Method for preparing titanium dioxide nano-tube

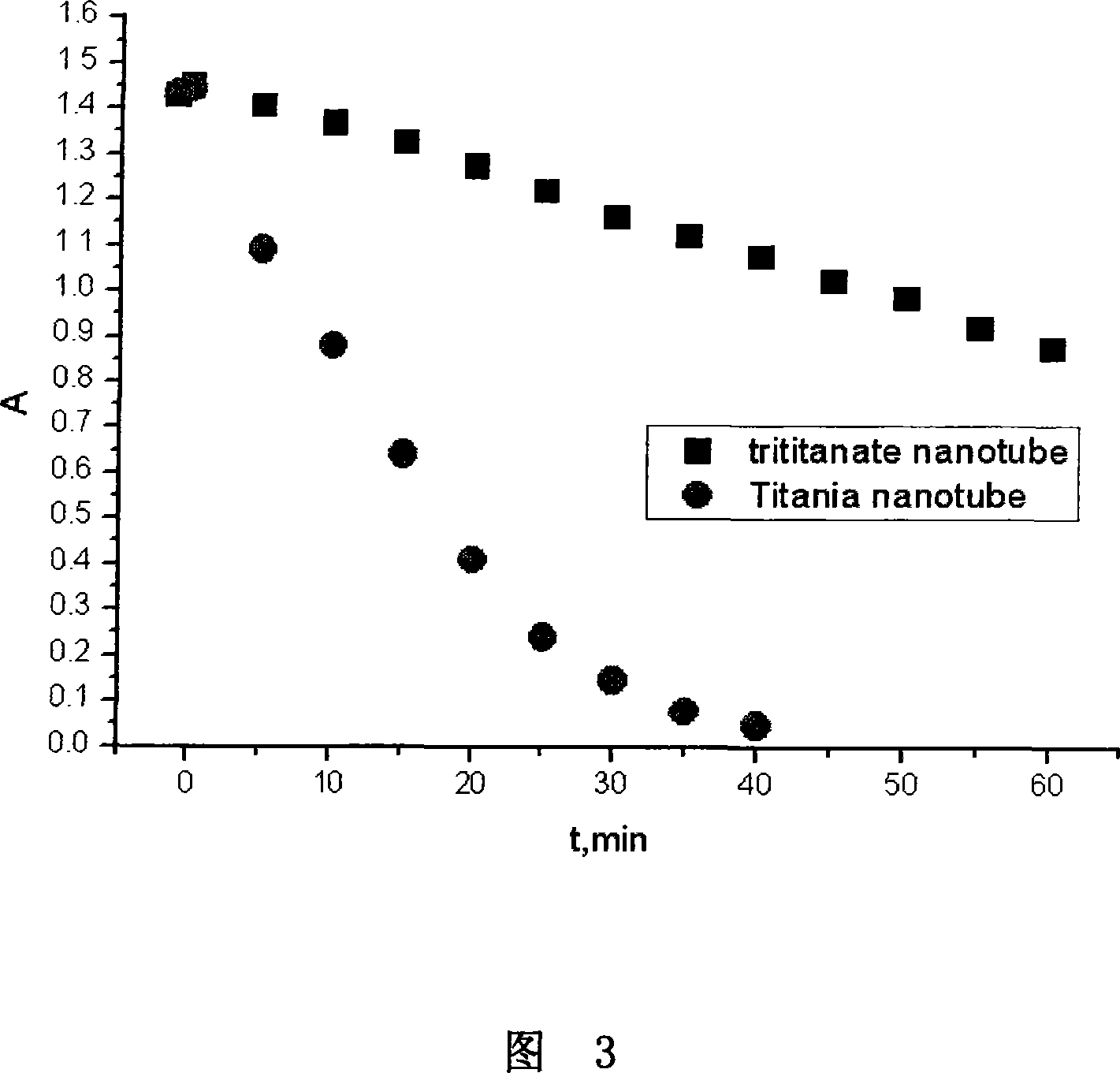

A titanate nanotube and nanotube technology, which is applied in the field of photocatalysis and information, can solve the problems of tubular structure damage, low photocatalytic activity, and inability to perform high temperature treatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

