Biological active coating on surface of titanium or titanium alloy and preparation method thereof

A bioactive, titanium alloy technology, applied in the field of surface modification of biomedical materials, can solve the problems of low density of coating structure, difficult coating, high price, etc., to improve cell adhesion ability, improve surface bioactivity, Increase the effect of surface bioactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

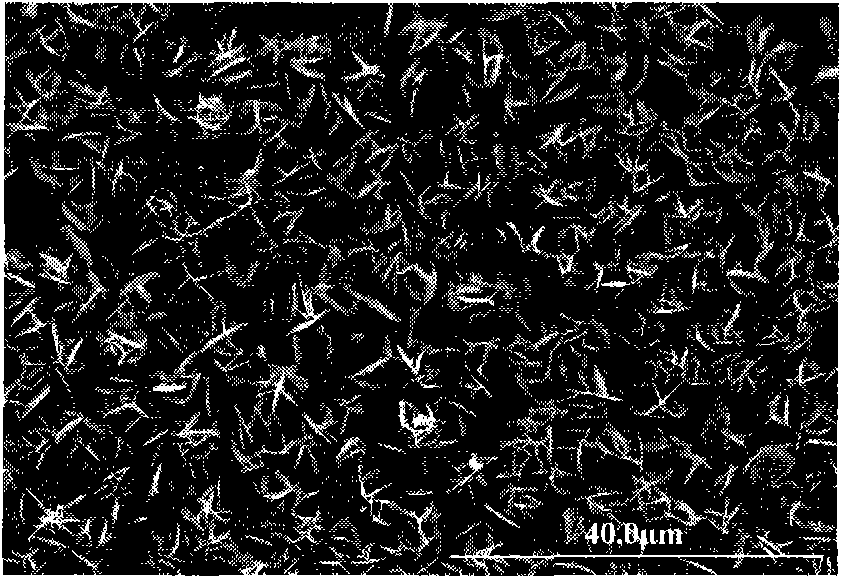

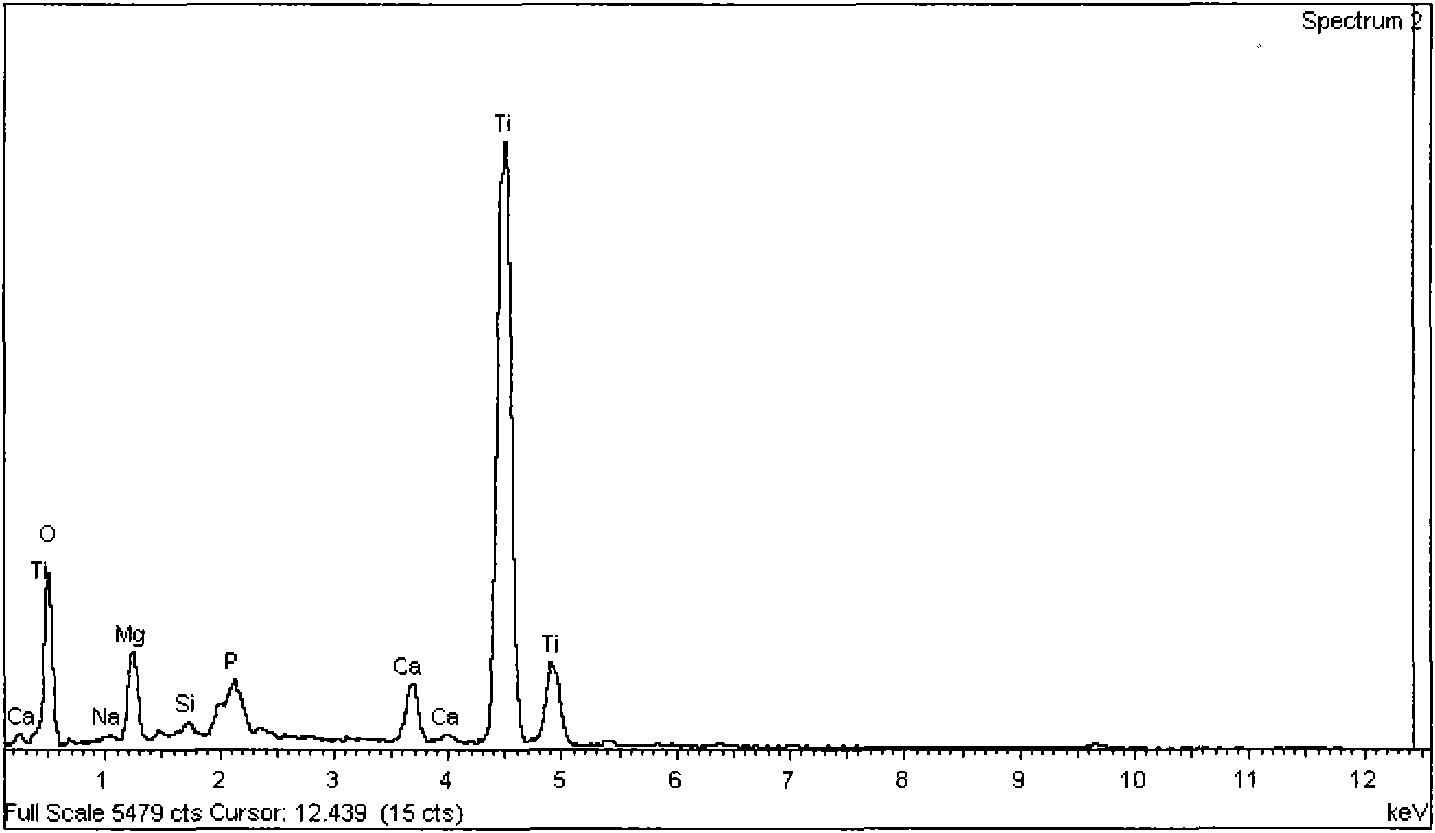

[0020] Adopt the method of the present invention to process on commercial pure titanium surface, specifically as follows:

[0021] (1) Commercially pure titanium was selected, and the sample was polished to 800# with water-resistant sandpaper, washed with acetone and deionized water for 20 minutes each, and air-dried at 40°C.

[0022] (2) Using stainless steel as the cathode and titanium metal as the anode, prepare 3M sulfuric acid solution as the electrolyte, and use the electrolyte as the conductive medium to perform anodic oxidation treatment. The electrolysis parameters are: the temperature of the electrolyte is 20°C, the electrolysis voltage is 30V, and the anodic oxidation time is 1min, so that a titanium dioxide film is formed on the titanium surface.

[0023] (3) Soak the anodized titanium sample in NaOH solution, the concentration of NaOH solution is 5M, the treatment temperature is 80°C, and the treatment time is 48h. After alkaline treatment, gently wash with disti...

Embodiment 2

[0029] Adopt the method of the present invention to process on commercial pure titanium surface, specifically as follows:

[0030] (1) Commercially pure titanium was selected, and the sample was polished to 800# with water-resistant sandpaper, washed with acetone and deionized water for 20 minutes each, and air-dried at 40°C.

