Patents

Literature

40results about How to "Quick mesh" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

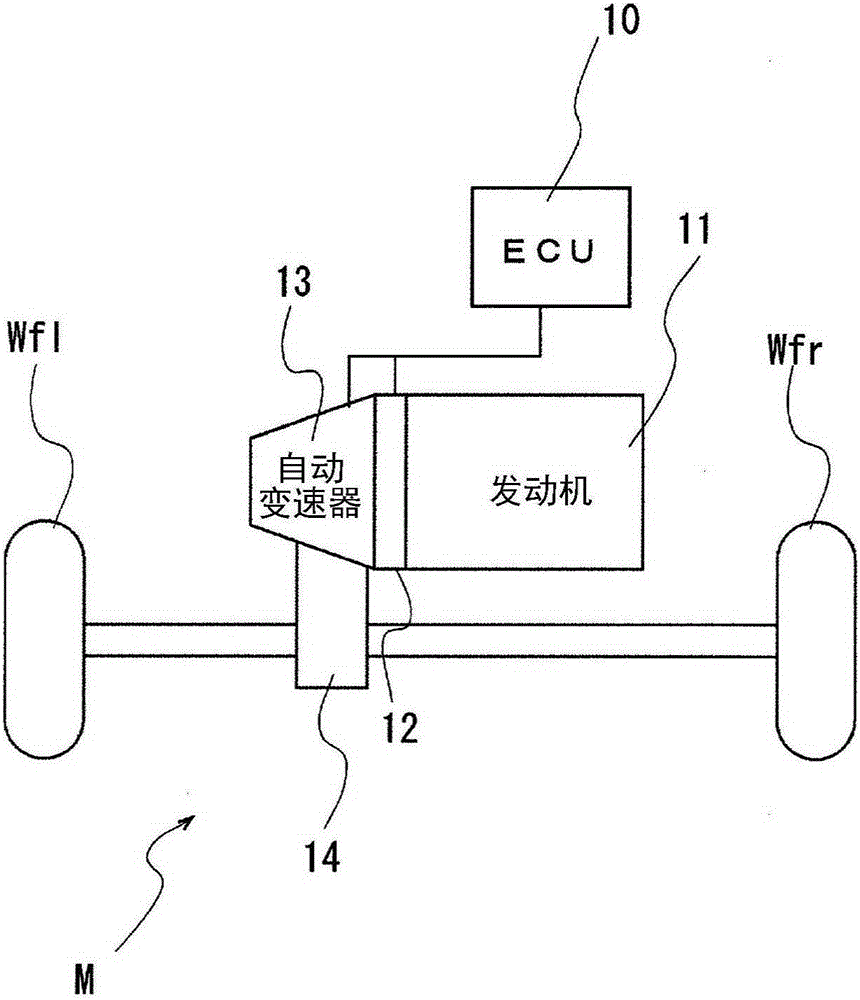

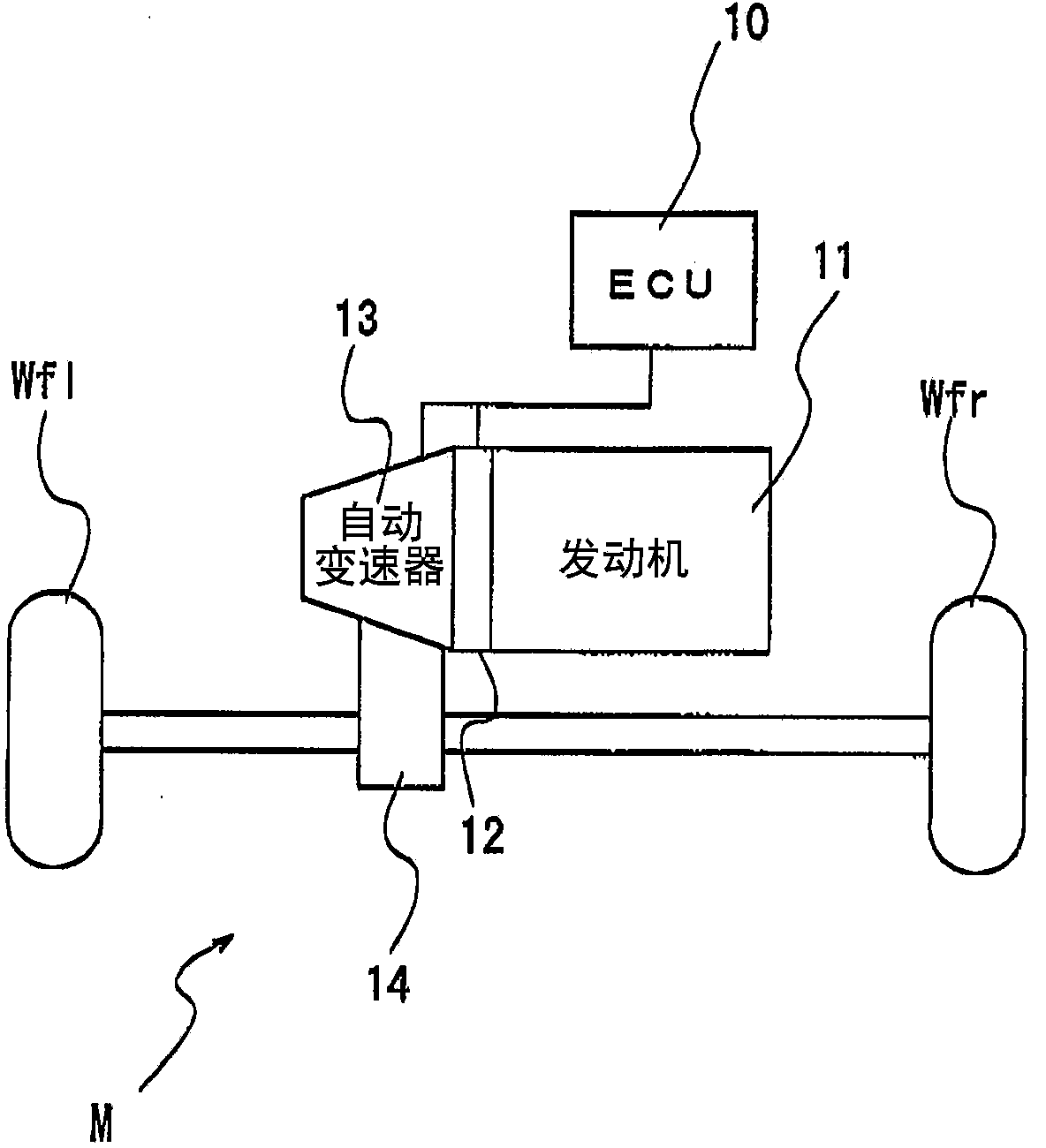

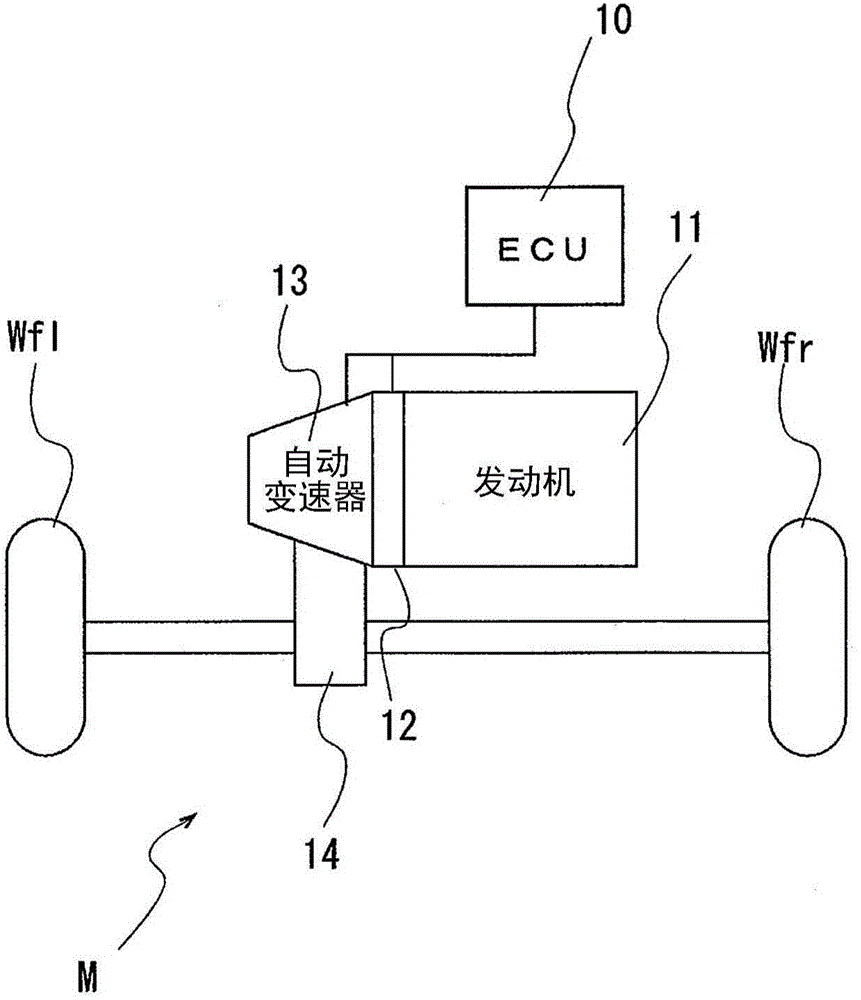

Dog clutch control device for automatic transmission

InactiveCN105247254AButt fastIncrease speedControlled membersGearing controlAutomatic transmissionControl theory