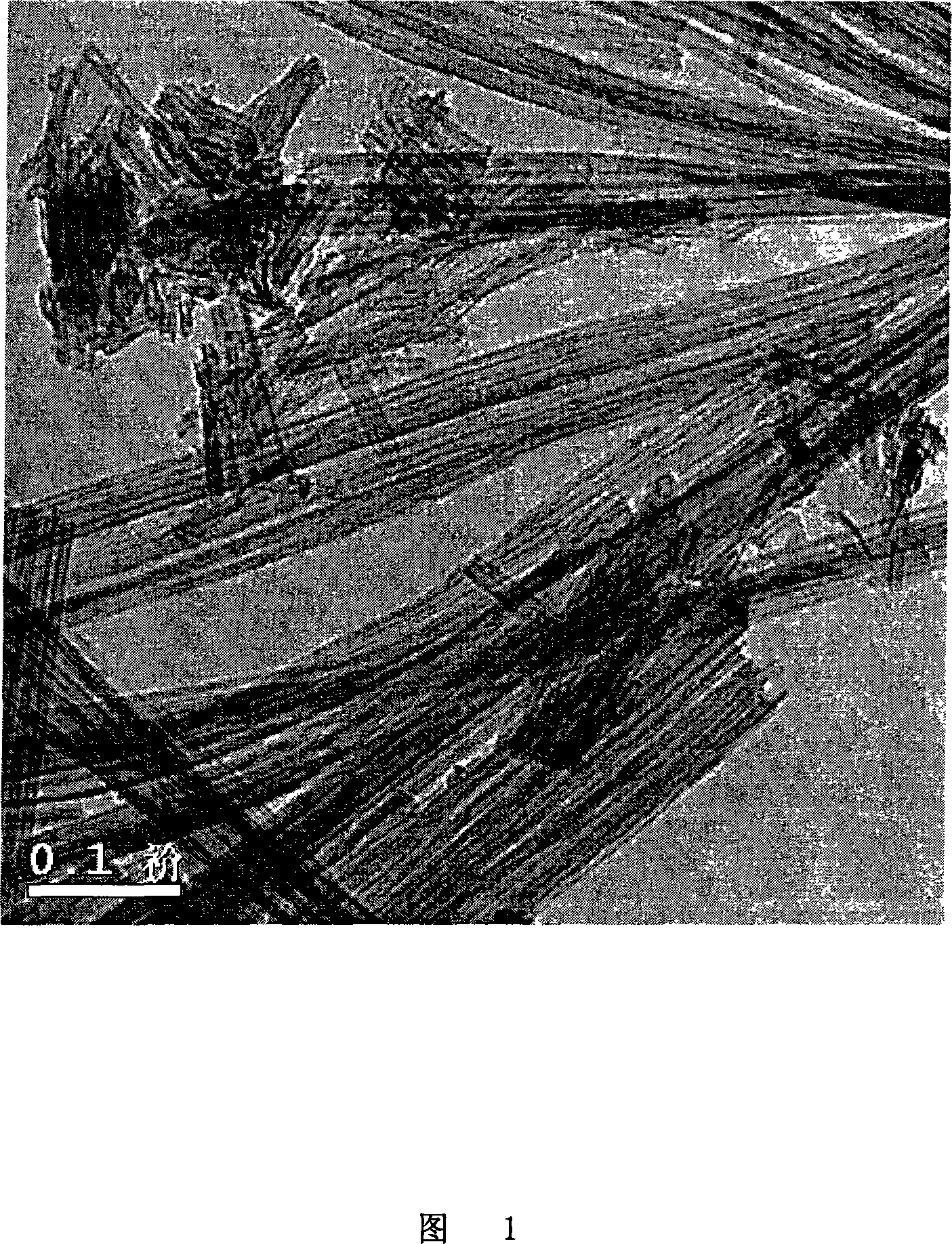

[0029] (1) Preparation of titanate nanotubes

[0030] (1) Weigh anatase TiO 2 2g;

[0031] (2) Prepare 10mol / L NaOH 40ml;

[0032] (3) Prepare 0.1mol / L HCl;

[0033] (4) 2g TiO2 and the prepared NaOH solution are put into a polytetrafluoroethylene flask equipped with a condensing device;

[0034] (5) heating and stirring, controlling the reaction temperature to be about 100°C, and the reaction time is 12h;

[0035] (6) Cool to room temperature after completion of the reaction, and take out the white precipitate;

[0036] (7) Wash several times with deionized water until the conductivity of the supernatant is lower than 70us / cm;

[0037] (8) Wash the white precipitate with prepared 0.1mol / L HCl, and let it stand for 5h (hour);

[0038] (9) Wash several times with deionized water until the conductivity of the supernatant is lower than 5us / cm;

[0039] (10) Fresh titanate nanotubes are obtained, which is designated as sample A.

[0040] (2) Preparation of titanium dioxid...

Embodiment 2

[0063] (1) The method for preparing titanate nanotubes is the same as in Example 1.

