Sodium ion electrochemical capacitor

An electrochemical and capacitor technology, applied in the field of capacitors, can solve the problems of high cost and limited content, achieve high energy density and power density, good cycle life, and reduce costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

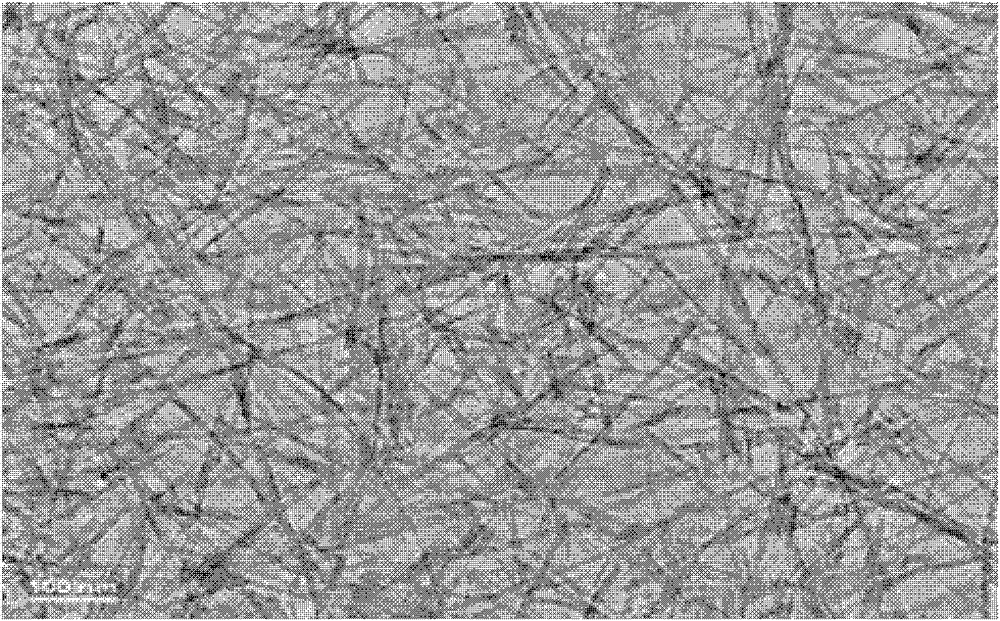

[0040] Dissolve 0.4g of sodium molybdate in 40ml of distilled water and sonicate for 0.5h, adjust the pH to 1.2 with 1M HCl and 1MNaOH, inject it into a 50ml stainless steel reaction kettle, heat it at 160°C for 24h, and cool it down to room temperature naturally. Then wash and centrifuge with distilled water for 3 times, wash and centrifuge with absolute ethanol for 3 times, and finally vacuum dry at 60° C. for 10 h to obtain molybdenum oxide nanobelts.

[0041] Molybdenum oxide in the following examples was prepared from Example 1.

Embodiment 2

[0043] Dissolve 1 g of commercially available titanium dioxide and tetrabutyl titanate in 80 ml of 10 M sodium hydroxide solution, stir at room temperature for 3 hours, then transfer to a 100 ml reactor, and heat at 150°C for 48 hours. After hydrothermal cooling to room temperature, the product was transferred to 1000 ml of secondary water and washed to pH 7-8. After drying at 60°C, it was calcined at high temperatures of 300°C, 400°C, 500°C and 600°C for 5 hours. Label the uncalcined sodium titanate nanotubes as T 0 , the sodium titanate nanotubes calcined at 300 °C are marked as T 1 , the sodium titanate nanotubes calcined at 400 °C are marked as T 2 , the sodium titanate nanotubes calcined at 500 °C are marked as T 3 , the sodium titanate nanotubes calcined at 600 °C are marked as T 4 .

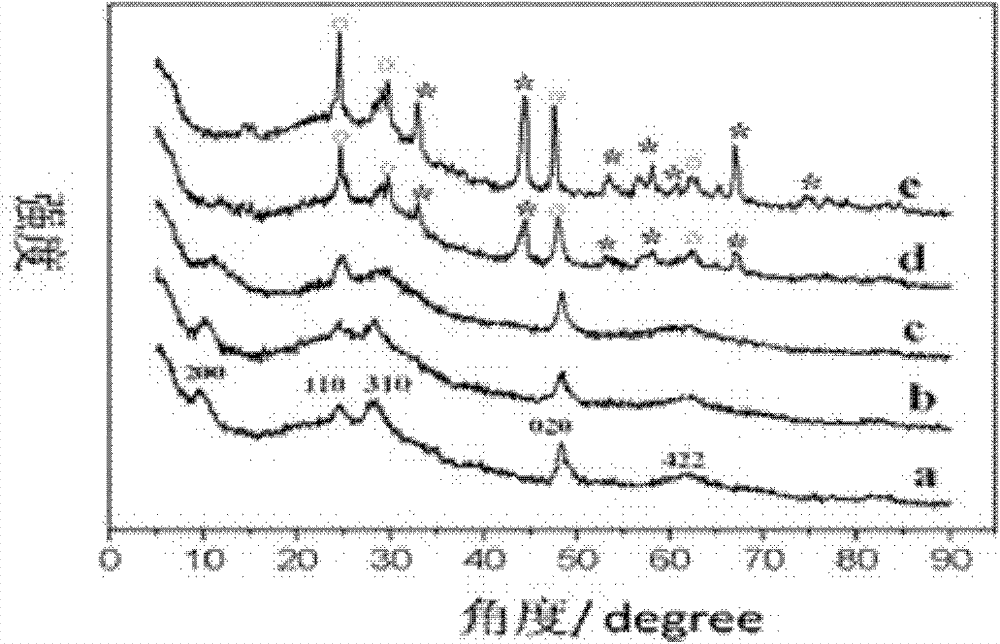

[0044] Rigaku D / max-IIB diffractometer was adopted, Cu target Kα ray was used as X-ray source, the scanning range was 5°~60°, and the scanning speed was 1° / min. According to the PDF d...

Embodiment 3

[0048] 6mgT 1 ~T 4 , coke, molybdenum sulfide, molybdenum oxide and niobium oxide mixed with 3 mg of conductive adhesive and coated on the stainless steel battery collector net to form a film, dried in vacuum at 180 ° C for 3 hours, then transferred to an anhydrous oxygen-free argon-saturated In the glove box, respectively, T 1 ~T 4 , coke, molybdenum sulfide, molybdenum oxide and niobium oxide as the positive electrode, metal sodium as the negative electrode, 1.5M sodium perchlorate organic solution as the electrolyte, a polyethylene film and a glass fiber as the diaphragm, assembled into a button battery , Under the operating voltage of 0.1 ~ 2.5V for charge and discharge test.

[0049] Figure 8 It is the charge-discharge specific capacity curve of sodium titanate single electrode, Figure 8 The middle curve is T 1 The single-electrode charge-discharge specific capacity curve, the curve is T 2 The single-electrode charge-discharge specific capacity curve, the ▲ curve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com