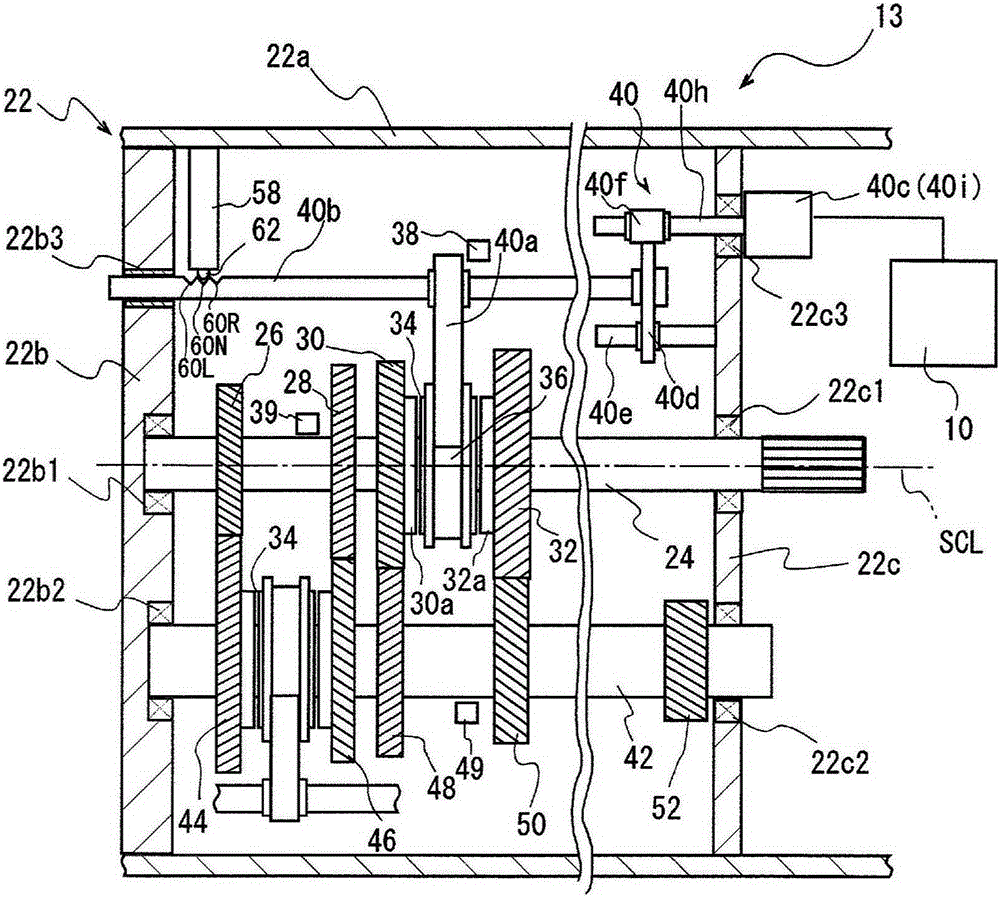

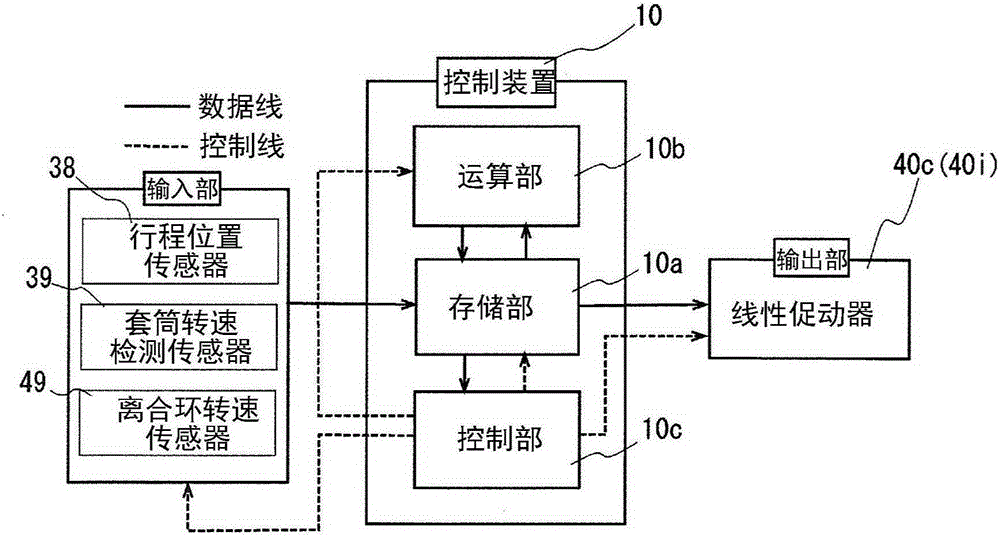

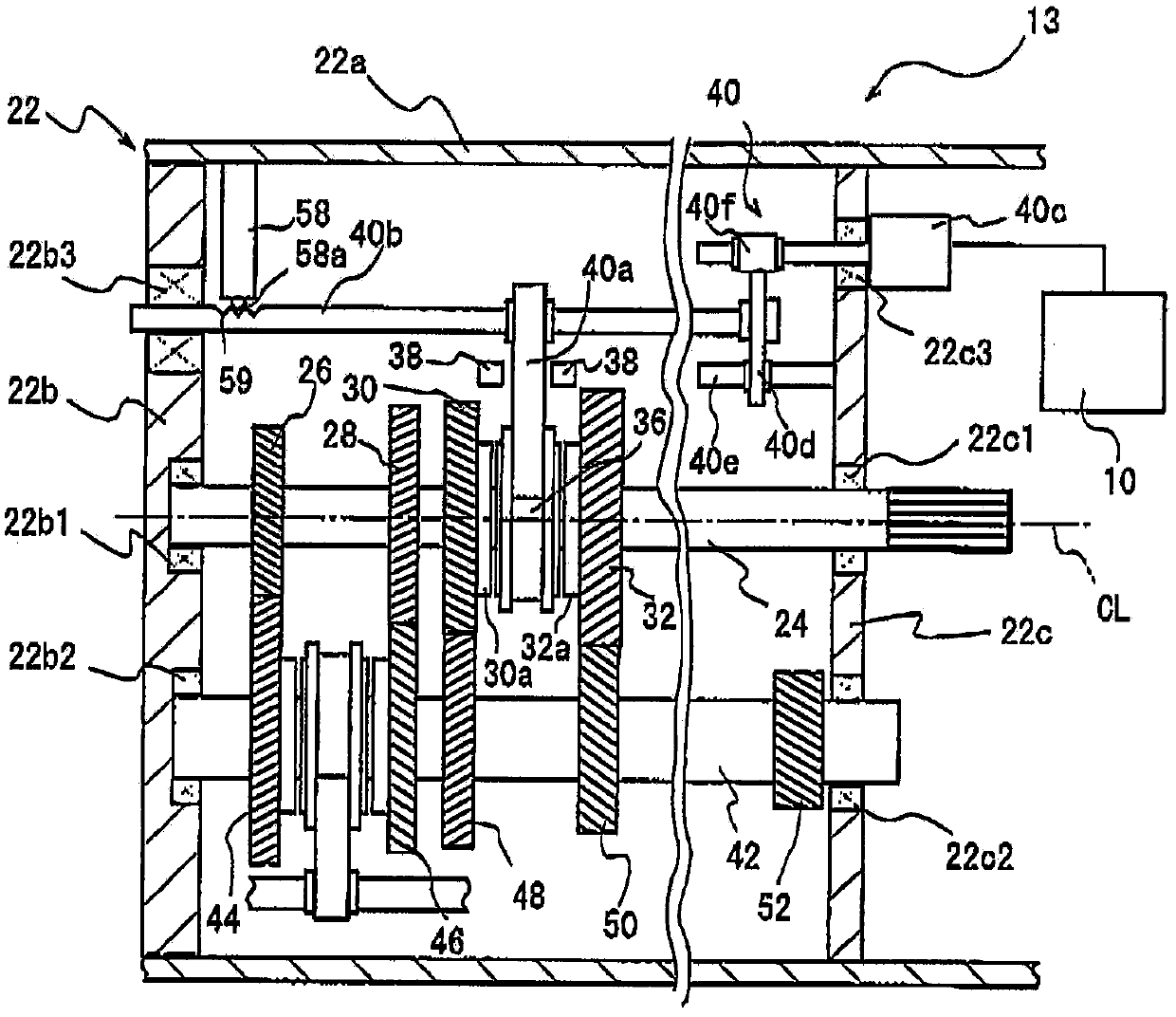

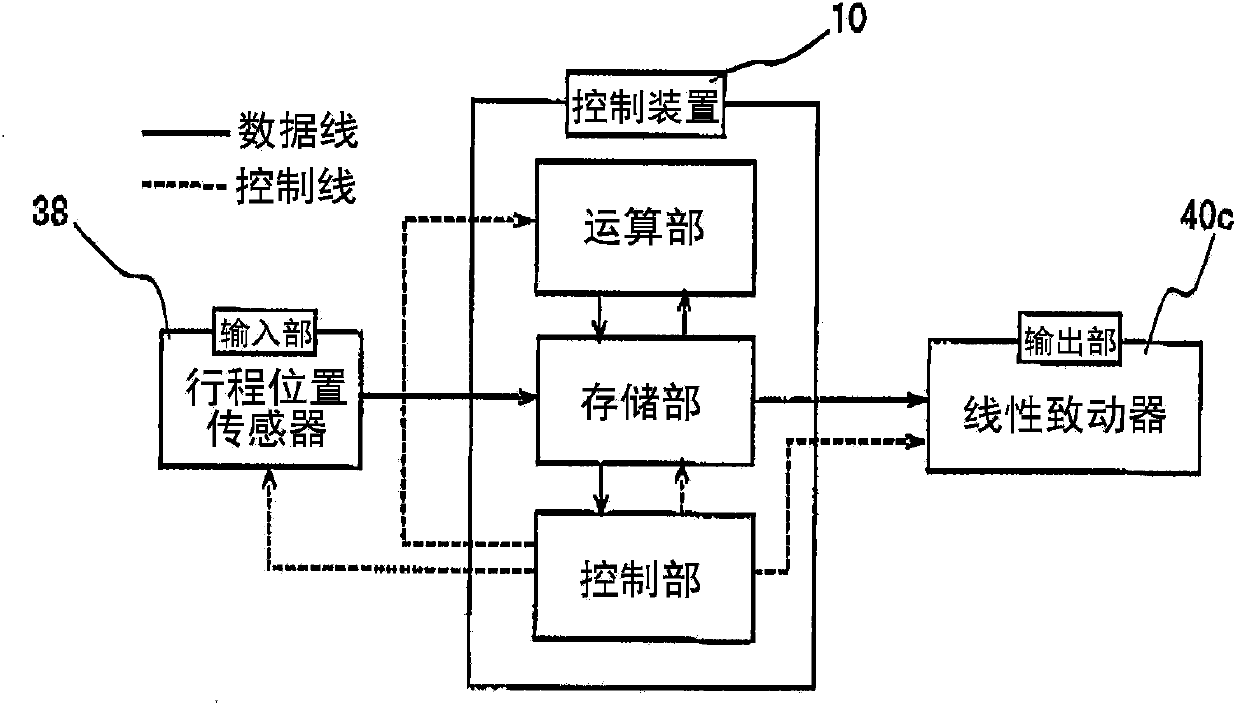

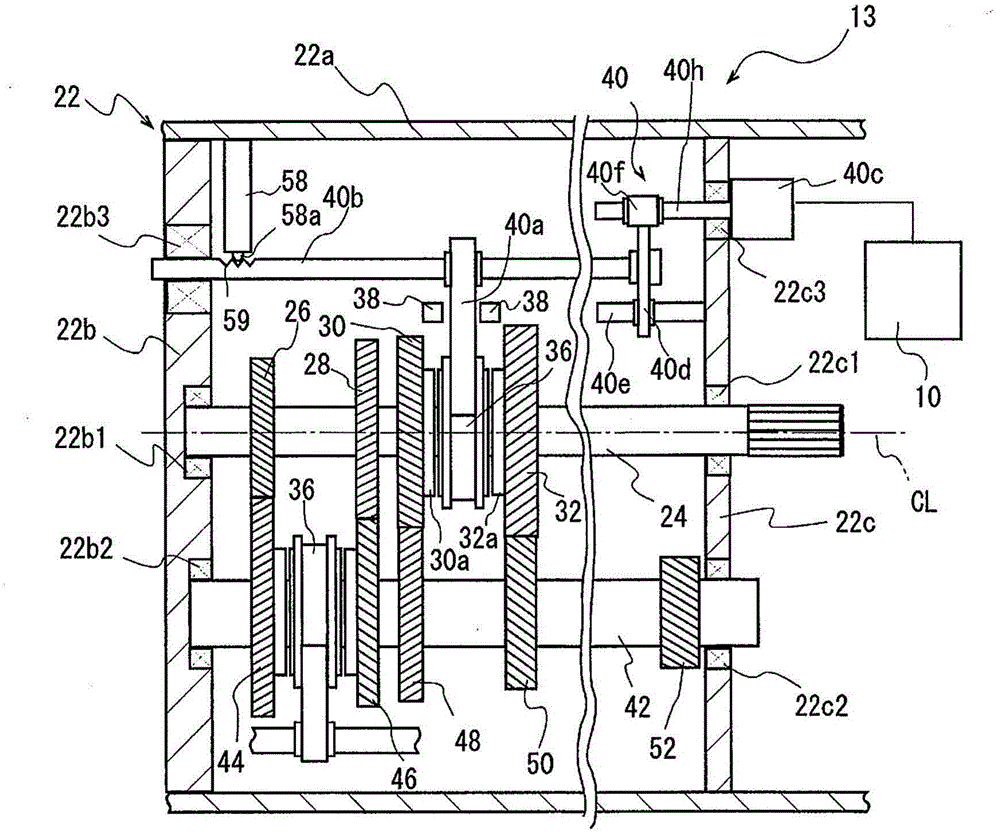

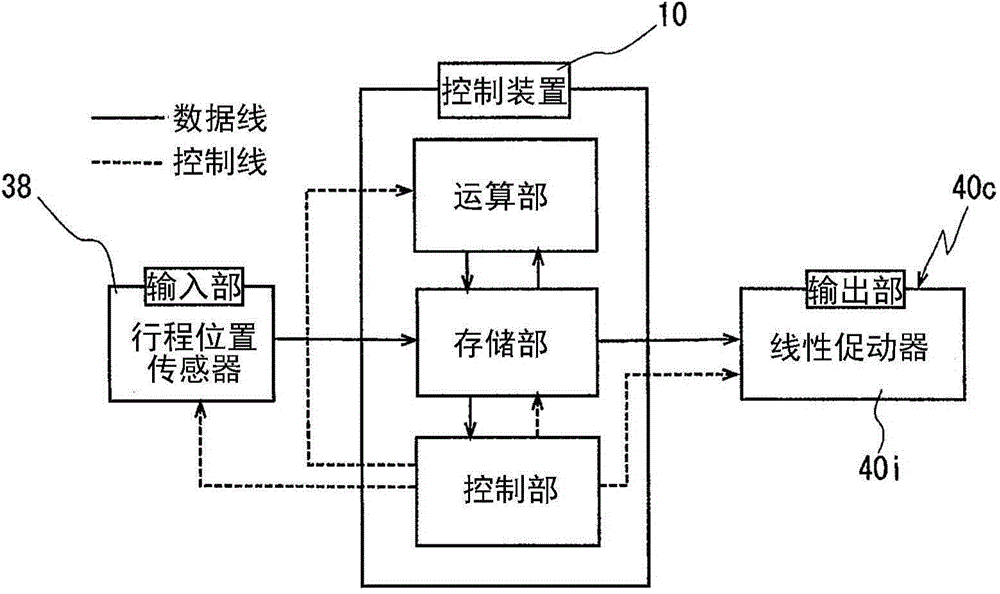

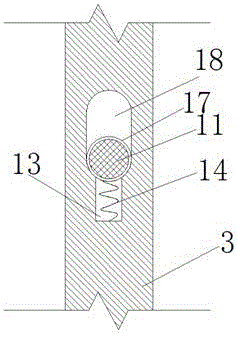

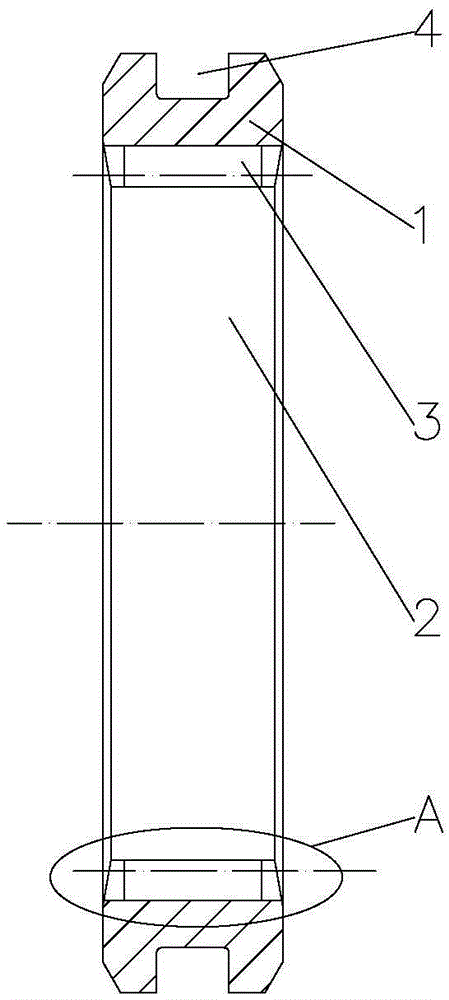

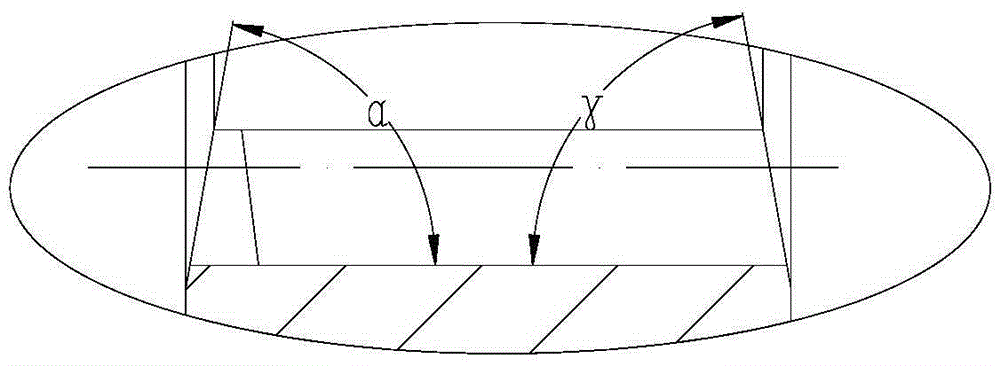

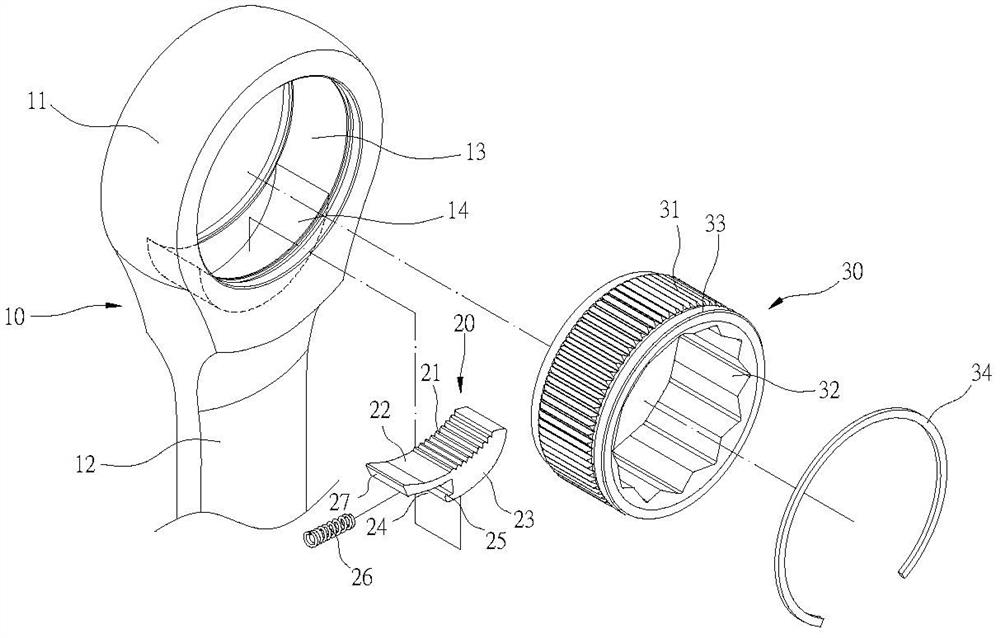

Provided is a dog clutch control device for an automatic transmission that makes it possible to perform a speedy shifting operation when, during shifting, a sleeve is moved and engaged with the dog clutch. A control device (10), which has a calculation unit (10b) for calculating the speed of movement of the sleeve (36) on the basis of the position detected at a predetermined time by a stroke position sensor (38) for detecting the position of movement of the sleeve (36), and which controls the operation of a shaft device (40) on the basis of the position detected by the stroke position sensor and the speed of movement of the sleeve, applies, after high teeth (36a1) of the sleeve have passed a chamfered portion (30b3) of clutch front teeth of the clutch ring (30), a stopping thrust load (F4) for stopping the forward movement of the high teeth before the high teeth come into contact with the end surfaces (30b6) of clutch back teeth (30b2) of the clutch ring.

