Patents

Literature

59results about How to "Fast embedding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

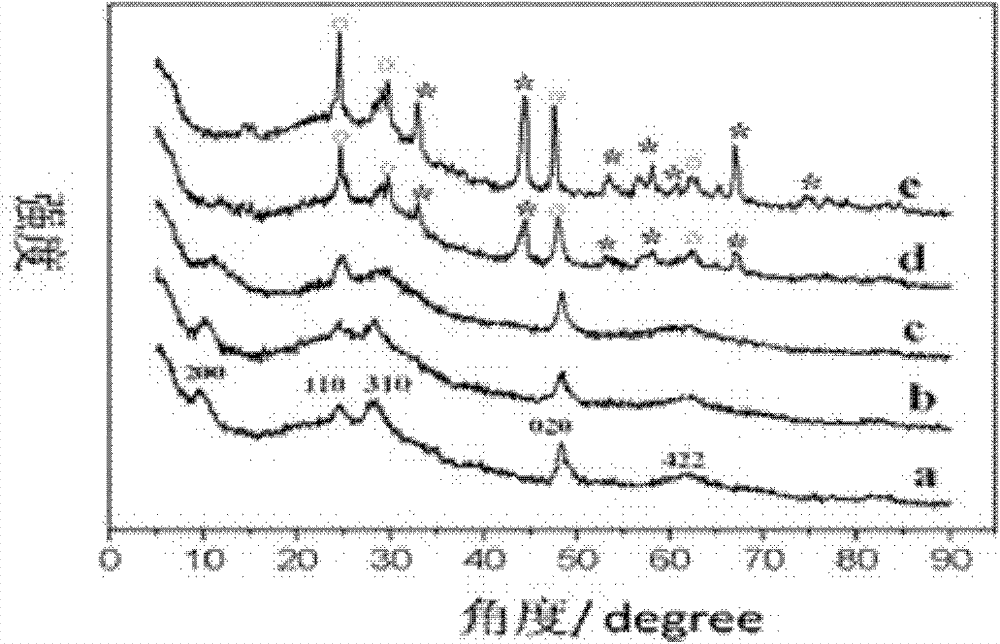

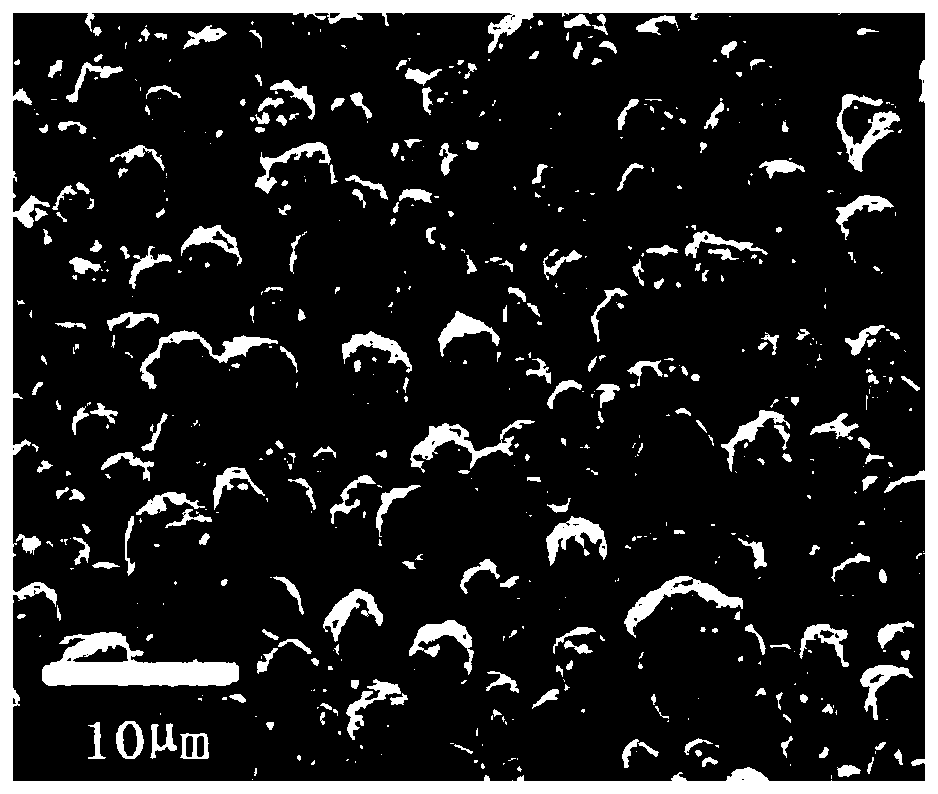

Carbon-coated metal sulfide electrode material, preparation method and application thereof

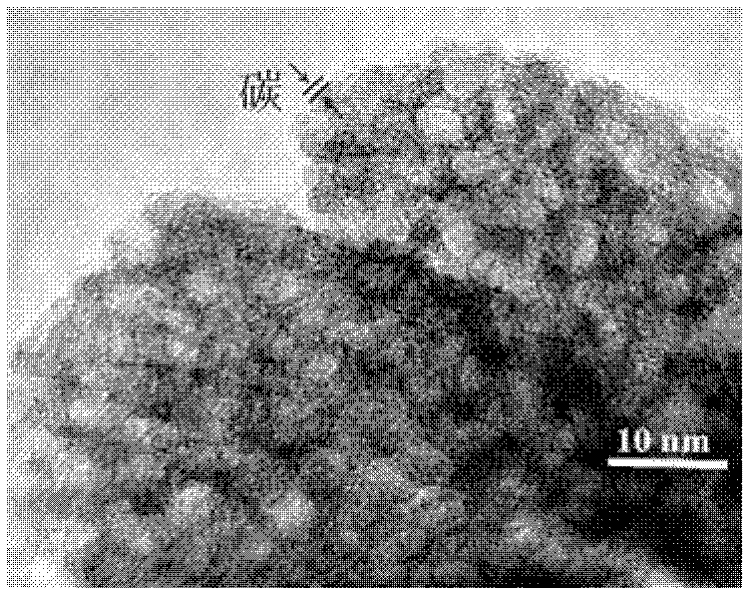

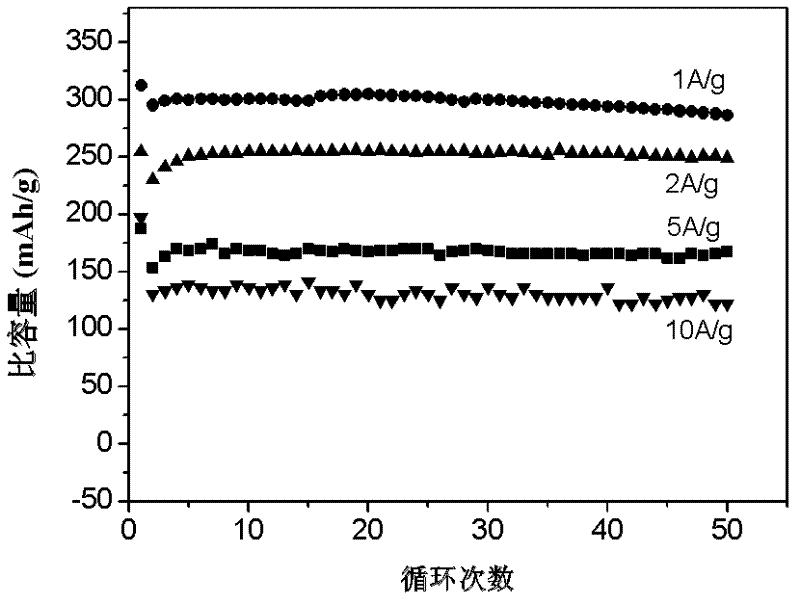

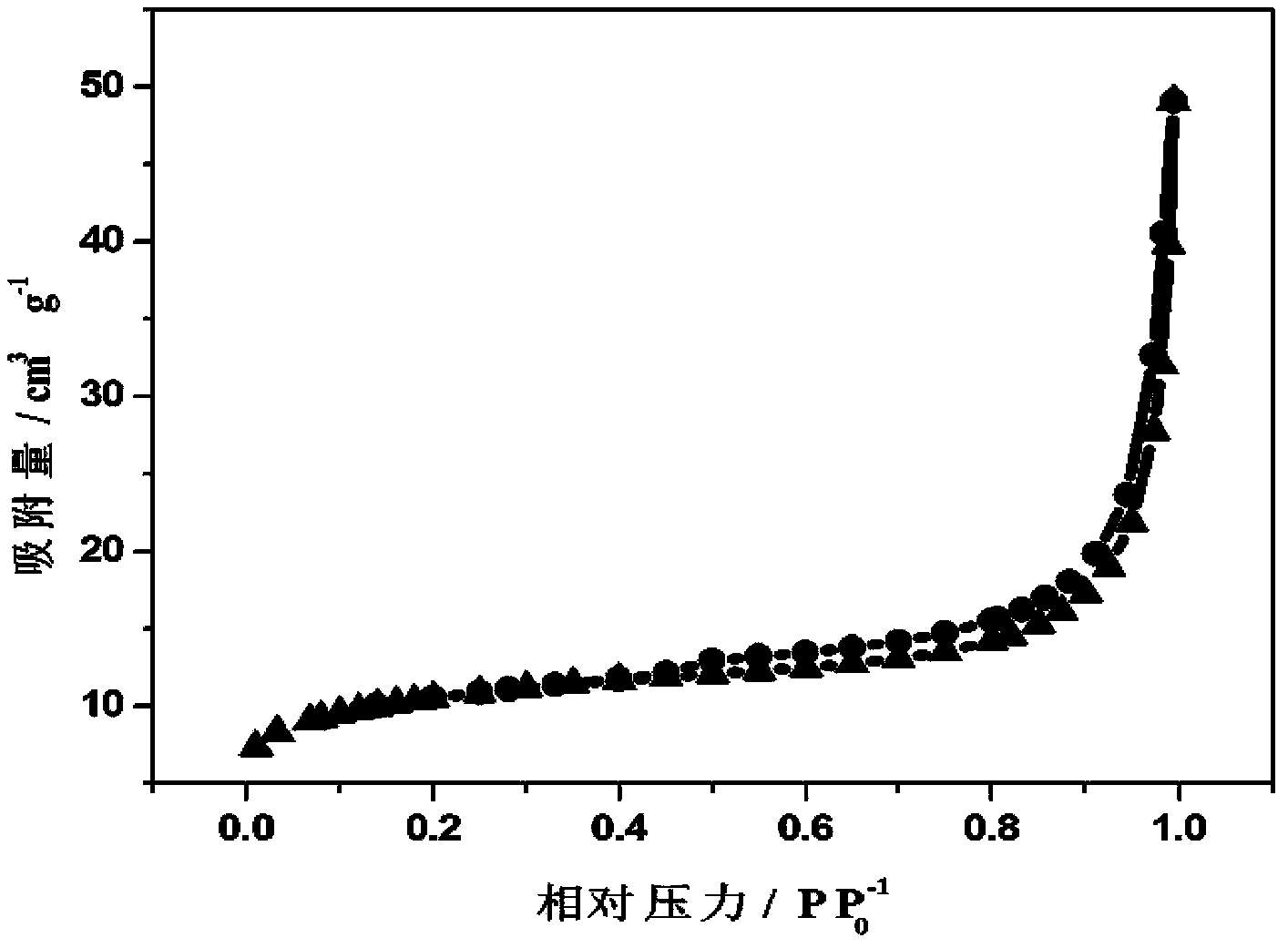

InactiveCN104716319AImprove cycle performanceGuarantee structureCell electrodesSecondary cellsNanowireMetallic sulfide

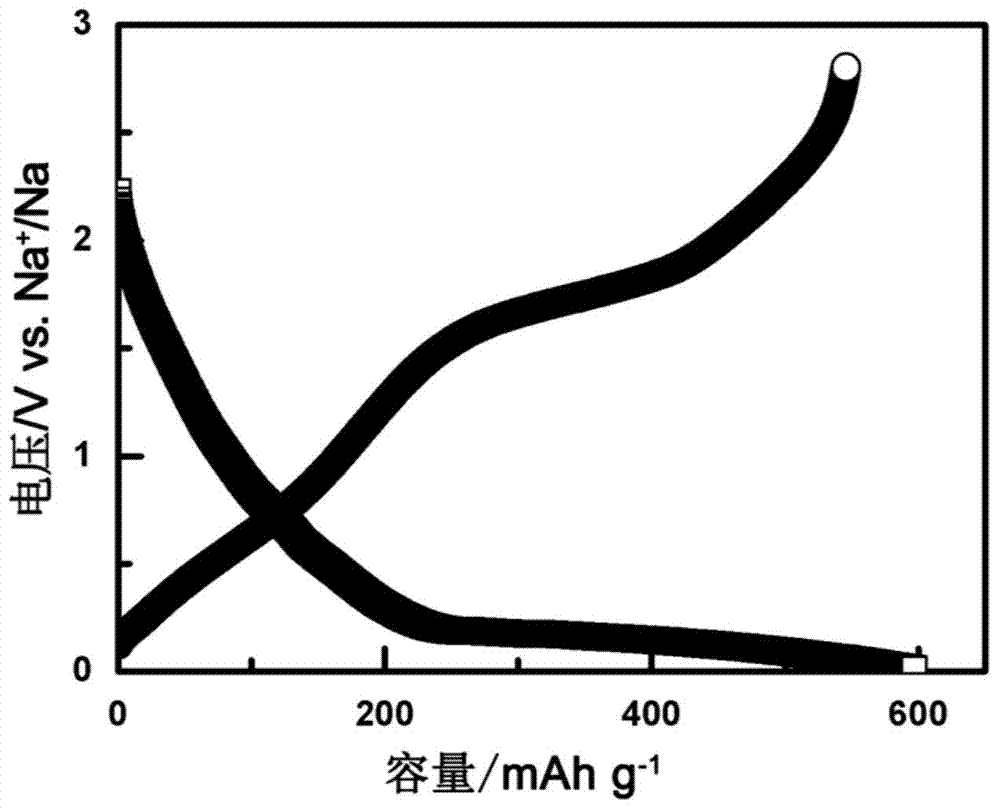

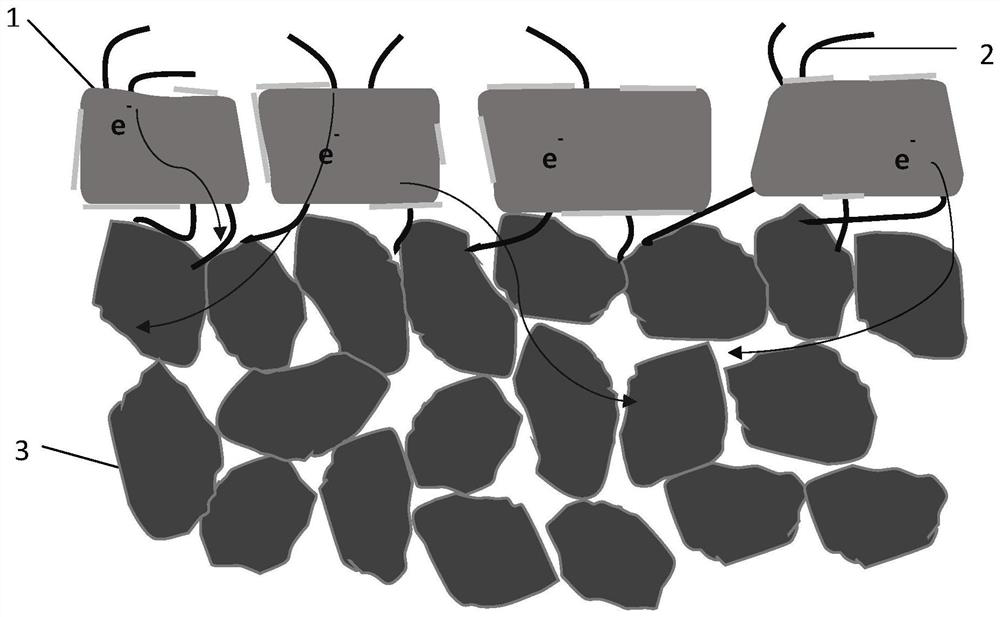

The invention discloses a carbon-coated metal sulfide electrode material, a preparation method and application thereof. The electrode material consists of hemisphere-like bilayer structure particles, the inner layer is a metal sulfide, and the outer layer is a carbon material. The hemisphere surface of the metal sulfide is coated by the carbon material, and the section is exposed. The general chemical formula of the metal sulfide is MSx, wherein M is one element from the fourth main group metal elements to the seventh main group metal elements, and x is greater than or equal to 1 and smaller than or equal to 3. The method includes the steps of: (1) covering a nanowire template with a metal sulfide precursor to form a uniformly and orderly dispersed nanoscale product; (2) covering the surface of the metal sulfide with a layer of uniform and dense carbon material film; and (3) removing the nanowire template so as to obtain the carbon-coated metal sulfide electrode material. The electrode material has stable structure and good cycle performance, and can acquire reversible capacity of more than 300mAh g<-1> in nonaqueous electrolyte sodium ion batteries.

