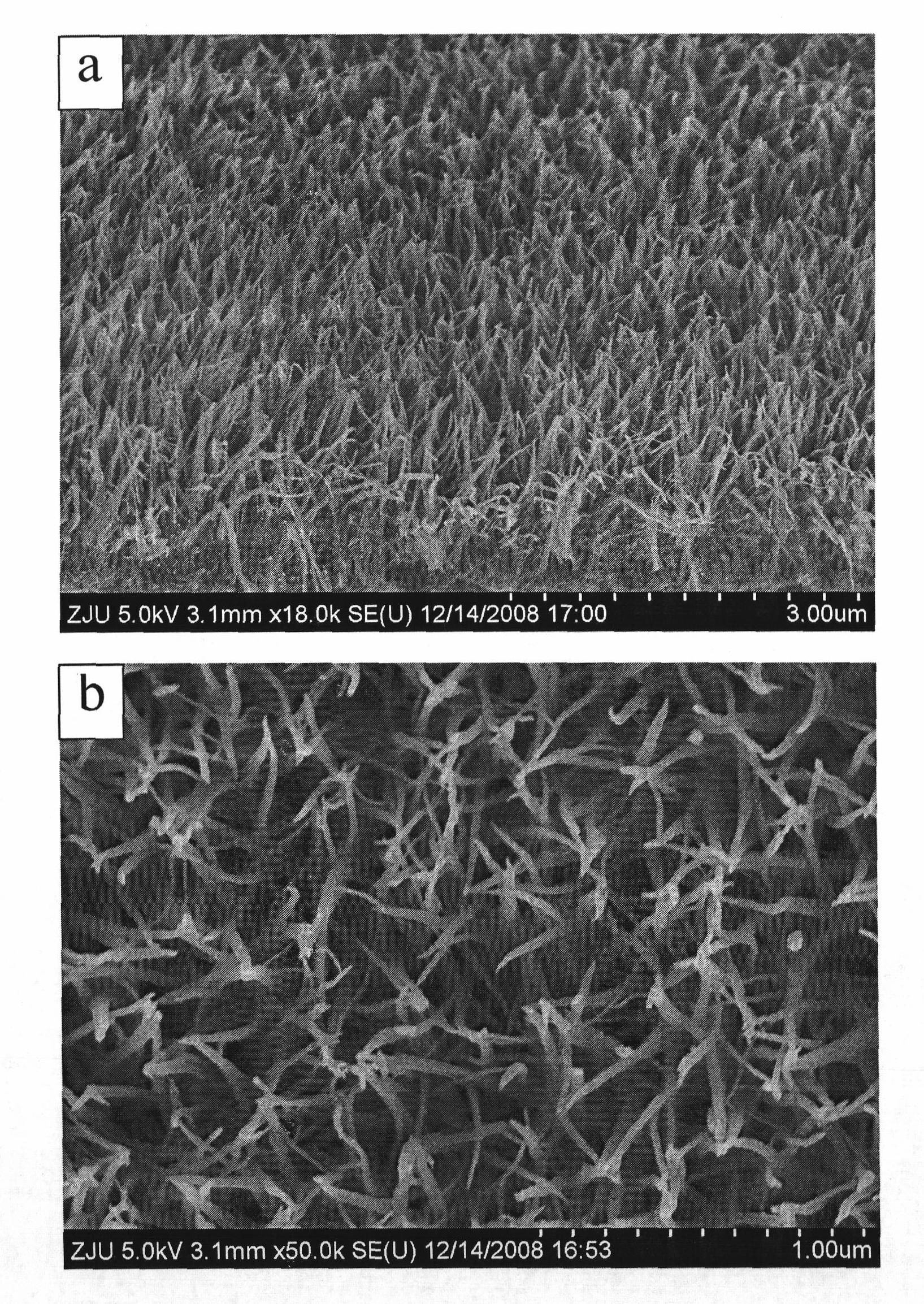

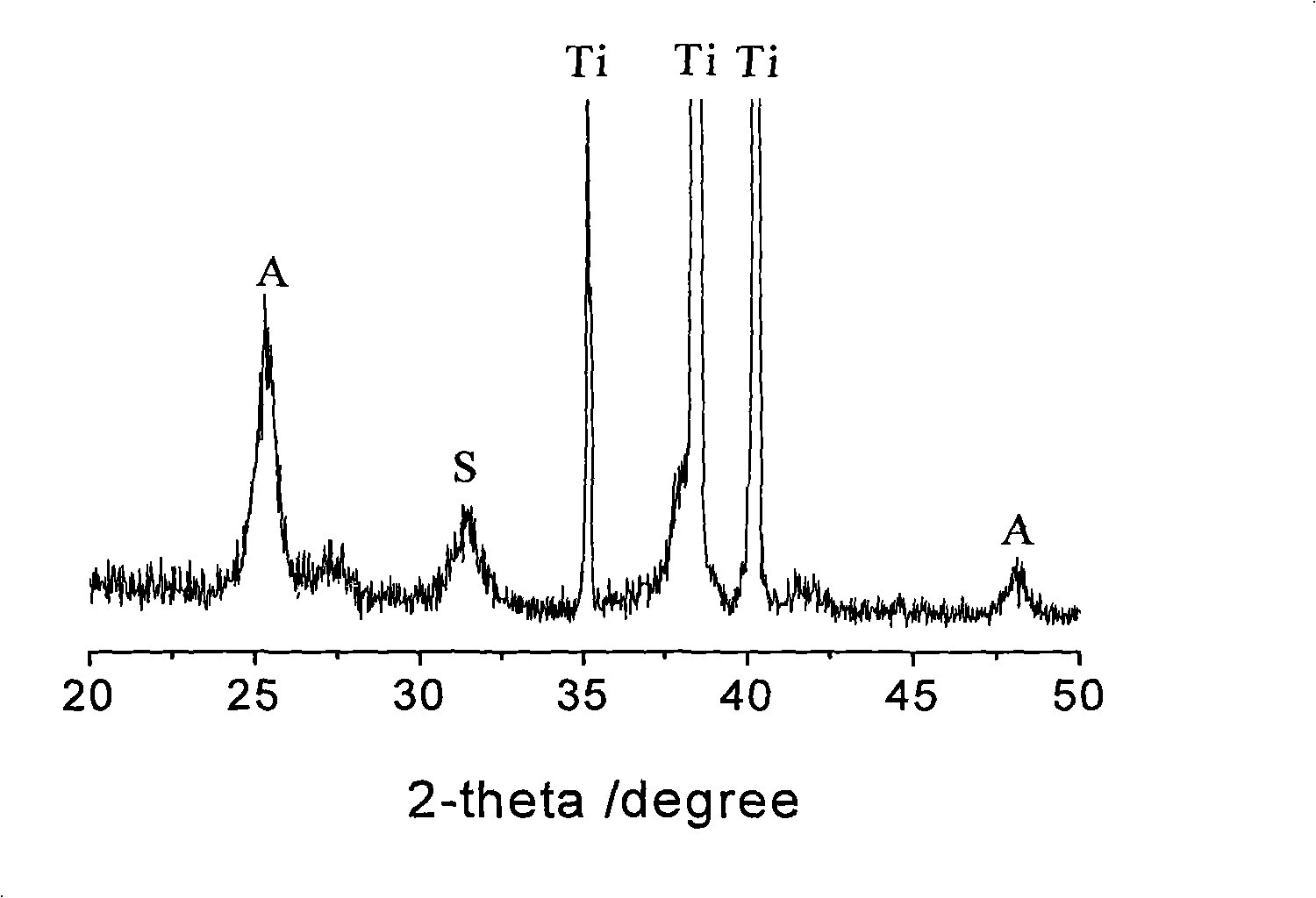

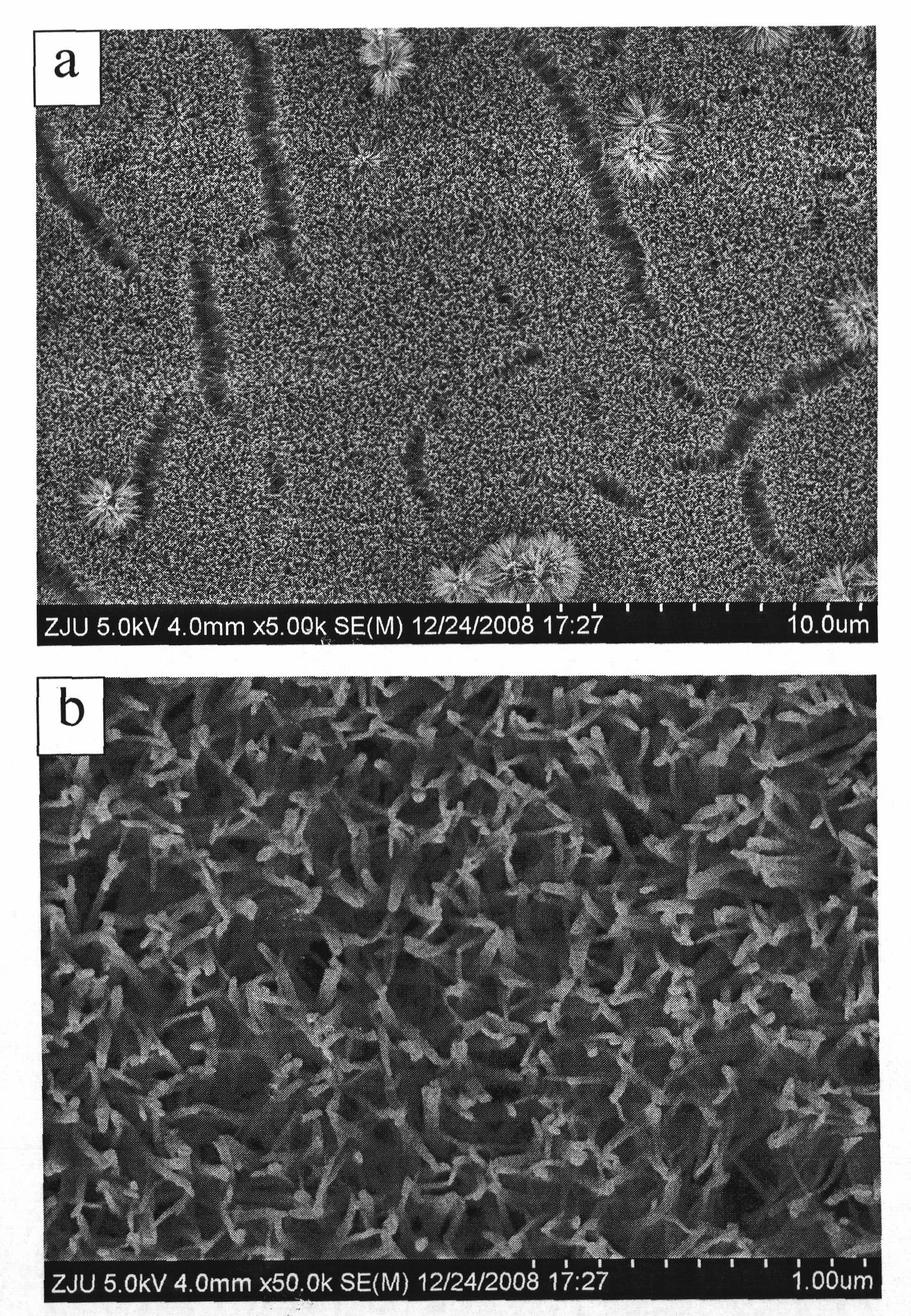

The invention discloses a method for preparing a titanium dioxide nano-wire array film. The method comprises the following steps: mixing hydrofluoric acid, nitric acid and deionized water to prepare an acid wash; adding melamine and nitric acid into a hydrogen peroxide solution to obtain a reaction solution; washing the surface of a metal titanium plate by the acid wash to be immersed in the reaction solution to react for 60 to 72 hours at a temperature of between 60 and 90 DEG C; and washing the reacted titanium plate by the deionized water to be dried, and insulating the titanium plate for 1 to 2 hours at a temperature of between 350 and 550 DEG C. The method for preparing