Owner:AISIN SEIKI KK

Dog clutch control apparatus for automated transmission

InactiveCN103967969ASpin difference reducedQuick meshGearing controlInterengaging clutchesClutch controlAutomatic transmission

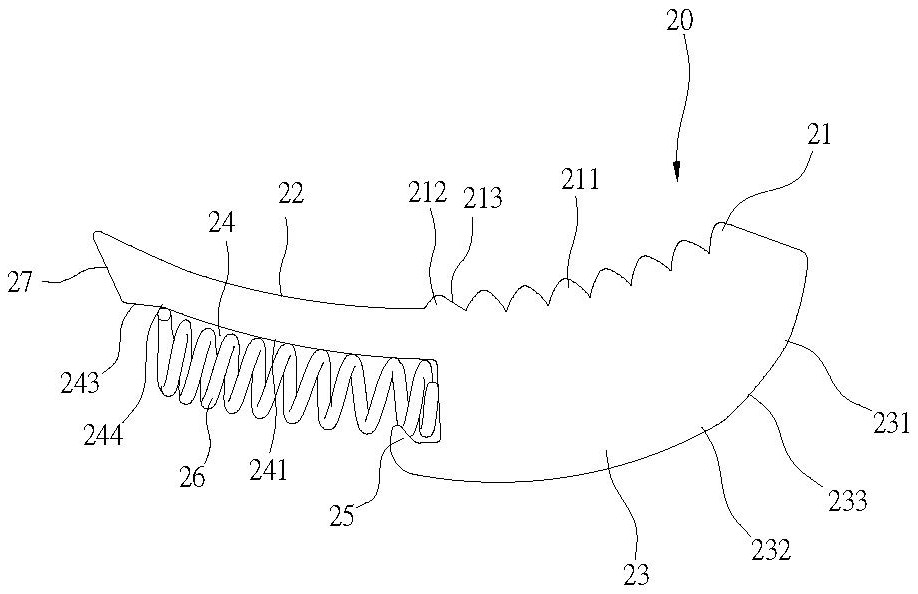

The invention provides a dog clutch control apparatus for an automated transmission, and can move a sleeve in a speed change to realize quick action of a speed change when the sleeve is engaged with a dog clutch. A spline (36a) of the sleeve is formed by high teeth (36a1) and a low tooth (36a2), a dog clutch portion has a dog cluth speed change mechanism formed by clutch front teeth (30b1) and clutch rear teeth (30b2) and a control apparatus which controls action of an axial driving device based on a detection position of a stroke position sensor (38), and the control apparatus controls a thrust load so as to ensure that the thrust load which generates a relative rotation between the sleeve and the dog cluth position against a frictional force generated by contact between an end surface (36a4) of each of the high teeth of the sleeve and a front end surface (30b6) of each of the clutch rear teeth of the dog slutch position is applied to the sleeve in a rotation adjustment range in which the high teeth of the spline advance from a front end part of the clutch front teeth to a front end part of the cluth rear teeth.