Owner:HUAZHONG UNIV OF SCI & TECH

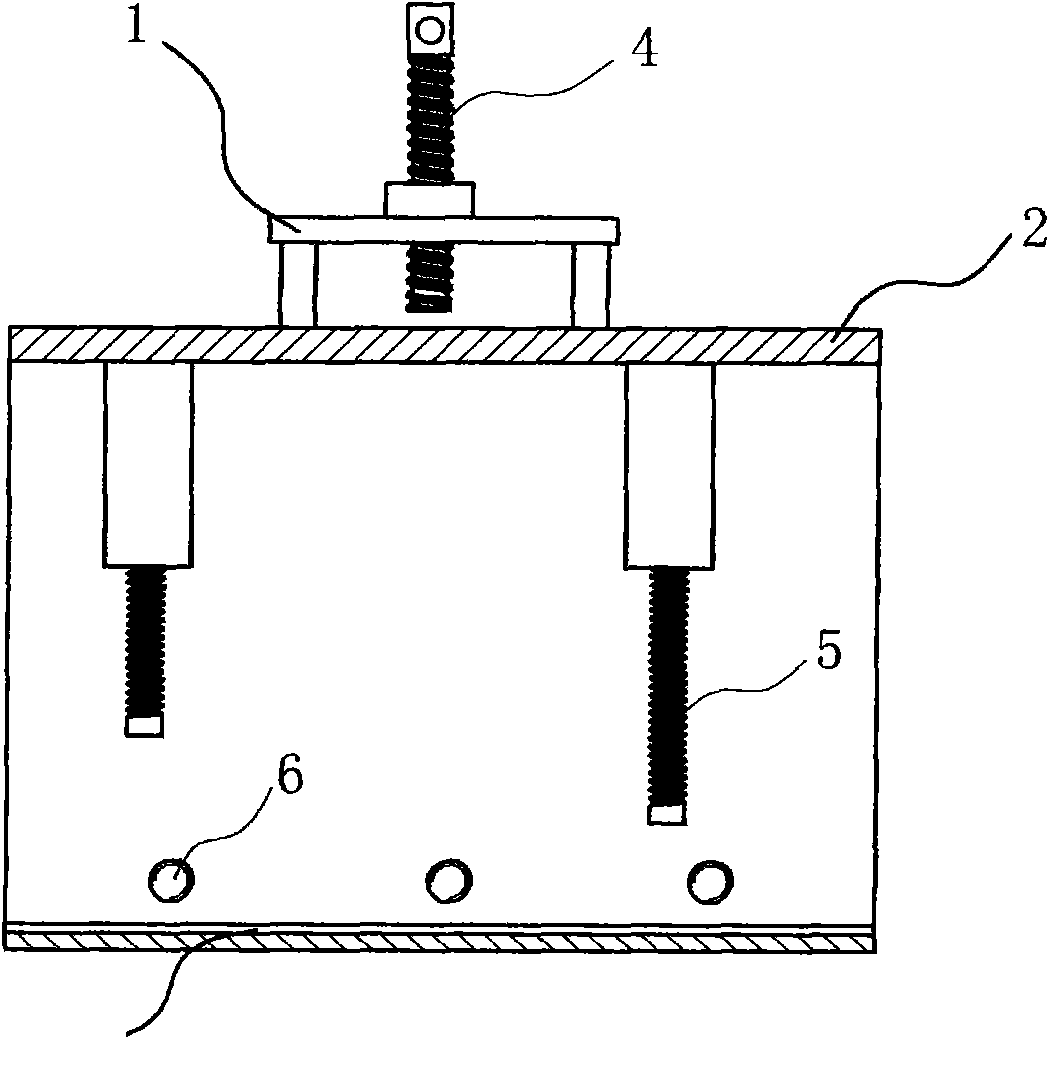

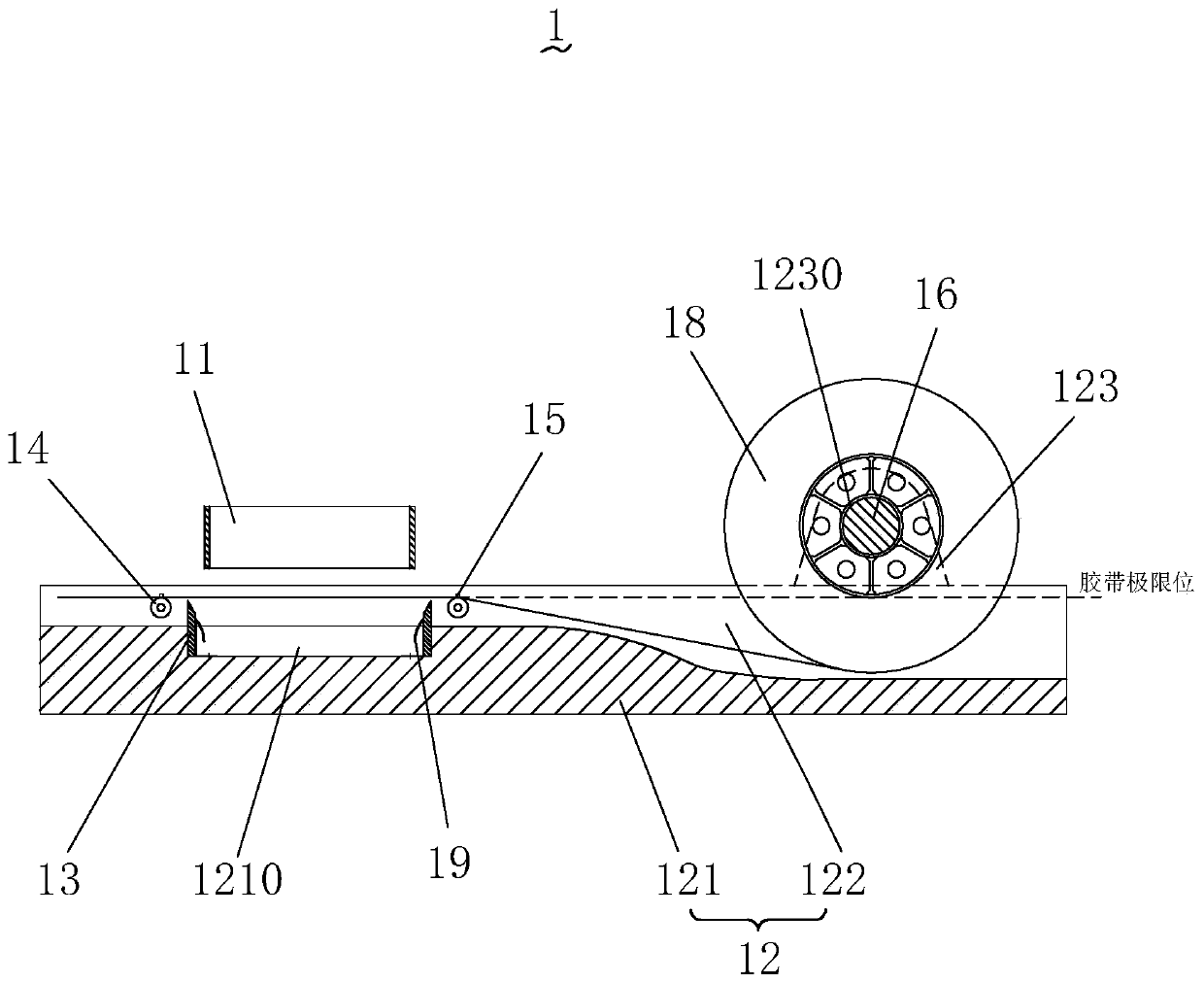

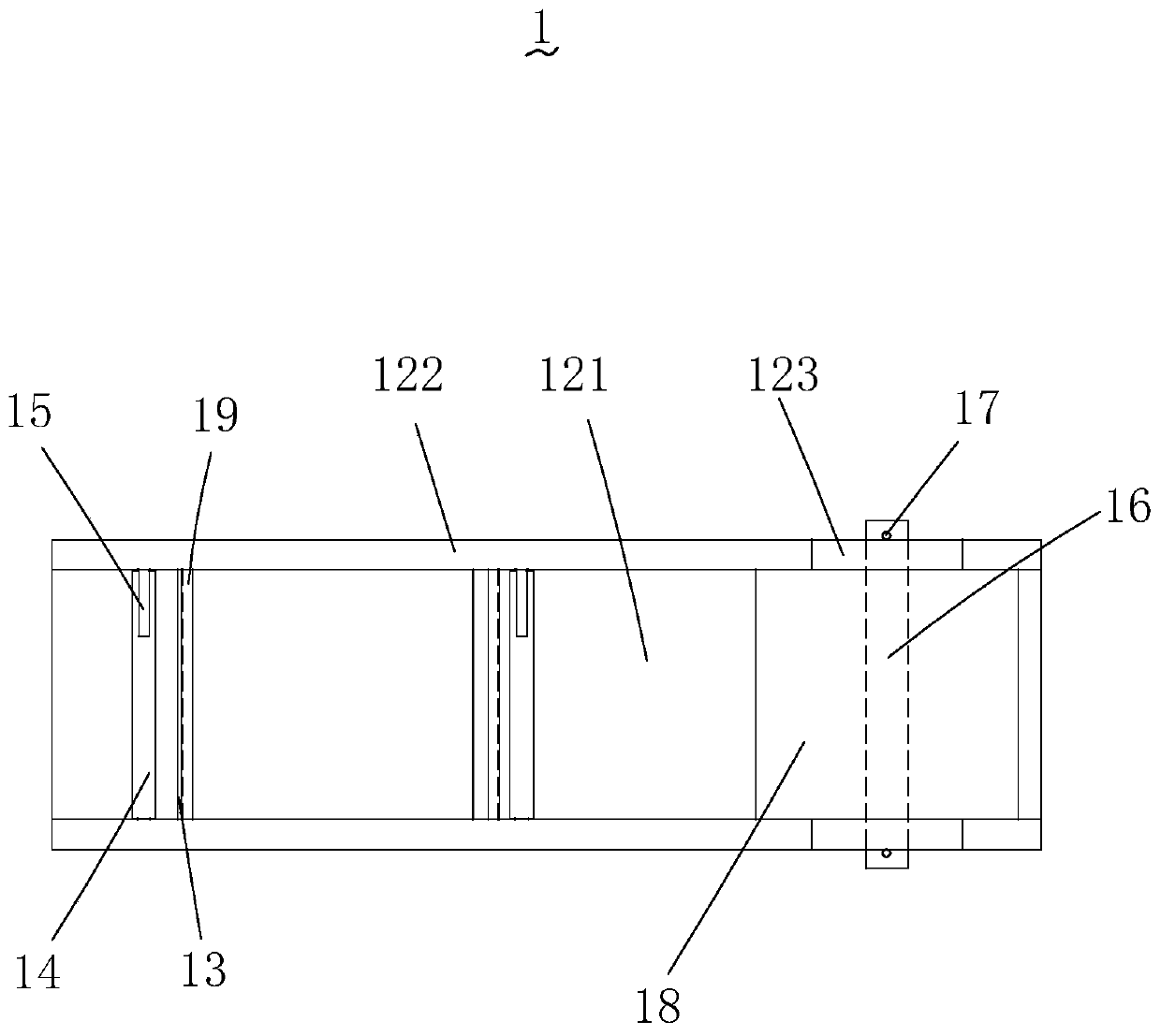

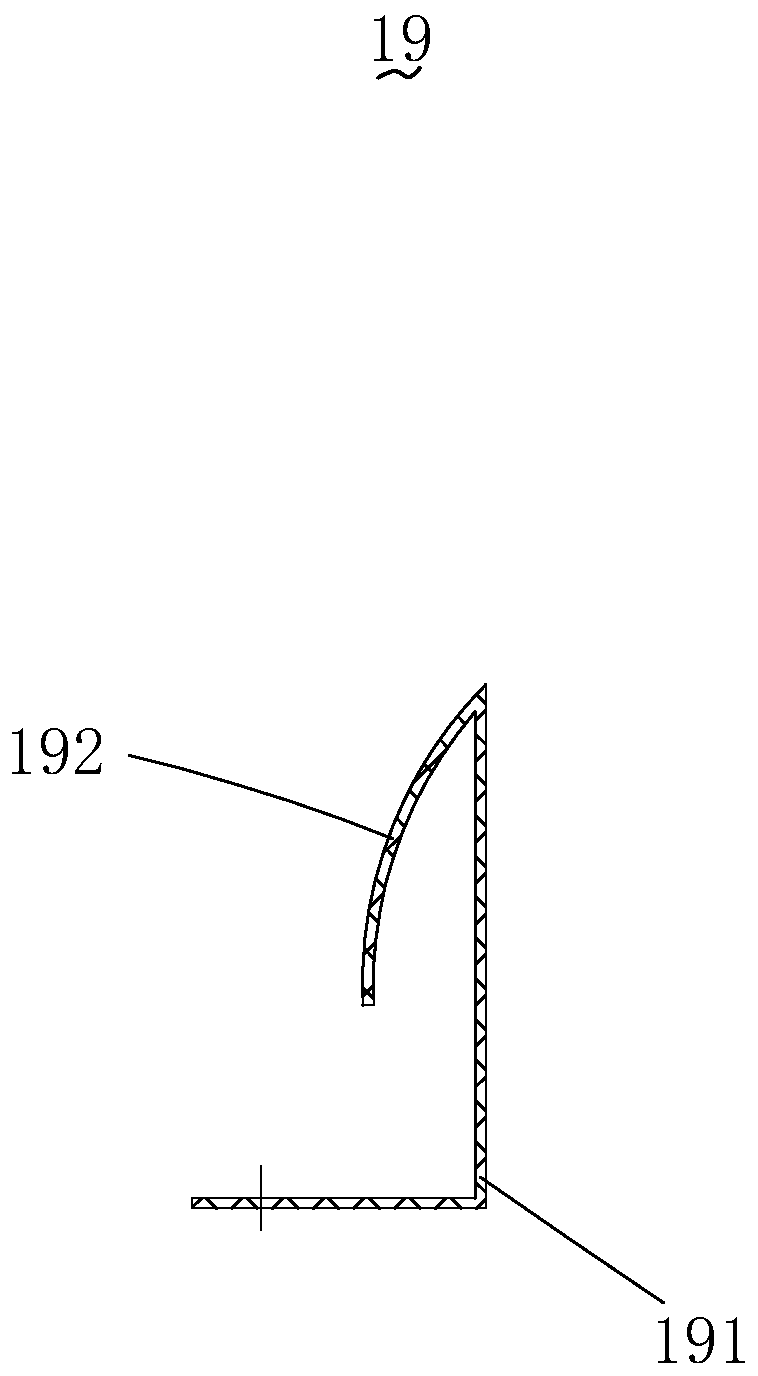

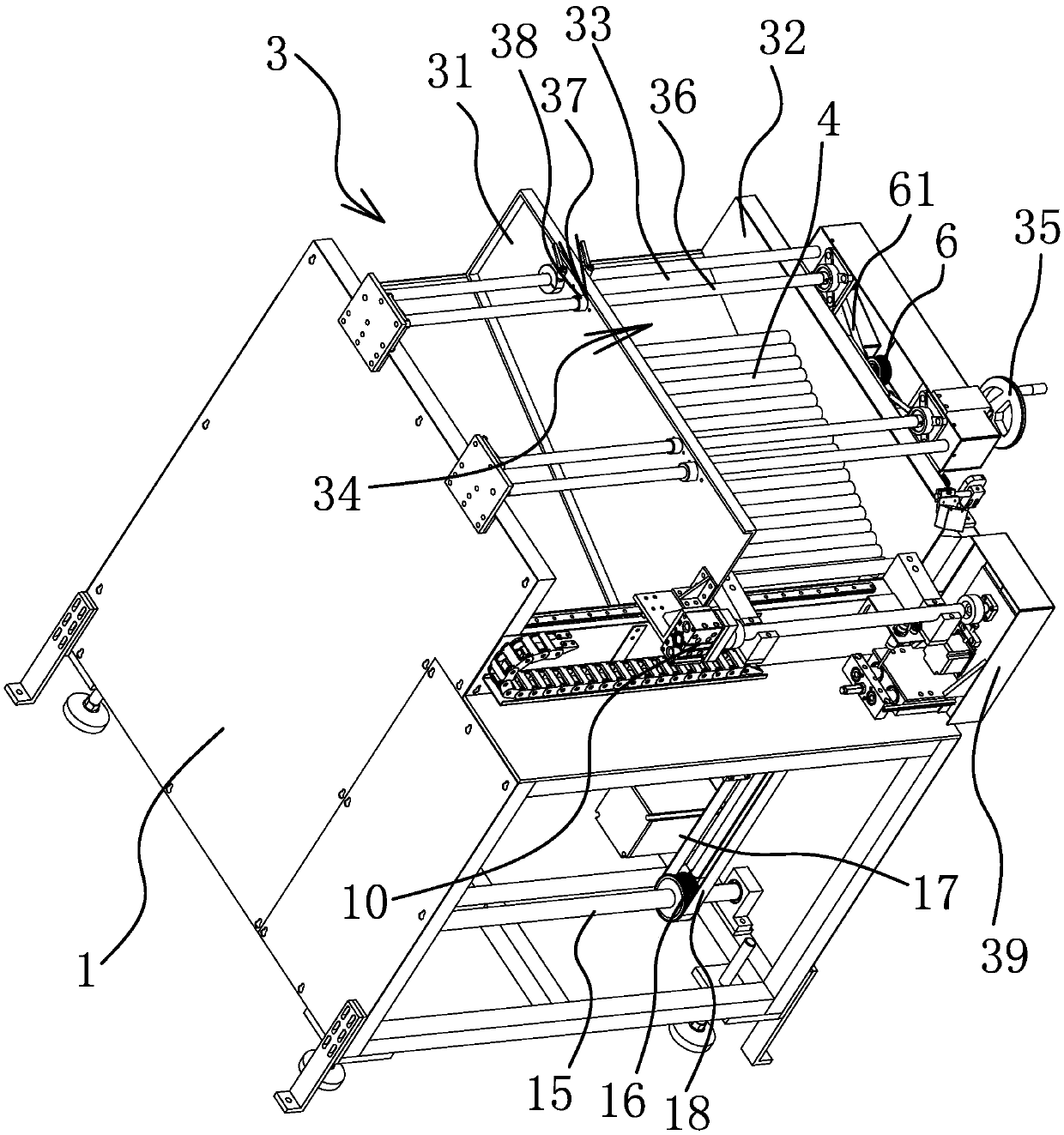

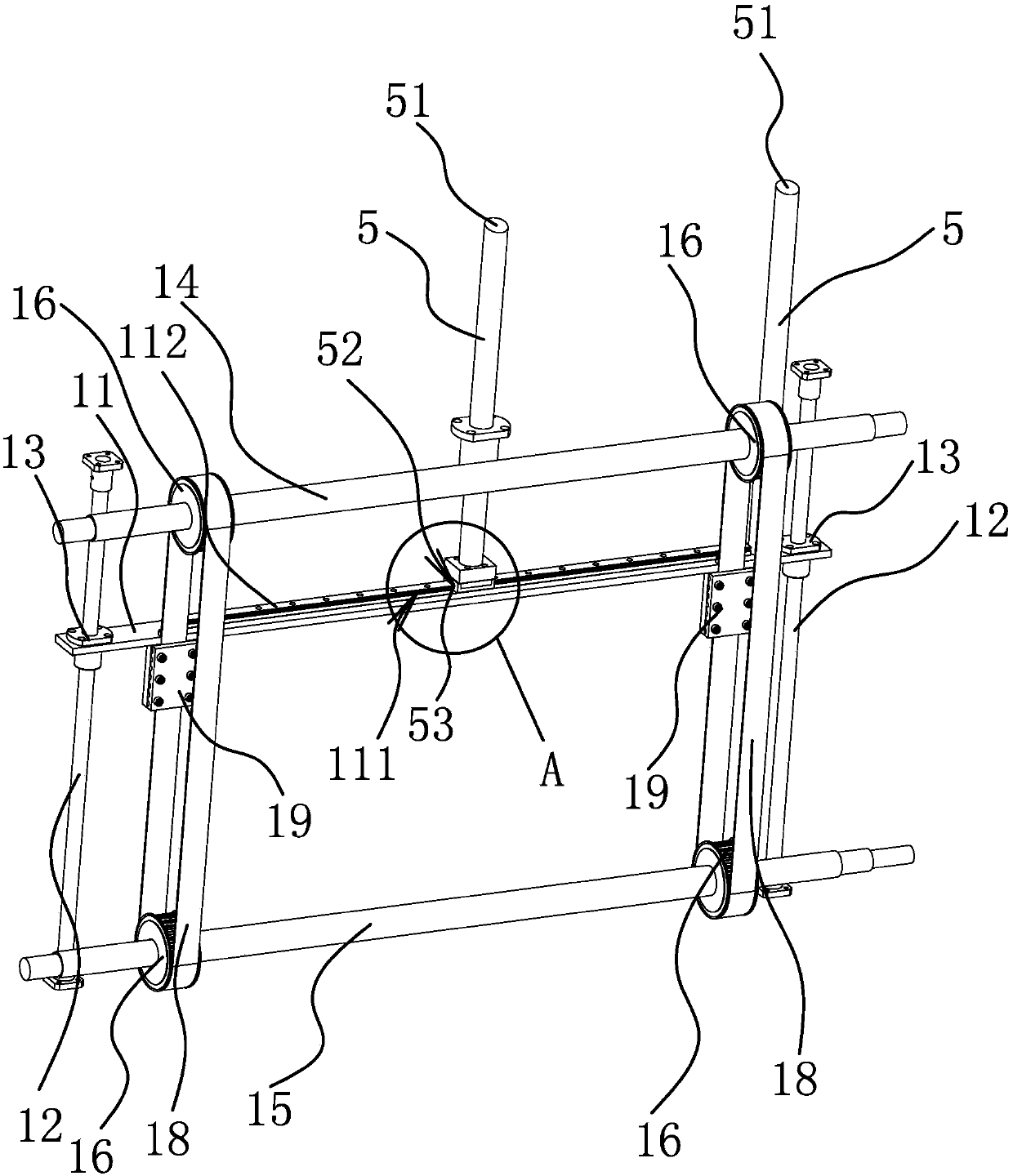

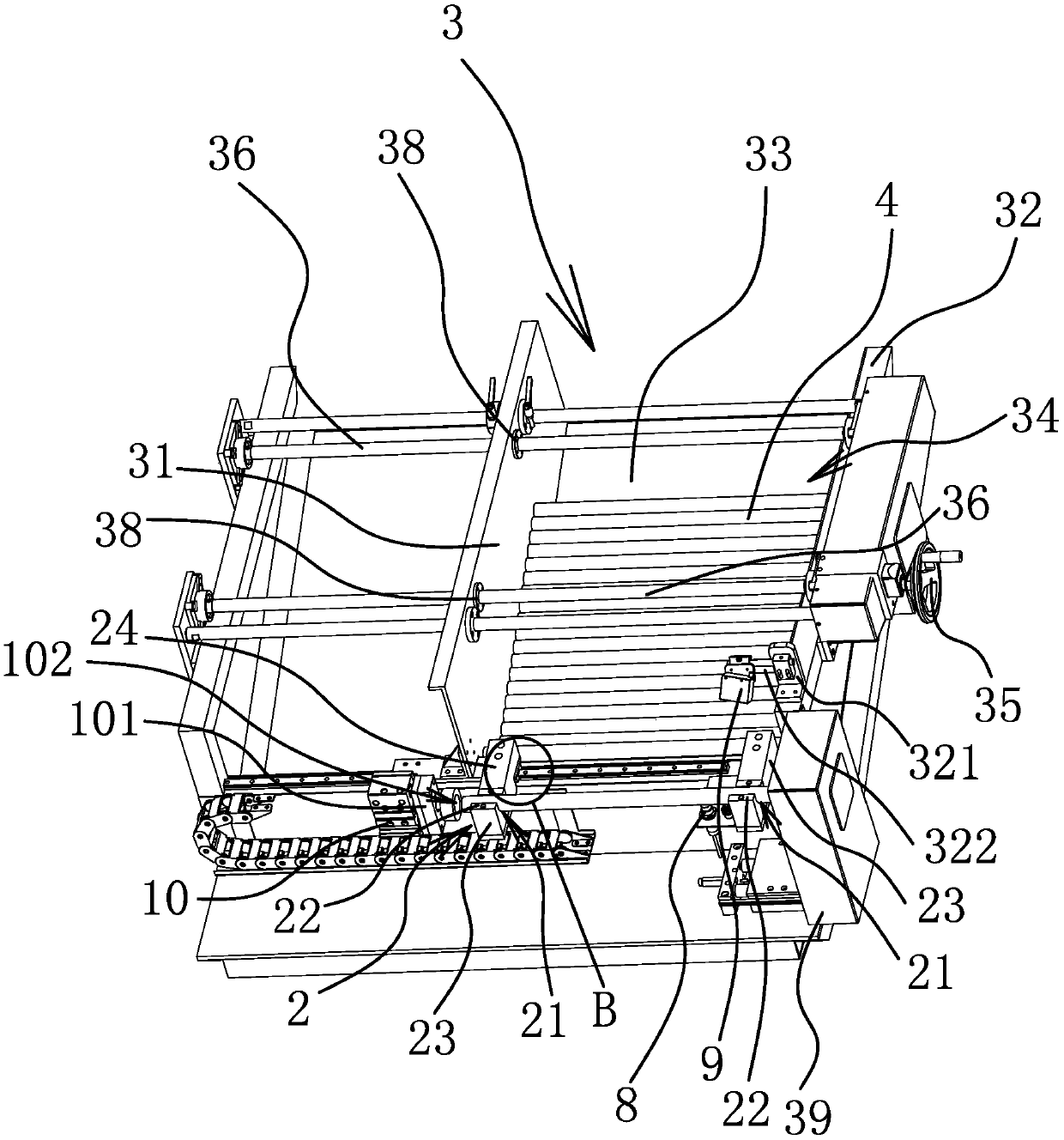

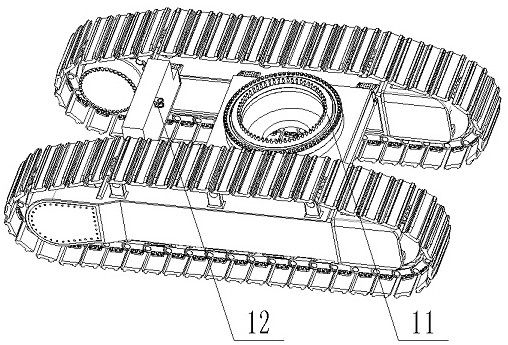

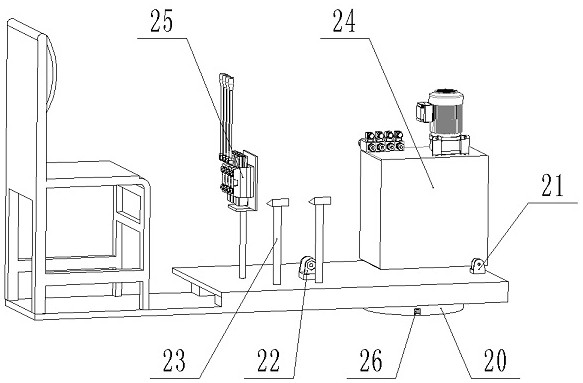

Special-shaped part machining quick clamping device

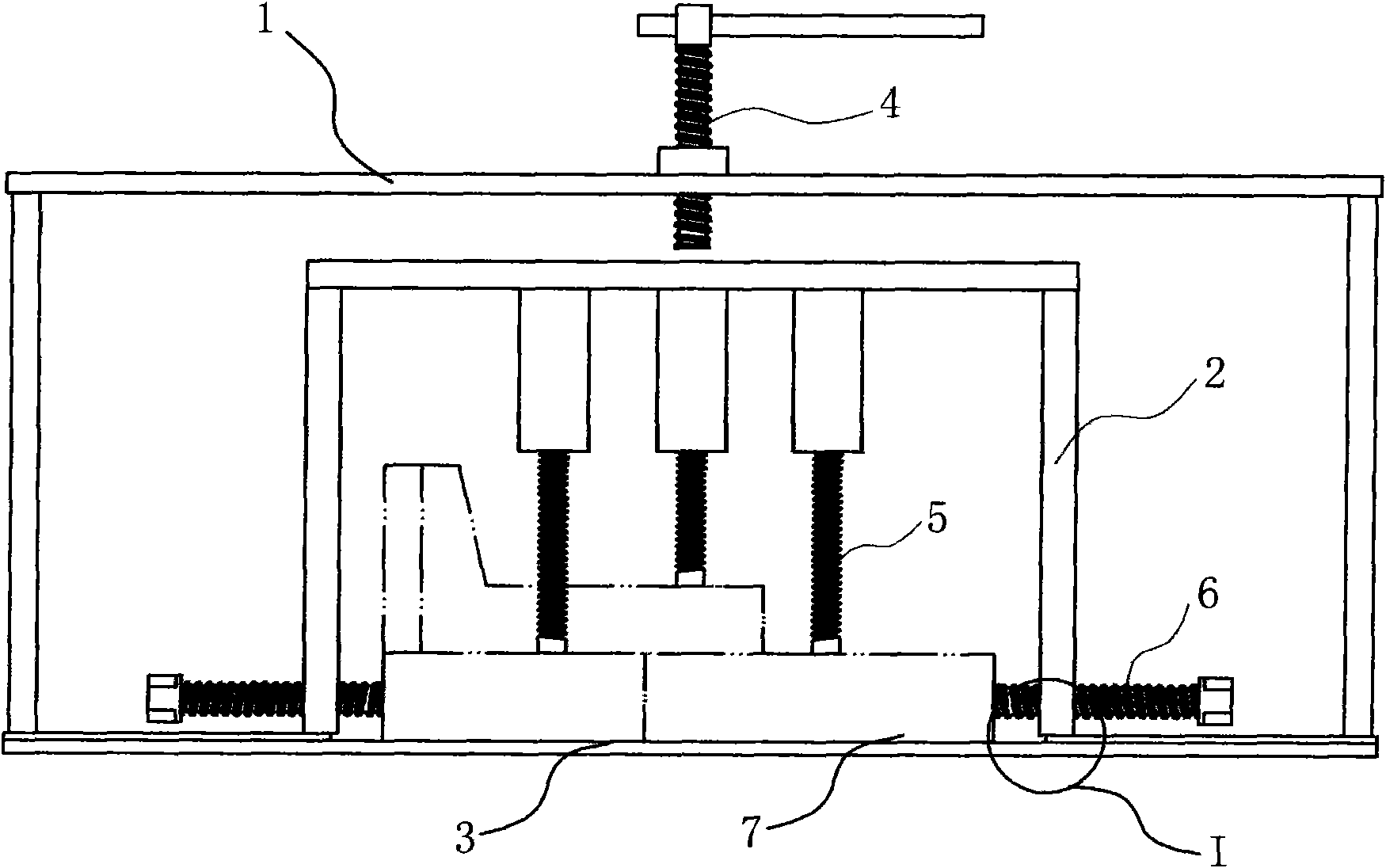

InactiveCN101804609AFast embeddingRealize "fast food" operationWork holdersPositioning apparatusEngineeringSwitching time

The invention discloses a special-shaped part machining quick clamping device, which comprises a positioning tooling, a machining tooling, a machining tooling positioning device and a machining tooling clamping device, wherein a part positioning device is arranged on the positioning tooling, and the machining tooling is arranged in the positioning tooling and is provided with a space for accommodating parts; and a part clamping device is arranged on the machining tooling, and the machining tooling positioning device and the machining tooling clamping device are arranged on the positioning tooling. The arrangement of the part positioning device on the positioning tooling and the part clamping device on the machining tooling, and the arrangement of the machining tooling positioning device and the machining tooling clamping device between the machining tooling and the positioning tooling realize the clamping of special-shaped parts and quick embedding in equipment, shortens operating switching time, eliminates the adjustment process on a machine tool, realizes fast food type operation, and simultaneously has simple structure and convenient use.