[0031] (2) Using stainless steel as a cathode and titanium metal as an anode, prepare a 5M sulfuric acid solution as an electrolyte, and use the electrolyte as a conductive medium to perform anodic oxidation treatment. The electrolysis parameters are: the temperature of the electrolyte is 20°C, the electrolysis voltage is 20V, and the anodic oxidation time is 3min, so that a titanium dioxide film is formed on the titanium surface.

[0032] (3) Soak the anodized titanium sample in NaOH solution, the concentration of NaOH solution is 5M, the treatment temperature is 60°C, and the treatment time is 24h. After alkaline treatment, gently wash with distilled...

Embodiment 3

[0036] Adopt method of the present invention to process on Ti6Al4V surface, specifically as follows:

[0037] (1) Ti6Al4V is selected, and the sample is polished to 800# with water-resistant sandpaper, washed with acetone and deionized water for 20 minutes each, and air-dried at 40°C.

[0038](2) Using stainless steel as the cathode and Ti6Al4V sample as the anode, prepare 1M sulfuric acid solution as the electrolyte, and use the electrolyte as the conductive medium to perform anodic oxidation treatment. The electrolysis parameters are: the temperature of the electrolyte is 20°C, the electrolysis voltage is 30V, and the anodic oxidation time is 1min, so that a titanium dioxide film is formed on the surface of the Ti6Al4V sample.

[0039] (3) Soak the anodized Ti6Al4V sample in NaOH solution, the concentration of NaOH solution is 5M, the treatment temperature is 80°C, and the treatment time is 48h. After alkaline treatment, gently wash with distilled water and air dry at 40°C....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com