Owner:AISIN SEIKI KK

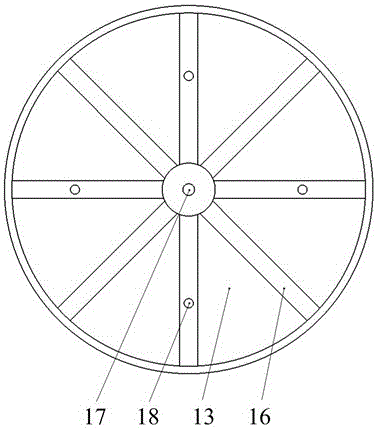

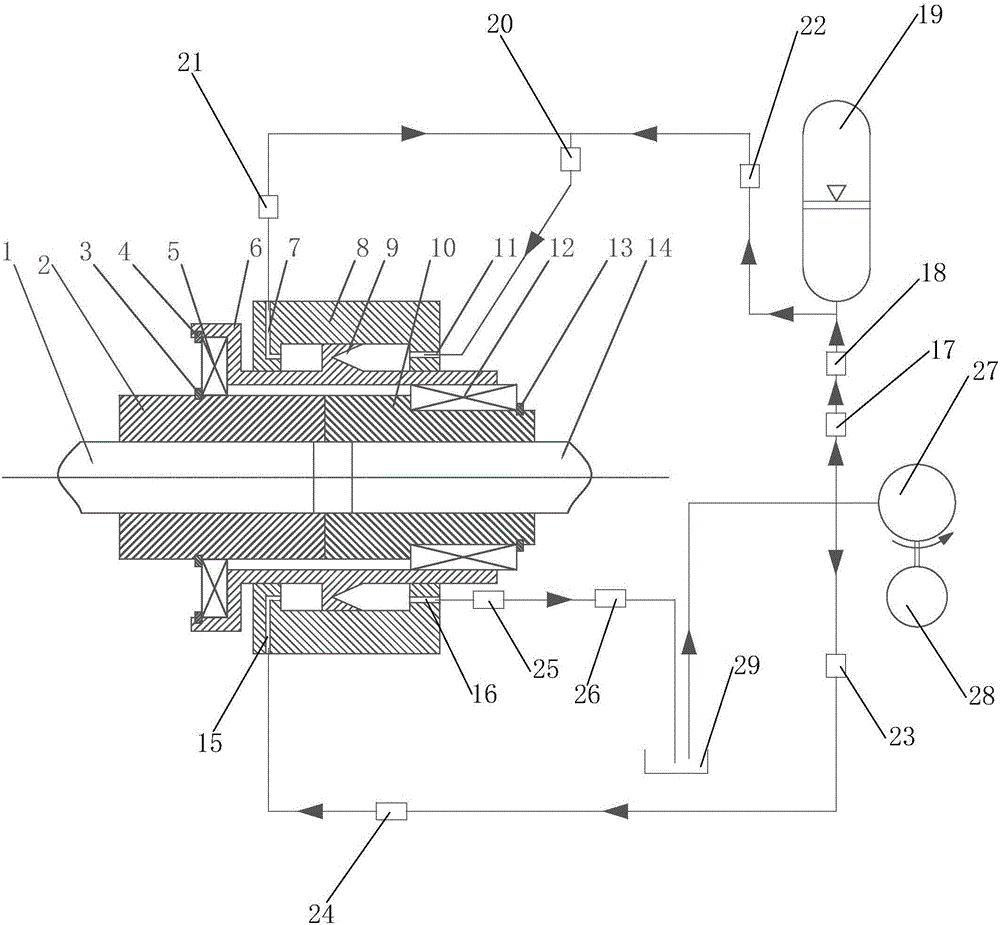

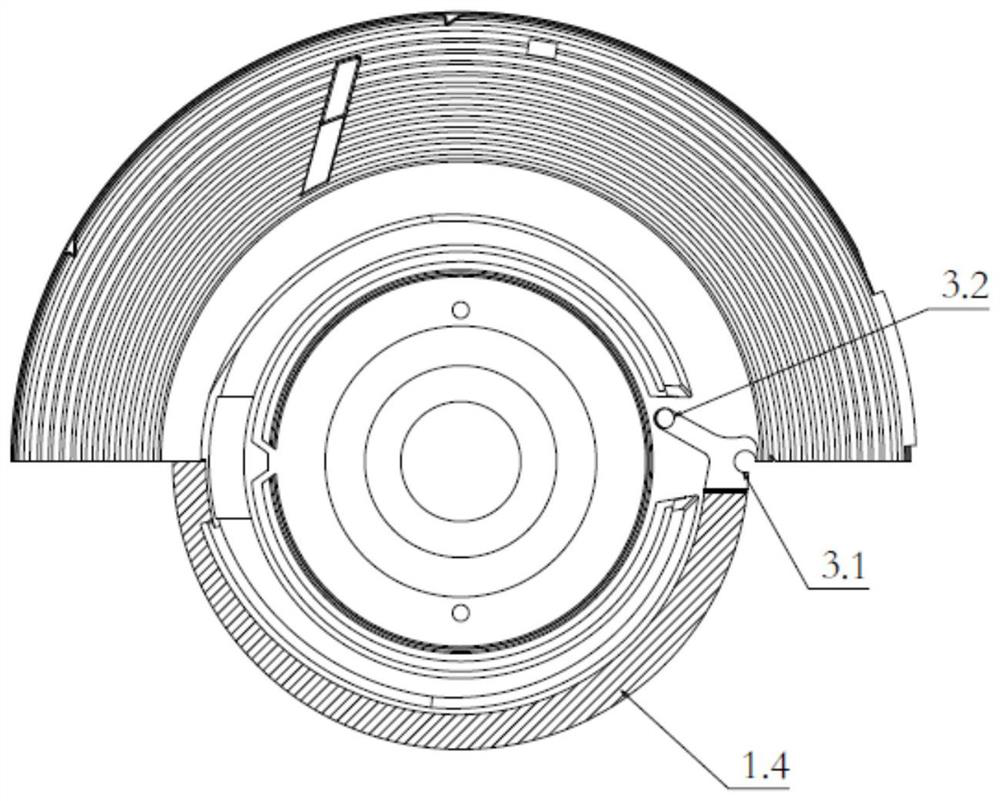

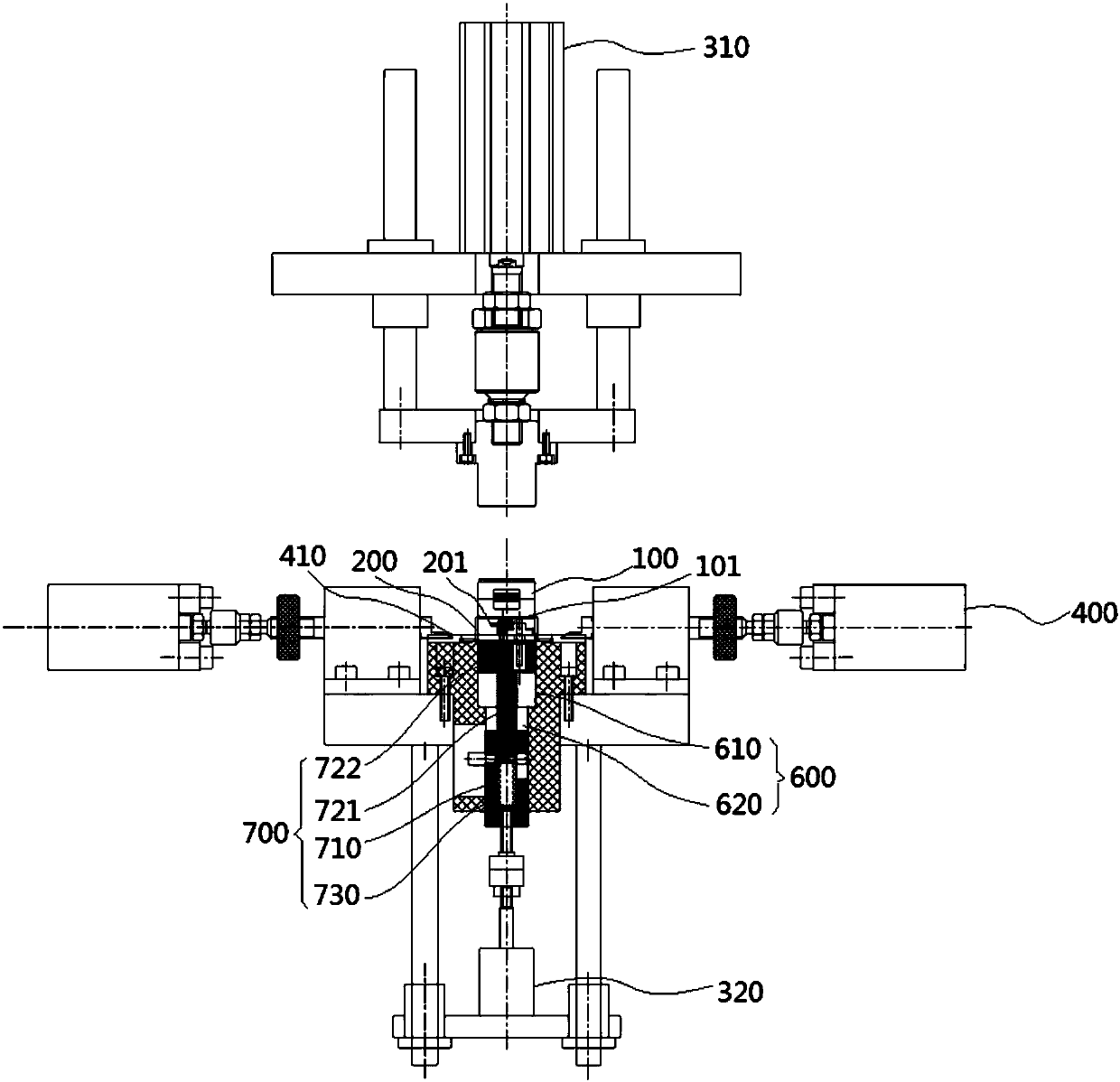

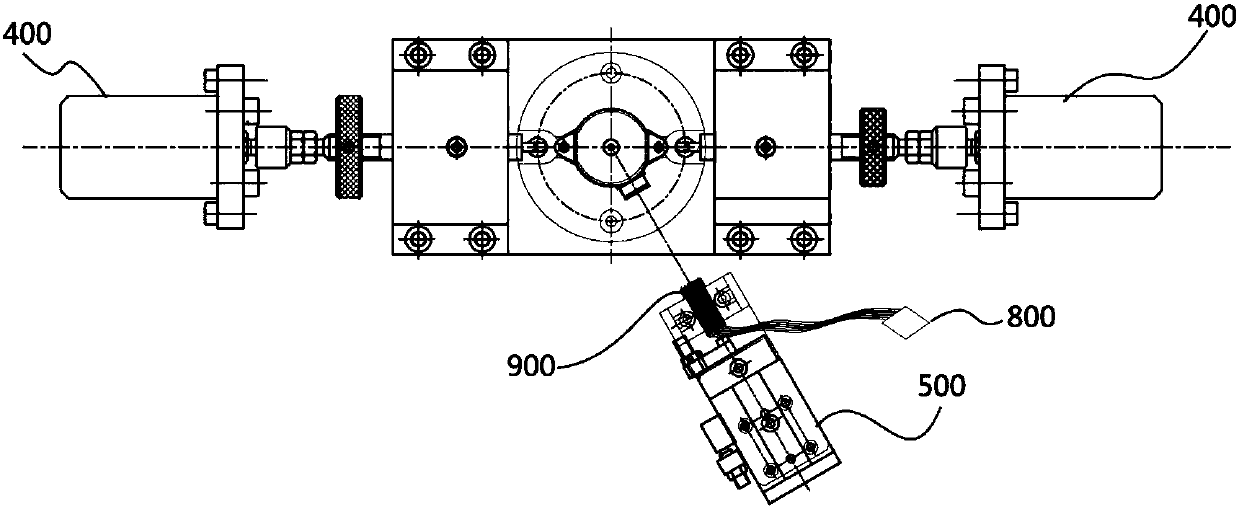

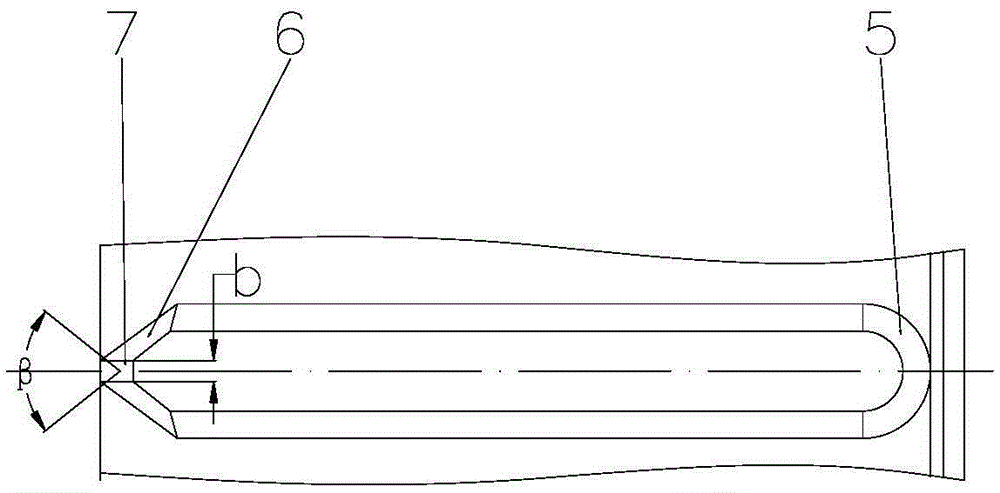

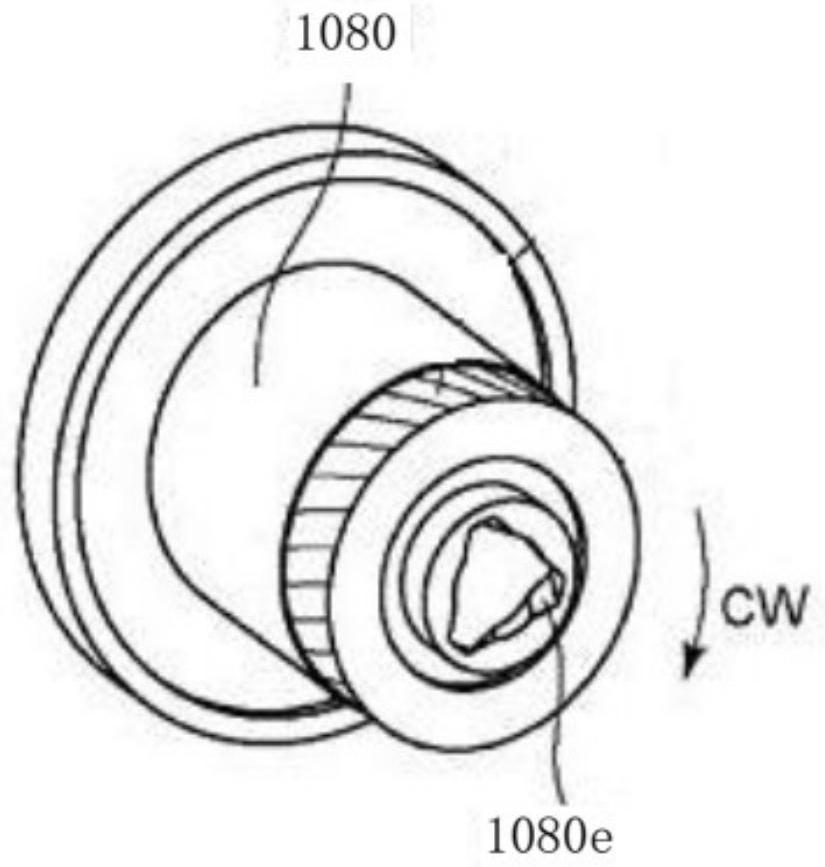

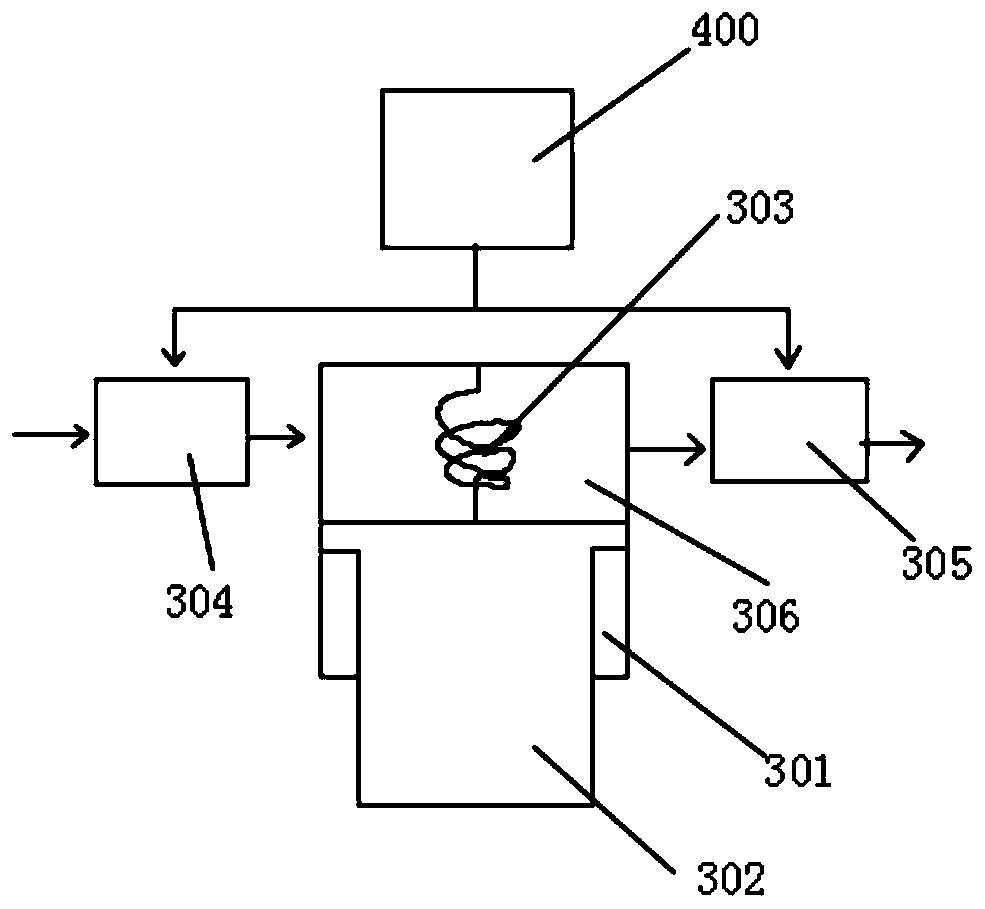

Pulping equipment based on high-pressure water jet and combined type rotor pulping

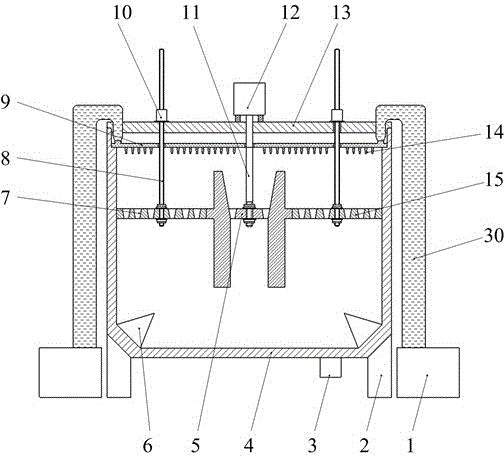

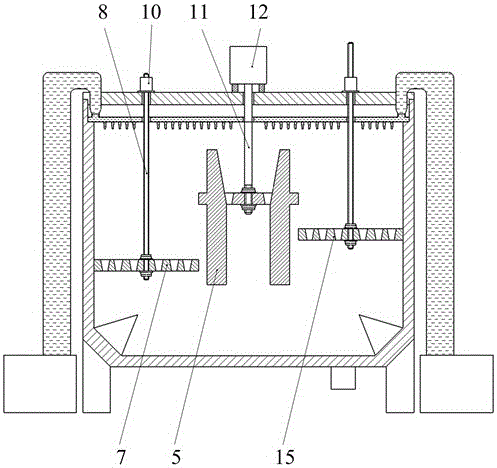

ActiveCN106522006AEasy to collectPromote fragmentationPaper recyclingRaw material divisionPulp and paper industryHigh pressure water

The invention provides pulping equipment based on a high-pressure water jet and combined type rotor pulping. The equipment mainly comprises a high-pressure water conveying device, a water jet pulping device, a combined rotor pulping device and a pulp generating device. The pulping equipment based on the high-pressure water jet and combined type rotor pulping is characterized in that preliminary pulping of the high-pressure water jet replaces a feed cylinder to inject water, and a mobile smashing knife in the combined rotor pulping device freely adjusts the height and assists in smashing feed. According to the pulping equipment based on the high-pressure water jet and combined type rotor pulping, a pulping blind area at the bottom of the feed cylinder and a 'rotary cake' phenomenon are eliminated through a triangular smashing knife, freely combined non-blind-area and efficient secondary pulp is achieved through the combined rotor pulping device, fast engagement and separation of the rotor and the mobile smashing knife are achieved through special structural teeth, and pulping efficiency is improved and uniform feed smashing is achieved through high-pressure exhaust pipes and conical holes which are distributed circumferentially evenly and in a dispersed mode of an arithmetic progression.

Owner:UNIV OF JINAN

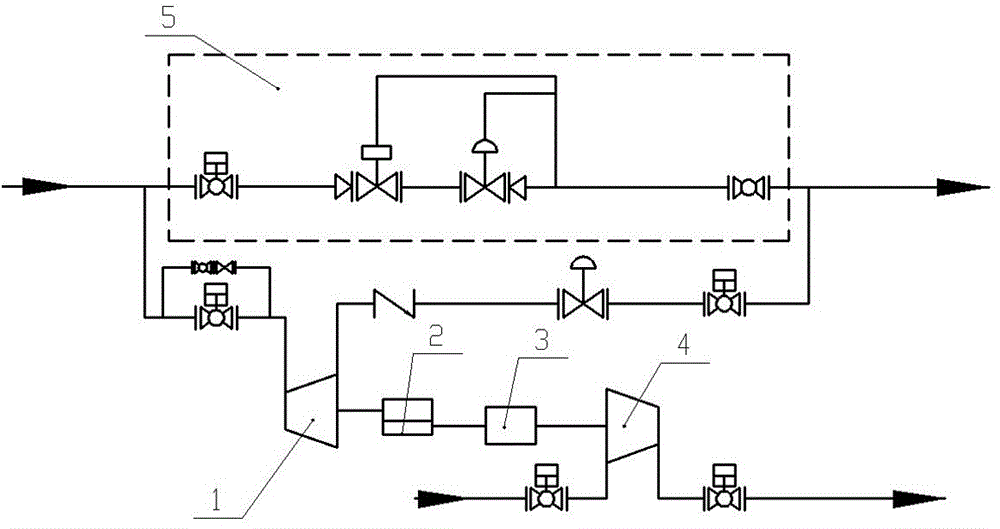

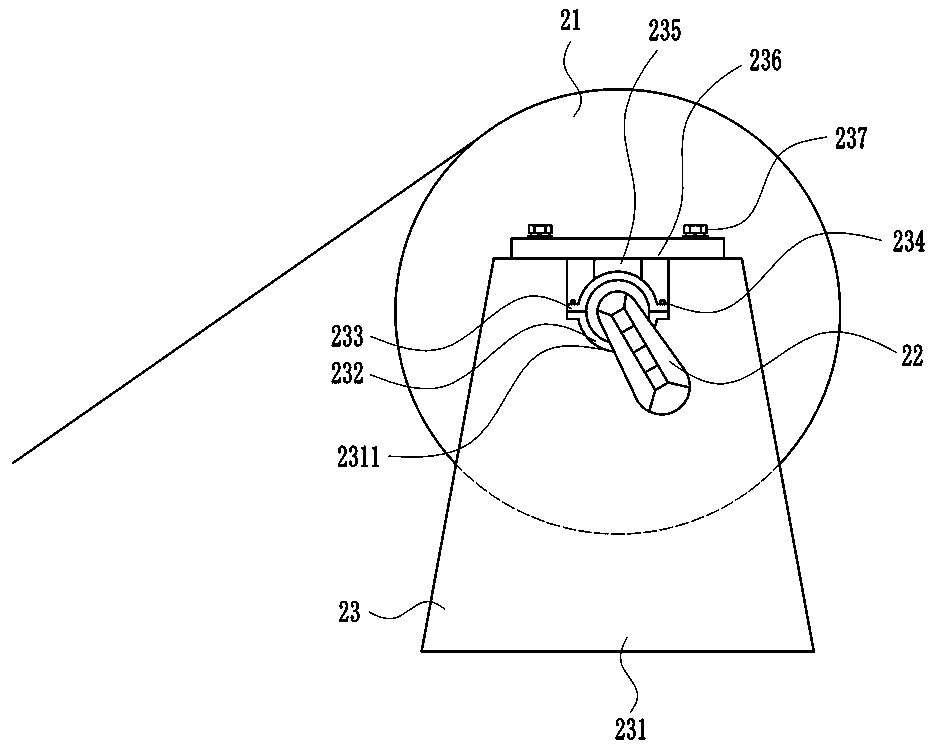

Natural gas differential pressure energy recovery unit device

InactiveCN105757455AReduce self-consumptionAchieve full utilizationPipeline systemsSteam engine plantsClutchGas pipeline

The invention provides a natural gas differential pressure energy recovery unit device which is arranged between a natural gas inlet pipeline and a natural gas low pressure equipment pipeline.The device comprises a turbo expander, a gas inlet pipeline of the turbo expander is connected with the natural gas inlet pipeline, an exhaust pipeline of the turbo expander is connected with the equipment pipeline in need of natural gas, the turbo expander is further connected with a clutch, an output shaft of a motor is coaxially connected with a compressor, and the other end of the motor is coaxially connected with the turbo expander through the clutch.Compared with the prior art, the turbo expander of the natural gas differential pressure energy recovery unit device and a pressure regulator subcircuit are arranged in parallel, when the turbo expander breaks down and the clutch separates quickly, a gas circuit can be switched to the pressure regulator subcircuit rapidly, and normal operation of a system is not influenced.Through arrangement of the turbo expander, a pressure regulator can be effectively replaced to achieve the function of lowering the pressure, meanwhile, action is conducted outward, the compressor is driven to run, self-consumed electricity is effectively reduced, and full utilization of energy is achieved.