Owner:SHANDONG WEIFANG FOTON MOLD

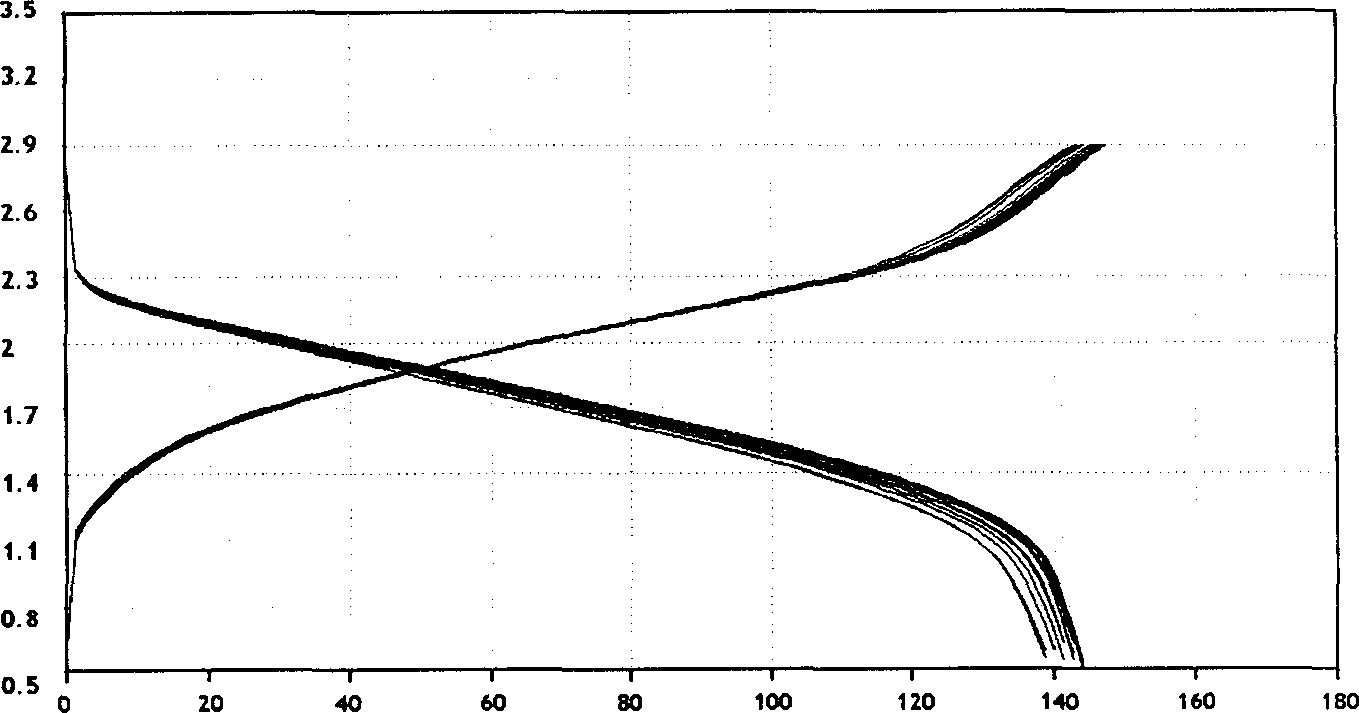

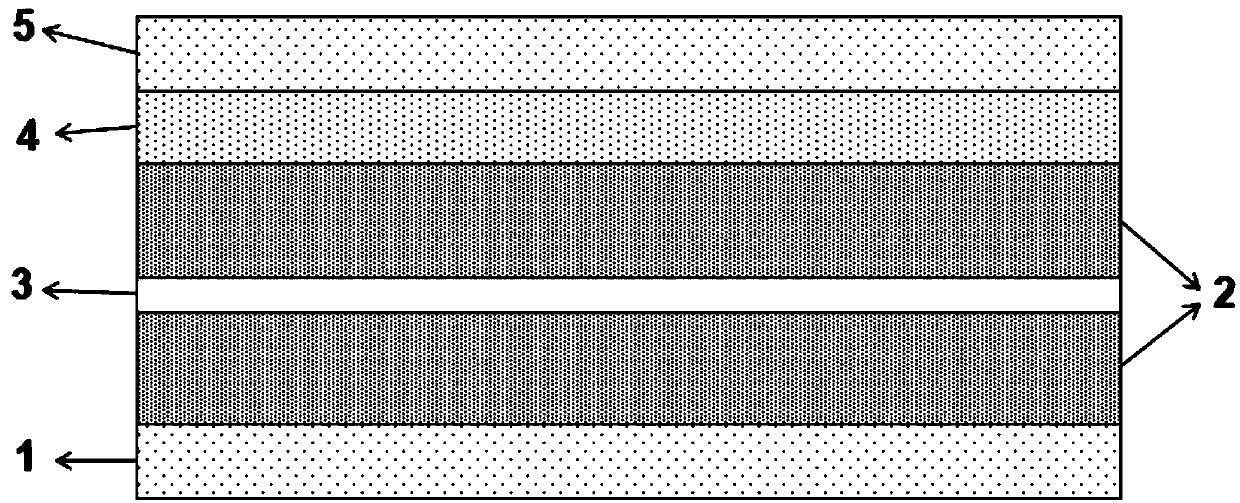

Sodium ion electrochemical capacitor

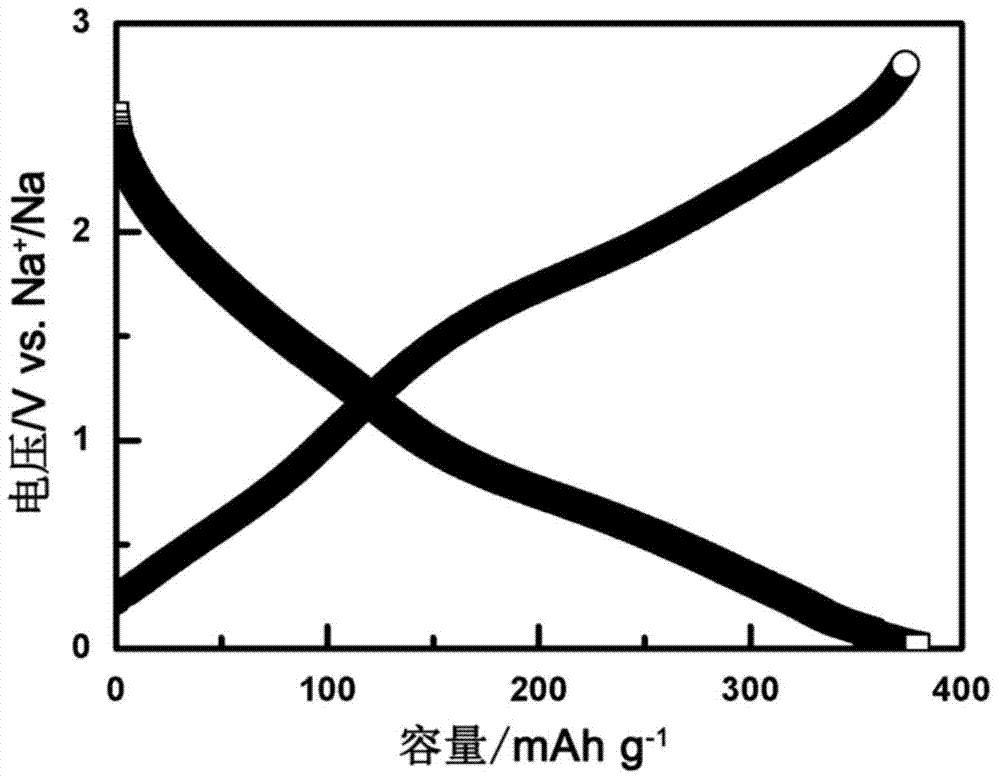

ActiveCN103198928AIncrease layer spacingLow costHybrid capacitor electrolytesHybrid capacitor electrodesBarium titanateSodium titanate

The invention provides a sodium ion electrochemical capacitor which comprises a positive pole, a negative pole, an electrolyte, and a membrane arranged between the positive pole and the negative pole, wherein the negative pole of the sodium ion electrochemical capacitor is made of coke or molybdenum sulfide or molybdenum oxide or niobium oxide or sodium titanate, and the electrolyte is an organic solution of neutral sodium salt. The five negative pole materials are all of layered structures, so sodium ions in the electrolyte can be intercalated and released from the surfaces of negative pole materials, and namely a redox reaction is generated. Interlamellar spacing of the negative pole materials is large, rapid intercalation and releasing of the sodium ions with large sizes are benefited, accordingly energy density and power density of the sodium ion electrochemical capacitor are improved, and the cycle life of the sodium ion electrochemical capacitor is prolonged. Meanwhile, the negative pole of the sodium ion electrochemical capacitor is made of the coke or the molybdenum sulfide or the molybdenum oxide or the niobium oxide or the sodium titanate, and the electrolyte is the organic solution of the neutral sodium salt, so cost of the capacitor is effectively reduced.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

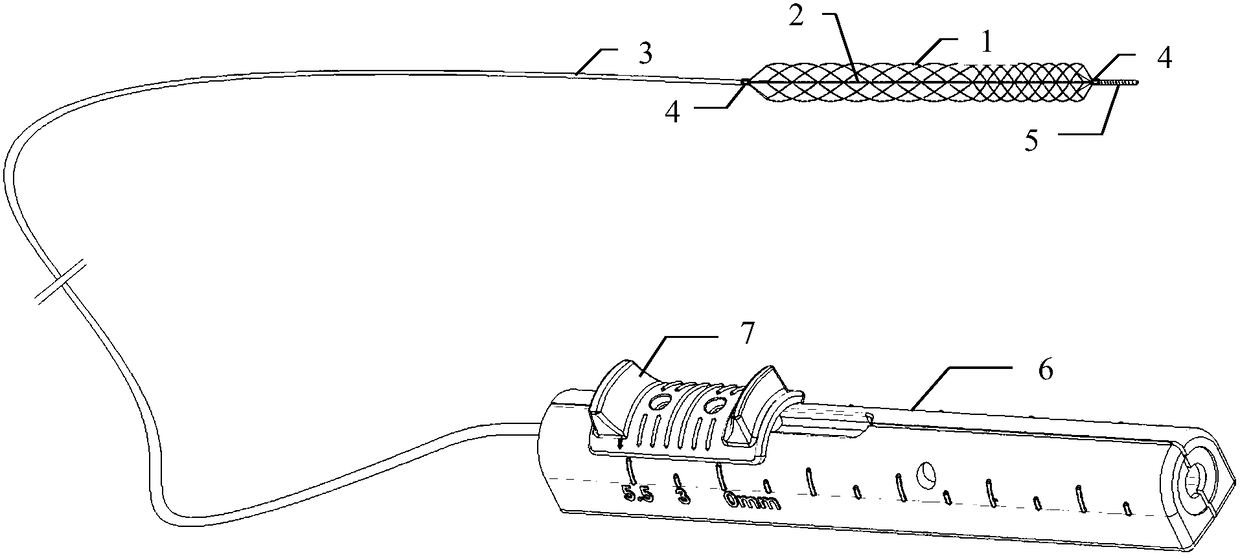

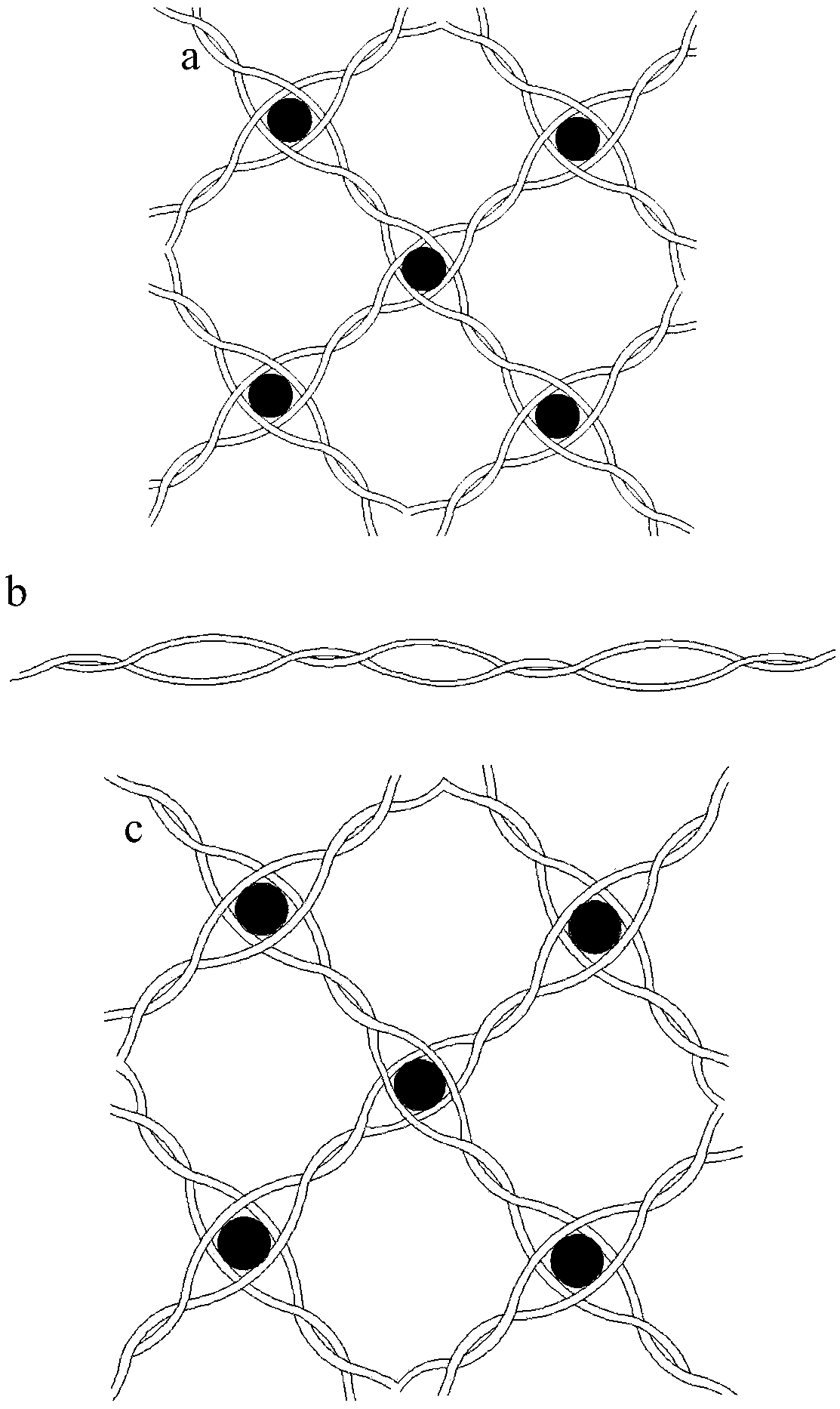

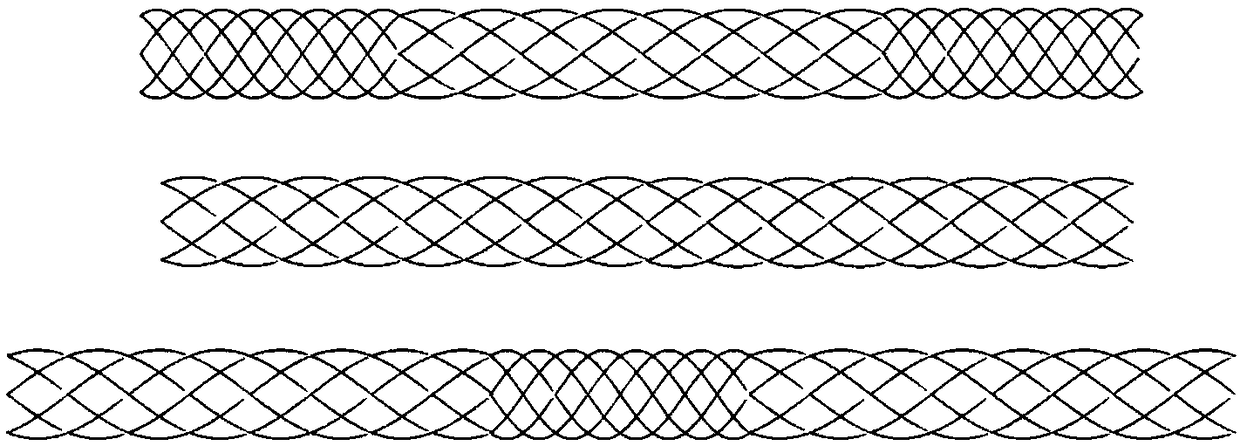

Thrombus removing device

The invention provides a thrombus removing device, comprising a thrombus removing bracket, a conveying system and a pushing handle. Compared with the prior art, the device makes the mesh stent adjustable according to the diameter of the blood vessel at the lesion position through the movement of the mandrel in the outer tube, and improves the matching property of the thrombectomy stent and the lesion blood vessel. At the same time, the mesh gap of reticular stent gradually narrows from proximal to distal end, and the mesh design of dense cooperation ensures that stent can be embedded into blood vessel quickly, and increases the combination and fishing capacity of stent and thrombus. Furthermore, increasing the density of the distal stent mesh can effectively prevent small thromboemboli from falling off the stent and reduce the damage to the vessel wall when the stent passes through the vessel. Finally, the distal end of the bracket is provided with a spring, which increases the flexibility of the thrombectomy bracket; Finally, the maneuverability of the bolt removing bracket is improved by the cooperation of the push handle shell and the push hand.

Owner:CHANGZHOU KEYNEUT MEDICAL TECH CO LTD

Exotic atom-doped porous carbon material and preparation method and application thereof

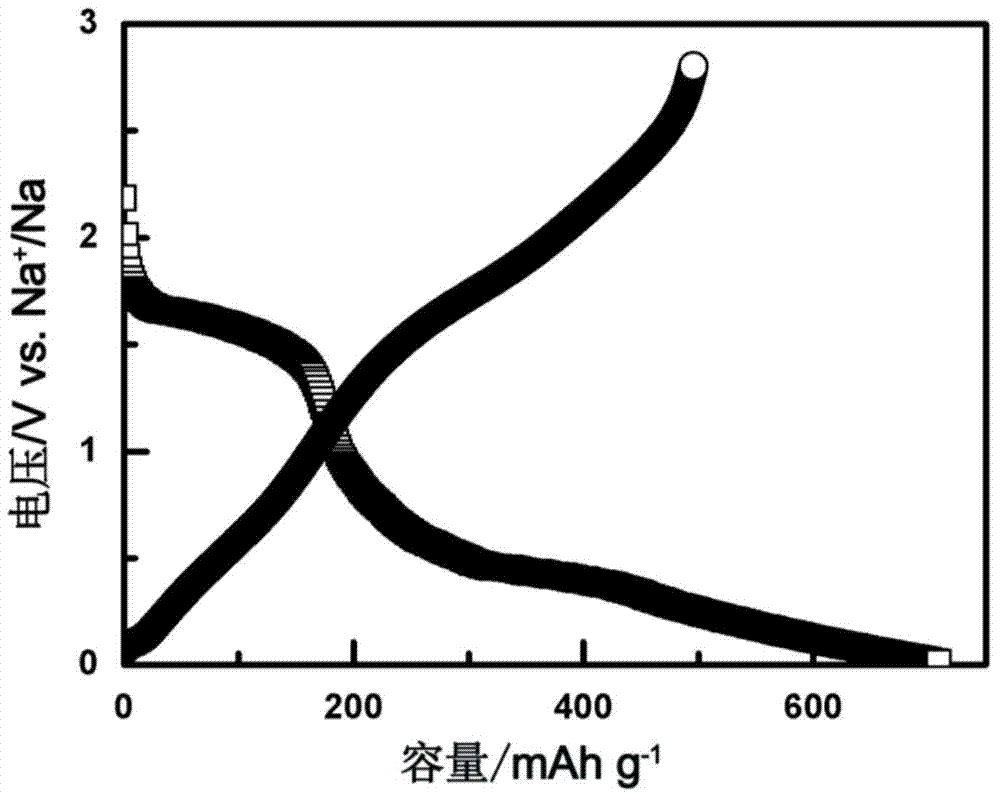

ActiveCN110148733ALarge specific surface areaImprove sodium storage performanceCell electrodesCross-linkN dimethylformamide

The invention discloses an exotic atom-doped carbon material and a preparation method and an application thereof. The doped carbon material prepared according to the method is a honeycomb three-dimensional multi-level porous structure material, wherein macropores are constructed by mutually cross-linked flakes, the flakes are stacked by nanoparticles, and random mesopores and micropores are distributed between the nanoparticles. The preparation method comprises the steps of firstly dissolving polyacrylonitrile into an N, N-dimethylformamide solution, then adding one or more reagents containingtarget doping atoms into the solution, conducting a solvothermal reaction to obtain a precursor, placing the precursor in a protective atmosphere for calcination so as to obtain a single or multi-atom doped carbon material with uniform nanometer size and excellent electrochemical performance. Sodium-ion batteries show high specific capacity, excellent rate performance and ultra-long cycle stability when the exotic atom-doped carbon material is used as a negative electrode material of the sodium-ion batteries.

Owner:CENT SOUTH UNIV

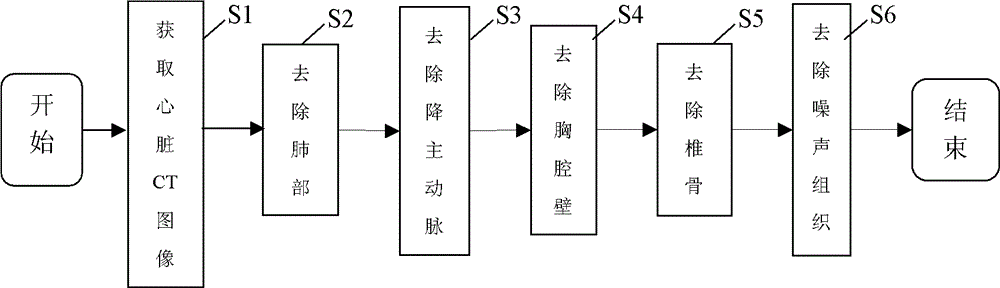

Whole heart extracting method based on heart CT image

InactiveCN103985122ARealize remote auxiliary diagnosisAdaptableImage enhancementImage analysisThoracic structureThoracic cavity

A whole heart extracting method based on a heart CT image comprises the steps of obtaining the heart CT image, removing the lung part, the descending aorta part, the thoracic cavity wall part and the vertebra part of the heart CT image to obtain a middle image, and removing the noise part in the middle image. The whole heart extracting method based on the heart CT image gradually removes the non-heart parts such as the thoracic cavity wall, the lung, the vertebra and the descending aorta in an reverse angle mode to achieve the purpose of extracting the whole heart, has the advantages of being high in self-adaptation performance, high in operation efficiency, accurate in extraction effect and the like, can be rapidly embedded in an existing medical network, and achieves remote auxiliary diagnosis.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

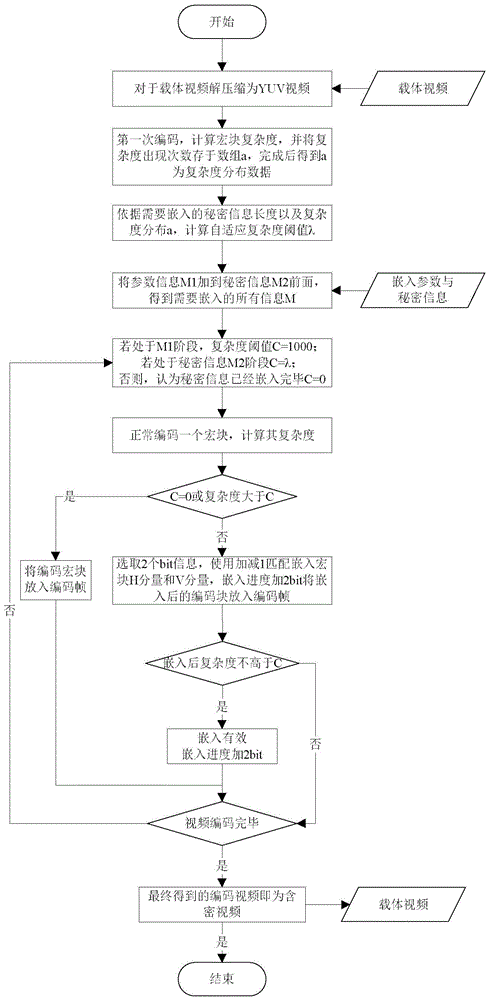

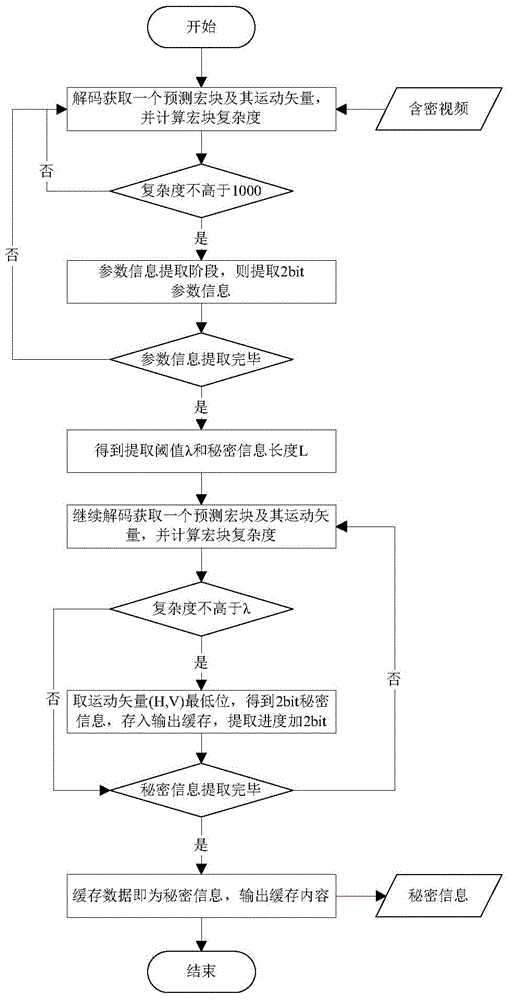

Adaptive video motion vector steganographic method based on macro-block complexity

ActiveCN105704489ASmall increase in residualGood anti-detection abilityDigital video signal modificationSelective content distributionPattern recognitionLocal optimum

The invention discloses an adaptive video motion vector steganographic method based on macro-block complexity. The method uses video motion vector to perform information hiding, and the imbedded process comprises one decompression process and two compression processes: first, a given carrier video is decompressed into an uncompressed YUV video; then, a first simulating compression process is carried out, complexity of each macro-block is recorded, and video sequence complexity distribution data is obtained; finally, a complexity threshold is selected according to the complexity distribution and the secret information quantity to be imbedded, and the second compression is carried out, wherein, plus / minus 1 matching imbedding is used when secret information is embedded; According to the method, high local optimum probability of low complexity macro-block and holding characteristic of plus / minus 1 matching imbedding to adjacent correlation are utilized; the secret-containing video generated by the imbedding algorithm has advantages such as low bit rate, high image quality, fast imbedding speed, and strong anti-detection capability.