the titanium dioxide nano-wire array film does not need a template or a catalyst, and has the advantages of simpleness and feasibility, low cost, pure film, regular size arrangement, perfect crystallization, large specific surface area and firm combination with a substrate, and the titanium dioxide nano-wire arrayfilm has wide application in photocatalysis, photoelectrocatalysis, thin-film solar cell, gas sensor, cold cathode electronic emission and other fields.

Description

A method for preparing titanium dioxide nanowire array film technical field The invention relates to a method for preparing titanium dioxide nanowire arrays. Background technique TiO thin films have a wide range of potential applications in photocatalysis, photoelectrocatalysis, gas sensors, thin-film solar cells, electrochromic thin films, and field emission. Titanium dioxide ordered array films with nanostructures such as nanorods, nanoflowers, nanotubes, and nanowires have extremely high specific surface areas, and thus exhibit excellent performance in the above applications. In addition, compared with dense films composed of ordinary nanoparticles, ordered array films such as titanium dioxide nanorods and nanowires have better space charge separation effects, which are important for photocatalysis, photoelectrocatalysis and photoanodes. . So far, whether it is anatase or rutile phase titanium dioxide nanowire arrays, most of them are made by the following different m...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C23C22/05C01G23/047

Inventor 吴进明薛红星

Owner ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com