Owner:HUADIAN ZHENGZHOU MECHANICAL DESIGN INST

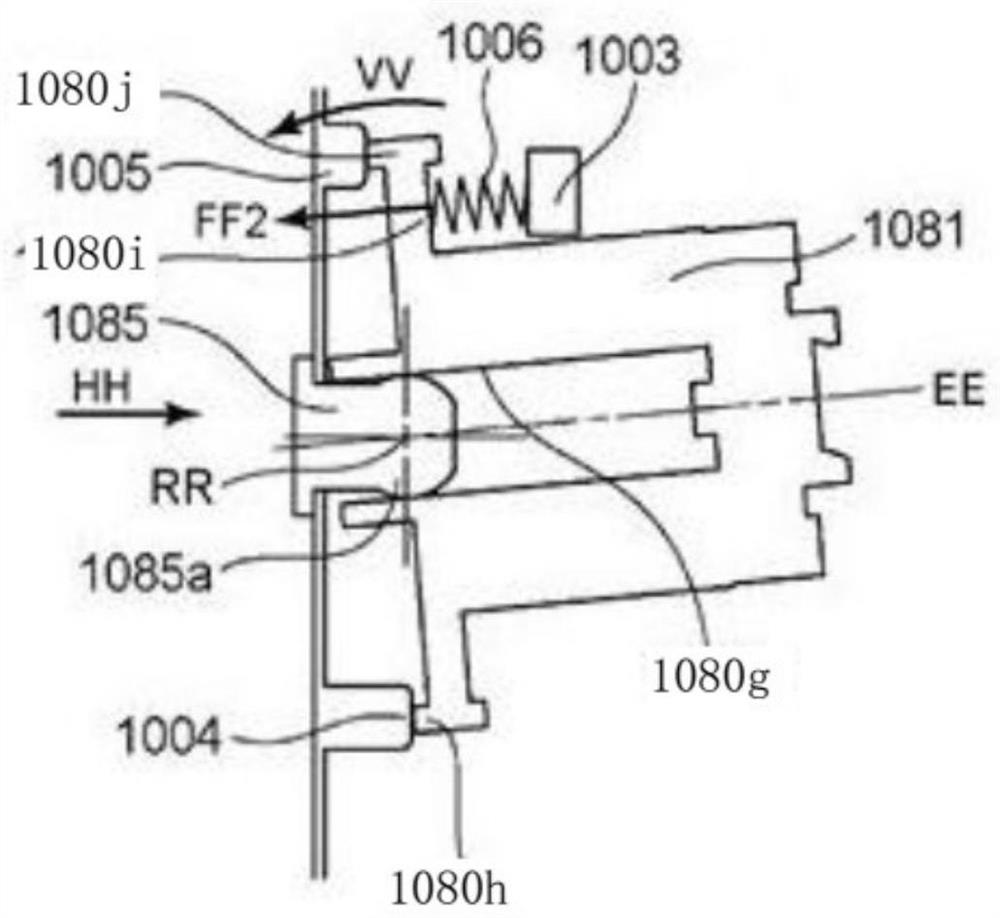

Automatic transmission dog clutch control unit

InactiveCN104343954AQuick meshAvoid duplication of workGearing controlInterengaging clutchesAutomatic transmissionControl theory

A dog clutch control unit for an automatic transmission (13) includes: a dog clutch transmission mechanism including: a rotating shaft; a clutch ring (30, 32, 44, 46); a clutch hub (34); a sleeve (36) fitted to the clutch hub by means of a spline; an axially moving unit (40); a dog clutch portion (30a); and a stroke position sensor (38), the spline having high teeth higher than remaining low teeth, and the dog clutch portion including the same number of clutch front teeth as the high teeth, and the dog clutch portion including clutch rear teeth; and a control unit (10) configured to control an action of the axially moving unit on the basis of a detected position detected by the stroke position sensor.

Owner:AISIN SEIKI KK

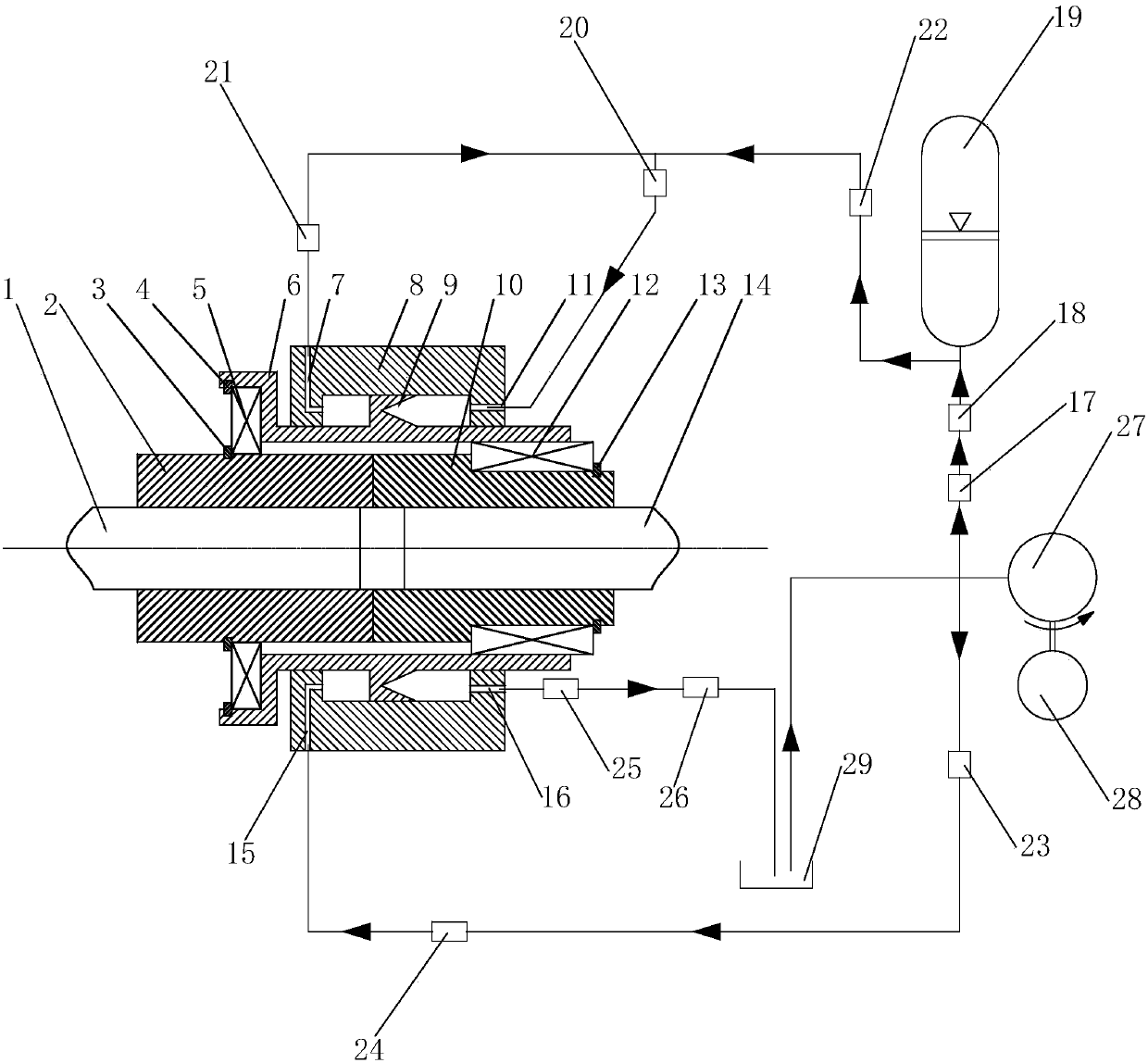

Quick large-torque clutch system

ActiveCN106090087AEasy to separateAvoid damageFluid actuated clutchesCoupling-brake combinationCouplingRolling-element bearing

The invention discloses a quick large-torque clutch system which comprises a clutch device, a hydraulic oil pump, a motor, a disengagement oil way, an engagement oil way and an oil storage tank. The clutch device comprises an input shaft, a first coupling, a first snap spring, a second snap spring, a rolling bearing, a bearing bush, a cylinder wall sleeve, a second coupling, a sliding bearing, a third snap spring and an output shaft. Compared with existing clutch devices, the clutch device arranged in this way overcomes shortcomings by learning strong points and has the characteristics of large transmission torque, rapid action response, simple structure and easy operation. The quick large-torque clutch system further comprises the disengagement oil way and the engagement oil way, the first coupling and the second coupling are quickly disengaged in a high speed state through the disengagement oil way, the first coupling rotating at high speed is slowly and gradually engaged with the second coupling stopping rotating through the engagement oil way, and thus the operation stability of equipment is improved, and the service life of the equipment is prolonged.

