Electrochemical capacitor and preparing method of active mesocarbon microbeads

A technology of mesophase carbon microspheres and capacitors, applied in the field of electrochemistry, can solve the problems of high cost and limited content of capacitors, and achieve the effects of high power density, high energy density and low specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The embodiment of the present invention discloses a preparation method of low specific surface area active mesophase carbon microspheres, comprising the following steps:

[0037] Heating and cooling the mesophase carbon microspheres to obtain heat-treated mesophase carbon microspheres;

[0038] The heat-treated mesophase carbon microspheres are mixed with the basic compound, heated and cooled to obtain activated mesophase carbon microspheres.

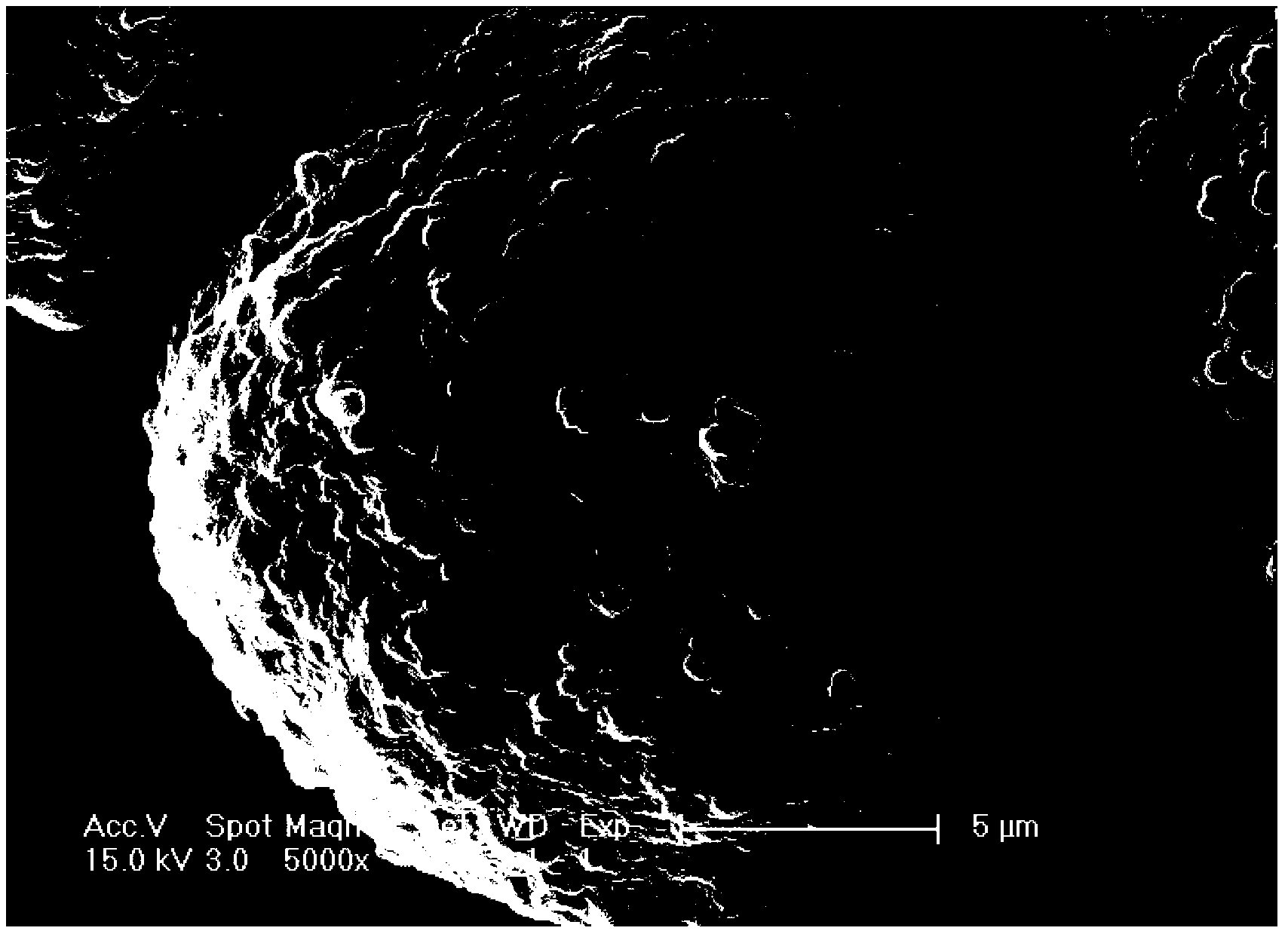

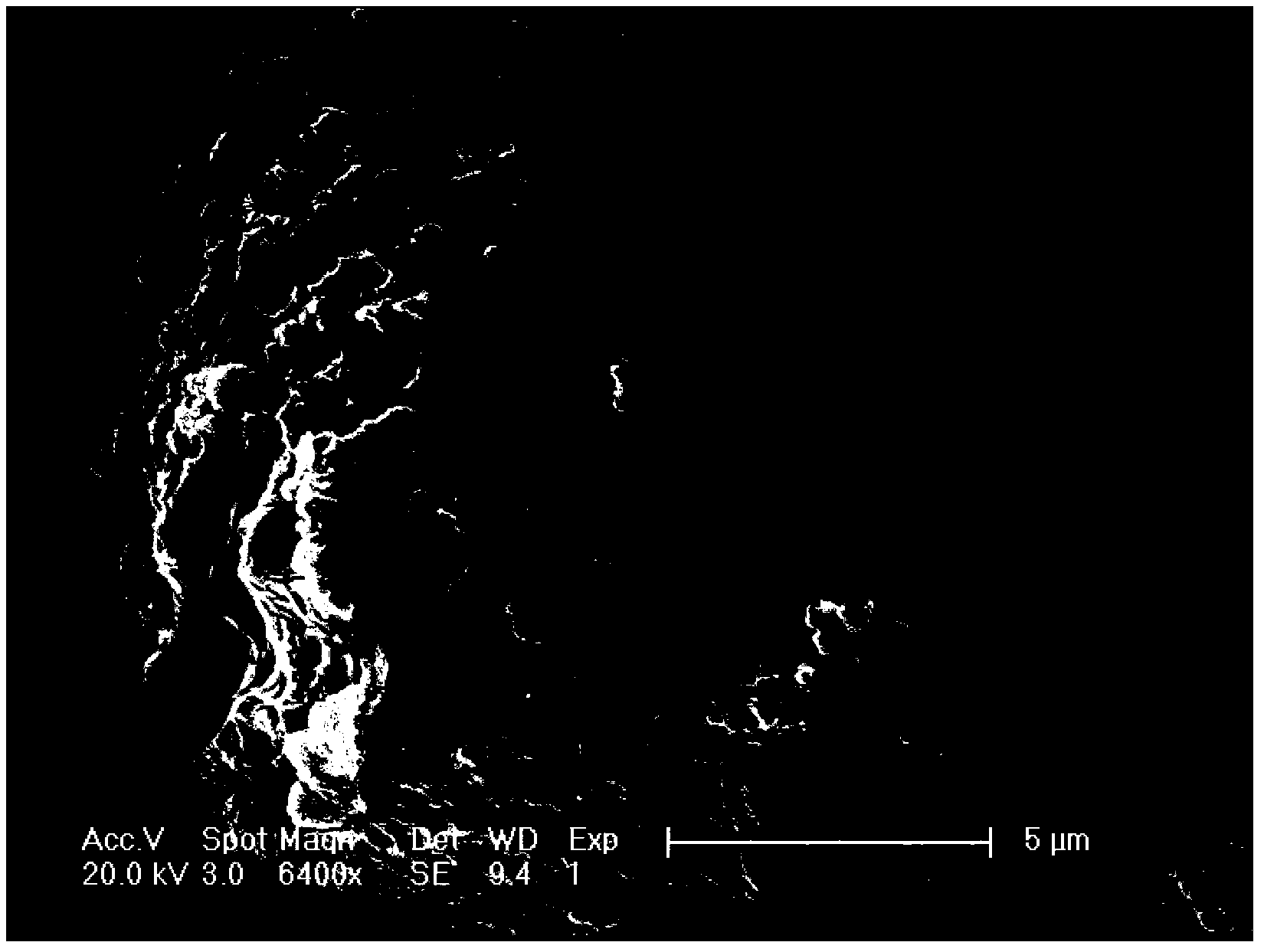

[0039]In the prior art, the preparation of activated mesocarbon microspheres is to directly activate the mesocarbon microspheres with potassium hydroxide, but the specific surface area of the activated mesocarbon microspheres obtained by this method is relatively high, generally 3000m 2 / g~5000m 2 / g. Therefore the present invention provides a kind of preparation method of low specific surface area active mesophase carbon microspheres, first mesophase carbon microspheres are pretreated, the pores inside the mesophase carbon m...

