Silicon-hard carbon composite material and preparation method thereof

A composite material and hard carbon technology, applied in structural parts, electrical components, battery electrodes, etc., can solve the problems of no improvement in safety performance, poor cycle performance, and low specific capacity, so as to facilitate liquid absorption and retention, and increase the magnification Performance, the effect of improving the gram capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

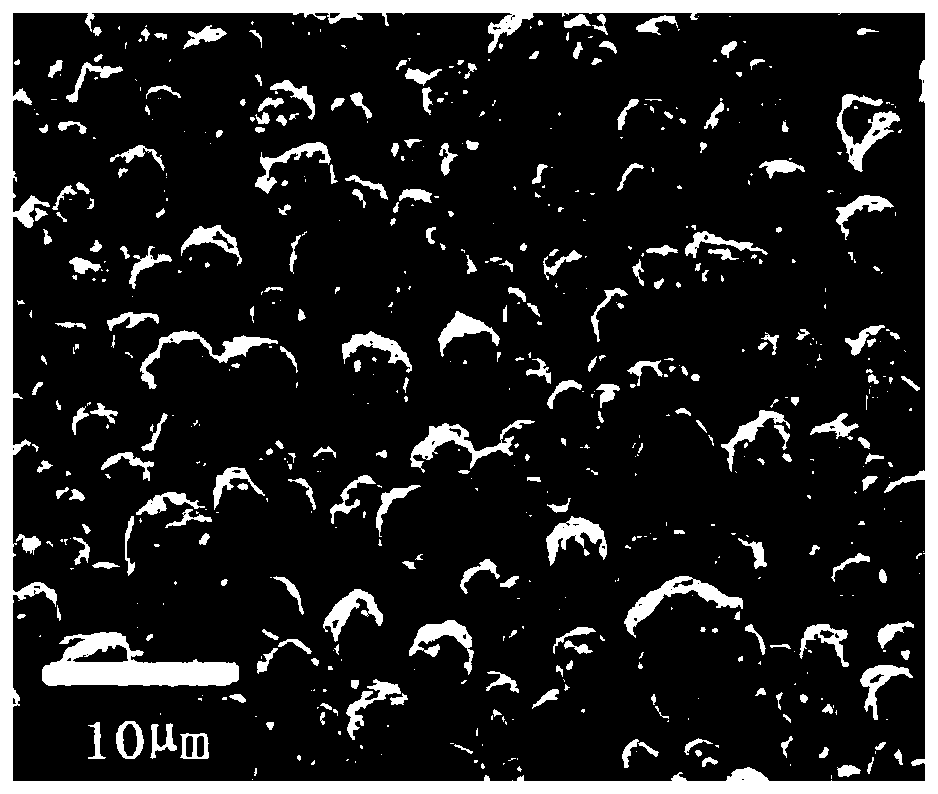

Image

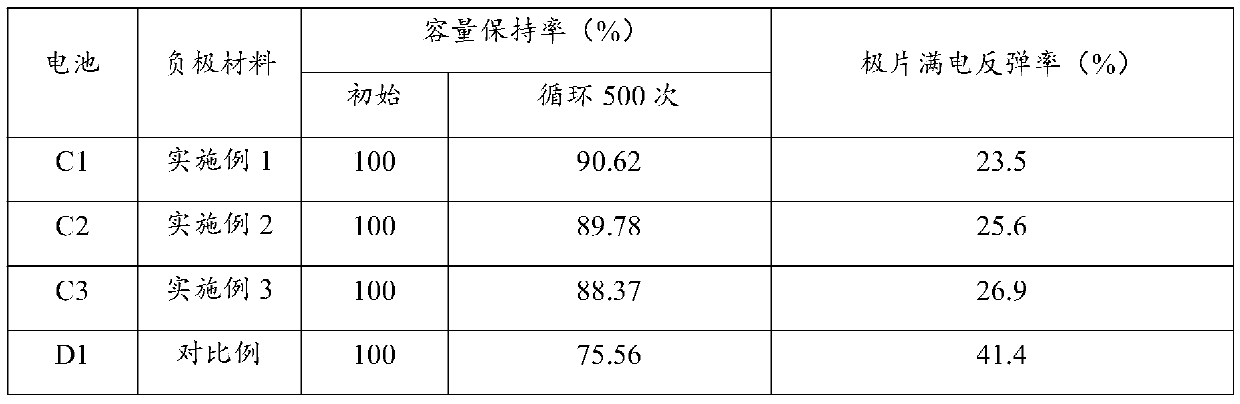

Examples

preparation example Construction

[0023] The invention provides a kind of preparation method of silicon-hard carbon composite material, comprises the following steps:

[0024] (1) Mix sulfonated polystyrene microspheres, alcohol solvent, tetramethylammonium hydroxide and piezoelectric material, and carry out compound reaction to obtain core material;

[0025] (2) The core material obtained in the step (1) is mixed with organic solvent, nano-silicon and phenolic resin, filtered and dried to obtain a composite material;

[0026] (3) eluting and removing the polystyrene in the composite material obtained in the step (2) to obtain a precursor material;

[0027] (4) Under a protective atmosphere, carbonize the precursor material obtained in the step (3) to obtain a silicon-hard carbon composite material.

[0028] The invention mixes sulfonated polystyrene microspheres, alcohol solvent, tetramethylammonium hydroxide and piezoelectric materials for compound reaction to obtain core materials.

[0029] In the present...

Embodiment 1

[0046] (1) 1g sulfonated polystyrene microspheres are added to 30g methanol solvent and stirred evenly, then 3g tetramethylammonium hydroxide and 3g lithium niobate are added to the above solution, then transferred to the autoclave, and Composite reaction at 600°C for 3 hours; after the composite reaction is completed, filter the composite reaction product, and dry the filtered solid to obtain a core material;

[0047] (2) Add 1g of core material to the organic solvent of 200g of dichloromethane / acetone (volume ratio 1:1) and stir evenly, add 15g of nano-silicon and 15g of phenolic resin, and disperse evenly by ultrasound, filter and dry to obtain composite materials;

[0048] (3) Add 100g of the composite material to 1000mL of tetrahydrofuran and soak for 6h, then centrifuge and dry to obtain the precursor material;

[0049] (4) Transfer the precursor material to a tube furnace, first pass an inert gas to discharge the air in the tube, then heat to 600°C and keep it warm for...

Embodiment 2

[0051] (1) Add 1 g of sulfonated polystyrene microspheres to 20 g of ethanol and stir evenly, then add 1 g of tetramethylammonium hydroxide and 1 g of ethanol to the above solution, then transfer to an autoclave, and The composite reaction is carried out for 6 hours; after the composite reaction is completed, the composite reaction product is filtered, and the filtered solid is dried to obtain a core material;

[0052] (2) Add 1g core material to the organic solvent of 50g dichloromethane / acetone (volume ratio 1:1) and stir evenly, add 10g nano-silicon and 10g phenolic resin, and after ultrasonic dispersion, filter and dry to obtain composite materials;

[0053] (3) Add 100g of the composite material to 500mL of tetrahydrofuran and soak for 1h, then centrifuge and dry to obtain the precursor material;

[0054] (4) Transfer the precursor material to a tube furnace, first pass an inert gas to discharge the air in the tube, then heat to 500°C and keep it warm for 6h, then cool d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com