Owner:中色正锐(山东)铜业有限公司

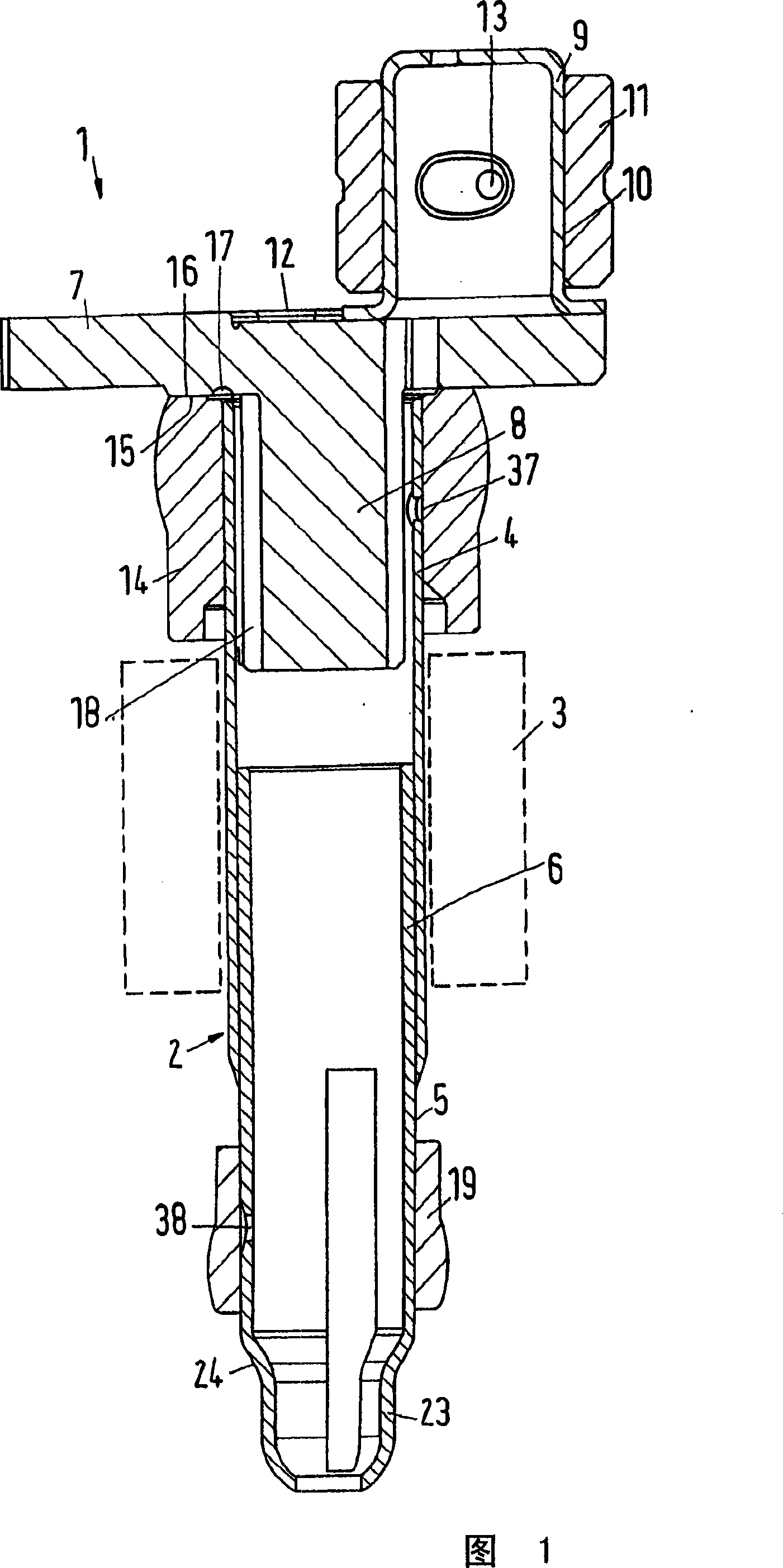

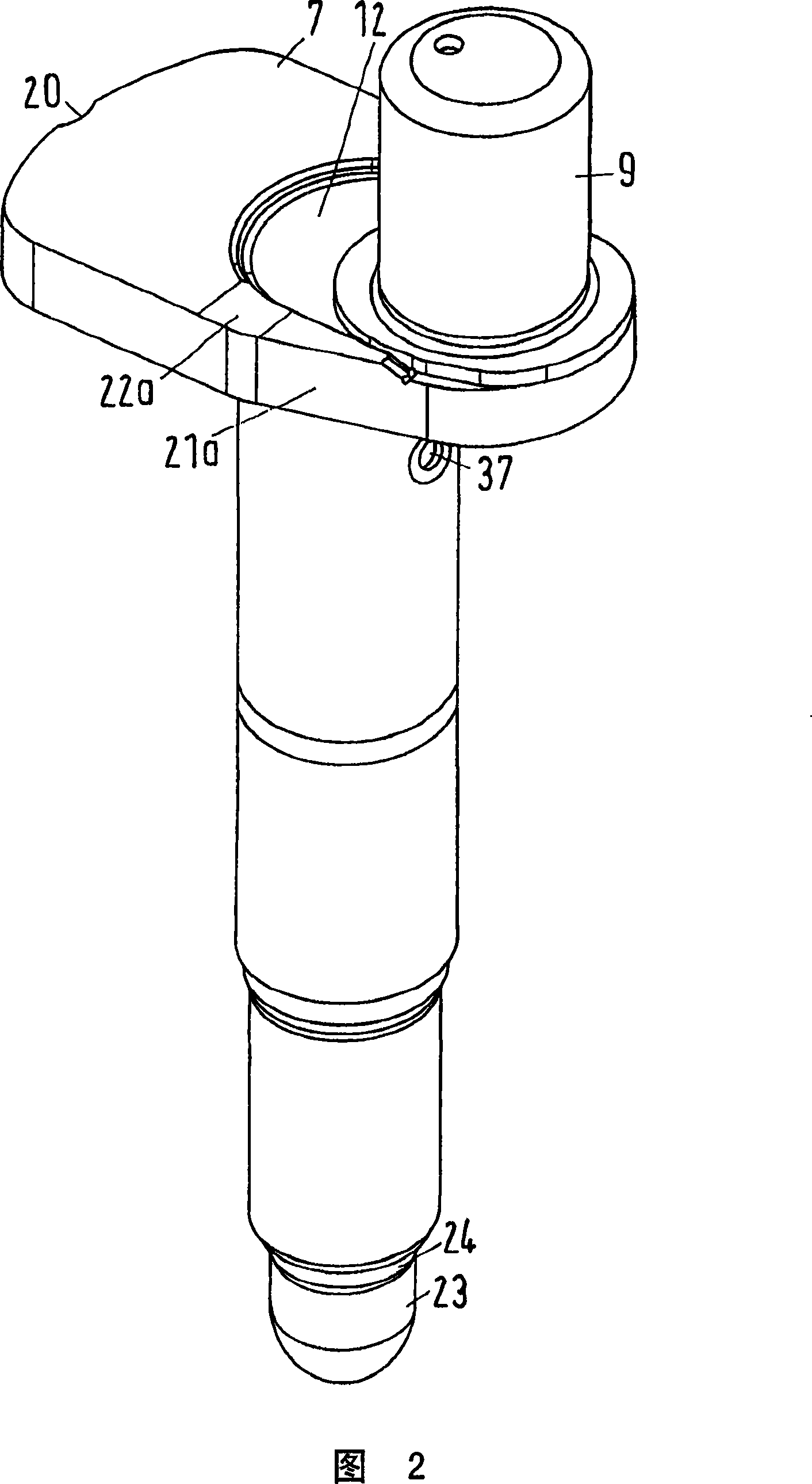

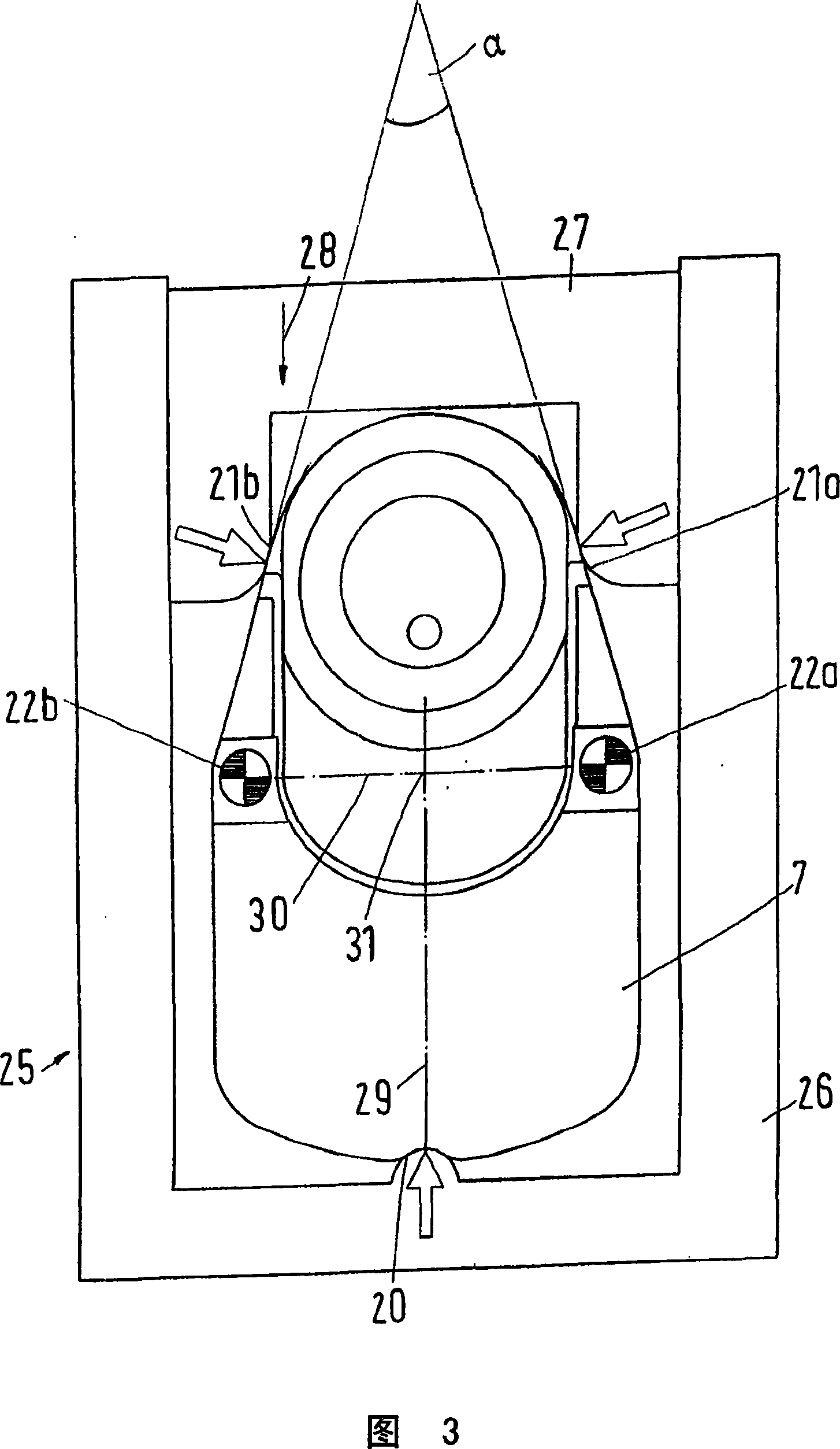

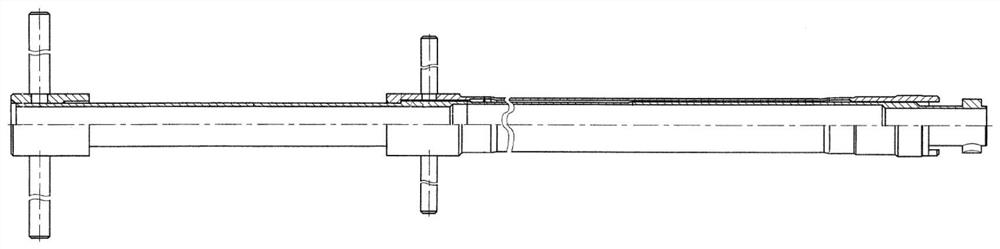

Compressor crankshaft, particularly refrigerant compressor crankshaft, and method for grinding such a crankshaft

ActiveCN101101016AQuick meshPrecise positioningCrankshaftsRevolution surface grinding machinesRefrigeration compressorEngineering

The invention concerns a compressor crankshaft, particularly a refrigerant compressor crankshaft ( 1 ) and a method for manufacturing such a crankshaft, with a shaft element ( 2 ), a crank pin ( 9 ) located eccentrically to the shaft element and a transition element ( 7 ) between the shaft element ( 2 ) and the crank pin ( 9 ). The purpose of the invention is to keep the manufacturing costs low. For this purpose, it is ensured that along its circumference the transition element ( 7 ) has at least one first reference point ( 20 ) and one second reference point ( 21 a , 21 b), with which the transition element ( 7 ) can be positioned in a holding fixture ( 25 ) of a working machine.