Owner:WUHAN UNIV

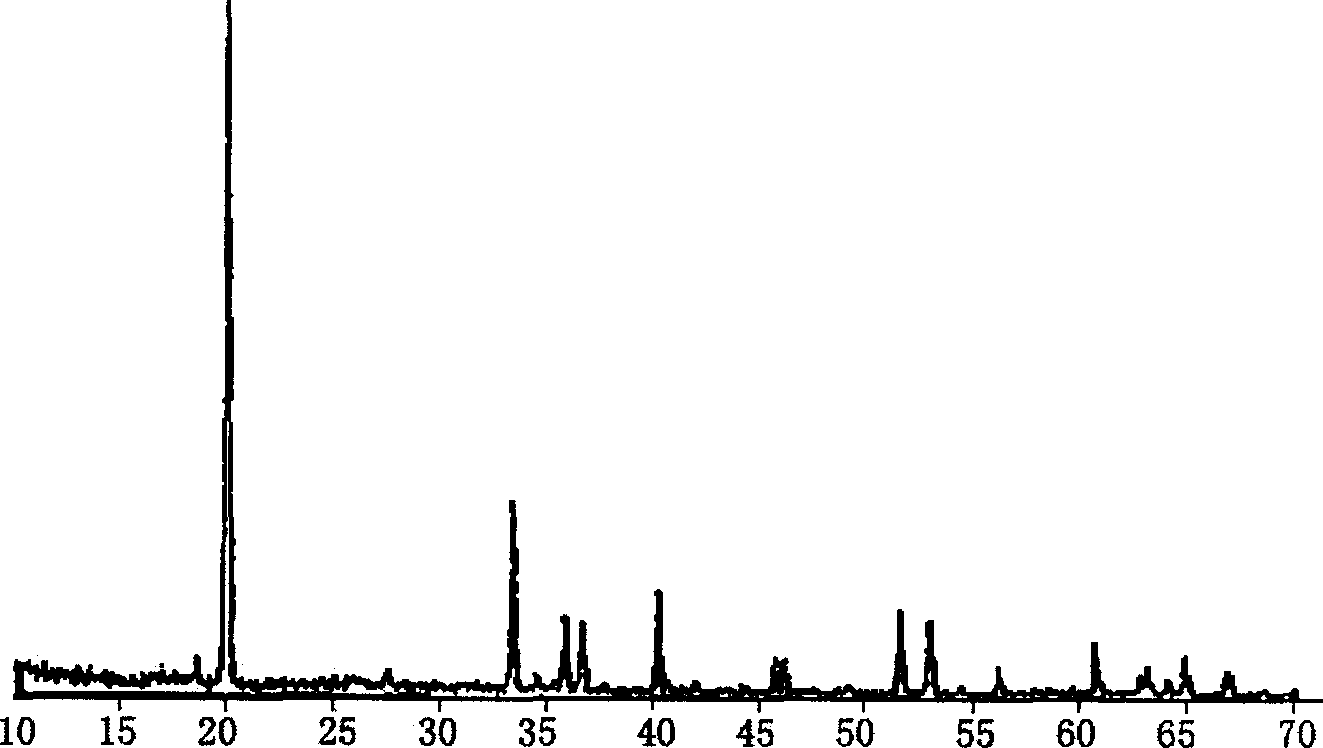

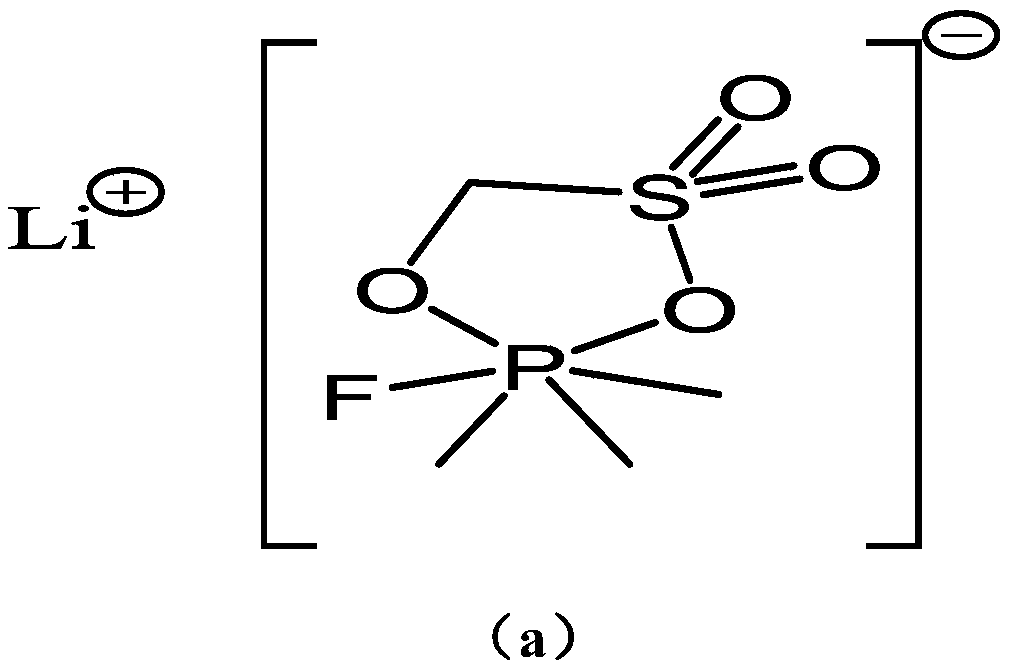

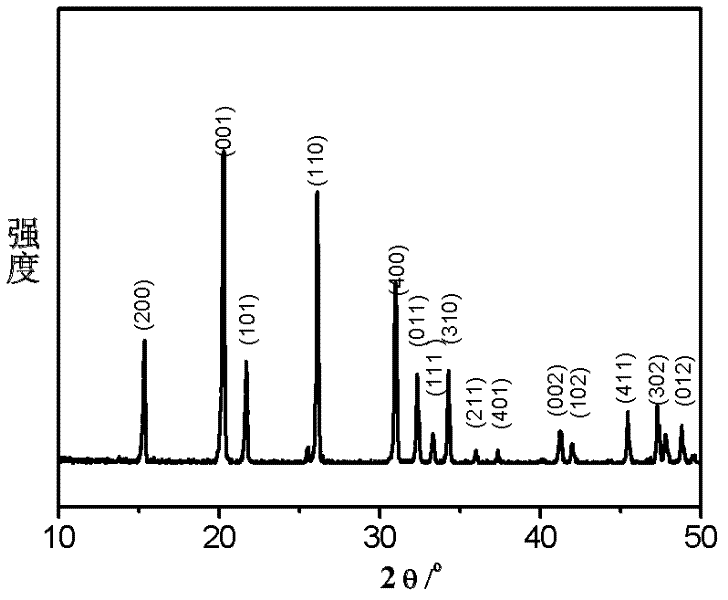

Composite oxide electrode material and producing method thereof, and mixed super capacitor

ActiveCN1674178ADoes not affect electrochemical capacityMultiple slotsElectrode manufacturing processesElectrolytic capacitorsCapacitorComposite oxide

A composite oxide electrode material is composite oxide of Li2Ti3O7 prepared from main metal elements of Li and Ti under simple and easy operated process, the composite oxide of Li2Ti3O7 is orthorhombic structure and specific capacity of the composite oxide is 140mAh / g. The mixed super capacitor made of this composite oxide has high specific capacity and excellent cyclic property.

Owner:SICHUAN INDIGO TECH CO LTD

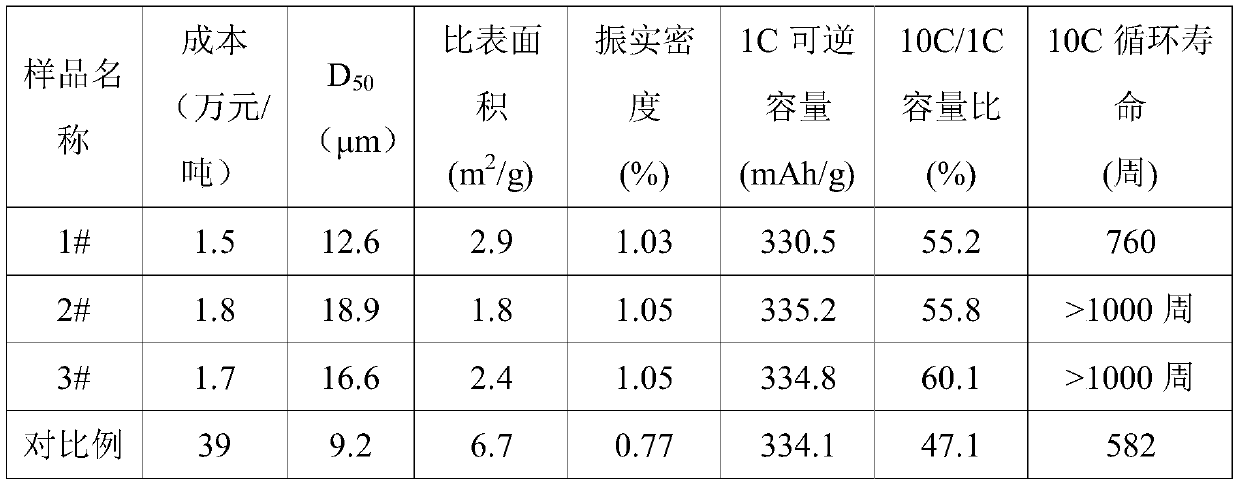

Rapid-charge microcrystalline graphite negative electrode material and production method thereof

ActiveCN110395725AGood value for moneySolution areaCarbon compoundsNegative electrodesCarbonizationFree cooling

The invention discloses a production method of a rapid-charge microcrystalline graphite negative electrode material. The production method of the rapid-charge microcrystalline graphite negative electrode material comprises the steps of firstly, mixing microcrystalline graphite waste and additives, transferring a mixture into granulation equipment, and conducting composite granulation under a condition of an inert atmosphere to obtain composite particles; and after the composite particles are cooled, conducting two-time grading through a grader, transferring composite particles subjected to two-time grading into a carbonization furnace for carbonization, and then conducting natural cooling, breaking up, magnetism removing and screening to obtain the rapid-charge microcrystalline graphite negative electrode material. By means of the production method of the rapid-charge microcrystalline graphite negative electrode material, the problems that in the prior art, the microcrystalline graphite waste has oversize specific surface areas and low tap density, so that a rapid-charge negative electrode material is hard to produce are solved.

Owner:HUNAN SHINZOOM TECH

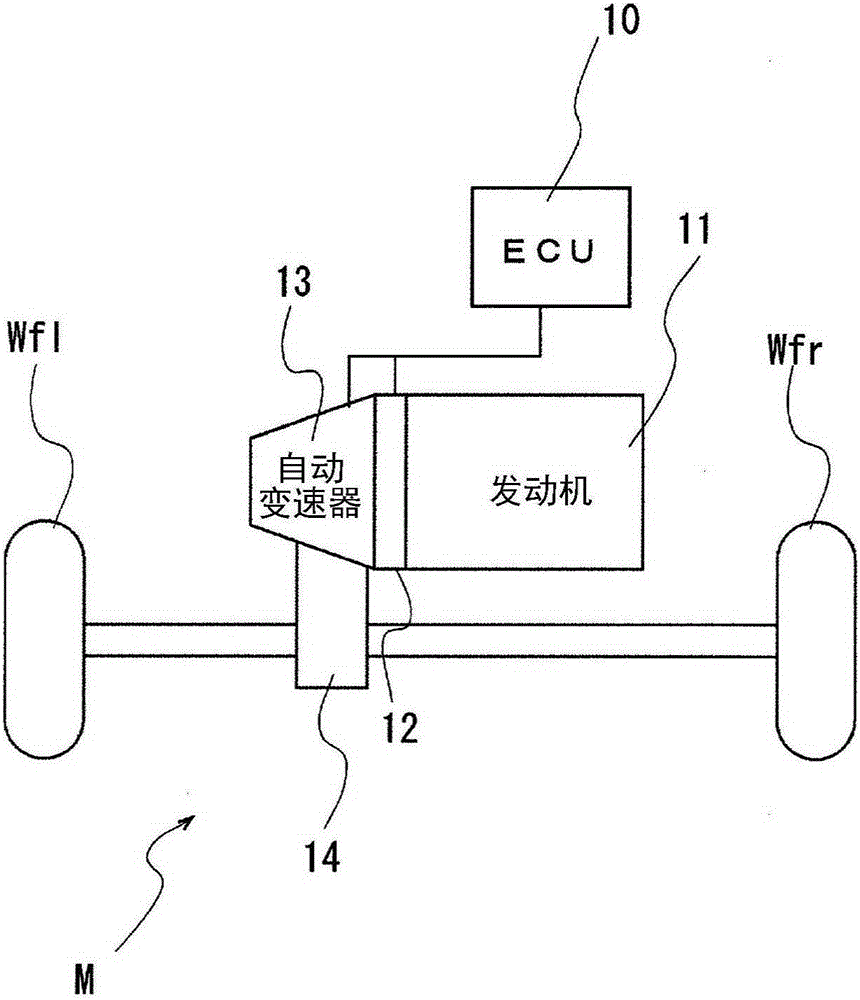

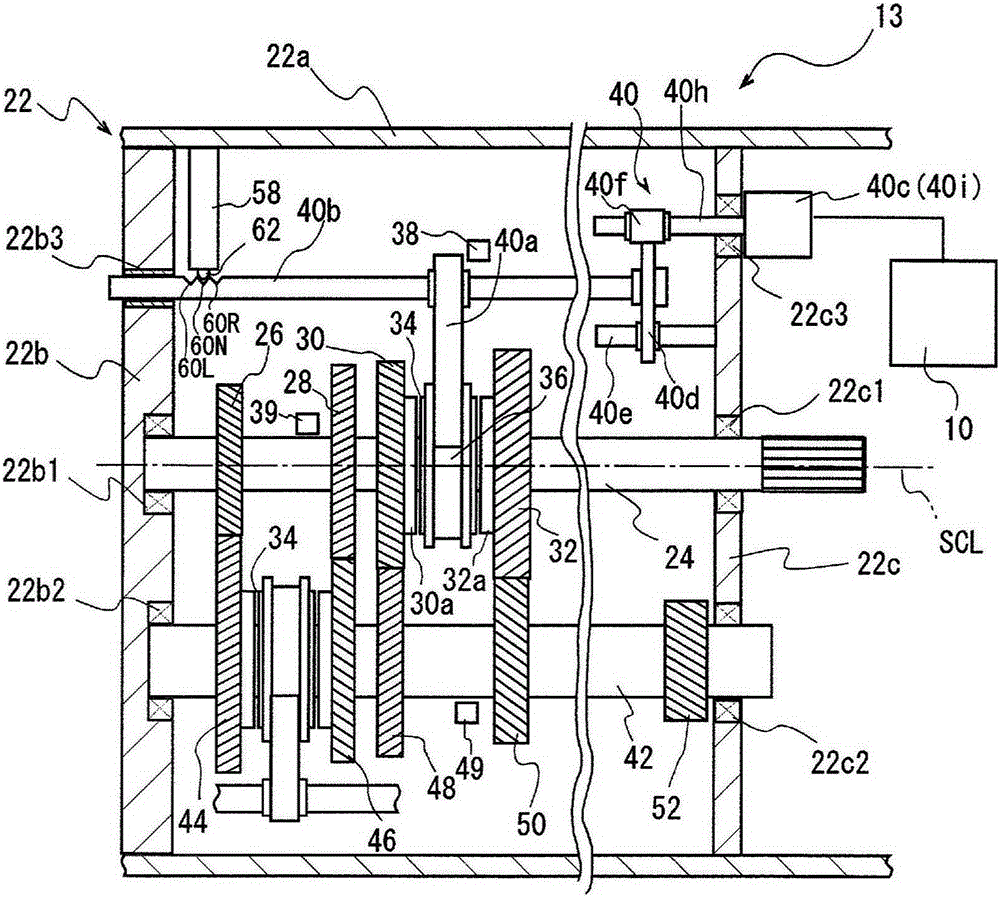

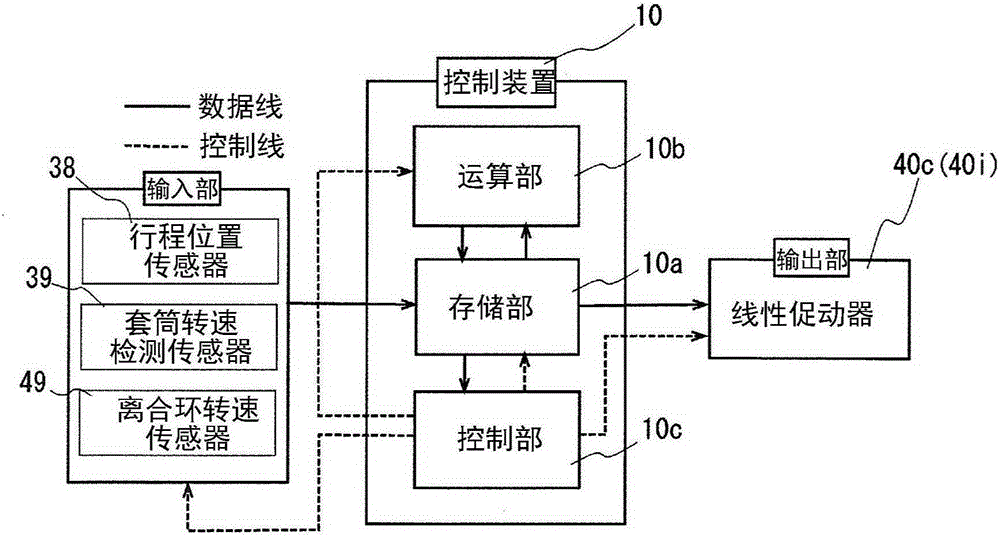

Dog clutch control device for automatic transmission

InactiveCN105247254AButt fastIncrease speedControlled membersGearing controlAutomatic transmissionControl theory

Provided is a dog clutch control device for an automatic transmission that makes it possible to perform a speedy shifting operation when, during shifting, a sleeve is moved and engaged with the dog clutch. A control device (10), which has a calculation unit (10b) for calculating the speed of movement of the sleeve (36) on the basis of the position detected at a predetermined time by a stroke position sensor (38) for detecting the position of movement of the sleeve (36), and which controls the operation of a shaft device (40) on the basis of the position detected by the stroke position sensor and the speed of movement of the sleeve, applies, after high teeth (36a1) of the sleeve have passed a chamfered portion (30b3) of clutch front teeth of the clutch ring (30), a stopping thrust load (F4) for stopping the forward movement of the high teeth before the high teeth come into contact with the end surfaces (30b6) of clutch back teeth (30b2) of the clutch ring.

Owner:AISIN SEIKI KK

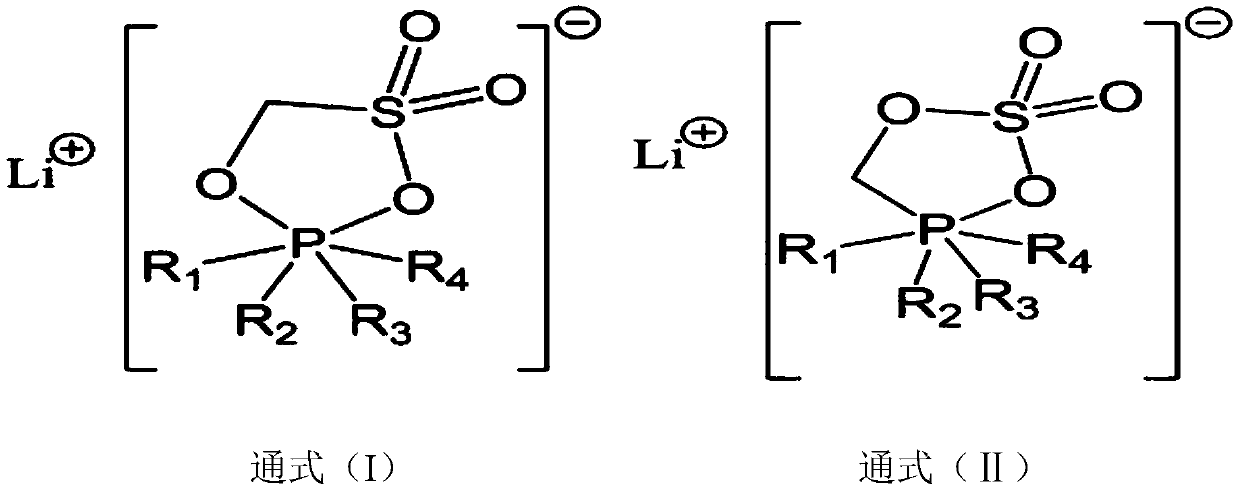

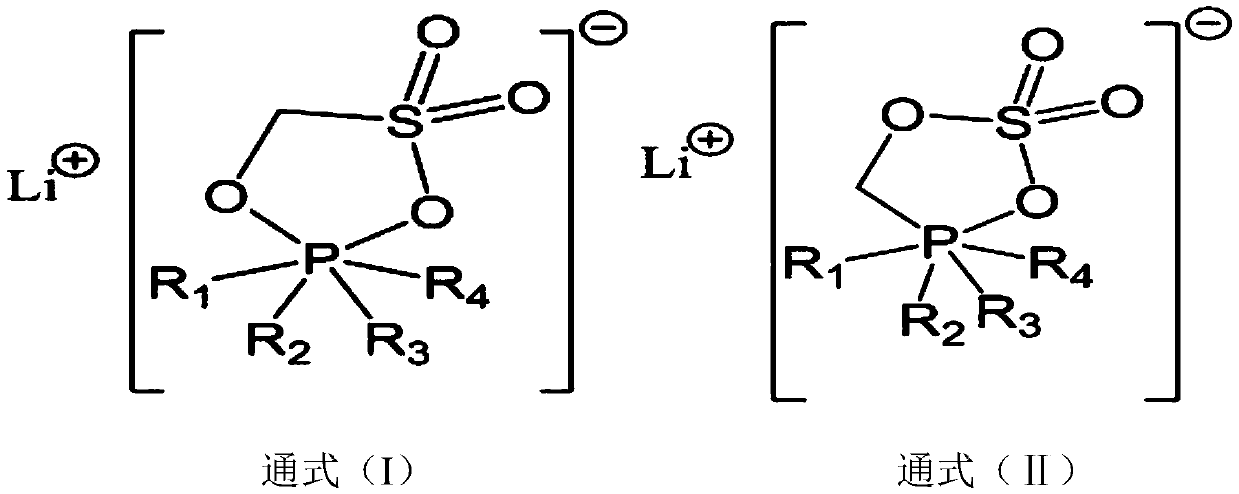

Low-temperature electrolyte and lithium battery using same

ActiveCN110061292AImprove solubilityImprove compatibilityFinal product manufactureElectrolyte accumulators manufactureOrganic solventLITHIUM PHOSPHATE

The invention discloses a low-temperature electrolyte and a lithium battery using the same, and relates to the technical field of lithium ion batteries. The low-temperature electrolyte comprises lithium salt, an organic solvent and an additive, wherein the lithium salt is alkyl sulfur-containing oxygen-containing fluoro lithium phosphate; compared with a traditional lithium salt, the electrolyte of the invention adopts alkyl sulfur-containing oxygen-containing fluoro lithium phosphate, so that a relatively high ionic conductivity is still achieved under the ultralow temperature condition of minus 50 DEG C; in addition, the alkyl sulfur-containing oxygen-containing fluoro lithium phosphate can form a low-impedance stable SEI membrane on the surface of the negative electrodes, so that the rapid intercalation and de-intercalation of the lithium ions under the low-temperature condition are facilitated, and the problem of lithium ion evolution caused by too low temperature is effectively solved, and more excellent low-temperature discharge and cycling performance in an ultralow-temperature environment can be shown.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Positive electrode material for lithium ion cells and preparation method thereof

The invention relates to a positive electrode material for lithium ion cells and a preparation method thereof. The material provided by the invention is porous vanadic anhydride with an amorphous carbon layer on the surface of vanadic anhydride, wherein the weight friction of vanadic anhydride is 80-99.9% and the weight friction of carbon is 0.1-20%. In comparison with the prior art, the preparation method provided by the invention has advantages of simple technological process, short reaction time, low production cost and the like.