Embodiment 1

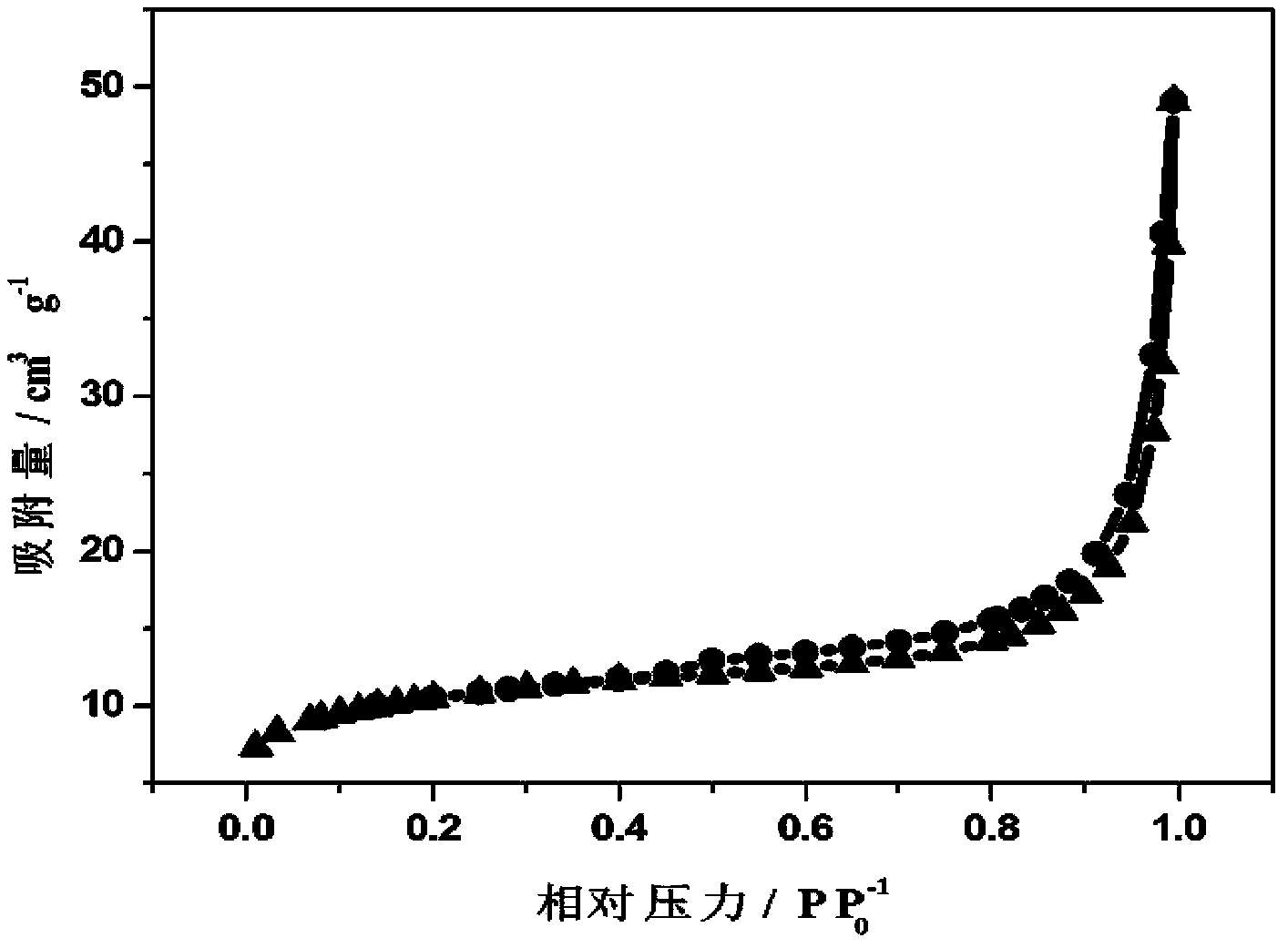

[0055]Put 4g of mesophase carbon microspheres in a porcelain boat and put them into a tube furnace. Under the protection of nitrogen, heat pretreatment at 500°C, 700°C, 900°C, and 1100°C for 6 hours, then cool to room temperature. The mesophase carbon microspheres heat-treated at 500°C are numbered M5, the mesophase carbon microspheres heat-treated at 700°C are numbered M7, the mesophase carbon microspheres heat-treated at 900°C are numbered M9, and the mesophase carbon microspheres heat-treated at 1100°C are numbered M9. The number of mesophase carbon microspheres is M11. Mix 2g of M5, M7, M9, and M11 with 8g of potassium hydroxide evenly, and then heat the mixture to 800°C for 2 hours under the protection of nitrogen, cool to room temperature, and wash with distilled water several times to remove residual alkali , until the pH value is neutral, and finally dried at 50-100°C to obtain activated mesophase carbon microspheres. The number of activated mesophase carbon microsphe...

Embodiment 2

[0060] Mix active mesophase carbon microspheres, polyvinylidene fluoride and acetylene black at a mass ratio of 8:1:1, add N-methylpyrrolidone dropwise to make a slurry, and use an automatic film applicator to evenly coat the current collector foil Aluminum, then baked at 80°C for 12 hours, and finally punched it into a disc electrode with a diameter of 1.4cm by a current collector punching machine for future use. The electrode sheet and separator were baked at 110°C for 6 hours in a vacuum state, and then moved into a glove box filled with argon to assemble a capacitor.

[0061] With M11-8 as the positive electrode, lithium iron phosphate, molybdenum trioxide, molybdenum disulfide and niobium oxide as the negative electrode respectively, two layers of glass fiber as the diaphragm, and 1M lithium hexafluorophosphate organic solvent as the electrolyte, assemble a button battery and connect it to the LAND series battery The test system performs charge and discharge tests. Figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com