Owner:SECOP GMBH

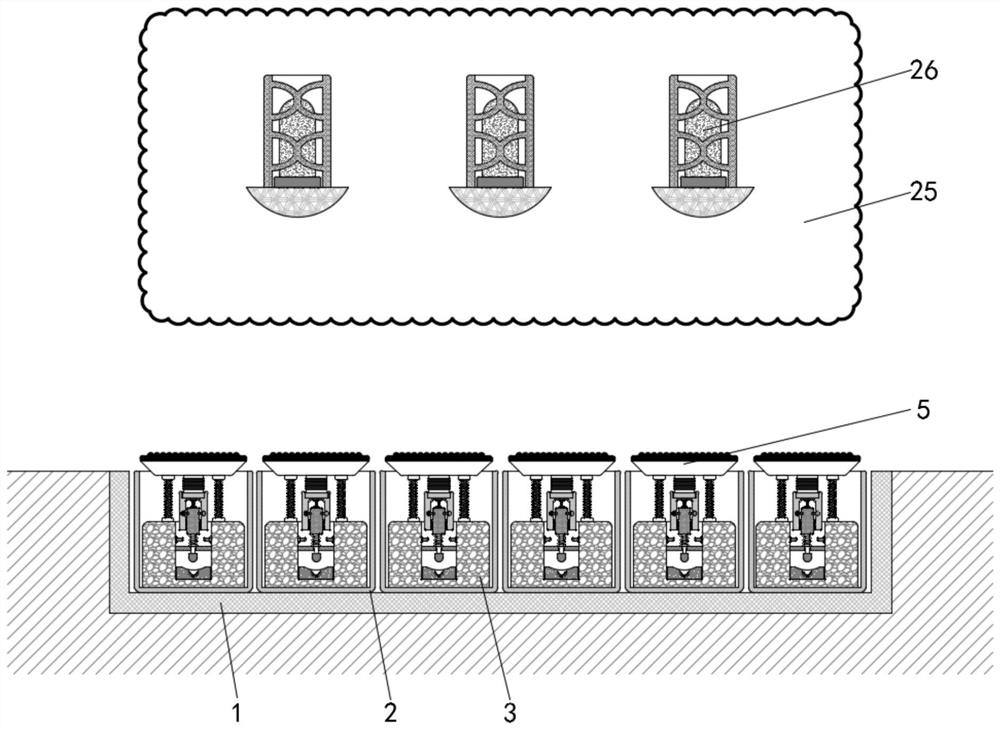

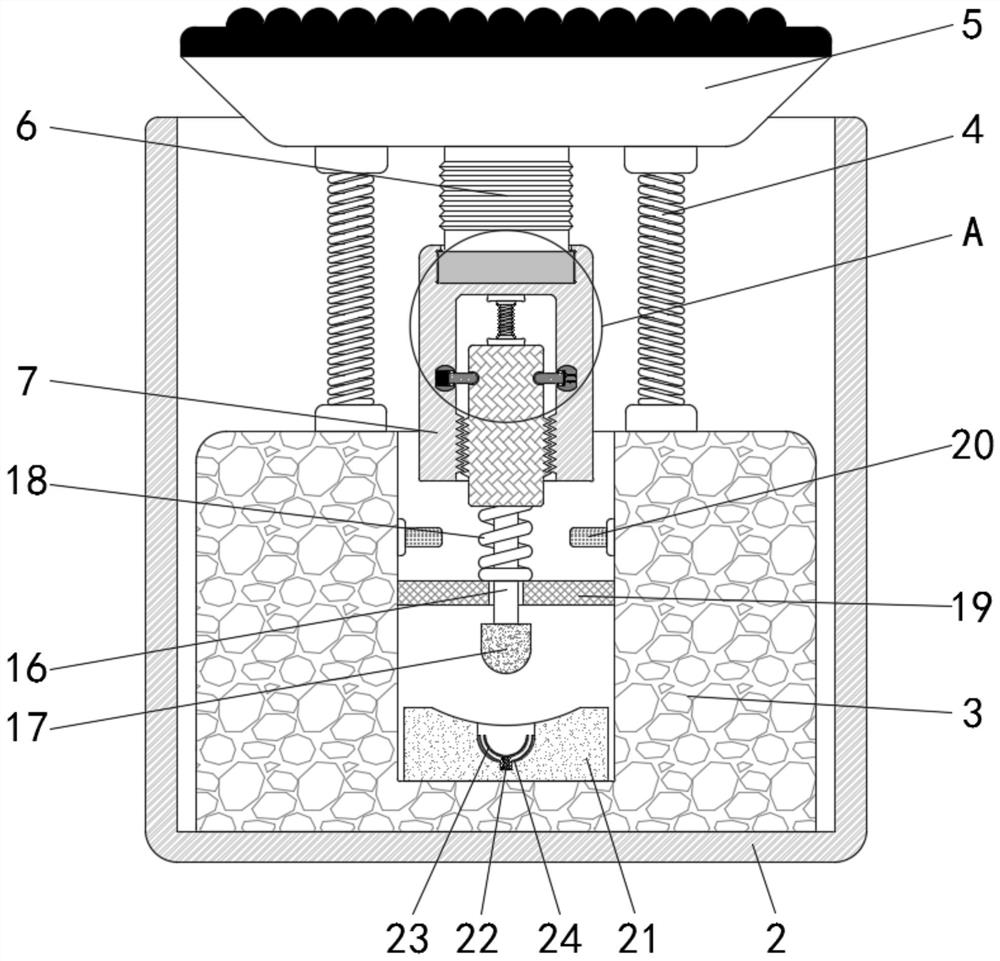

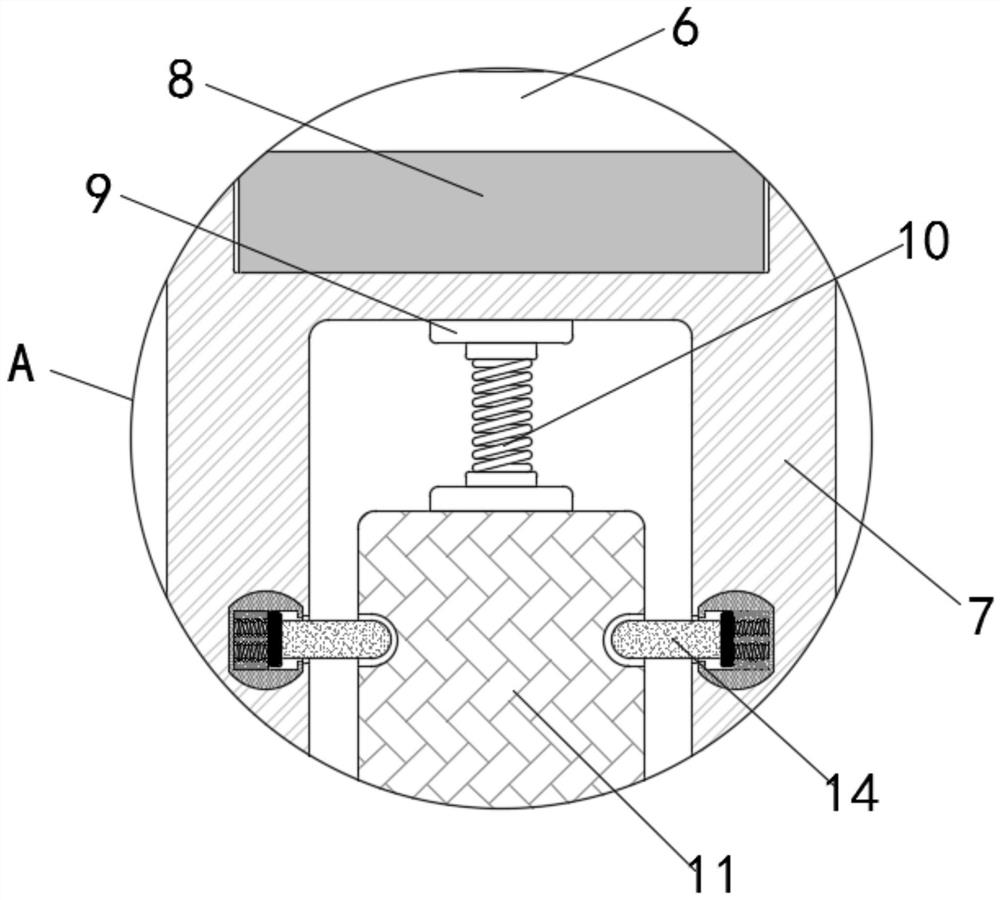

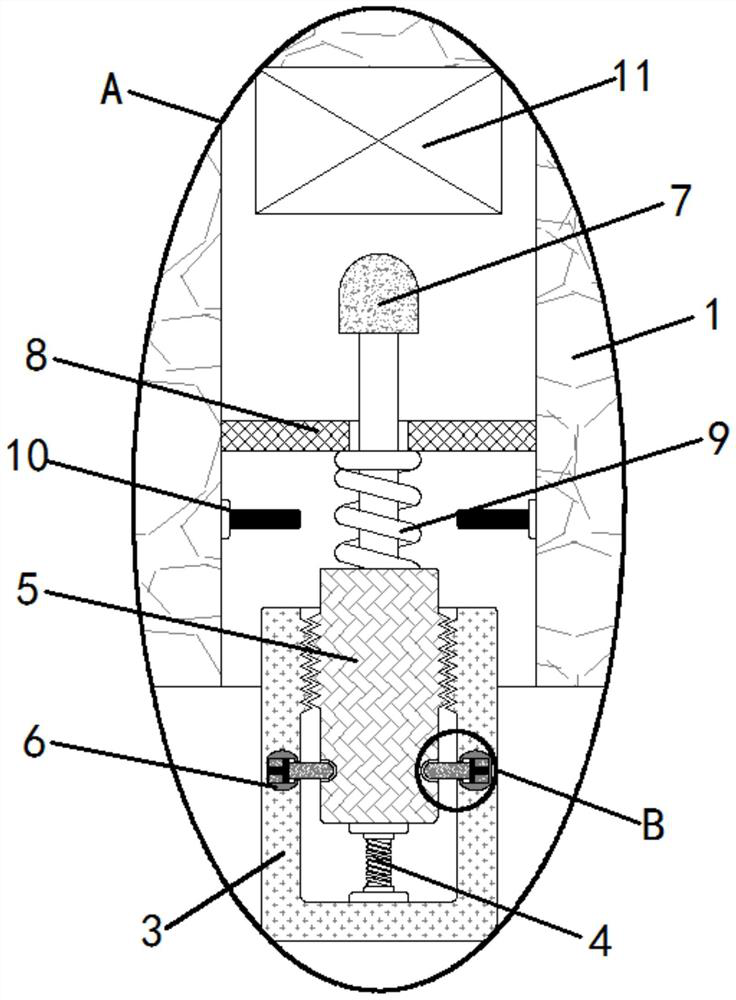

Intelligent manufacturing household lamplight automatic control device based on gravity induction

InactiveCN112413549AAvoid wastingConvenient lightingElectric circuit arrangementsAutomatic controlEngineering

The invention provides an intelligent manufacturing household lamplight automatic control device based on gravity induction. The device comprises a shell, a shell is fixedly installed on the inner wall of the shell, a fixed block is fixedly installed at the bottom of the inner wall of the shell, a support spring is fixedly installed on the upper side of the fixed block, a bearing plate is fixedlyinstalled at the upper end of the support spring, and a connecting piece is fixedly mounted on the lower side of the bearing plate. According to the intelligent manufacturing household lamplight automatic control device based on gravity induction, when a person stands on the bearing plate and stays, a movable part is driven to move downwards, the movable part abuts against a clamping groove through a centrifugal clamping piece so as to drive the movable block to move synchronously, the movable block is in contact with a first induction piece in a induction part through a induction piece, the first induction sheet and a second induction sheet are promoted to be in contact to generate an electric signal, so that a illuminating lamp on a wall main body emits light for illumination, better andmore targeted illumination is achieved, and energy waste is effectively avoided.

Owner:义乌文梦电子商务有限责任公司

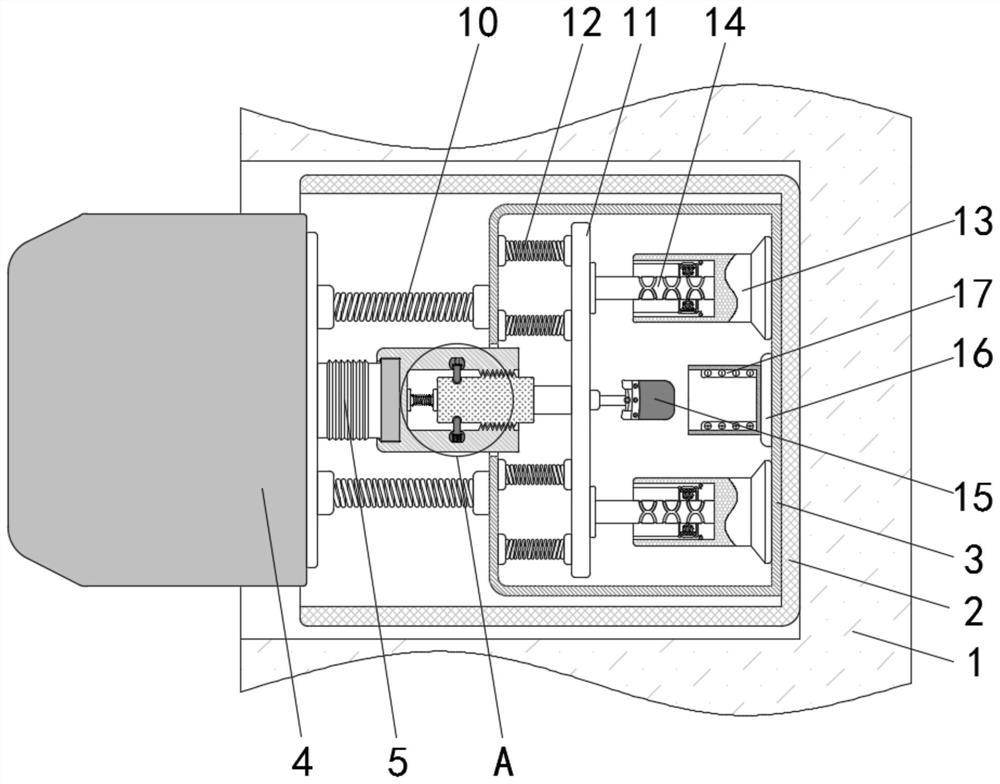

File management cabinet for effectively avoiding mistaken opening for enterprise management

InactiveCN112914279APrevent accidental openingPrevent openingBook cabinetsContact operating partsBusiness enterpriseControl switch

The invention provides a file management cabinet for effectively avoiding mistaken opening for enterprise management. The file management cabinet comprises a main body, a shell is arranged on the inner wall of the main body, a shell body is arranged on the inner wall of the shell, a control switch is arranged in the shell body, a buffer part is arranged on the right side of the control switch, and a first movable block is movably mounted on the right side of the buffer part. According to the file management cabinet capable of effectively avoiding mistaken opening for enterprise management, in the using process, when people accidentally touch a control switch, pushing force is generated on the control switch, so that a first movable block generates rapid pressure, and the first movable block and a second movable block are promoted to rotate rapidly in an engaged mode, so the effect of releasing pushing force of the control switch is achieved. Therefore, the situation that people unintentionally touch the control switch to open the storage cabinet is effectively avoided, the situation that people open the storage cabinet by mistake, and consequently, internal files are missing is effectively prevented, and the practicability of the file management cabinet is improved.