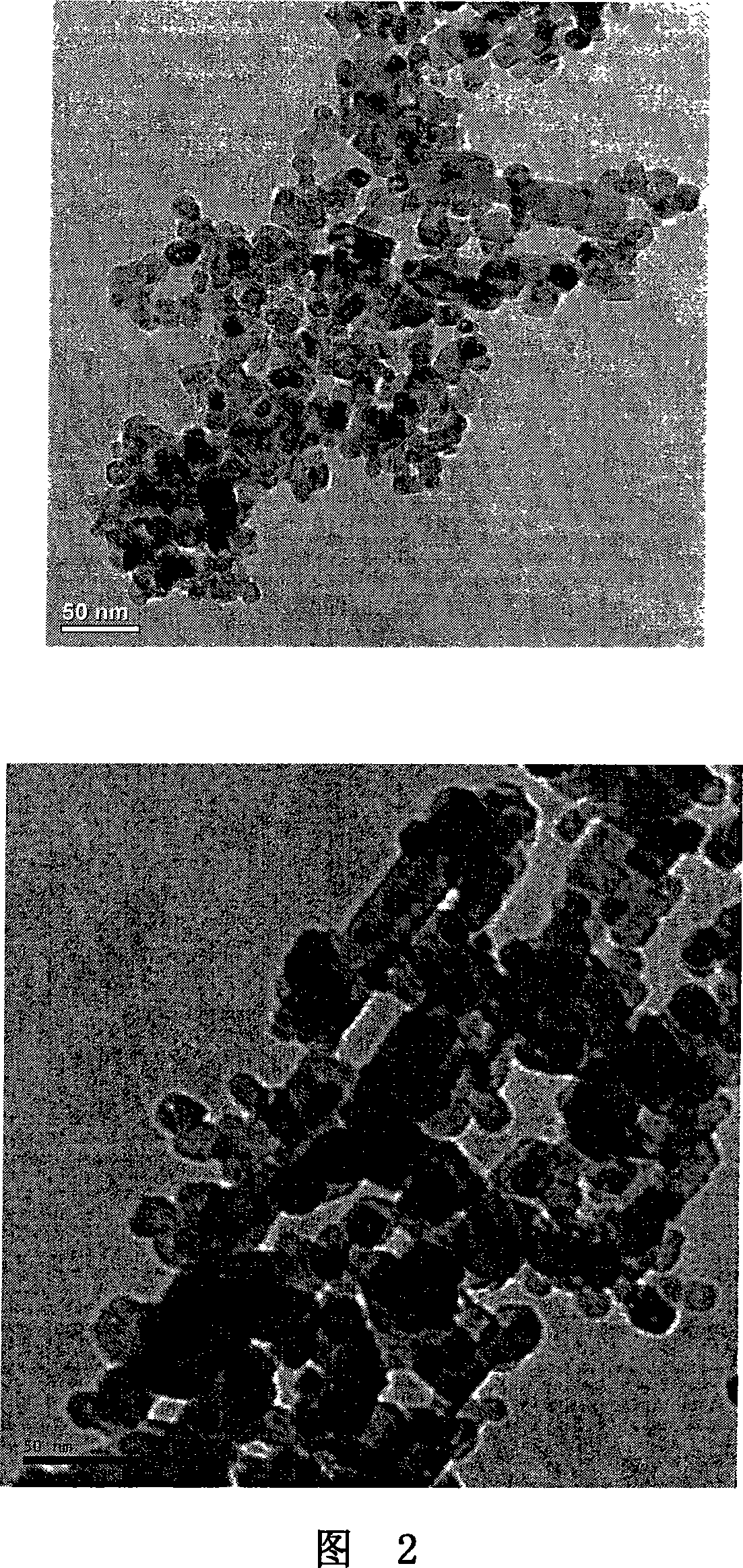

[0064] (2) Preparation of titanium dioxide nanotubes

[0065] ① Prepare 0.01mol / L ammonium fluorotitanate [(NH 4 ) 2 TiF 6 ] solution and 0.03mol / L boric acid [H 3 BO 3 ] solution, stand-by after filtration;

[0066] ②Take an appropriate amount of fresh titanate nanotube A and completely immerse it in the filtered mixed solution of ammonium fluorotitanate and boric acid for deposition;

[0067] ③(NH 4 ) 2 TiF 6 A coordination exchange equilibrium reaction occurs in aqueous solution:

[0068] [ TiF 6 ] 2 - + n H 2 O ⇔ TiF 6 - n ( OH ) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Tube inner diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com