Dog clutch control device for automatic transmission

A technology of claw clutches and automatic transmissions, which is applied in the direction of mechanical control devices, mechanical drive clutches, clutches, etc., can solve the problem that the sleeve and the idler gear cannot be engaged, and achieve the effect of fast shifting action and shortening the time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

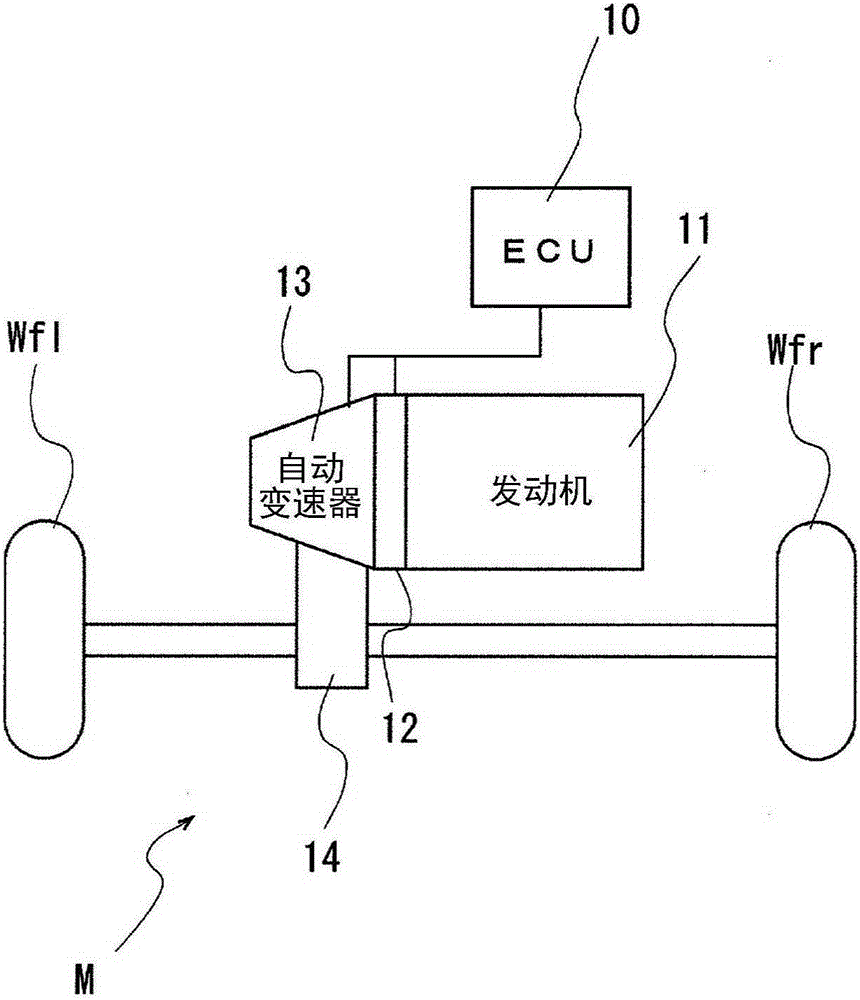

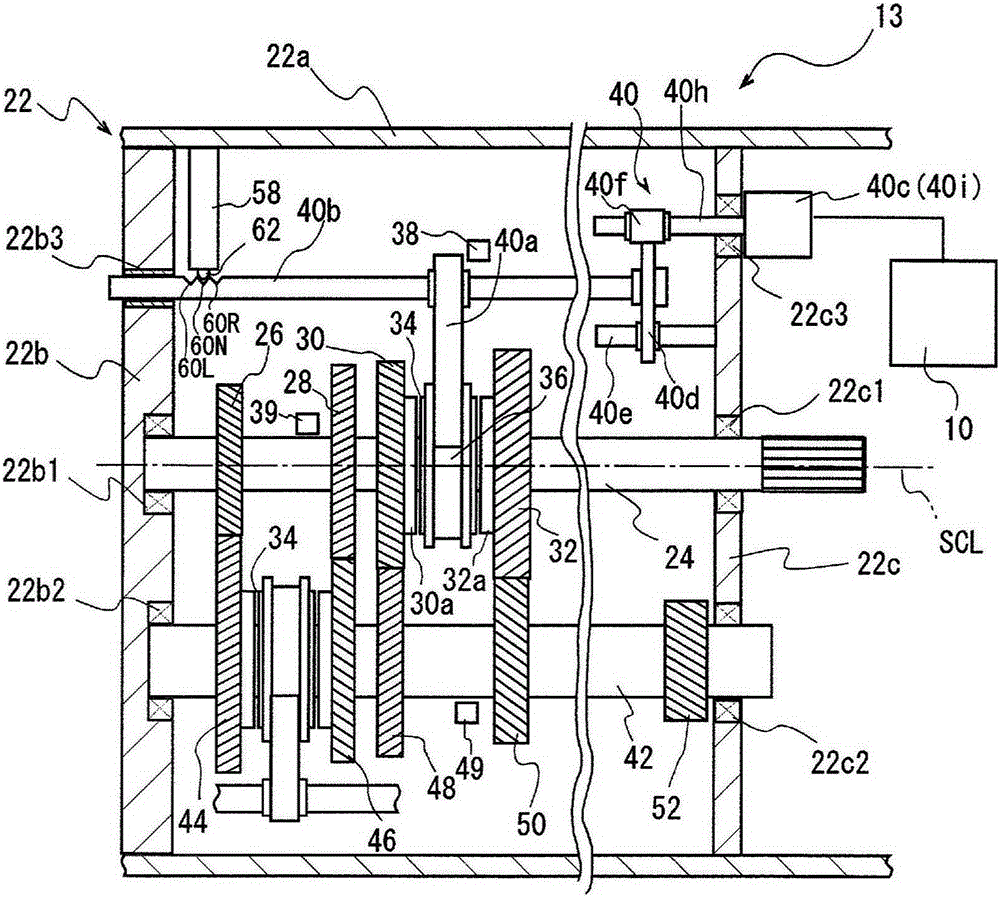

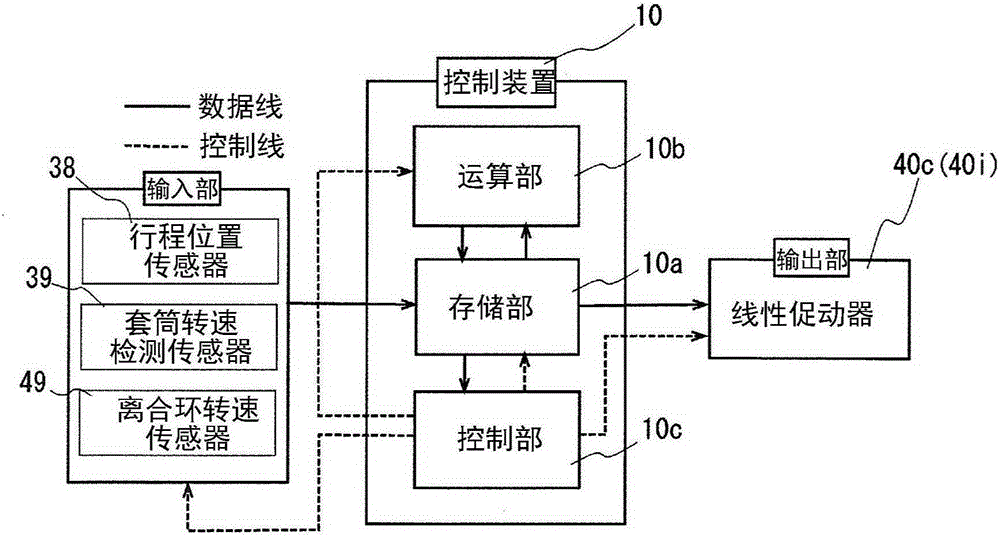

[0075] Next, a first embodiment in which an automatic transmission having the dog clutch control device for an automatic transmission of the present invention applied to a vehicle will be described with reference to the drawings. figure 1 It is a schematic diagram showing the structure of the above-mentioned vehicle.

[0076] Such as figure 1 As shown, the vehicle M includes an engine 11, a clutch 12, an automatic transmission 13, a differential device 14, and drive wheels (left and right front wheels) Wfl, Wfr. The engine 11 generates driving power by burning fuel. The driving force of the engine 11 is transmitted to drive wheels Wfl, Wfr via a clutch 12, an automatic transmission 13, and a differential device 14 (so-called FF vehicle).

[0077] The clutch 12 is automatically disengaged or engaged according to an instruction from a control unit (ECU) 10 . The automatic transmission 13 incorporates a dog clutch transmission mechanism, and automatically selects, for example,...

Embodiment 2

[0116] Next, a second embodiment in which an automatic transmission including the dog clutch control device for an automatic transmission of the present invention is applied to a vehicle will be described with reference to the drawings.

[0117]The shift pawl mechanism 58 of the dog clutch control device for an automatic transmission according to the present embodiment has a neutral positioning concave portion 60N for positioning the sleeve 36 at the neutral position and left and right meshing positioning concave portions for positioning the sleeve 36 at the meshing position. In addition to 60R and 60L, there are two stop positioning recesses 60SR and 60SL for stopping the high teeth 36a1 of the sleeve 36 in front of the front end surfaces 30b6 of the clutch rear teeth 30b2 of the third and fourth clutch rings 30 and 32, etc. This point is different from the first embodiment. Below, based on Figure 10 Give a detailed explanation. Since the other structures are the same, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com