Owner:CHANGZHOU POWERGENIE MATERIALS

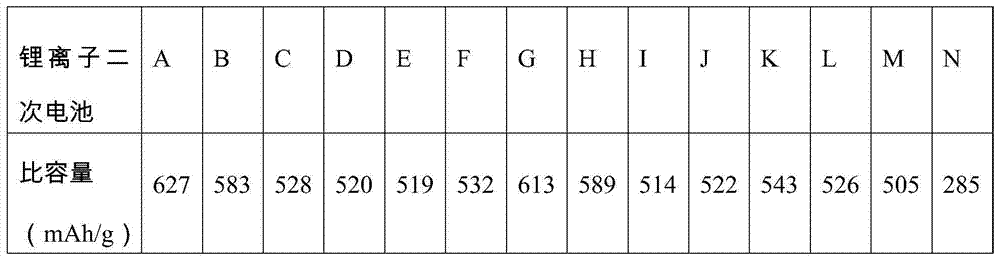

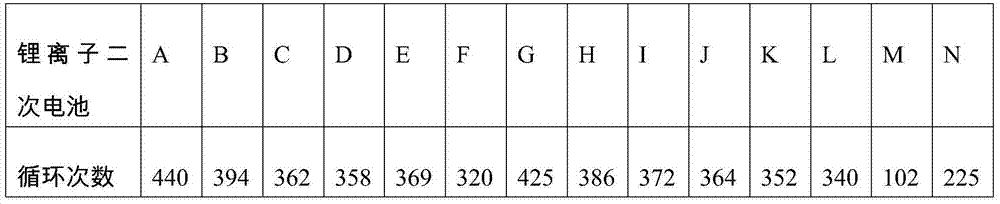

Negative-pole active material and preparation method thereof as well as lithium ion battery using negative-pole active material

ActiveCN104752721AHigh specific capacityFast embeddingCell electrodesSecondary cellsLithium electrodeMaterials science

The invention discloses a negative-pole active material. The negative-pole active material comprises a core material and a cladding material formed outside the core material, wherein the cladding material is constituted by a first material and a second material cladding outside the first material, and the first material can form an alloy with lithium; ionic conductance of the second material is 10<-5>-10<-4>S / cm, electronic conductivity is lower than 10<-10>S / cm. In addition, the invention discloses a preparation method of the negative-pole active material and a lithium ion battery using the negative-pole active material. The negative-pole active material has the advantages that the cycle performance and charge-discharge efficiency of a lithium ion battery is improved, and the service life of the battery is prolonged.

Owner:BYD CO LTD

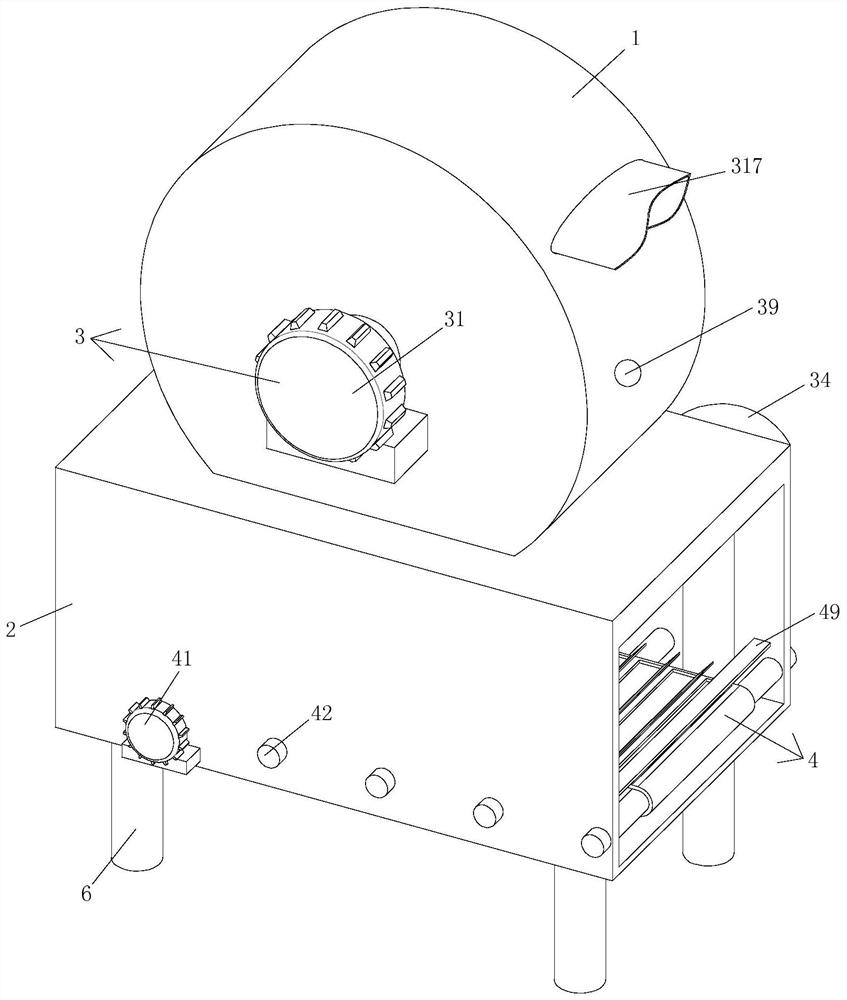

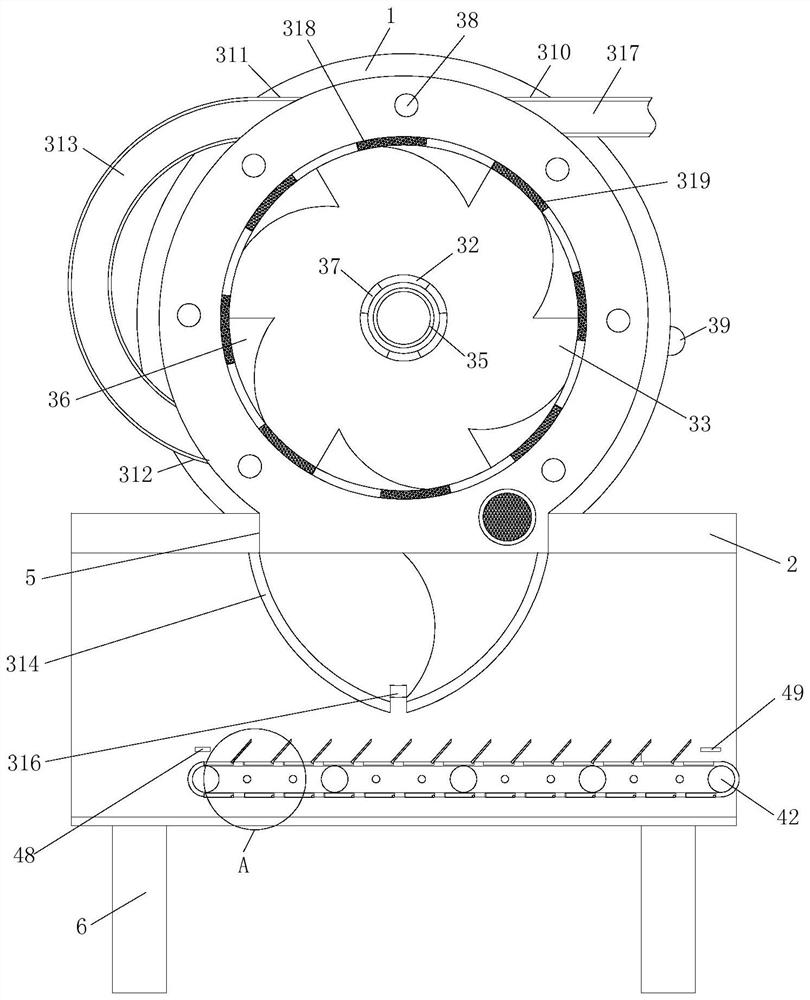

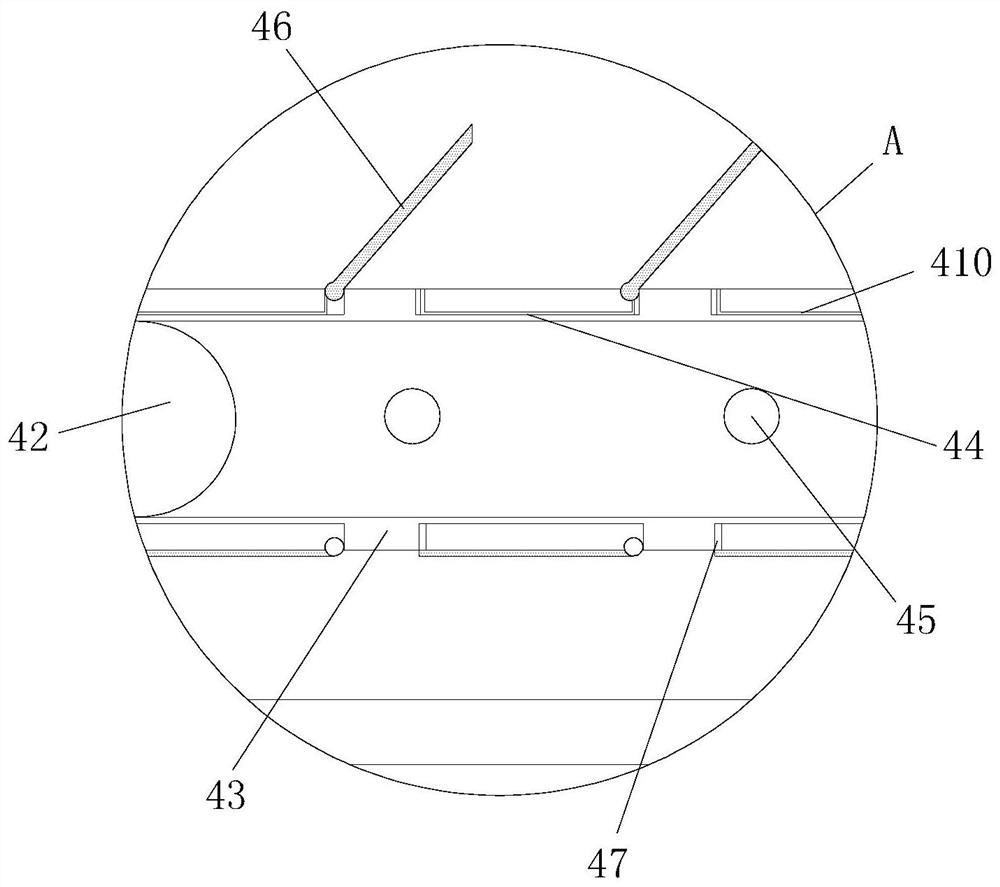

Embedded meat flavor powder essence drying device and drying process method thereof

ActiveCN112179079AAvoid drying overheatingImprove work efficiencyDrying gas arrangementsDrying chambers/containersEngineeringProcess engineering

The invention provides an embedded meat flavor powder essence drying device and a drying process method thereof, and relates to the field of minced meat essences. The embedded meat flavor powder essence drying device comprises a centralized drying box used for drying meat flavor powder, a dispersed drying box used for dispersed drying of the meat flavor powder, a rolling drying mechanism and a transmission drying mechanism, wherein the bottom of the centralized drying box is fixedly connected with the dispersed drying box, the surface of the centralized drying box is in an arc shape, and the surface of the dispersed drying box is in a rectangular shape. According to the embedded meat flavor powder essence drying device, a special multi-stage drying structure combining conveying and dryingis designed in order to solve the problems that in the existing embedded minced meat essence drying process, overheating is likely to happen, and an existing device cannot be easily combined with an existing embedding process; therefore, the problems that it is difficult for a common drying device to automatically adapt to the drying and embedding procedures of embedded powder essences, consequently, the grade of finished products is possibly reduced in the drying process, the processing continuity of the products may be also influenced, and the working efficiency is influenced to a certain extent are effectively solved.

Owner:武汉慧康利兹食品有限公司

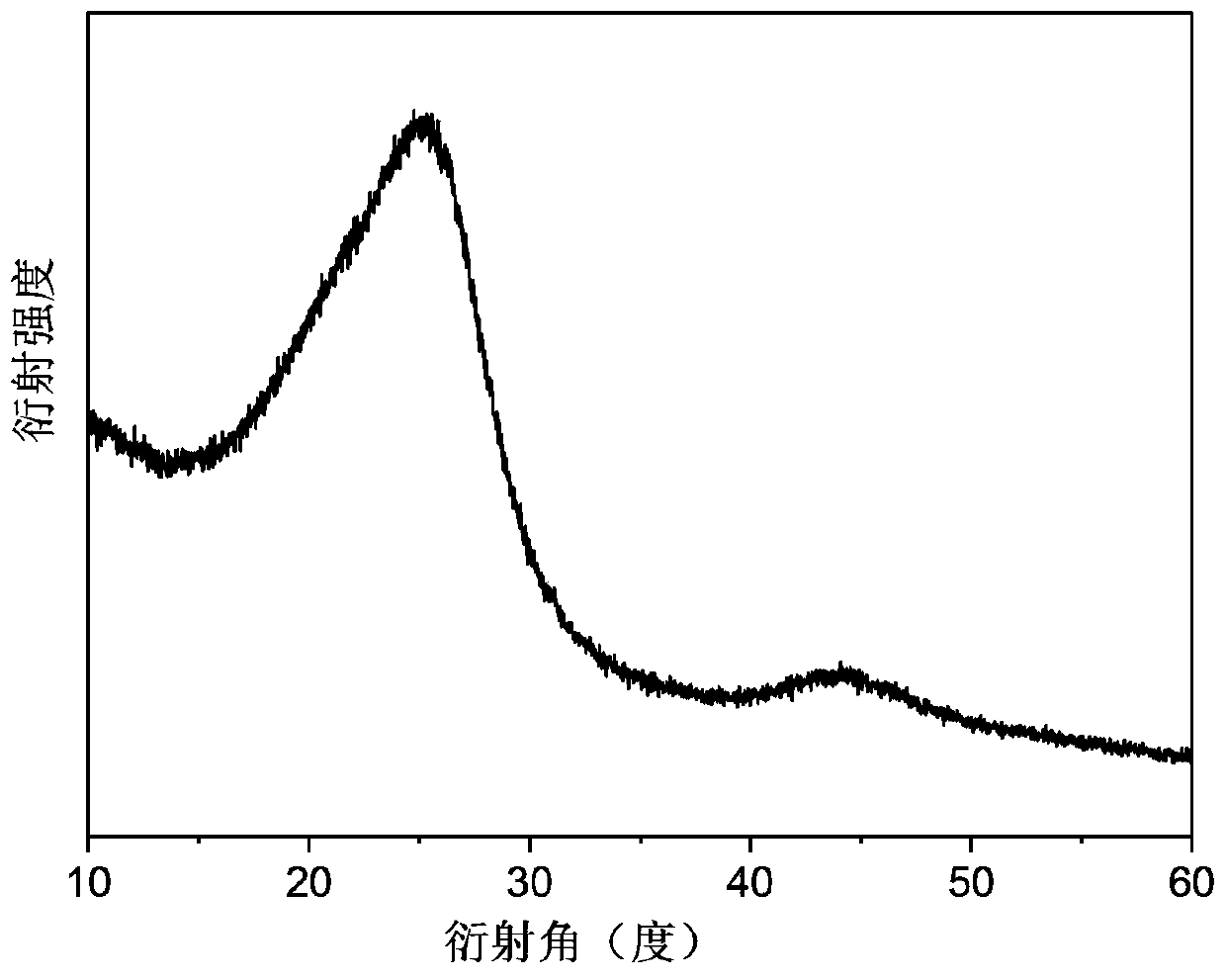

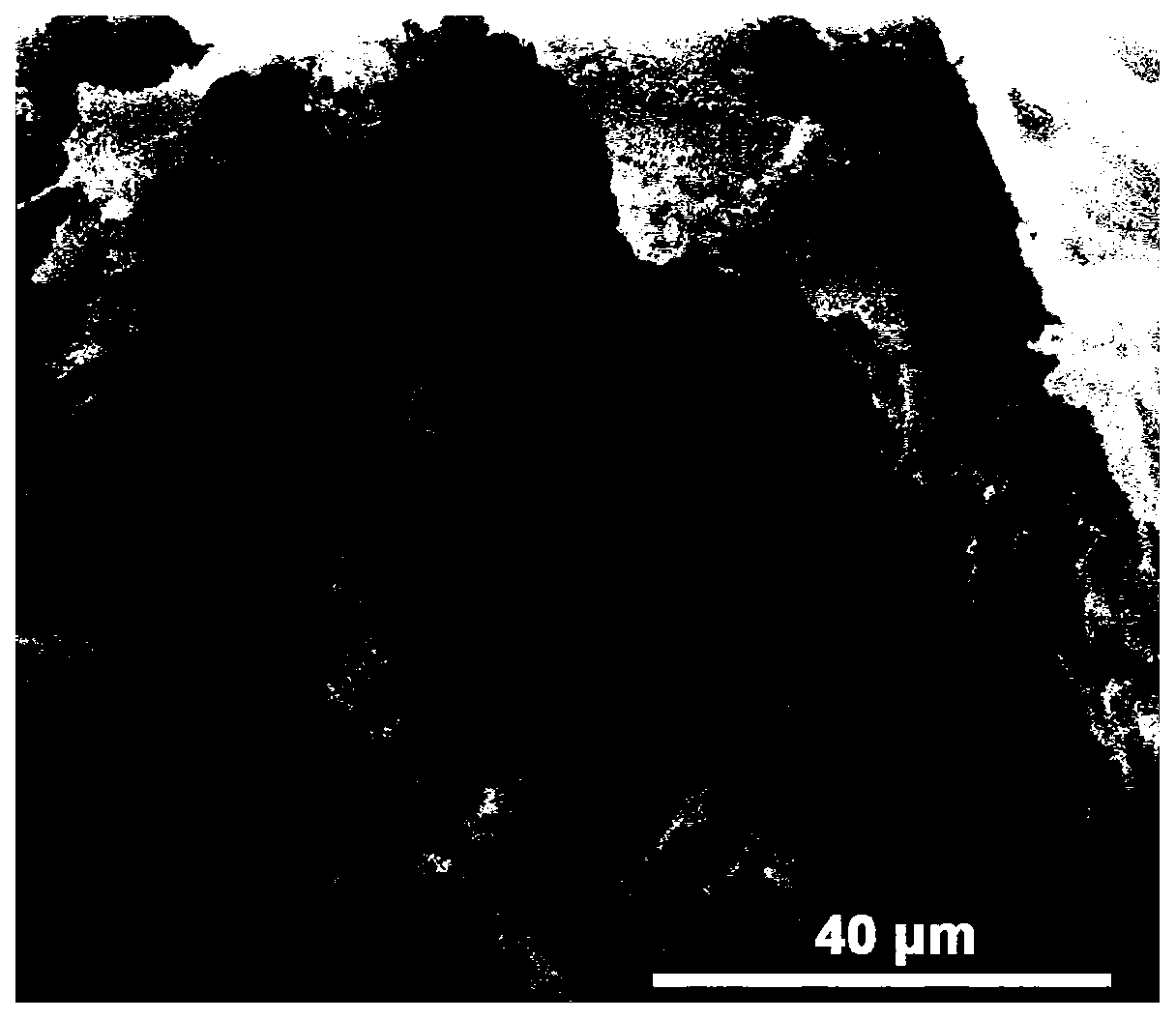

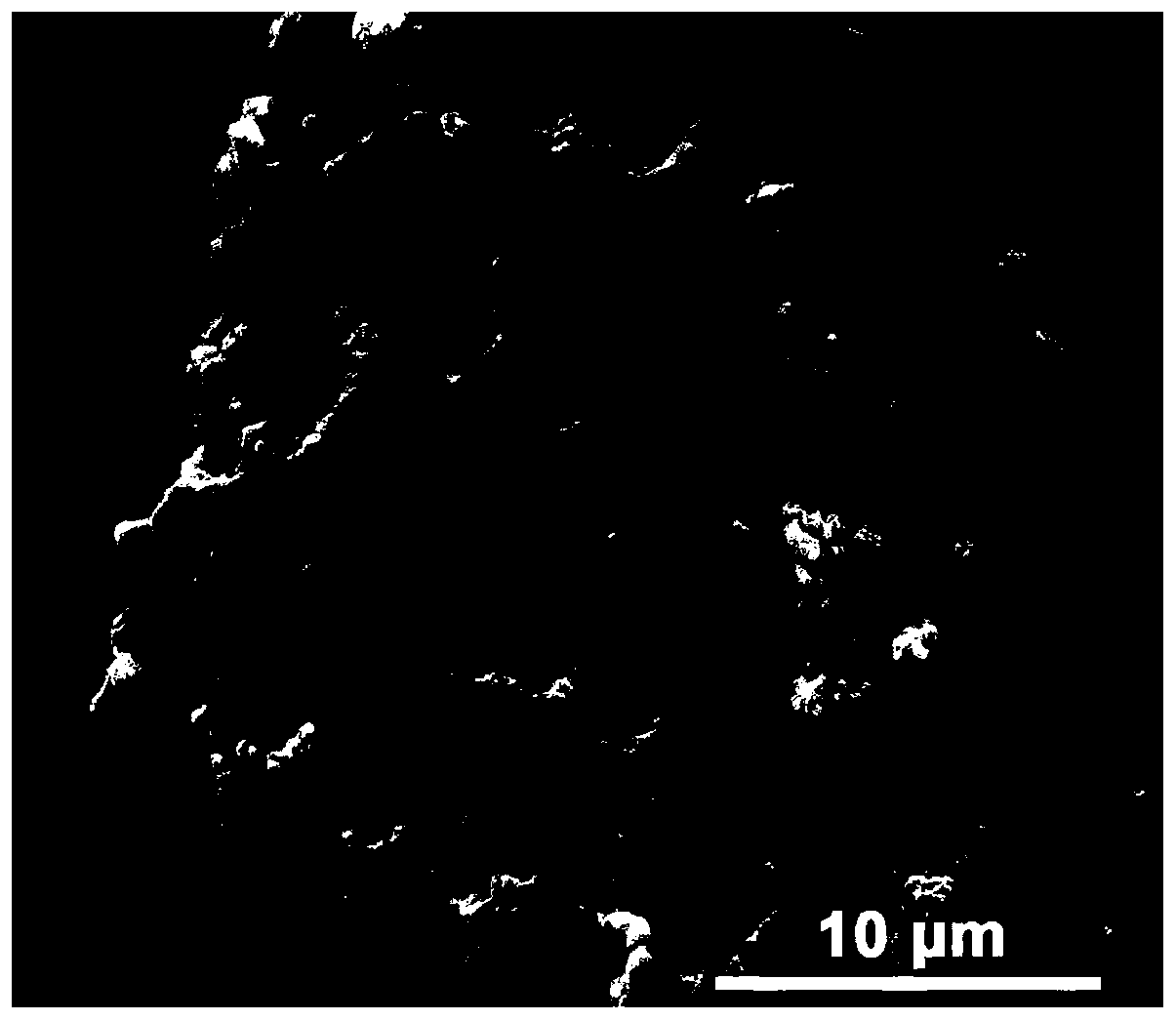

Silicon-hard carbon composite material and preparation method thereof

ActiveCN110098385AReduce bloatImprove cycle performanceCell electrodesSecondary cellsCarbon compositesMaterials preparation

The invention provides a silicon-hard carbon composite material and a preparation method thereof, and belongs to the technical field of lithium-ion battery material preparation. The preparation methodcomprises the steps of stably combining sulfonated polystyrene microspheres and a piezoelectric material to form a core material; mixing the core material with nano-silicon and phenolic resin, and enabling phenolic resin and nano-silicon to uniformly wrap the surfaces of the polystyrene microspheres; removing polystyrene through elution so as to form a piezoelectric material core with a porous structure; carbonizing phenolic resin into a carbon material through carbonization treatment to coat the surface of the core material, and thus forming the shell-core silicon-hard carbon composite material with the core being the porous piezoelectric material and the shell being hard carbon. The porous structure of the silicon-hard carbon composite material is conducive to absorbing and holding a liquid, the expansion of the silicon material is reduced, the G capacity development and cycle performance of the silicon-hard carbon composite material, the characteristics of large interlayer spacingand high lithium ion de-intercalation rate of hard carbon are given into full play, and the rate performance is improved. Meanwhile, the addition of the piezoelectric material improves the safety of the silicon-hard carbon composite material.

Owner:上海飞鸿创联新能源发展有限公司

Potassium ion battery negative electrode active material, potassium ion battery negative electrode material, potassium ion battery negative electrode, potassium ion battery and application thereof

ActiveCN109659528AImprove cycle lifeHigh specific capacityNegative electrodesSecondary cellsCapacitanceAlloy

The invention provides a potassium ion battery negative electrode active material, a potassium ion battery negative electrode material, a potassium ion battery negative electrode, a potassium ion battery and an application thereof, belonging to the technical field of potassium ion batteries. The potassium ion battery negative electrode active material provided by the invention comprises a ruthenium pentoxide composite material, wherein the ruthenium pentoxide composite material comprises a ruthenium pentoxide composite material containing a doping ions and / or a coating layer. The ruthenium pentoxide composite material has excellent potassium ion transport channels, can realize rapid insertion and de-intercalation of potassium ions, has stable crystal structure, adopts the reaction mechanism of intercalation and pseudocapacitance dual mechanism, prepares the potassium ion battery with the advantages of long cycle life, high specific capacity and low cost, can solve the problem of priceincrease caused by insufficient lithium resources, avoids the problems of expansion and pulverization of the alloy-type negative electrode of the potassium ion battery, slow dynamics of the intercalated carbon material and the like, and can be widely applied to electric tools, electronic equipment, electric vehicles or energy storage equipment.

