Negative electrode material used for lithium ion battery, preparation method, secondary and usage

A lithium-ion battery and negative electrode material technology, applied in the field of materials, can solve the problems of complex process and high cost, achieve excellent rate performance, and achieve the effect of charging and discharging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

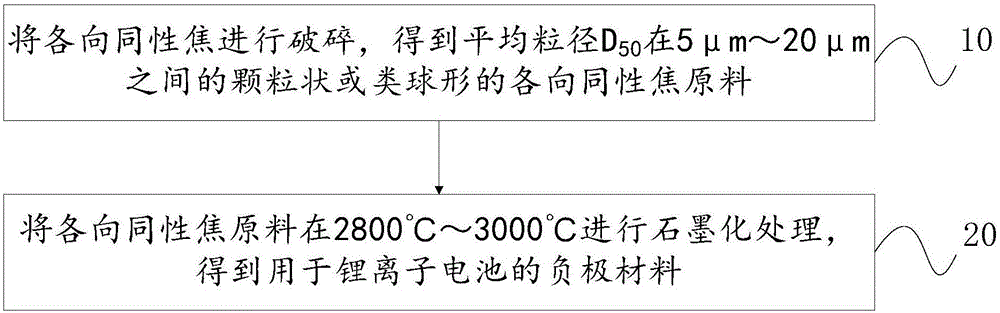

[0032] The preparation method of the above-mentioned negative electrode material will be described in detail below.

[0033] The present invention provides a kind of preparation method for the battery negative electrode material of lithium ion, and described preparation method comprises:

[0034] Step 10, crushing the isotropic coke to obtain the average particle size D 50 Granular or spherical isotropic coke raw materials between 5 μm and 20 μm;

[0035] Among them, the isotropic coke may include one or more of pitch coke, petroleum coke, and metallurgical coke.

[0036] Step 20, subjecting the isotropic coke raw material to graphitization treatment at 2800°C to 3000°C to obtain the negative electrode material for lithium-ion batteries;

[0037] Among them, the average particle size D of the prepared negative electrode material 50 Between 5 μm and 20 μm.

[0038] In order to better understand the technical solution provided by the present invention, the following specific...

Embodiment 1

[0040] The preparation method of the negative electrode material includes the following steps (1)-(2).

[0041] (1) Crushing the isotropic coke of petroleum coke to obtain the average particle size D 50 The raw materials between 7μm and 8μm are mainly granular or spherical in shape;

[0042] (2) The raw materials are subjected to graphitization treatment at 3000° C. to obtain negative electrode materials for lithium ion batteries.

[0043] The negative electrode material obtained in this embodiment is tested by a Malvern MS2000 laser particle size analyzer, and its average particle diameter D 50 is 7.1 μm.

[0044] The negative electrode material obtained in this embodiment was tested by an X-ray diffraction analyzer, and the degree of graphitization was 88.2%.

