Surface treatment method for improving biological property of medical metallic titanium

A surface treatment, titanium metal technology, applied in the field of titanium dioxide film, can solve the problems of limited improvement of biological properties, low controllability of substrate morphology, long time consumption, etc., to achieve excellent biological activity, improve biocompatibility and The effect of biological activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

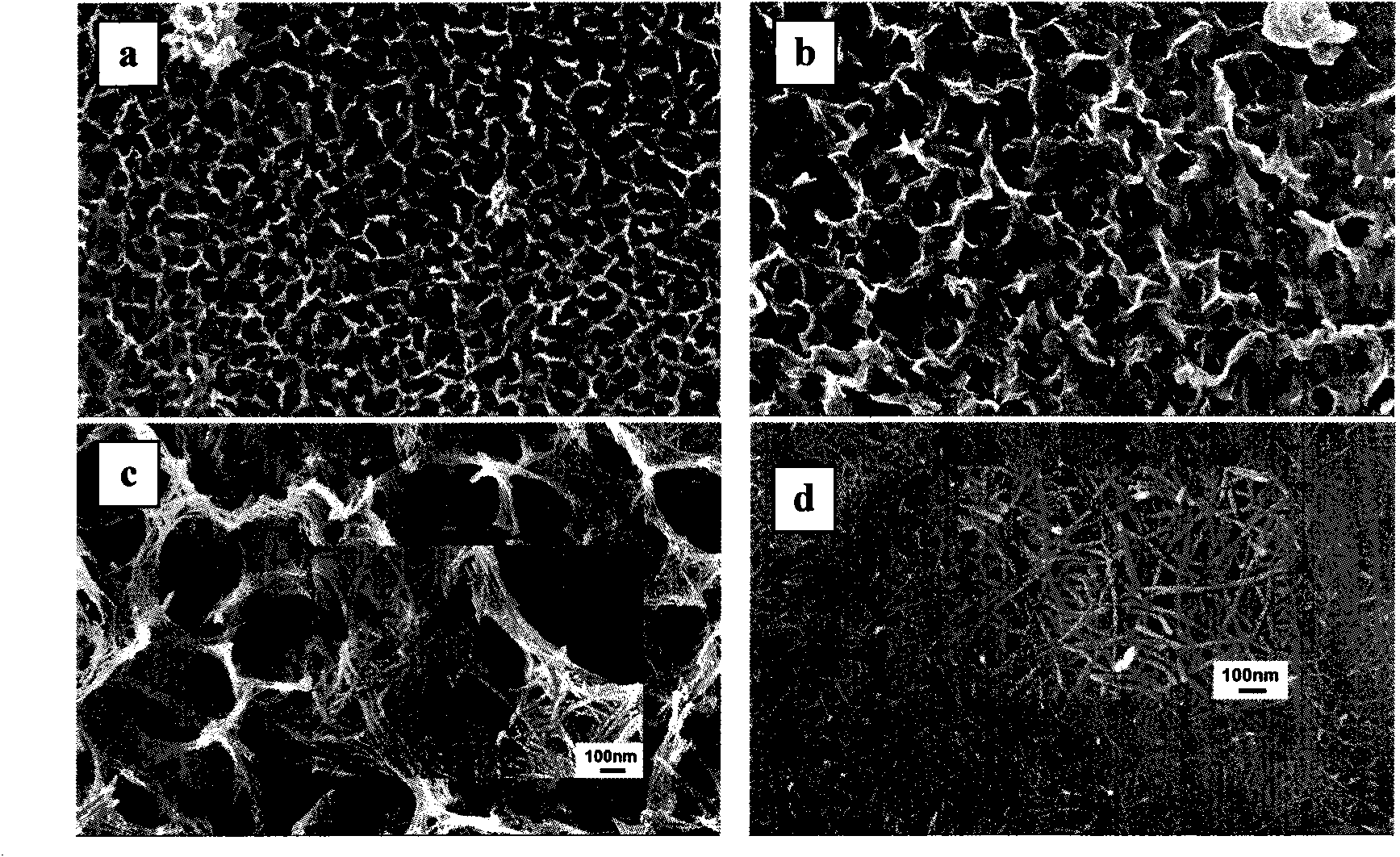

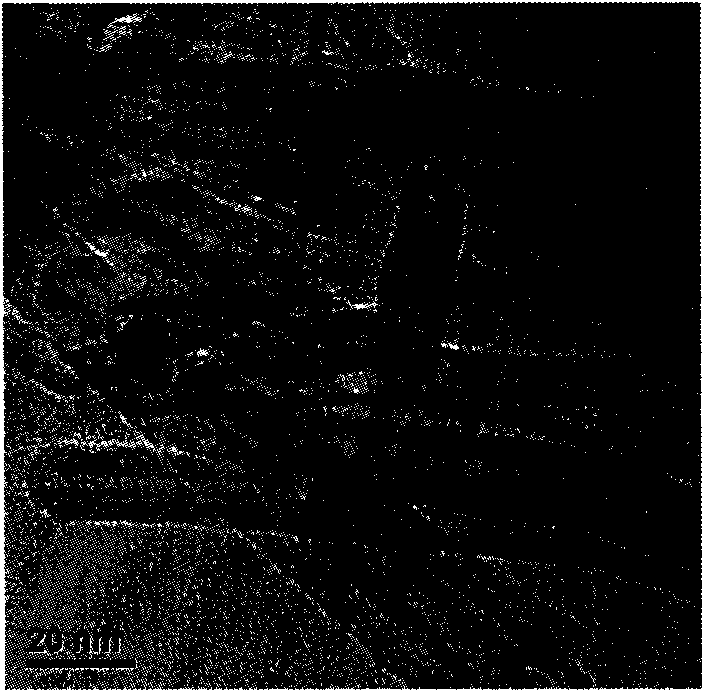

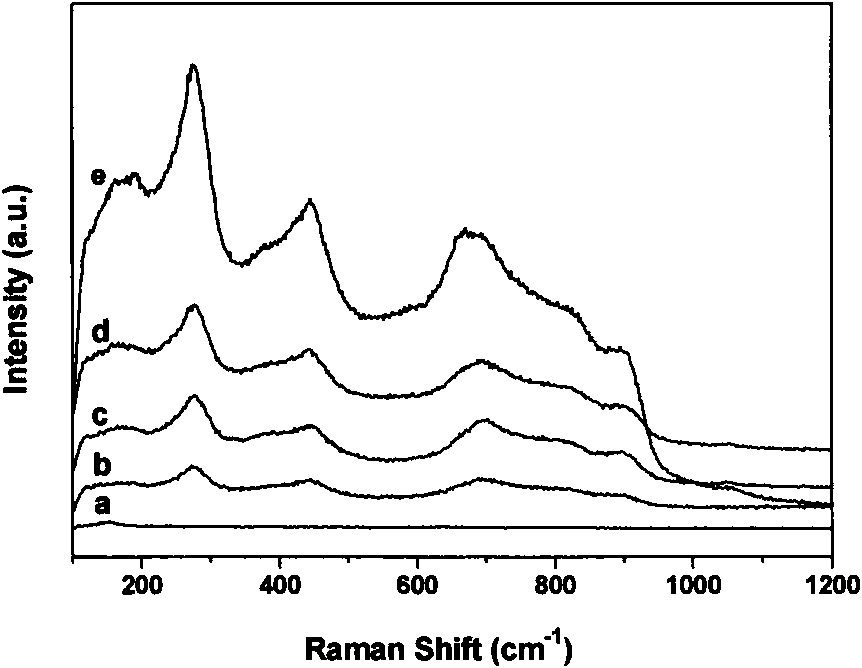

[0021] (1) The base material is a 10mm×10mm×2mm pure titanium plate, the surface is polished with water-grinding paper, and then treated in an acid etching solution containing 10% (v / v) nitric acid and 1% (v / v) hydrofluoric acid Rinse for about 1 min, then ultrasonically clean with acetone, ethanol, and pure water in sequence, and dry for later use. Place the sample in a high-pressure reactor filled with 10mol / L NaOH solution, react at 100°C for 6 hours, take it out, and wash it with pure water. The obtained sample looks like figure 1 d and figure 2 shown. The obtained sample was washed with pure water, dried at room temperature, put into a box-type resistance furnace and calcined at 450°C for 2h under an unprotected atmosphere, with a heating rate of 5°C / min, and its Raman spectrum was as follows: Figure 5 shown in e. It can be seen from the analysis that the surface component is anatase TiO 2 film layer.

[0022] (2) Soak the prepared sample in SBF solution, the temp...

Embodiment 2~10

[0023] Examples 2-10: According to the same method as Example 1, change the concentration of NaOH used, the temperature and time of alkali treatment, and obtain film layer samples with different nanometer surface structures. The specific parameters are shown in Table 1. For all The prepared film layer samples were subjected to simulated body fluid immersion experiments, and the surface component was anatase TiO 2 Or samples with nanotube structure on the surface can induce the formation of apatite, showing good biological activity. The results are as follows Figure 6-8 .

[0024] Table 1

[0025]

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com