Method for producing titanium dioxide by using titanium-containing blast furnace slag

A technology of titanium dioxide and blast furnace slag is applied in the field of comprehensive utilization of blast furnace slag, which can solve the problems such as failure to realize the resource utilization, ecological utilization, small processing capacity and secondary pollution of titanium-containing blast furnace slag, and achieves technical difficulty and equipment investment. The effect of cost reduction, slag discharge reduction and production energy consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

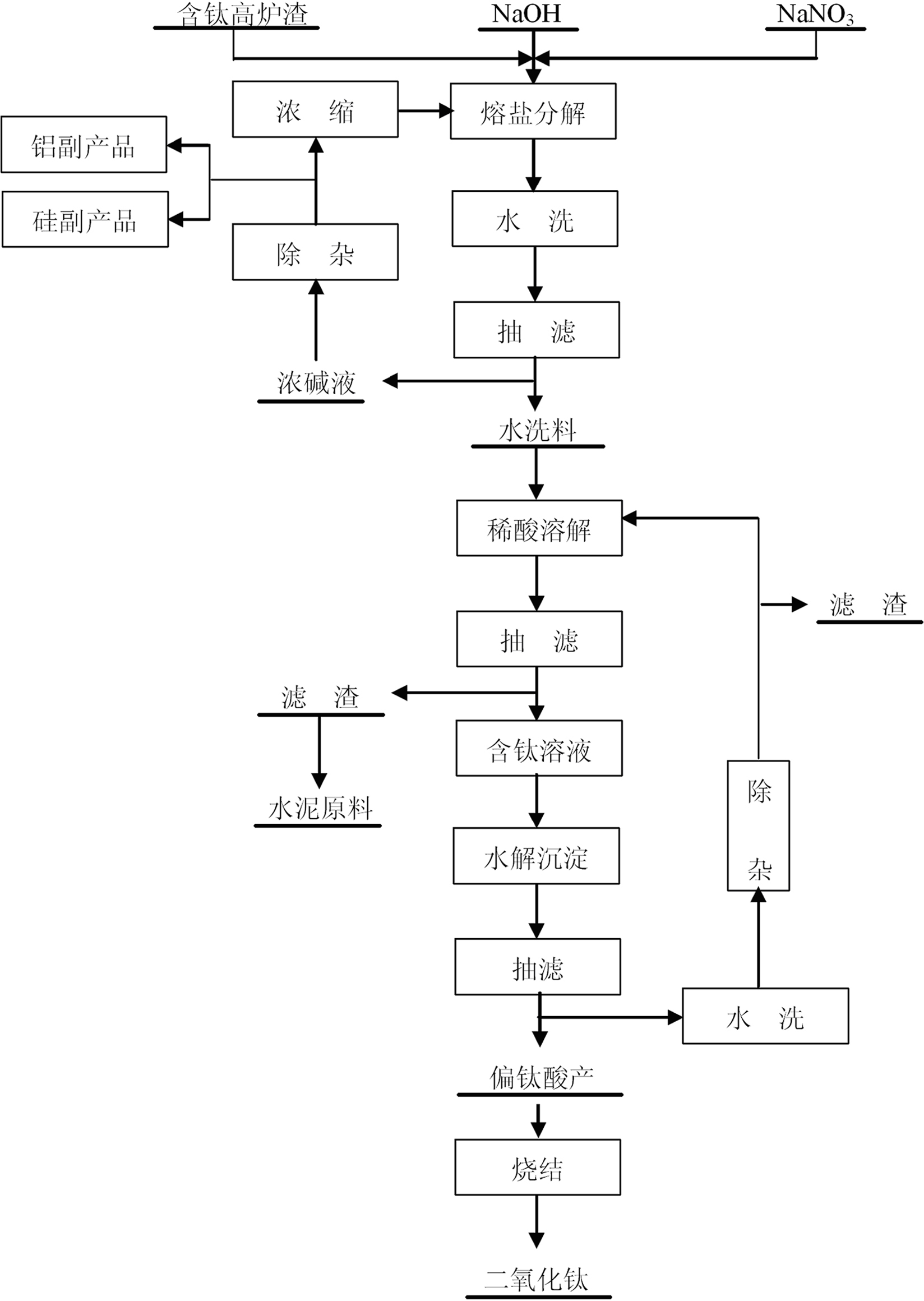

[0031] (1) The titanium-containing blast furnace slag was crushed, ball-milled for 24 hours and sieved to 200 mesh, and placed in a 3 In the molten salt system, the mass ratio of NaOH to titanium-containing blast furnace slag is 4:1, and NaOH and NaNO 3 The molar ratio is 4:1, and reacted for 3 hours at a temperature of 500°C to obtain an intermediate product composed of sodium titanate, sodium silicate and sodium metaaluminate, and the leaching rate of titanium reaches more than 72.5%;

[0032] (2) Then wash the above-mentioned intermediate product in water at 60°C and filter it for 3 times, the mass ratio of solid to liquid for each washing is 1:20, and the soluble sodium silicate and sodium metaaluminate enter into the solution containing NaOH and NaNO 3 Alkaline solution, solid phase sodium titanate to form washing material;

[0033] (3) NaOH and NaNO containing sodium silicate and sodium metaaluminate 3 After removing impurities and concentrating the lye, return to NaOH...

Embodiment 2

[0038] (1) The titanium-containing blast furnace slag was crushed, ball-milled for 36 hours and sieved to 200 mesh, and placed in a 3 In the molten salt system, the mass ratio of NaOH to titanium-containing blast furnace slag is 3:1, and NaOH and NaNO 3 The molar ratio is 3:1, and reacted for 3 hours at a temperature of 450°C to obtain an intermediate product composed of sodium titanate, sodium silicate and sodium metaaluminate, and the leaching rate of titanium reaches more than 70.5%;

[0039] (2) Then wash the above intermediate product in water at 60°C and filter it for 3 times, the mass ratio of solid to liquid for each washing is 1:40, the soluble sodium silicate and sodium metaaluminate enter into the solution containing NaOH and NaNO 3 Alkaline solution, solid phase sodium titanate to form washing material;

[0040] (3) NaOH and NaNO containing sodium silicate and sodium metaaluminate 3 After removing impurities and concentrating the lye, return to NaOH and NaNO in s...

Embodiment 3

[0045] (1) The titanium-containing blast furnace slag was crushed, ball-milled for 72 hours and sieved to 200 mesh, and placed in a 3 In the molten salt system, the mass ratio of NaOH to titanium-containing blast furnace slag is 5:1, and NaOH and NaNO 3 The molar ratio is 5:1, and reacted for 3 hours at a temperature of 550°C to obtain an intermediate product composed of sodium titanate, sodium silicate and sodium metaaluminate, and the leaching rate of titanium reaches more than 73.8%;

[0046](2) Then wash the above-mentioned intermediate product in water at 70°C and filter it 3 times, the mass ratio of solid to liquid for each washing is 1:30, and the soluble sodium silicate and sodium metaaluminate enter into the solution containing NaOH and NaNO 3 Alkaline solution, solid phase sodium titanate to form washing material;

[0047] (3) NaOH and NaNO containing sodium silicate and sodium metaaluminate 3 After removing impurities and concentrating the lye, return to NaOH and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com