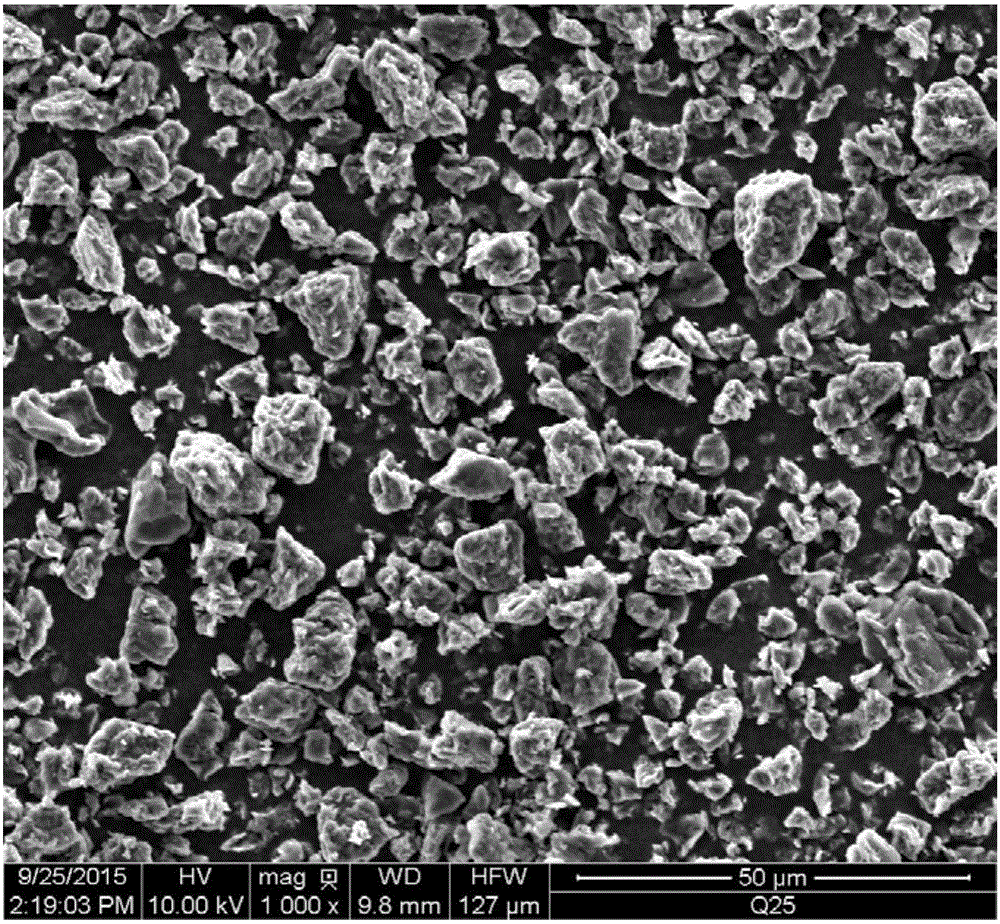

[0045] The topography of the negative electrode material obtained in this embodiment is shown in figure 2 .

[0046]The prepared negative electrode material for lithium-ion batteries, conductive agent and binder...

Embodiment 2

[0048] The preparation method of the negative electrode material includes the following steps (1)-(2).

[0049] (1) Crushing the isotropic coke of petroleum coke to obtain the average particle size D 50 The raw materials between 5 μm and 6 μm are mainly granular or spherical in shape;

[0050] (2) The raw material is subjected to graphitization treatment at 2800° C. to obtain the negative electrode material for the lithium ion battery.

[0051] The negative electrode material obtained in this embodiment is tested by a Malvern MS2000 laser particle size analyzer, and its average particle diameter D 50 is 5.6 μm.

[0052] The negative electrode material obtained in this embodiment was tested by an X-ray diffraction analyzer, and the degree of graphitization was 82.2%.

[0053] The method for making the battery is the same as in Example 1.

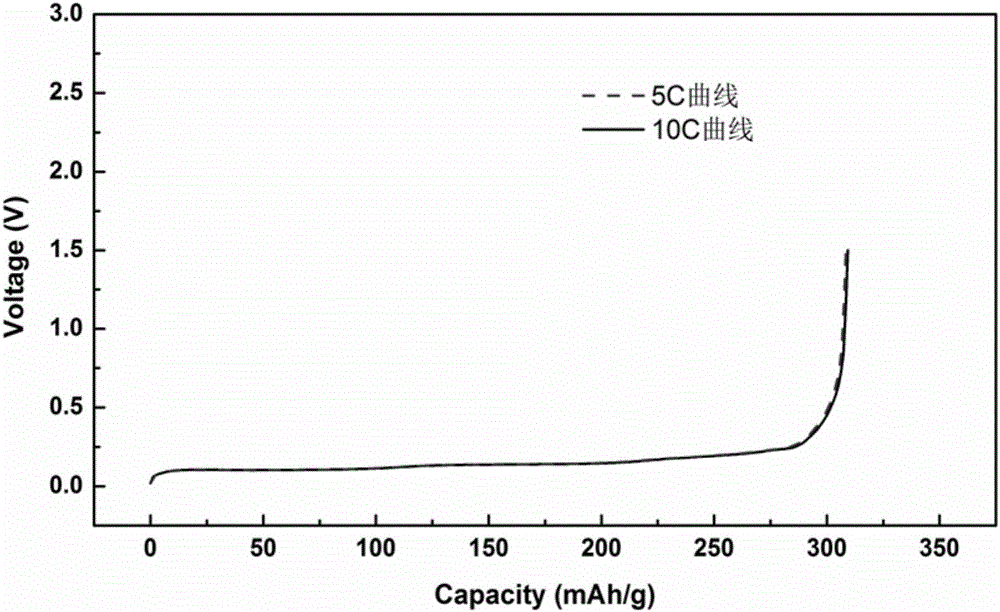

[0054] The battery made of the negative electrode material obtained in this example was tested under the charge and discharge current de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com