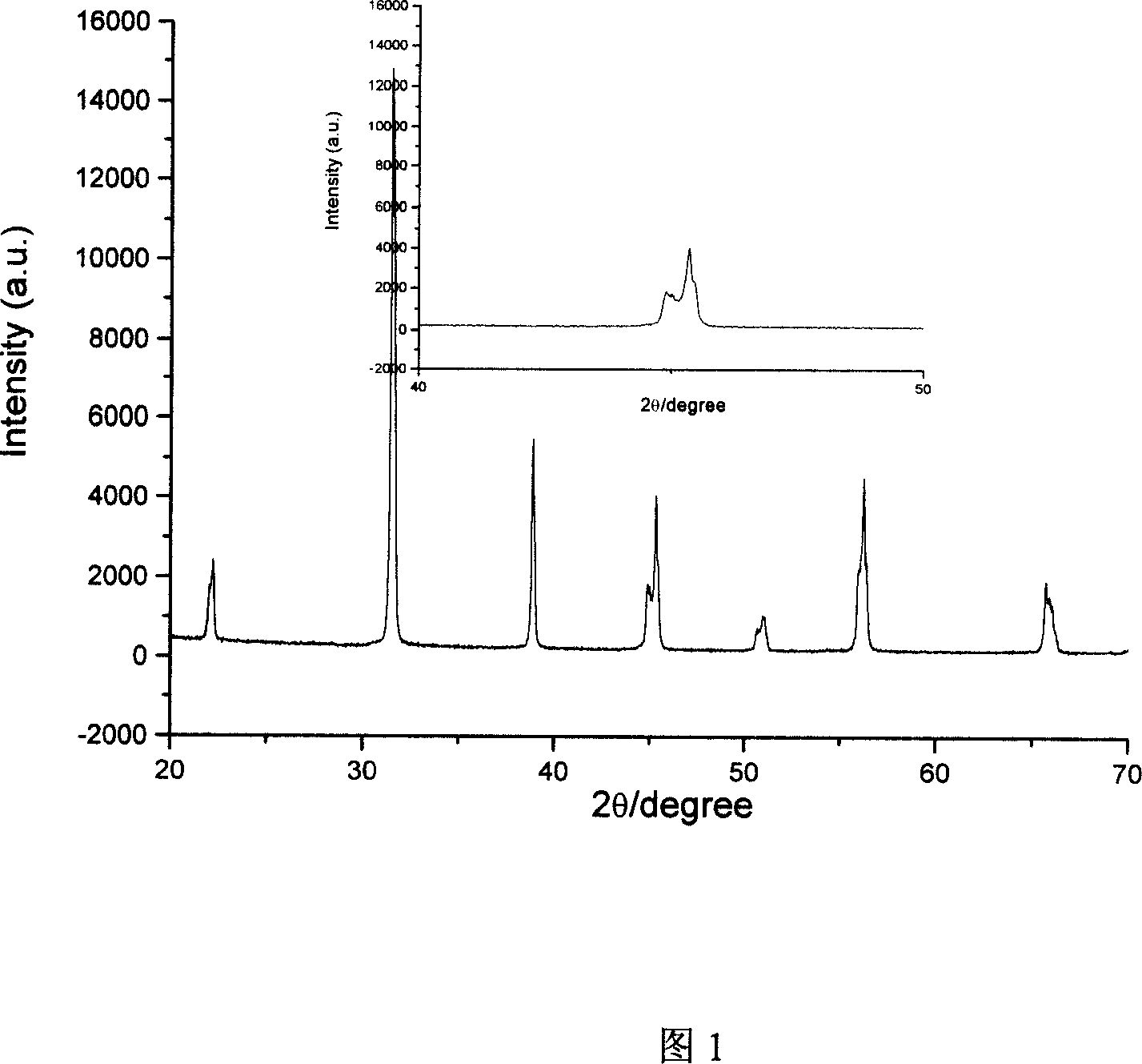

Method for preparing uniform dispersion square phase barium titanate nanocrystal

A technology of hydrothermal synthesis and phase barium titanate, which is applied in nanotechnology, nanotechnology, nanostructure manufacturing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] A method for preparing homogeneously dispersed tetragonal phase barium titanate nanocrystals by hydrothermal synthesis, the specific steps are as follows:

[0008] 1. Under heating and stirring, add the titanium source into the reaction kettle, add deionized water to dissolve, and adjust the pH value to 10-14 with alkali.

[0009] 2. Heating to dissolve Ba(OH) 2 ·8H 2 O, according to the molar ratio Ba / Ti = 1-2, add to the above reaction kettle, heat and stir for 1-3 hours, the temperature is 80-100 ° C, to ensure that the precursor is completely dissolved to form a homogeneous solution.

[0010] The order of the above steps 1 and 2 is not limited.

[0011] 3. The filling degree of the autoclave is 70-80%, and the autoclave is sealed and put into an oven at 100-200°C for reaction for 24-74 hours.

[0012] 4. Take out the reaction kettle, filter, wash the solid matter with ammonium chloride solution and deionized water several times until the filtrate is neutral, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com