Owner:SHENZHEN INST OF ADVANCED TECH

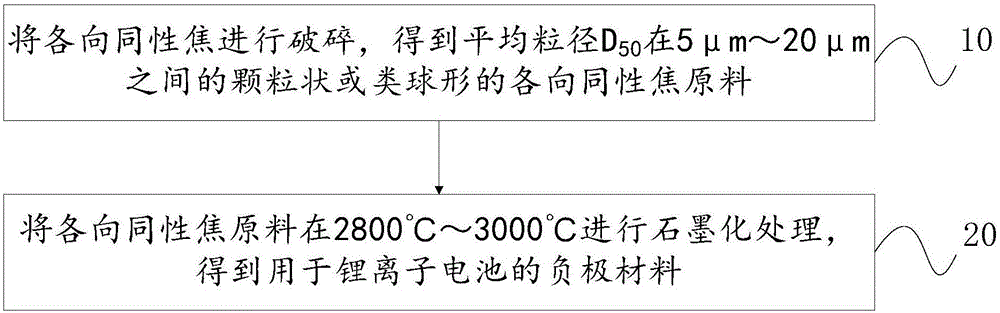

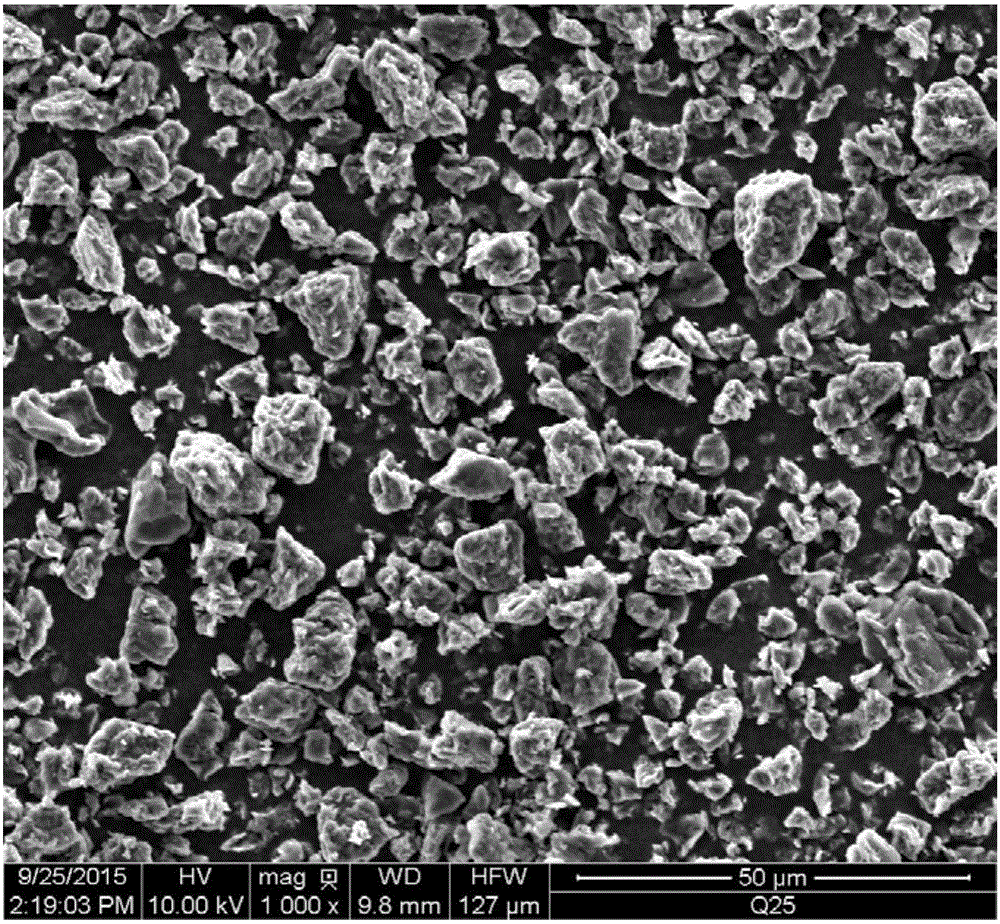

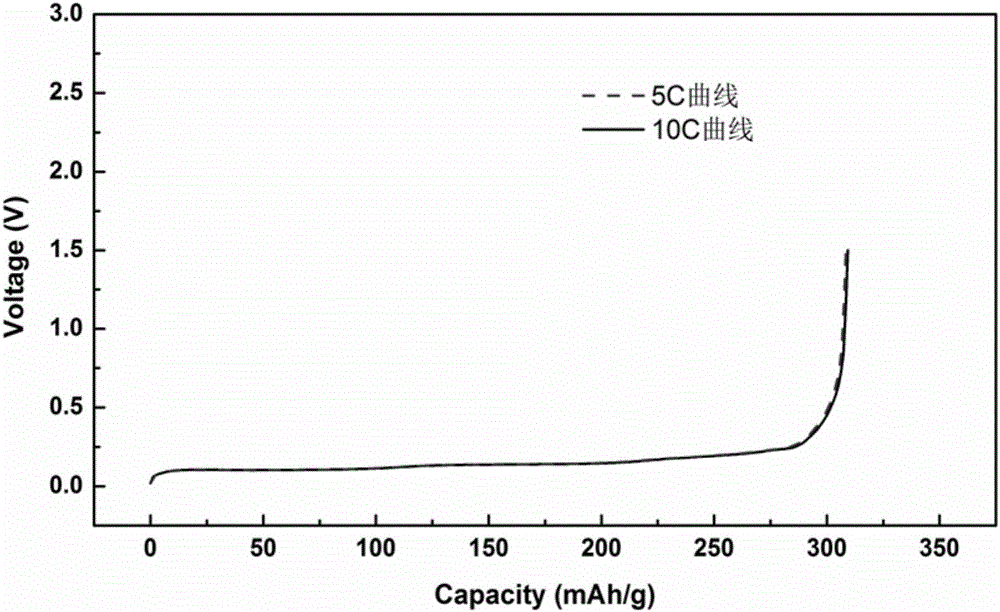

Negative electrode material used for lithium ion battery, preparation method, secondary and usage

InactiveCN106356530AFast charge and dischargeMeet the requirements of fast charging and dischargingGraphiteCell electrodesLithium-ion batteryMaterials science

The invention discloses a negative electrode material used for a lithium ion battery, a preparing method, a secondary battery and usage . The negative electrode material is prepared through graphitization on a raw material of isotropic coke in particles or round-likely roundness; the capacity of the negative electrode material is not less than 300mAh / g, the specific surface area is smaller than 5m<2> / g, the degree of graphitization ranges from 80 percent to 90 percent, and the average particle diameter D50 ranges from 5 [mu]m to 20 [mu]m.

Owner:江西紫宸科技有限公司

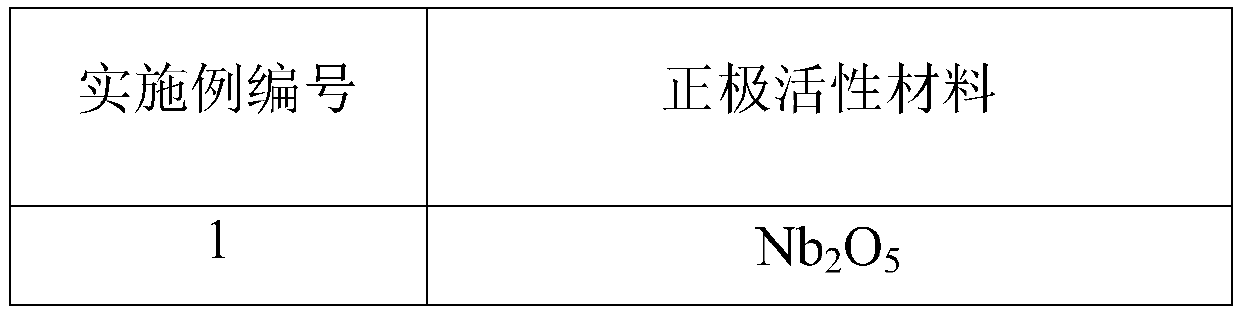

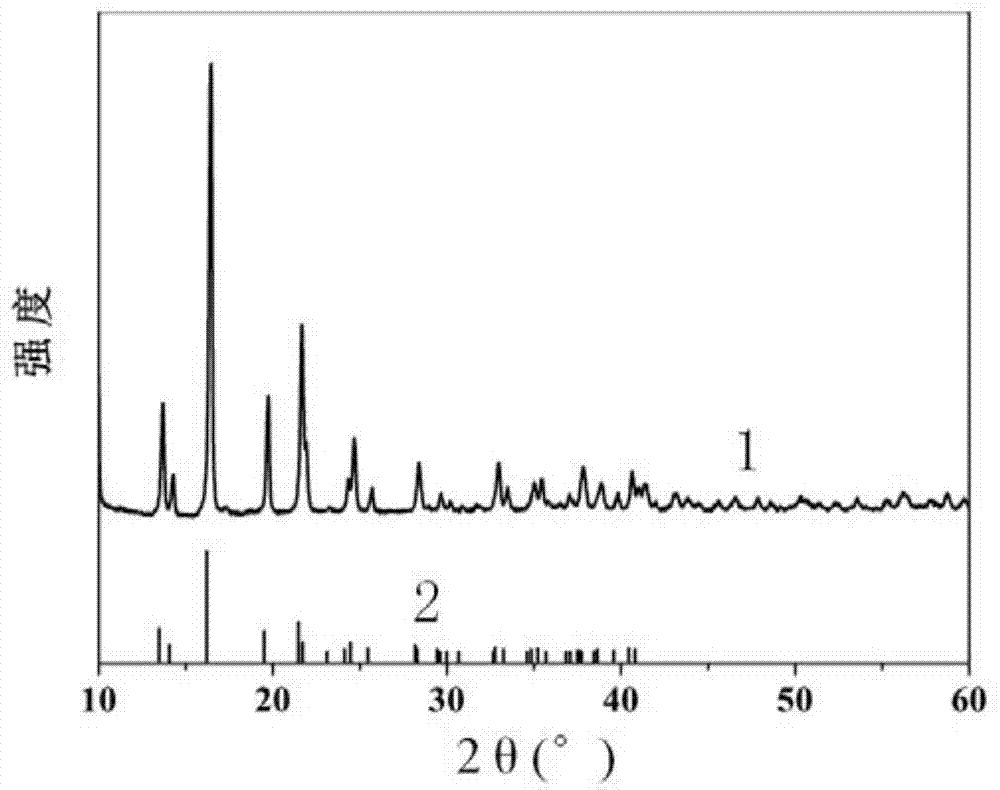

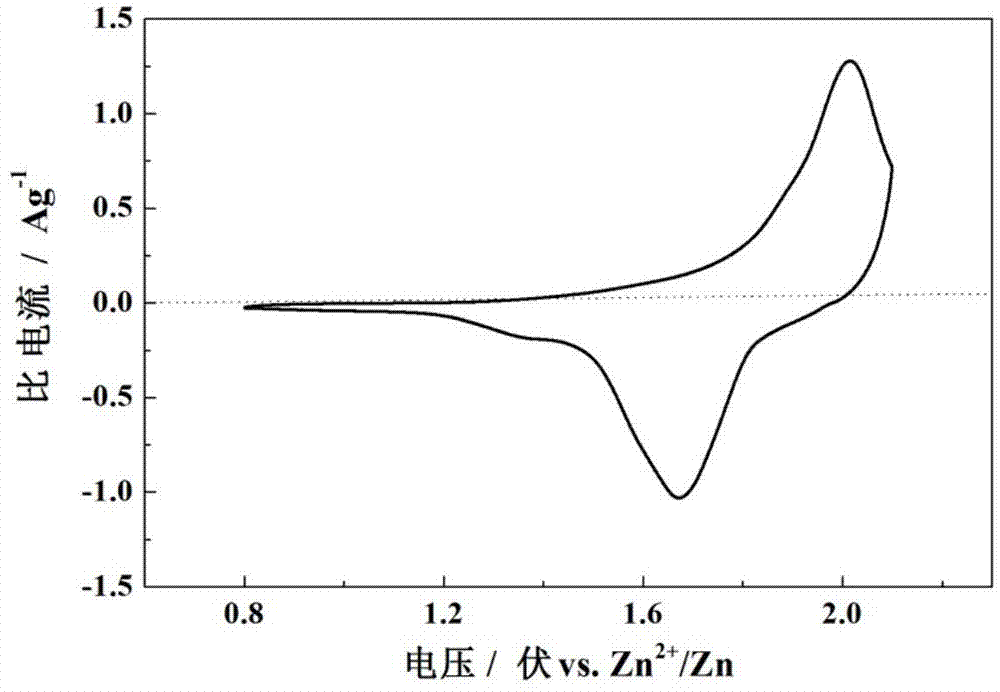

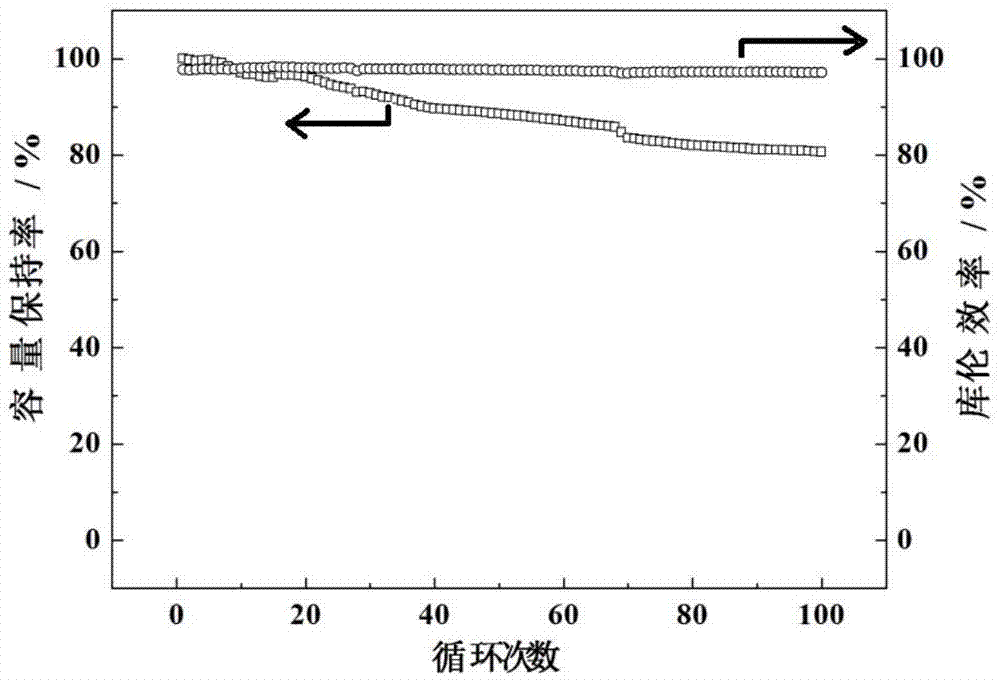

Zinc ion battery positive electrode active material, positive electrode material, zinc ion battery positive electrode, zinc ion battery and preparation method and application thereof

ActiveCN109671946AImprove cycle lifeHigh specific capacityCell electrodesFinal product manufactureZinc ionCrystal structure

The invention discloses a zinc ion battery positive electrode active material, a positive electrode material, a zinc ion battery positive electrode, a zinc ion battery and a preparation method and application thereof, and relates to the technical field of zinc ion batteries. The zinc ion battery positive electrode active material comprises niobium oxide or a composite material thereof. According to the invention, the niobium oxide or the composite material of the niobium oxide is applied to the positive electrode active material of the zinc ion battery. The niobium oxide or the niobium composite material has a rapid zinc ion transmission channel, so that the rapid intercalation and deintercalation of zinc ions can be realized. The prepared zinc ion battery has the advantages of long cyclelife, high specific capacity and low cost. The problems of limited lithium resource reserve and high cost of the existing lithium ion battery are solved. The problems of low capacity, poor stability of a positive electrode structure, slow intercalation dynamics and the like of the existing zinc ion battery positive electrode active material are solved.

Owner:SHENZHEN INST OF ADVANCED TECH

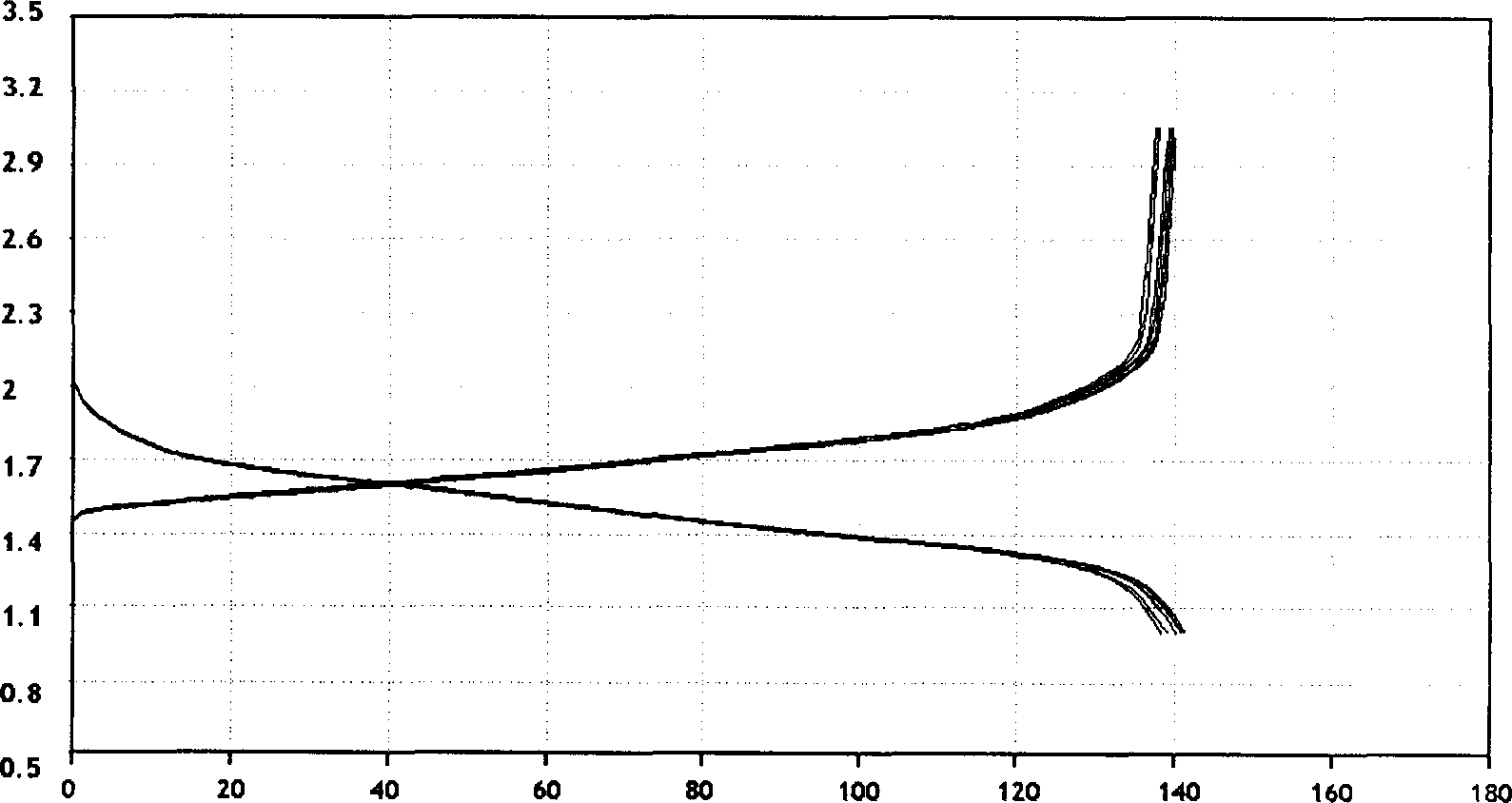

Electrochemical capacitor and preparing method of active mesocarbon microbeads

ActiveCN103515108AImprove power densityFast embeddingHybrid capacitor electrolytesHybrid capacitor electrodesHigh energyMicrosphere

The invention provides an electrochemical capacitor which comprises a positive electrode, a negative electrode, electrolyte and a diaphragm placed between the positive electrode and the negative electrode. The positive electrode is made of active mesocarbon microbeads. The negative electrode is made of lithium titanate or molybdenum disulfide or molybdenum trioxide or niobium oxide or titanium oxide. Meanwhile, the invention provides another electrochemical capacitor which comprises a positive electrode, a negative electrode, electrolyte and a diaphragm placed between the positive electrode and the negative electrode. The positive electrode is made of graphite or activated carbon. The negative electrode is made of active mesocarbon microbeads. The specific surface area of the active mesocarbon microbeads is 30m<2> / g-200m<2> / g. The invention further provides a preparing method of the active mesocarbon microbeads. The specific surface area of the obtained active mesocarbon microbeads is very low. The active mesocarbon microbeads with the low specific surface area are used in the electrochemical capacitor, so that the electrochemical capacitor has high energy density and high power density.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

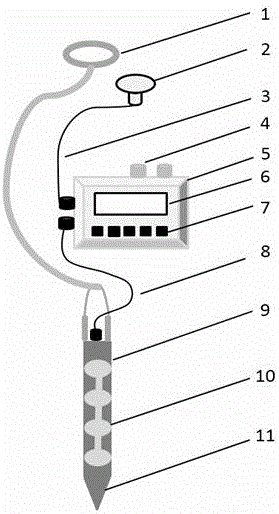

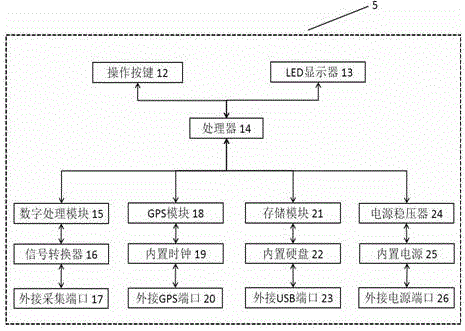

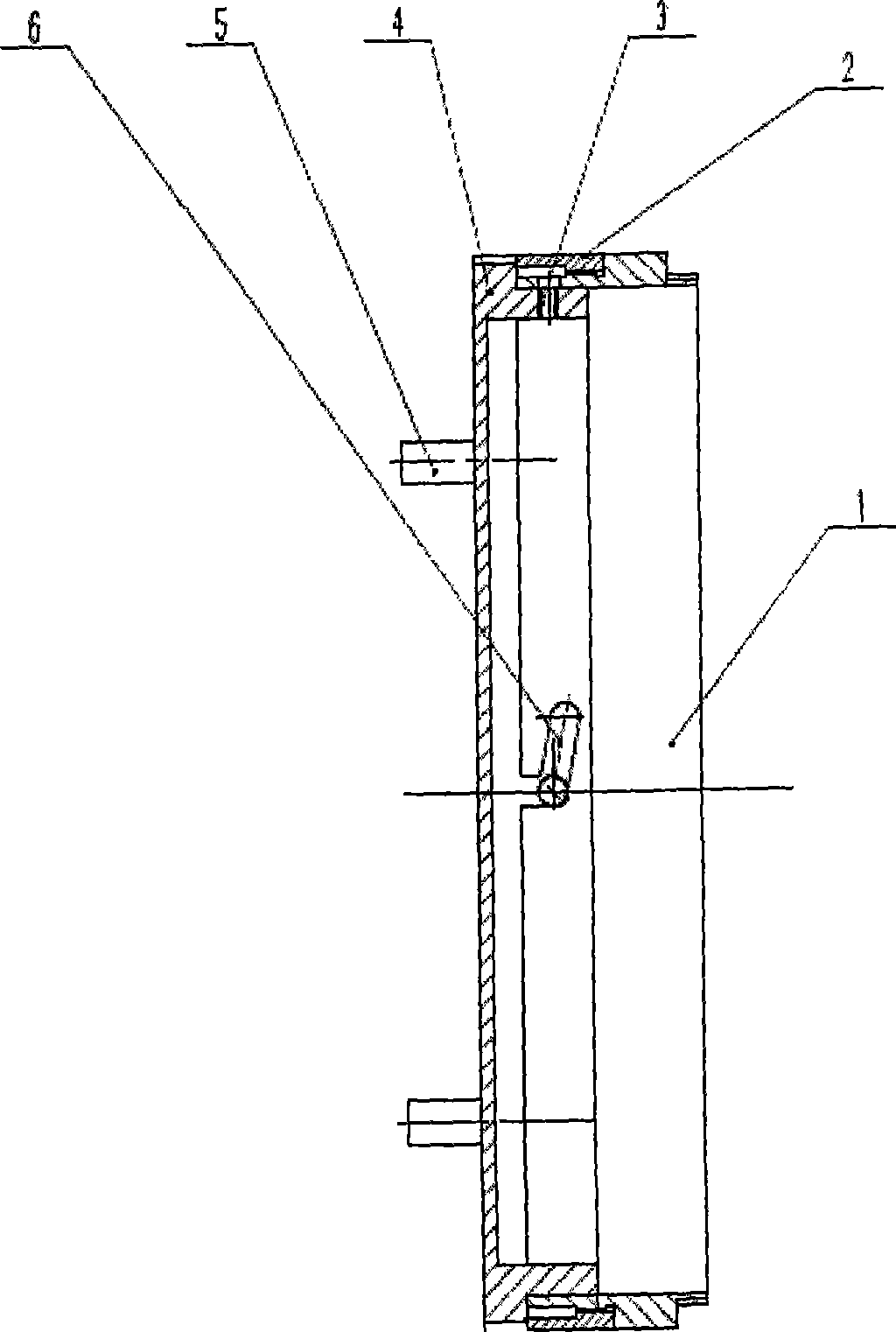

Ground shallow-embedded micro seismic monitoring node device

PendingCN106405633AEfficient deploymentLow costSeismic signal receiversUltrasound attenuationDynamic monitoring

The present invention provides a ground shallow-embedded micro seismic monitoring node device. The device comprises a node host, an external port, a collection detector, a collection protection device, a shallow-embedded rope and a GPS antenna; the node host is connected with the collection detector and the GPS antenna; the collection detector includes a series coil, a metal sheath and a metal drill bit; the metal sheath and the metal drill bit area wrapped around the series coil; and the shallow-embedded rope is fixed at the top end of the metal sheath. The ground shallow-embedded micro seismic monitoring node device is embedded below a low velocity layer to avoid earth surface noise disturbance and the complex near-surface severe absorption attenuation effect and realize the dynamic monitoring of the induced fractures in the unconventional oil and gas reservoir hydrofracture process so as to provide the reference base for the transformation of the reservoir fracture, and therefore the ground shallow-embedded micro seismic monitoring node device can be better applied to the unconventional oil and gas reservoir fine exploration and development.

Owner:CHINA PETROLEUM & CHEM CORP +1

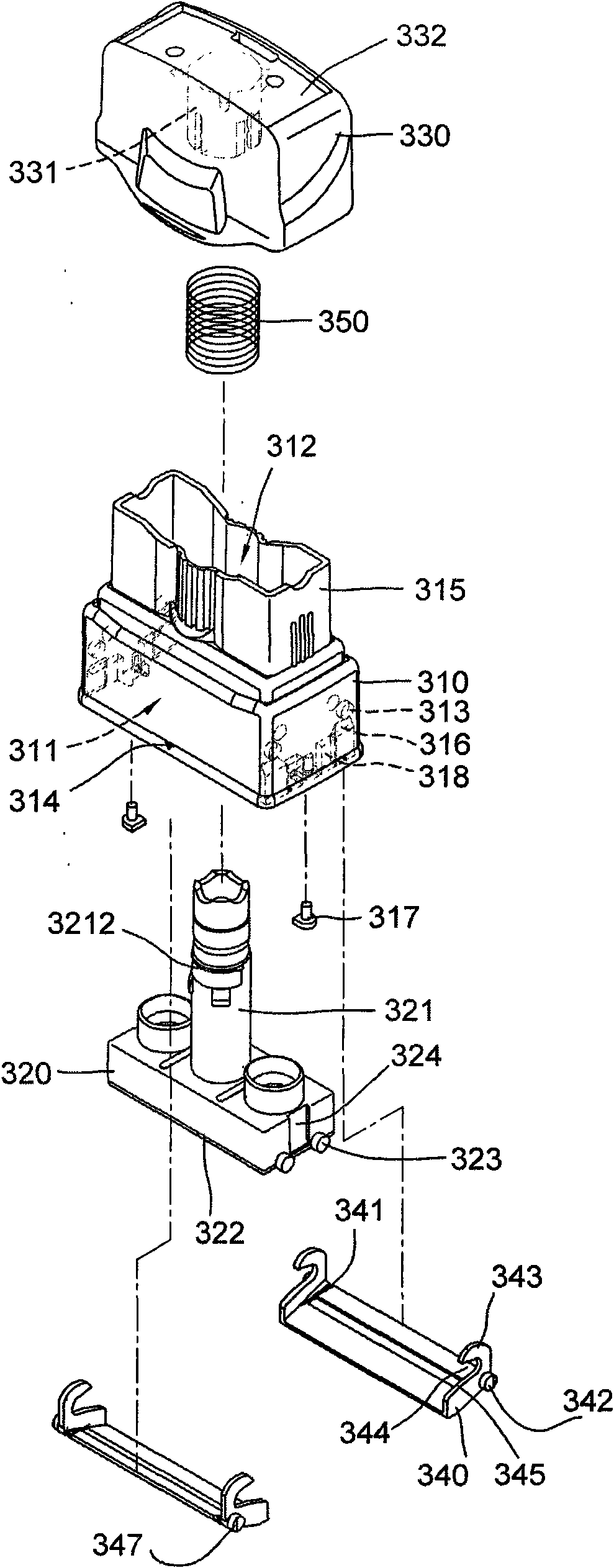

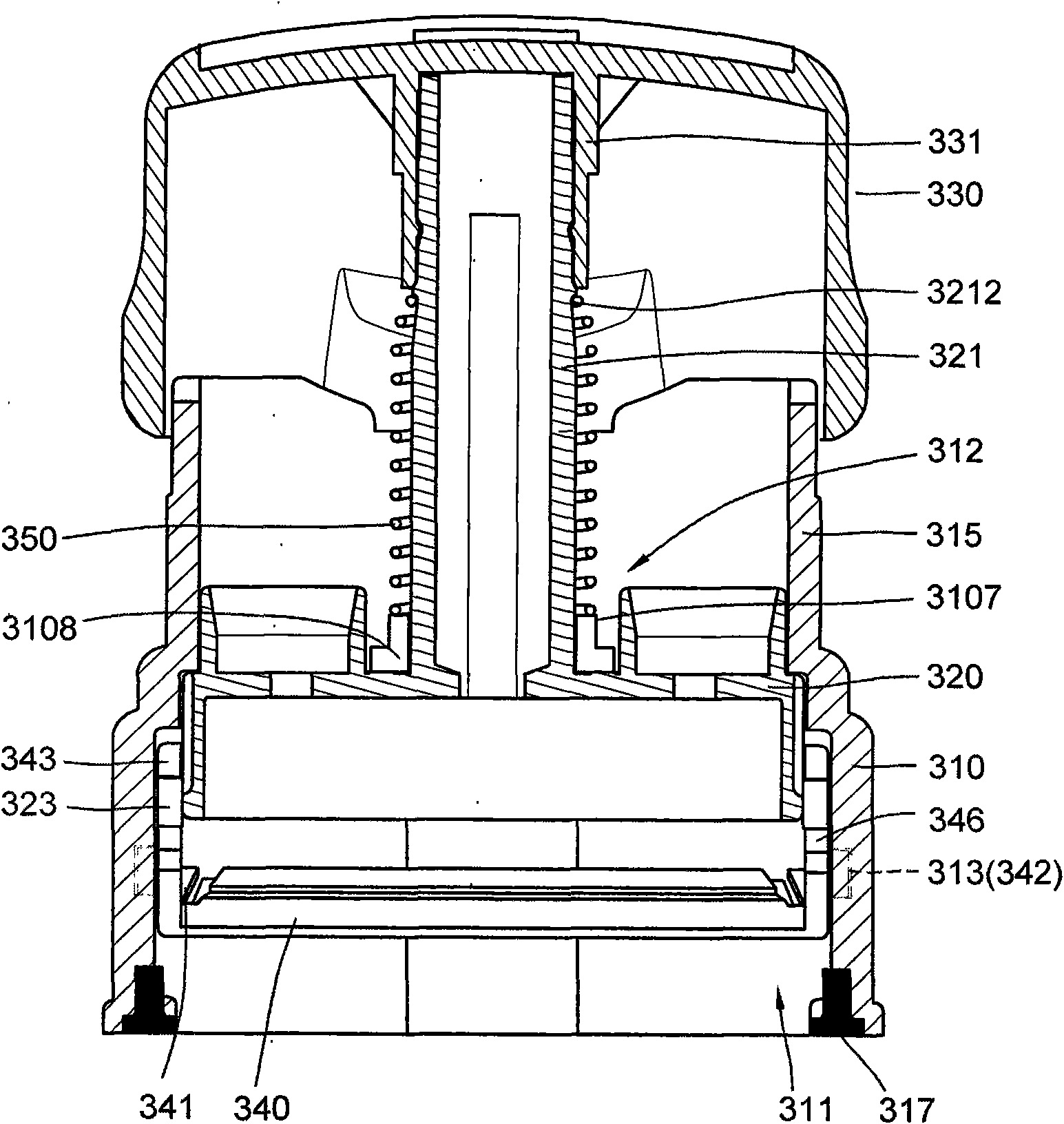

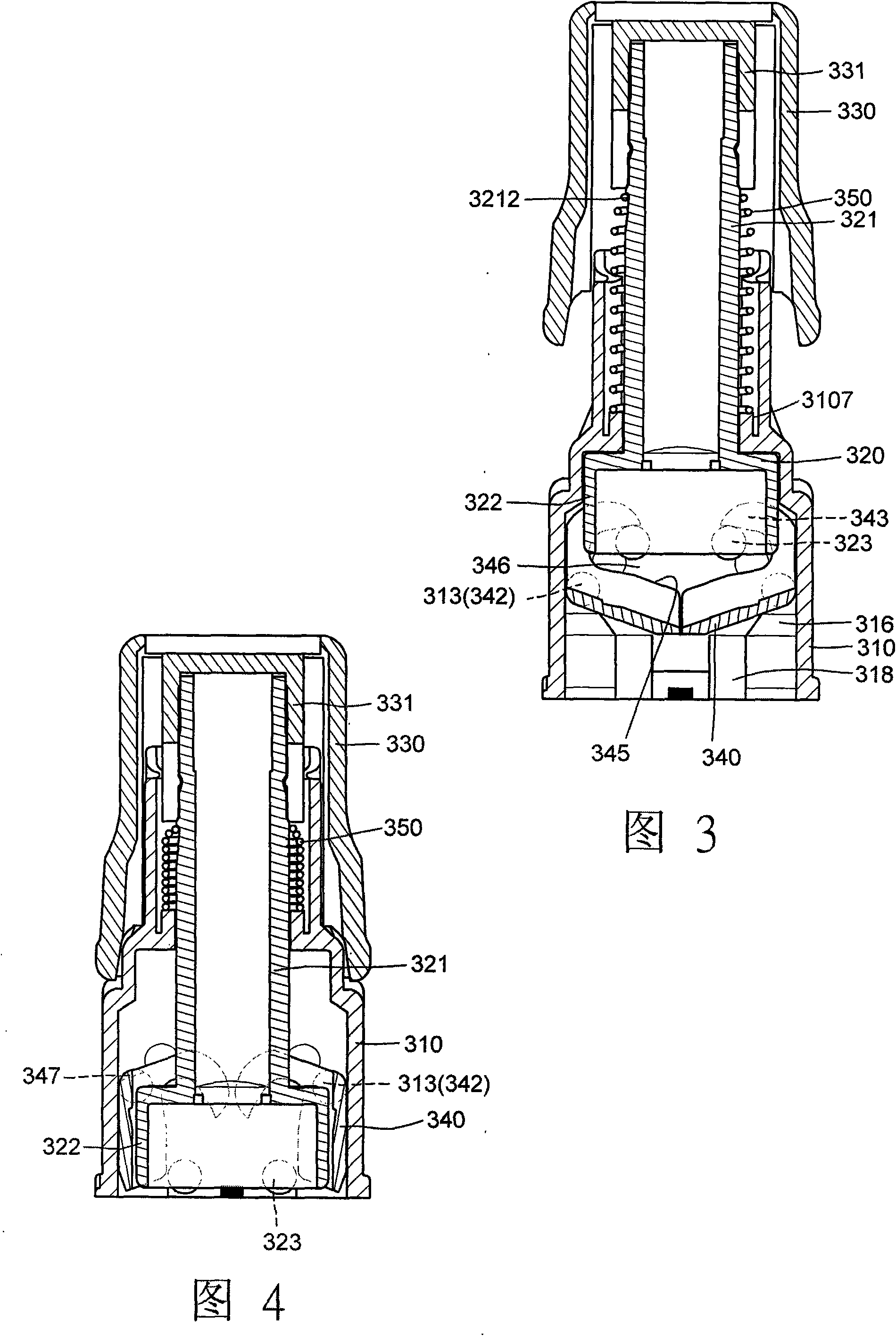

Stamp

ActiveCN101885275AFast embeddingPrinting area for expansionStampingEngineeringMechanical engineering

The invention provides a stamp, which mainly comprises a main body, a stamping body, a top cover and a seal cover, wherein the main body is provided with a through hole; the stamping body is provided with a column body and a stamping block, wherein the column body passes through the through hole of the main body, the stamping block is provided with a guide block and the column body is sleeved with a spring which is mutually propped against the main body; a combination body is arranged in the top cover and combined with the stamping body; two side ends of the seal cover are provided with a convex shaft respectively, and one side of the convex shaft is provided with a hooked plate; two side wall bodies of a main body accommodating space are provided with circular shaft holes; the seal cover is provided with a telescopic space, a gradually inward shrunk groove is formed in the seal cover, and the wall body of the main body is provided with an oblique sliding surface; therefore, the convex shafts at the side ends of the seal cover slide on the oblique sliding surface; and meanwhile, the telescopic space has the telescopic function, and the convex shafts at the side ends of the seal cover can be embedded into the circular shaft holes so that the seal cover is smoothly positioned in the accommodating space and can smoothly and uniformly turn over up and down along with the stamping body.

Owner:林长亿

Lithium supplementing material and preparation method thereof, negative electrode and lithium ion battery

PendingCN112993251AAdd channelHelp with transmissionNegative electrodesElectrode collector coatingMetallic lithiumLithium metal

The invention relates to a lithium supplementing material and a preparation method thereof, a negative electrode and a lithium ion battery, the lithium supplementing material comprises metal lithium particles and a conductive material, the conductive material comprises a built-in section embedded in the metal lithium particles and an exposed section located outside the metal lithium particles; and the electronic conductivity of the conductive material is greater than 100s / cm. The lithium supplementing material disclosed by the invention can realize electron conduction between the lithium metal particles and the negative electrode active material through the conductive material, increases an electron conduction channel, is beneficial to lithium ion transmission, realizes a rapid embedding process of lithium ions, and remarkably improves the lithium supplementing efficiency, so that formation of dead lithium is effectively inhibited, and potential safety hazards caused by the fact that dendritic crystals pierce a diaphragm are avoided.

Owner:BYD CO LTD

Fastening lens cover device

The invention discloses a cassette lens cap device which comprises a closing ring, an outer housing, an attachment clip, a lens cap and two handlebars; the closing ring is screwed onto a lens cone or a lens hood of an optical instrument by thread arranged at one end, and the other end of the closing ring is provided with two L-shaped grooves which mutually form the angle of 180 degrees; then, the attachment clip is screwed onto the lens cap by the thread in order to be convenient for the installation of the lens cap; the two handlebars are riveted on the lens cap; the outer side of the periphery of the closing ring and the attachment clip is provided with the outer housing, so that the cassette lens cap device is more beautiful; when in installation, the handlebars on the lens cap are firmly held by the two hands, the attachment clip on the lens cap is embedded into the groove of the closing ring, the lens cap is lightly turned, the attachment clip is screwed into the closing ring along a notch, and the lens cap is closely fixed on the closing ring; when the lens cap device is needed to be taken down, the handlebars on the lens cap are firmly held by the two hands, the lens cap is turned, the attachment clip is screwed out of the closing ring along the groove, and the lens cap is taken down; the device has simple operation and convenient use.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

Sealing structure and method for wall hole

InactiveCN109488036ASimple construction processImprove efficiencyBuilding repairsBuilding construction

The invention discloses a sealing structure and method for a wall hole. The sealing structure comprises a wall and a hole formed in the wall, and comprises a waterproof sealing plug, and the waterproof sealing plug is plugged into the wall hole from the outer side and / or the inner side of the wall. The waterproof sealing plug is in a circular truncated cone shape, the diameter of the top face of the waterproof sealing plug is smaller than the diameter of the wall hole, and the diameter of the bottom face of the waterproof sealing plug is larger than the diameter of the wall hole. When the sealing structure is installed, the top face of the waterproof sealing plug is inserted into the wall hole firstly, and is rapidly embedded into the wall through hammering, the technology is simple, and the efficiency is high. The waterproof sealing plug is formed by waterproof and elastic vinyl plastic, and has the good waterproof performance. According to the sealing structure and method for the wall hole, the technology is simple, the efficiency is high, the construction period is short, time of work high above the ground of constructors is shortened, hidden danger is reduced, the sealing effect is good, and leakage of an outer wall is effectively prevented.

Owner:玉田县长春建筑工程有限公司

Secondary battery

ActiveCN103972582AImprove Coulombic efficiencyNot prone to explosionCell electrodesSecondary cellsSpace groupIron cyanide

The invention provides a secondary battery. The secondary battery comprises a positive electrode, a negative electrode, and an isolating membrane and electrolyte which are arranged between the positive electrode and the negative electrode; the positive electrode comprises a divalent metal ion iron cyanide complex; the secondary battery adopts the divalent metal ion iron cyanide complex as an positive electrode active material; the divalent metal ion iron cyanide complex is of a rhombohedral structure, belongs to the R-3c space group, and uses (Fe(CN)6) as a structural unit so that a three-dimensional frame network with a special pore passage structure is formed. positive ions can be rapidly embedded into and released from pore passages in a three-dimensional frame, and the three-dimensional frame is stable during embedding and releasing of the positive ions; the secondary battery adopting the divalent metal ion iron cyanide complex as the positive electrode active material has the high coulombic efficiency and the long cycle life; the divalent metal ion iron cyanide complex has the low reaction activity and the prepared battery is difficult to explode.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

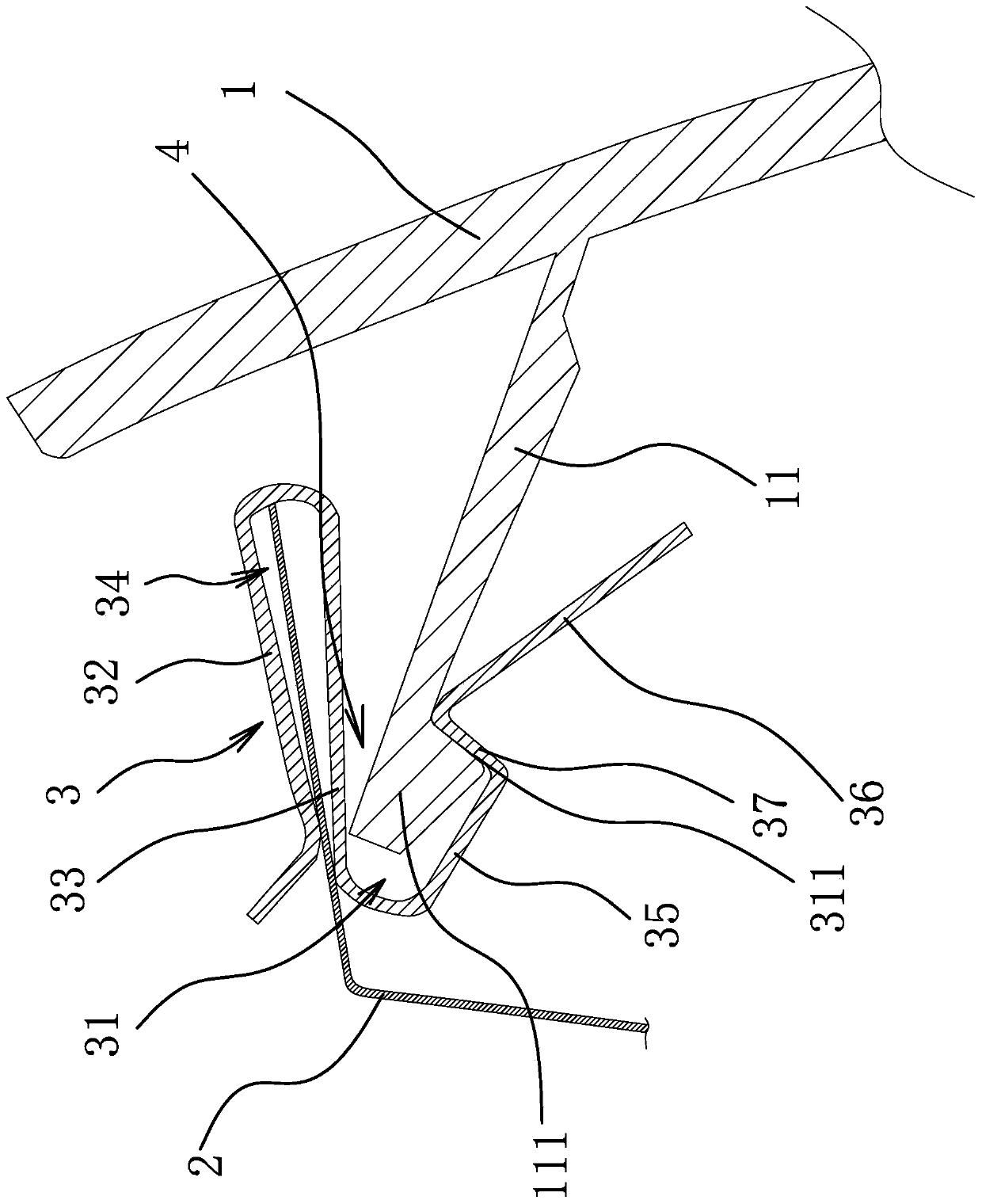

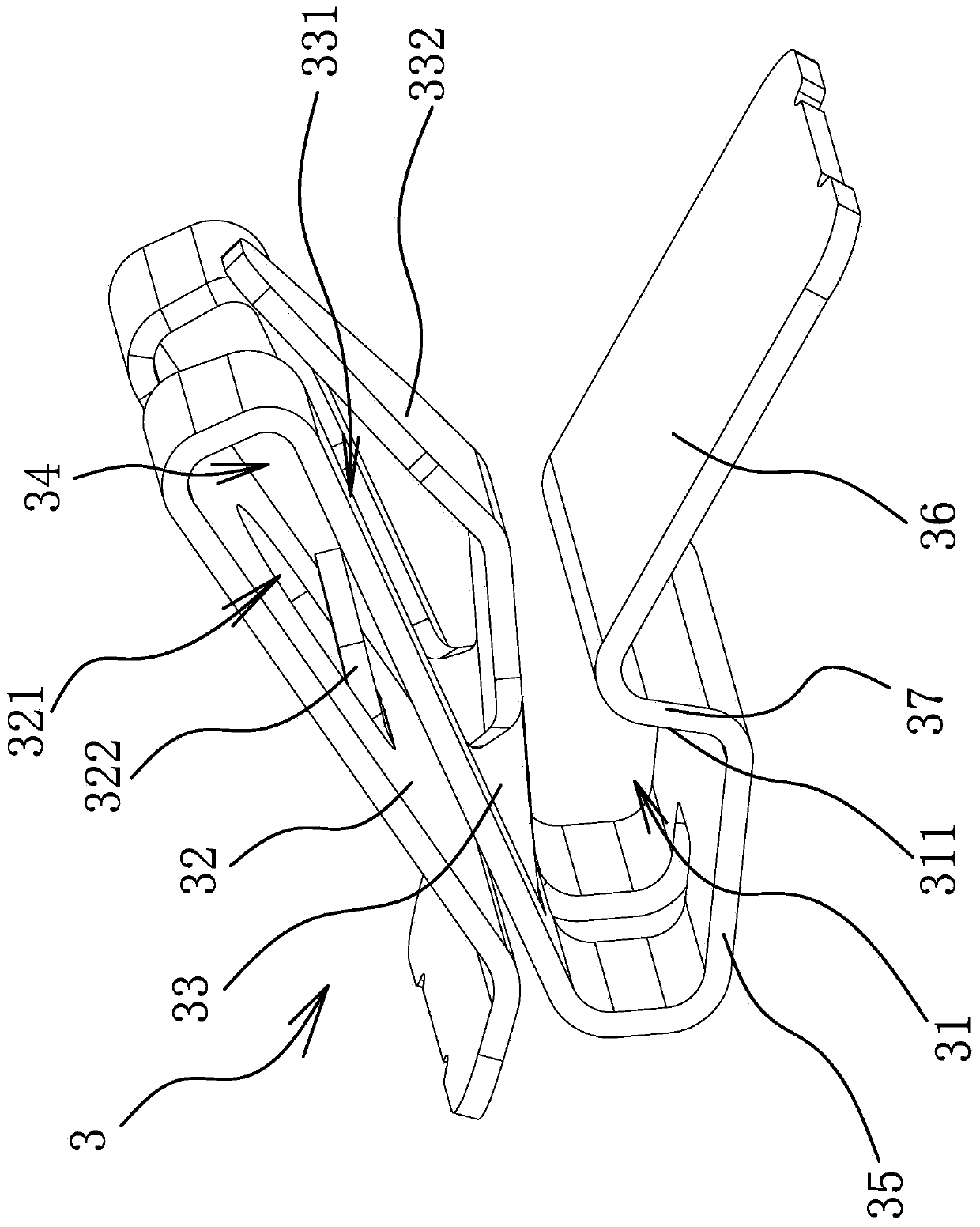

Paraffin embedding device for tissue positioning and embedding and embedding method thereof

PendingCN109781494AEfficient embeddingFast embeddingPreparing sample for investigationParaffin oilsMechanical engineering

The invention relates to a paraffin embedding device for tissue positioning and embedding. The paraffin embedding device comprises an embedding mold and a glue sealing base, wherein the glue sealing base comprises a bottom plate and side plates arranged on the two sides of the bottom plate; a groove penetrating through the bottom plate in the width direction is formed in the part, at one end of the sealing glue base, of the bottom plate; blades with cutting edges exposed out of the bottom plate are fixedly mounted on the inner walls of the two ends of the groove; the side plates at the two ends of the groove are provided with rotating shafts which are transversely arranged on the glue sealing base; elastic pressing sheets are further arranged on the side plate on one side of the upper parts of the rotating shafts; fixing seats are arranged on two side plates at the other end of the sealing glue base; the fixing seats on the two side plates are provided with through holes, supporting shafts transversely arranged on the glue sealing base penetrate through the through holes, the supporting shafts are provided with PET transparent adhesive tapes, the embedding mold is a box body with the top and the bottom hollowed out, the length of the embedding mold is smaller than that of the groove by 5-20 mm, and the width of the embedding mold is equal to that of the bottom plate. The problem that a knee joint cannot be embedded correctly due to the fact that paraffin is solidified too fast in the embedding process of a traditional mold is solved.

Owner:XIANGYA HOSPITAL CENT SOUTH UNIV

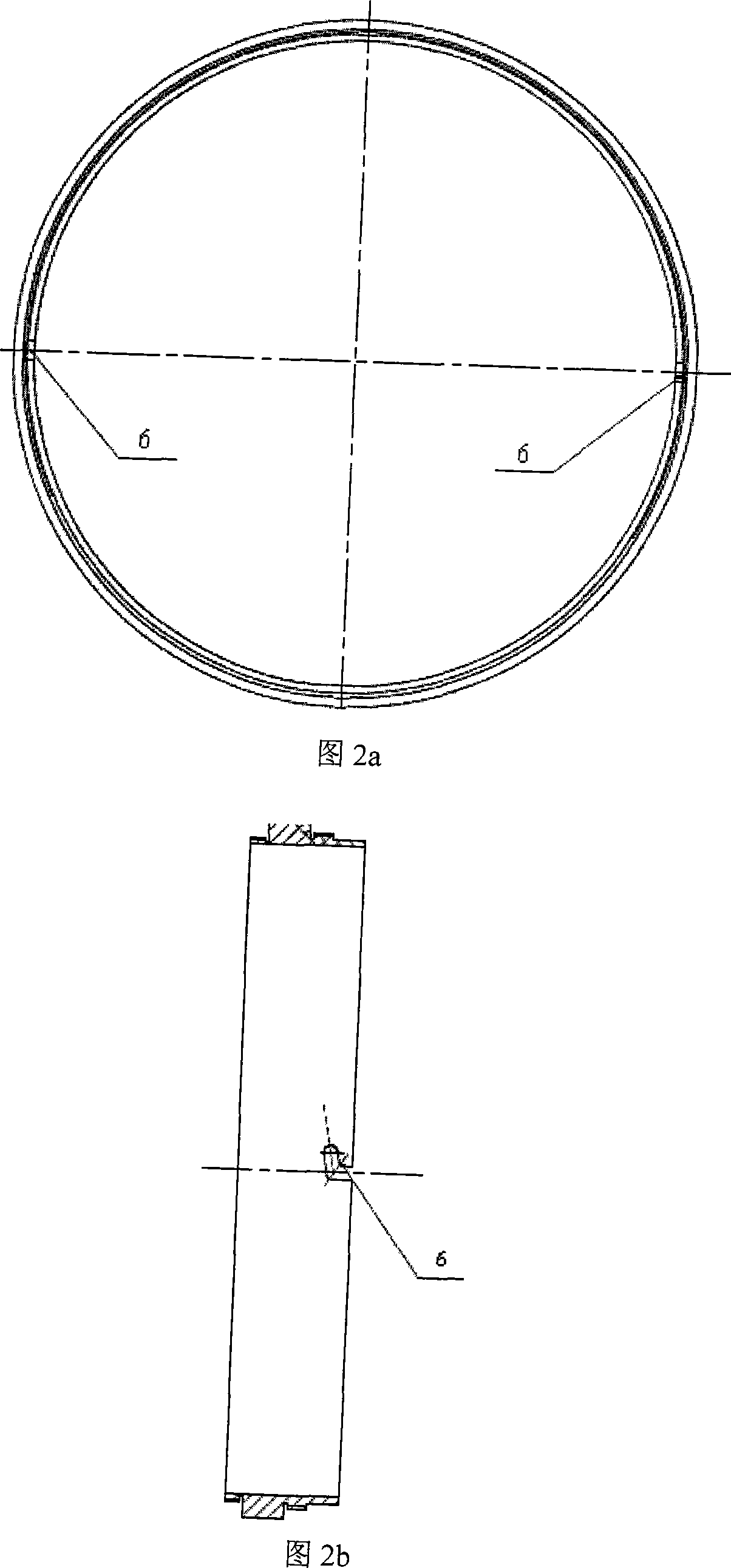

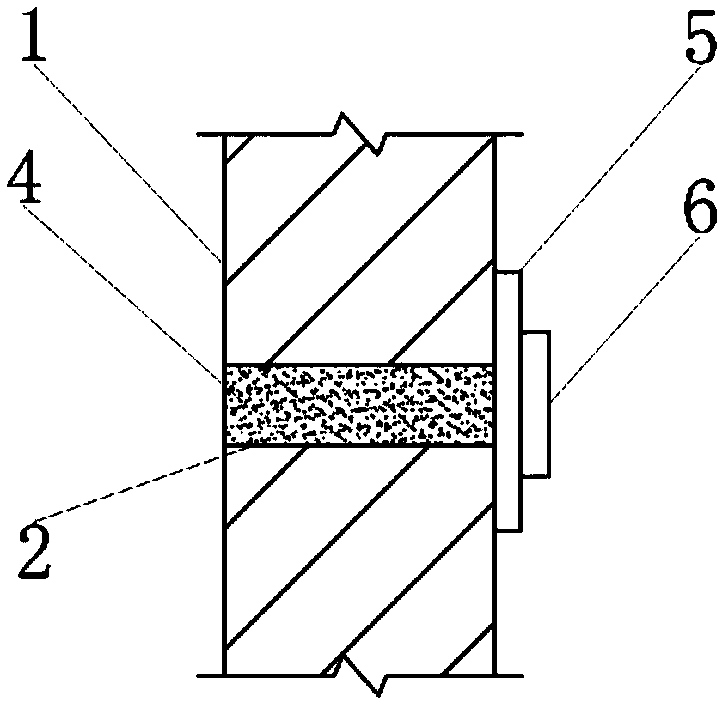

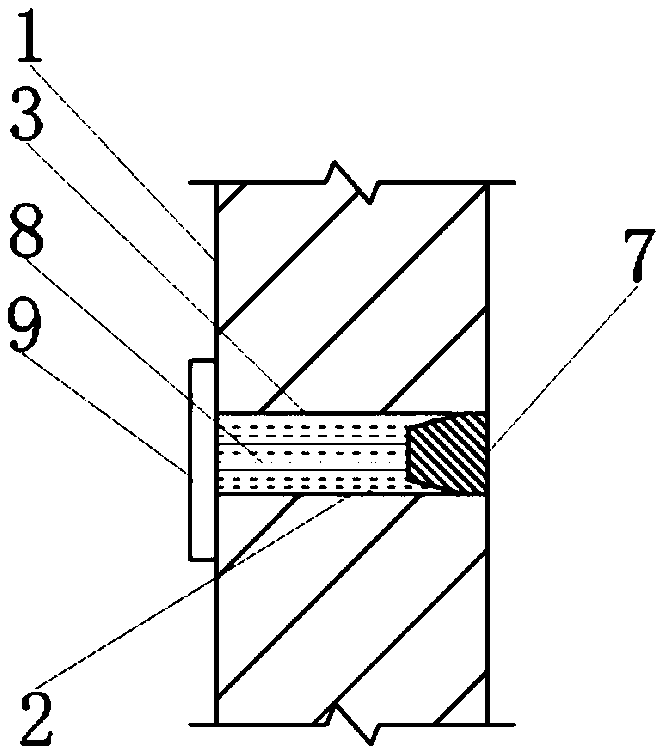

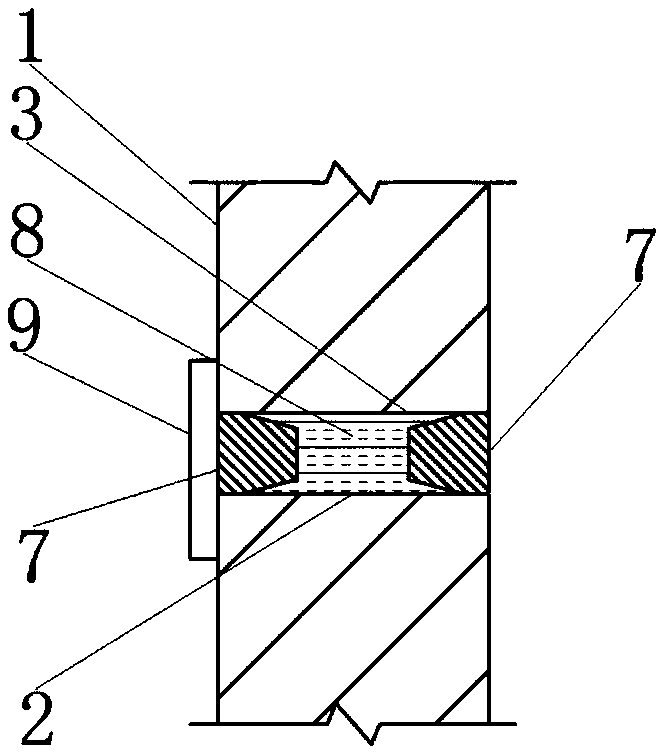

Circular tube welding seam detecting and positioning mechanism

PendingCN107900165AEasy weld inspectionImprove the efficiency of weld inspectionMetal-working feeding devicesMetal working apparatusElectric machineStructural engineering

The invention provides a circular tube welding seam detecting and positioning mechanism, and belongs to the technical field of machining equipment. The circular tube welding seam detecting and positioning mechanism solves the problem of low detecting efficiency of an existing welding seam detecting device. The circular tube welding seam detecting and positioning mechanism comprises a base, and a worktable and a positioning seat are arranged on the base; a feeding bin is provided with a bottom plate capable of conveying a workpiece, the positioning seat is provided with a limiting groove for allowing the workpiece to be placed, and the workpiece can rotate in the limiting groove; the base is provided with a rotating motor, a proximity switch and a clamping air cylinder, and the rotating motor is arranged on one side of the workpiece; one end of the rotating motor is provided with a rotating groove for allowing the end part of the workpiece to be embedded, and the clamping air cylinder can push the workpiece until one end of the workpiece is embedded in the rotating groove; and the feeding bin is provided with a sensor, when the approaching switch detects that the workpiece is located in the limiting groove, the rotating motor can be driven to drive the workpiece to rotate, and the sensor can conduct welding seam detecting on the workpiece. The circular tube welding seam detecting and positioning mechanism can improve the efficiency of workpiece welding seam detecting.

Owner:ZHEJIANG QIANJIANG ROBOT CO LTD

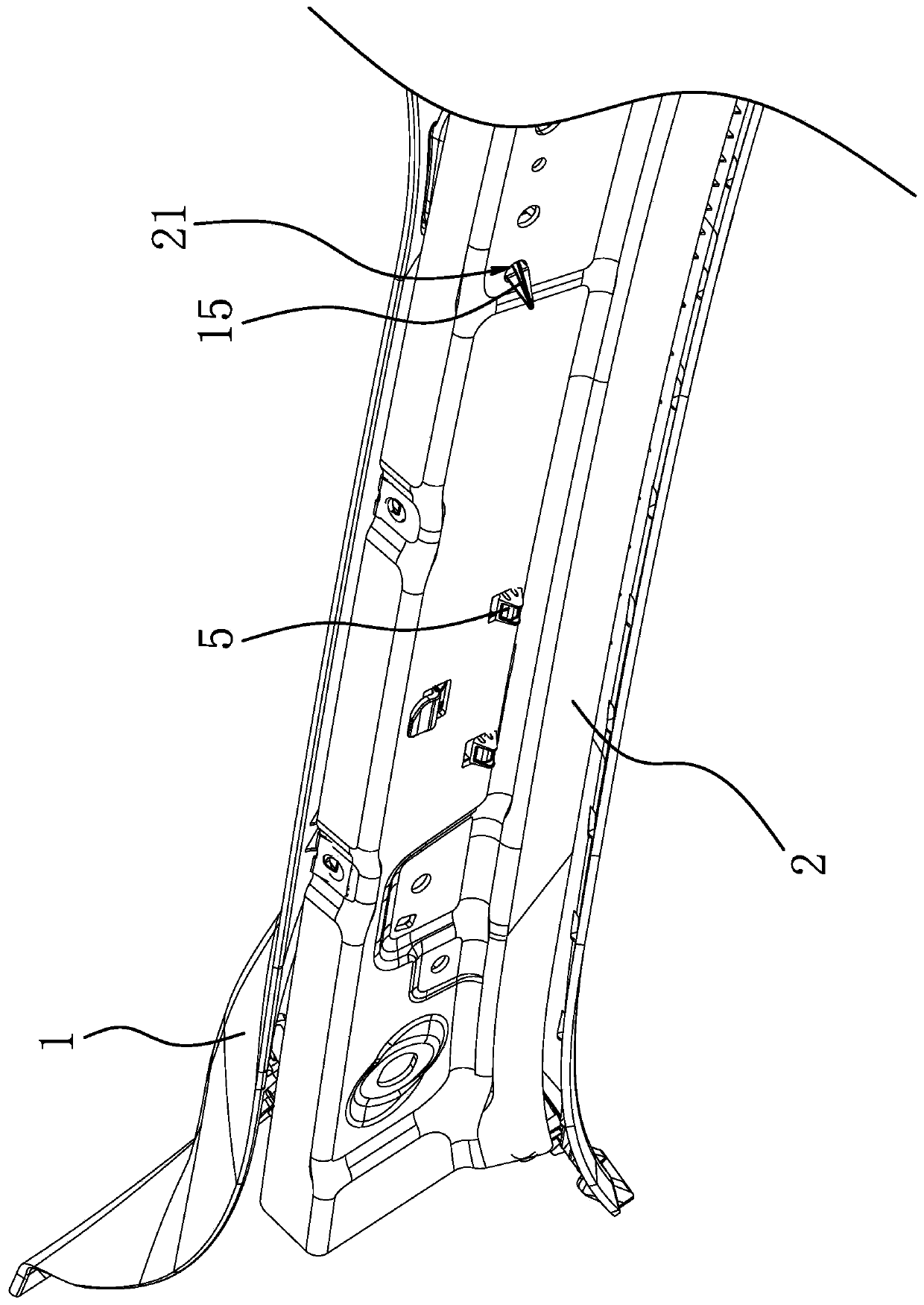

Mounting structure of A-pillar trim and automobile body metal plate

ActiveCN111301309AInhibit sheddingAvoid breakingSuperstructure subunitsSuperstructure connectionsStructural engineeringMechanical engineering

The invention provides a mounting structure of an A-pillar trim and an automobile body metal plate, and belongs to the technical field of automobiles. The problem that when an air curtain of an existing A-pillar trim is exploded, the A-pillar trim is prone to falling off or deforming is solved. The mounting structure of the A-pillar trim and the automobile body metal plate comprises a connecting assembly capable of positioning the A-pillar trim on the automobile body metal plate, the mounting structure comprises a buckle connected with the automobile body metal plate and a limiting block arranged on one side of the A-pillar trim, a clamping groove is formed in the buckle, the limiting block can be embedded into the clamping groove and is connected with the buckle in a clamped mode, a gap allowing the limiting block to move is formed between the limiting block and the groove wall of the clamping groove, and when the A-pillar trim panel moves towards the automobile body metal plate afterbeing not positioned with the automobile body metal plate, the A-pillar trim panel can drive the limiting block to move towards the gap. The mounting structure of the A-pillar trim and the automobilebody metal plate is small in required space, and the stability of connection between the A-pillar trim and the automobile body metal plate can be improved.

Owner:GEELY AUTOMOBILE INST NINGBO CO LTD +1

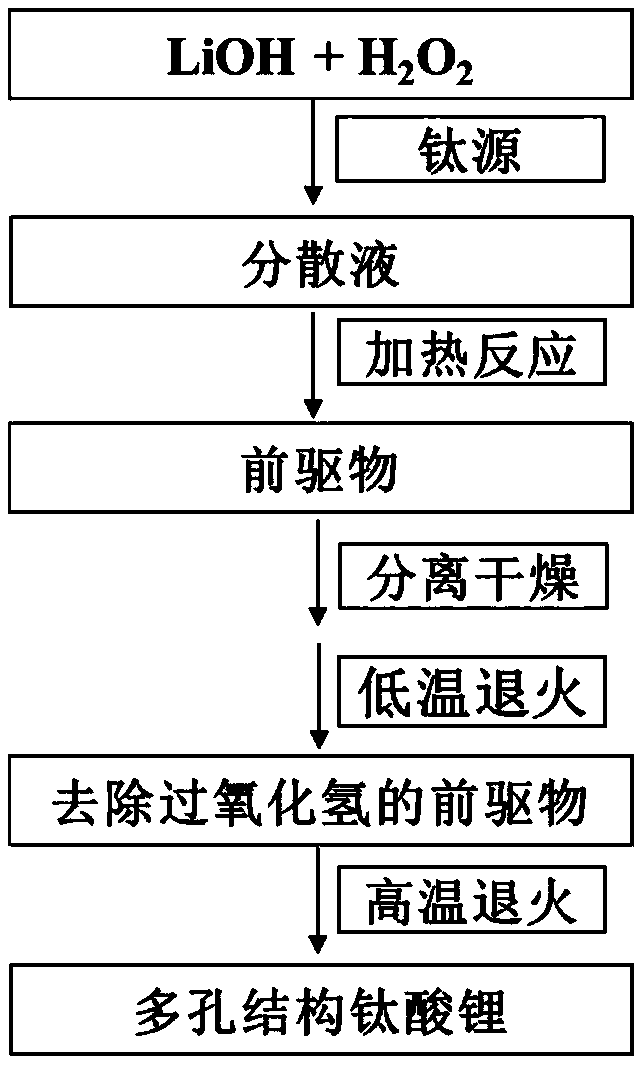

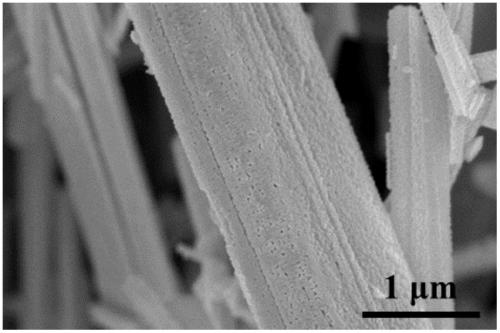

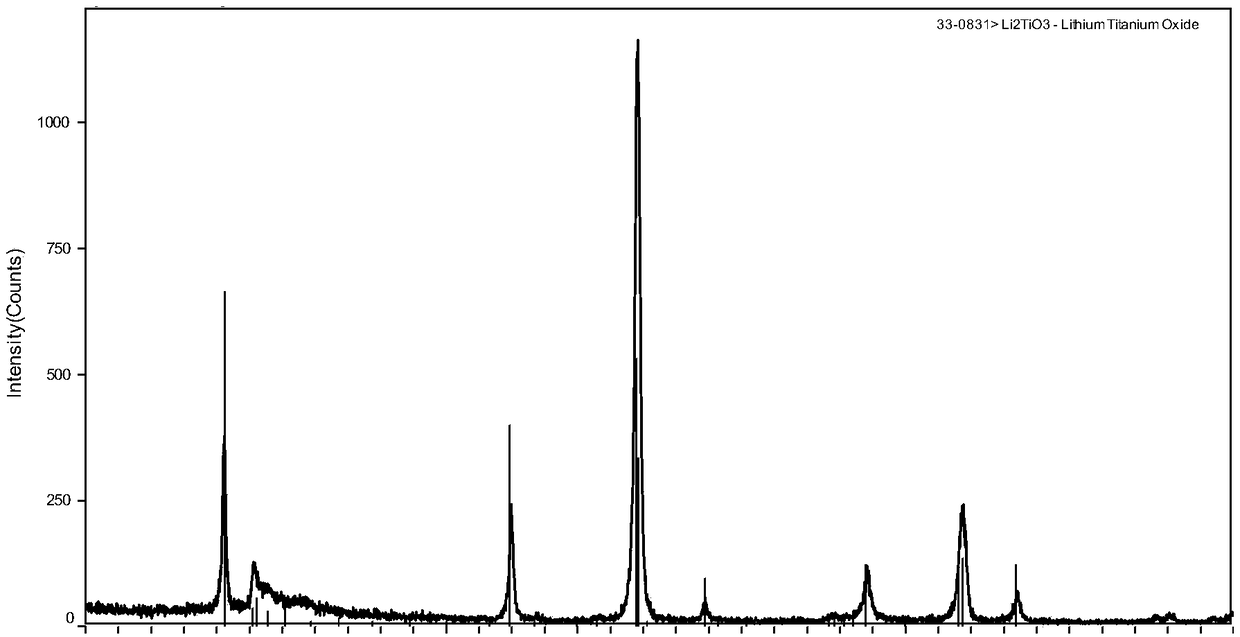

Lithium titanate of porous structure as well as preparation method and application thereof

ActiveCN109319829AAdjustable percentageCrystal phase adjustableAlkali titanatesCell electrodesLithium hydroxideAqueous solution

The invention provides lithium titanate of a porous structure as well as a preparation method and application thereof. The preparation method comprises the following steps of S1, dispersing a titaniumsource into a hydrogen peroxide water solution containing lithium hydroxide to obtain a dispersion solution; S2, performing heating reaction on the dispersion solution obtained in the S1 to obtain precursors; S3, separating and drying the precursors obtained in the S2; S4, performing low-temperature annealing treatment on the dried precursors; S5, performing high-temperature annealing treatment on the precursors subjected to low-temperature annealing treatment in S4 to obtain the lithium titanate of the porous structure. The lithium titanate of a linear porous structure, a linear and regularparticles existence porous structure and a regular particle porous structure can be prepared by the method, and these structures cannot be realized by other methods.

Owner:PETROCHINA CO LTD

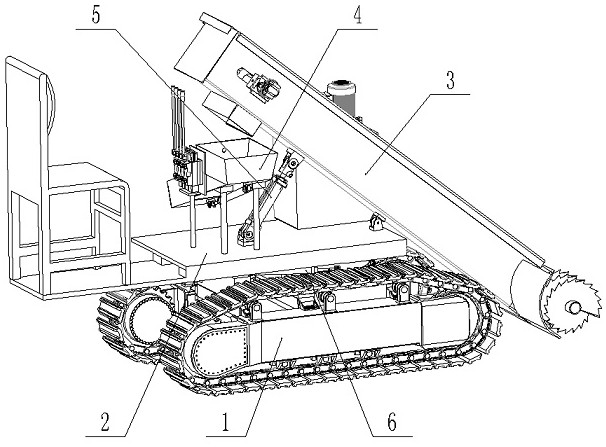

Swing type aggregate conveyor

InactiveCN112645077ARealize clean reprintImprove work efficiencyConveyorsEarth drilling and miningAutomotive engineeringSprocket

The invention discloses a swing type aggregate conveyor, and relates to cleaning and conveying equipment for coal dust accumulated in a coal mine roadway. The swing type aggregate conveyor comprises a crawler belt walking part, a rotary rack, a swing hydraulic cylinder, an aggregate transfer part, an inclination adjusting hydraulic cylinder and a discharging part, wherein, the rotary rack is composed of a rotary seat, a front-end hinge lug seat, a rear-end hinge lug seat, a swing hinge lug seat, a supporting column, an oil tank and a control console; the rotary seat of the rotary rack is hinged and supported on a rotary base of the crawler belt walking part; the aggregate transfer part is composed of a left spiral blade shaft, a right spiral blade shaft, a coupler, a driven chain wheel shaft, a scraper chain, a scraper, a left supporting seat, a right supporting seat, a conveying groove, a driving chain wheel assembly and a tensioning device; and the discharging part is composed of a feeding port, a discharging groove, a telescopic groove and a telescopic hydraulic cylinder. The equipment can be actively pushed to take materials, the aggregate transfer part can swing along with the rotary rack, coal dust in front of and on the front side of the aggregate transfer part can be conveniently and quickly conveyed into the scraper conveyor or a mine car, the number of coal dust cleaning personnel is reduced, and the coal dust cleaning work efficiency is improved.

Owner:HENAN POLYTECHNIC UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com