Owner:广州迈荣贸易有限公司

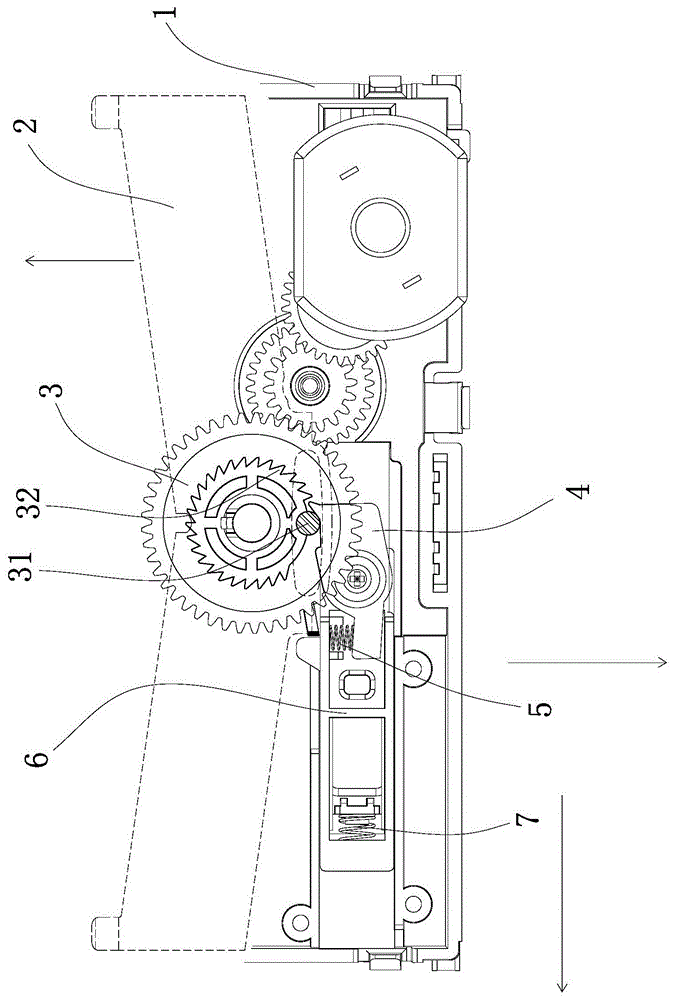

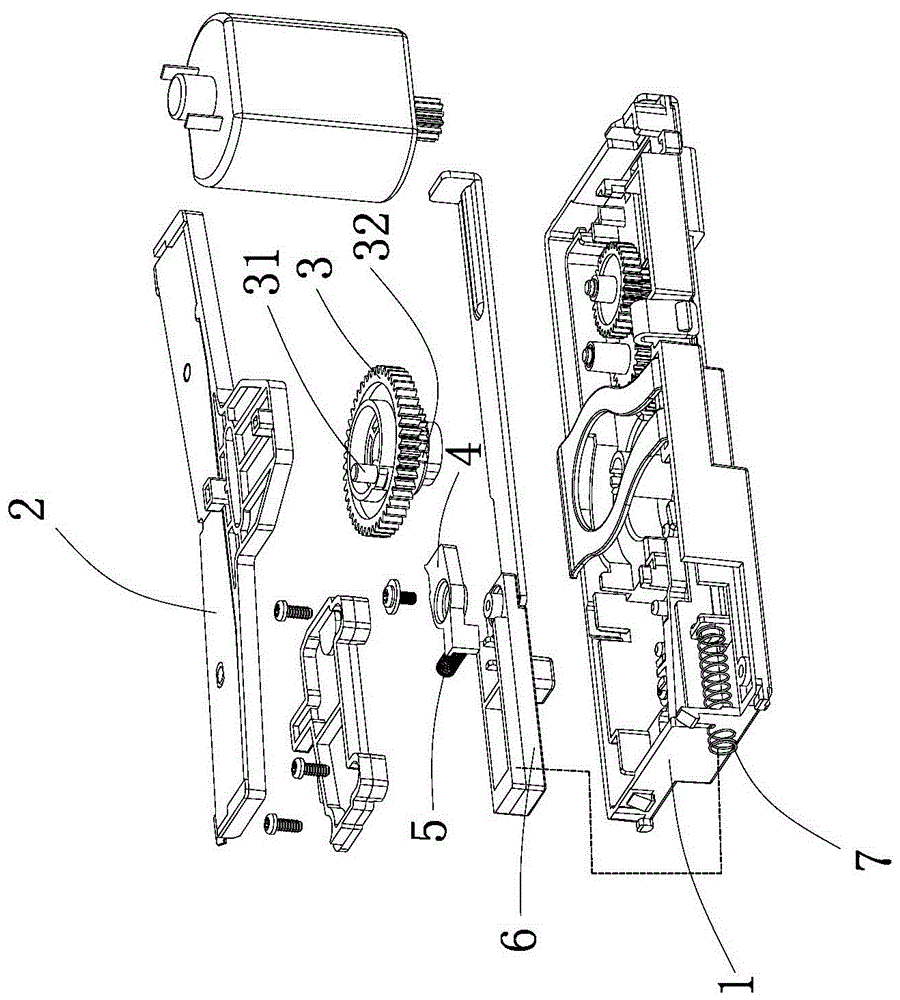

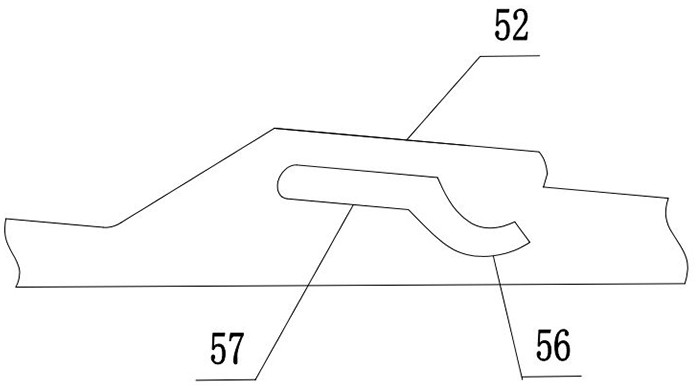

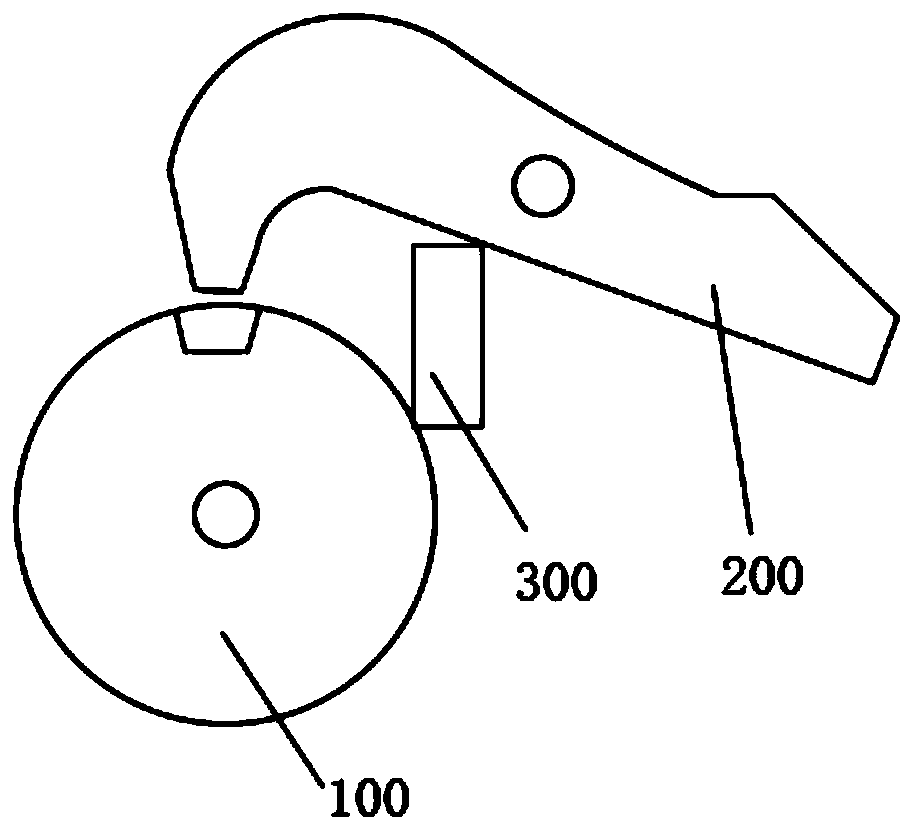

Stuck eliminating structure of thermal printer with cutter

The invention relates to a stuck eliminating structure of a thermal printer with a cutter, the structure comprises a cutter gear, a cutter reset ratchet, a retract pawl and a retract pull rod which can move relative to the cutter gear, the cutter reset ratchet is coaxially connected with the cutter gear, the retract pawl is connected with the retract pull rod, the retract pull rod and the retract pawl are connected with a reset device, and the retract pawl is engaged with the cutter reset ratchet under the function of the retract pull rod. According to the invention, the retract pull rod is driven by outside force, the retract pawl is driven by the retract pull rod, so that the retract pawl is engaged with the cutter reset ratchet and pushes the cutter reset ratchet to rotate in reverse direction, then the cutter gear coaxially connected with the cutter reset ratchet is driven to realize retract action, when the driving force disappears, the retract pull rod turns back to an initial position under the function of the reset device, the retract pawl turns back to the initial position under the function of the reset device and the retract pull rod, and fast feed-retract switching of a moving cutter group is realized.

Owner:XIAMEN PINNACLE ELECTRICAL +1

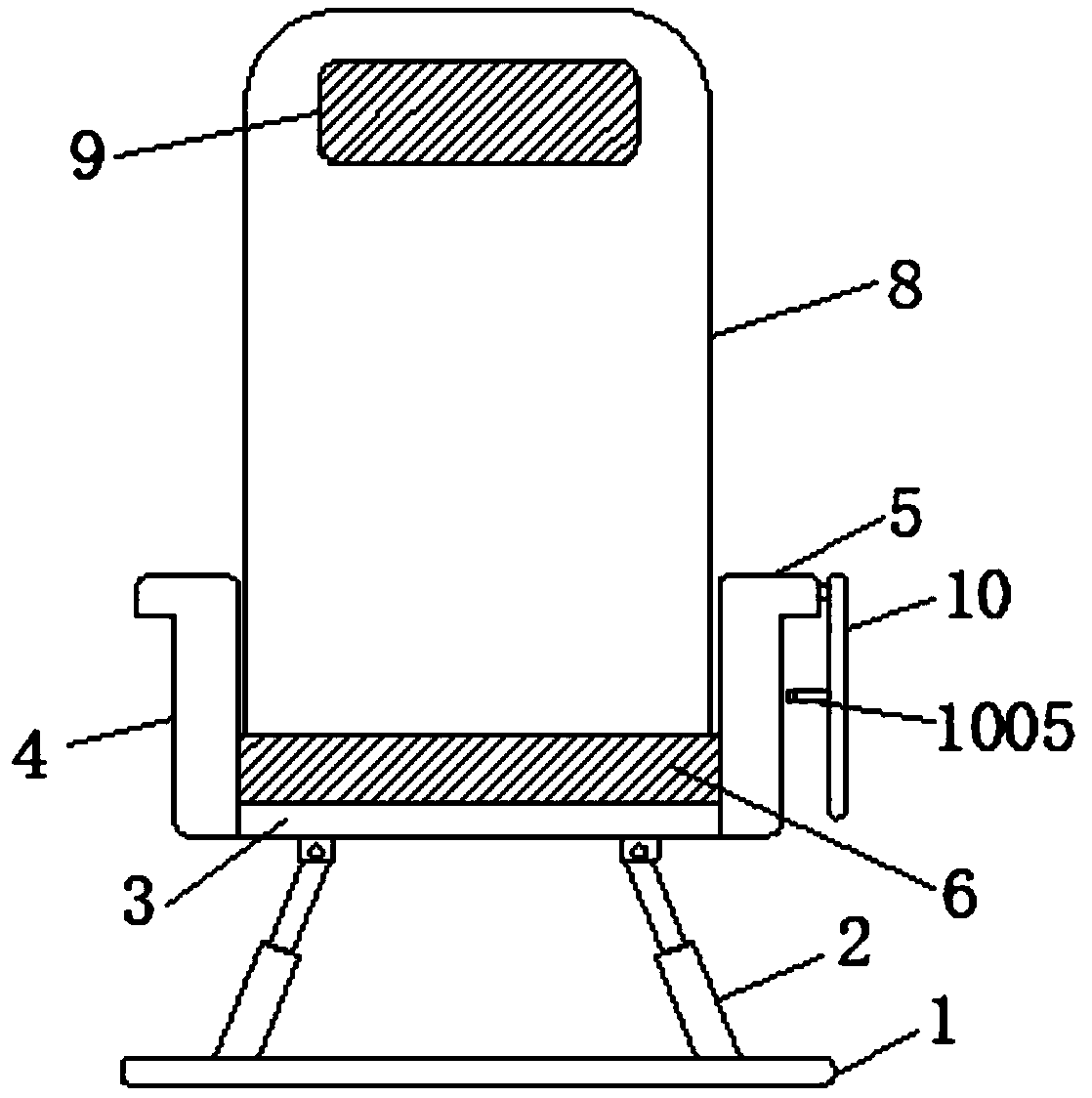

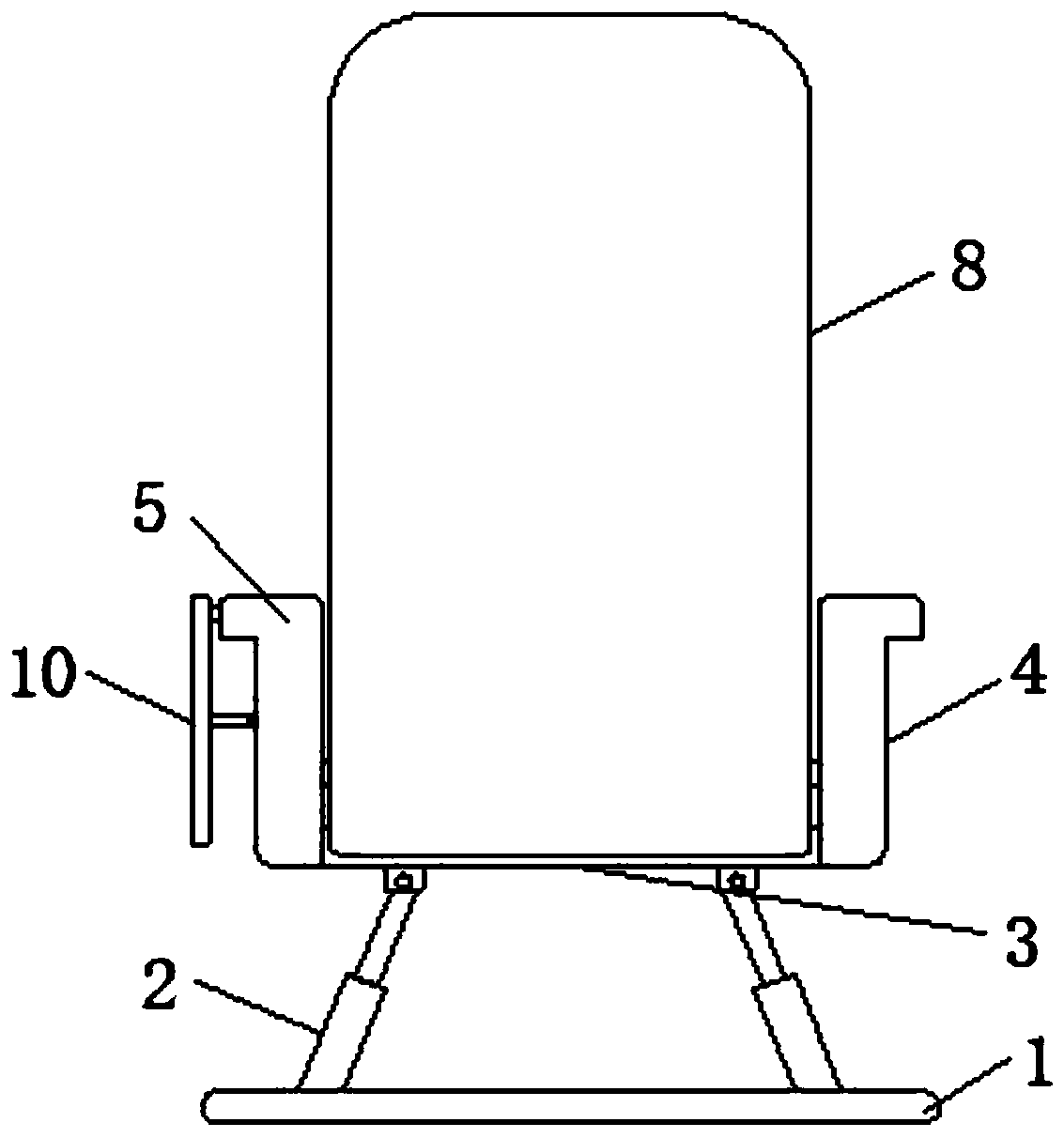

An adjusting device for an aircraft lumen adjusting chair

The invention discloses an adjusting device for an aircraft lumen adjusting chair, Including mounting base, A shock absorbing cylinder is fixedly installed on the front side and the rear side of the mounting base top, A seat bottom plate is fixedly installed between the tops of the shock absorbing barrels, a first shield plate and a second shield plate are fixedly installed on both sides of the seat bottom plate, a main rotating shaft is movably connected between the rear sides of the first shield plate and the second shield plate, a backrest is fixedly connected in the middle of the main rotating shaft, and a placing plate is arranged on one side of the second shield plate. Through the shock absorber, main shaft, an arc block, a first sector block, The rotating plate, the second sector block, the sliding chucking slot, the moving plate, the pushing plate, the chucking teeth and the gear are arranged, so that the seat can effectively cushion the bumps generated by the aircraft, and theseat can be conveniently adjusted so that the passengers can rotate at different angles according to their personal needs, so that the seat of the aircraft can make passengers feel more comfortable when riding.

Owner:晨龙飞机(荆门)有限公司

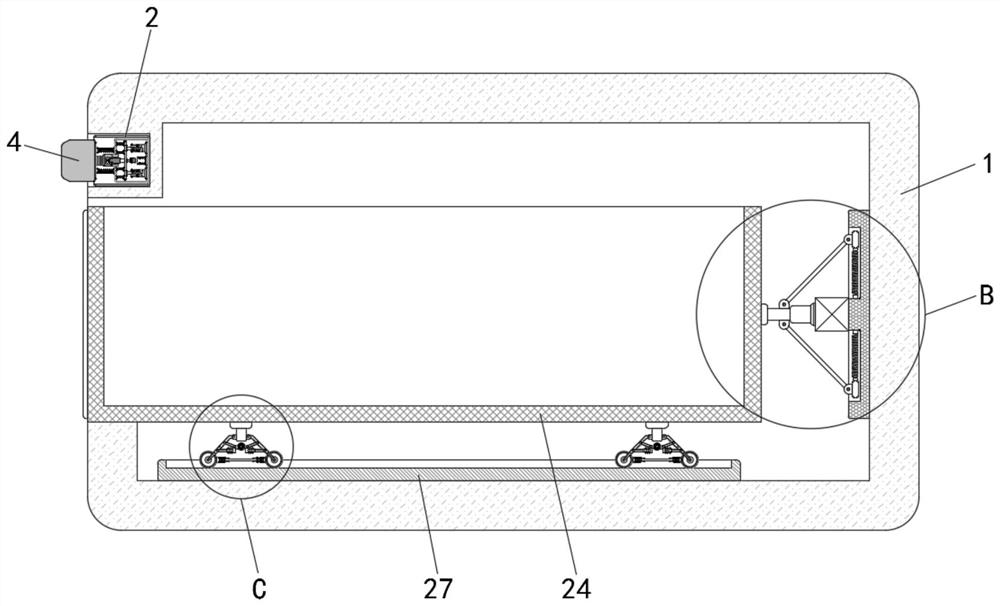

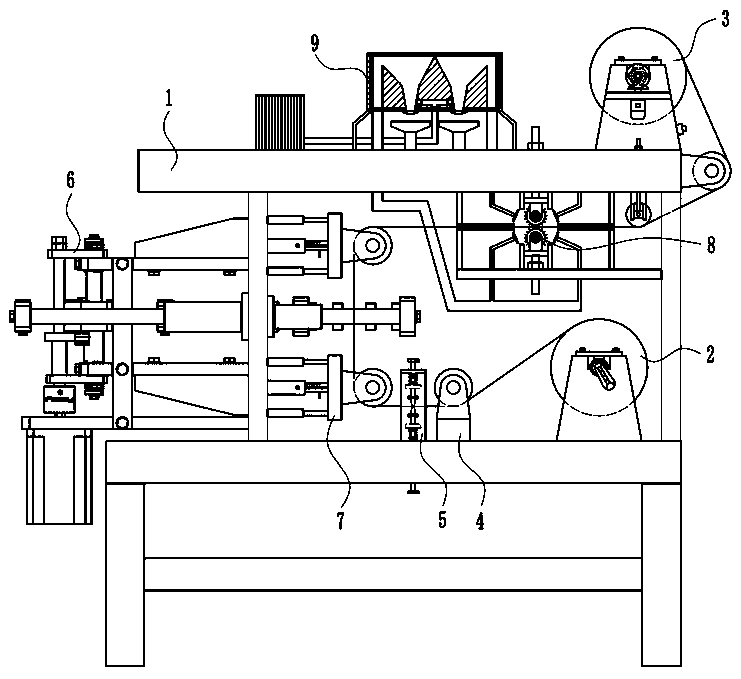

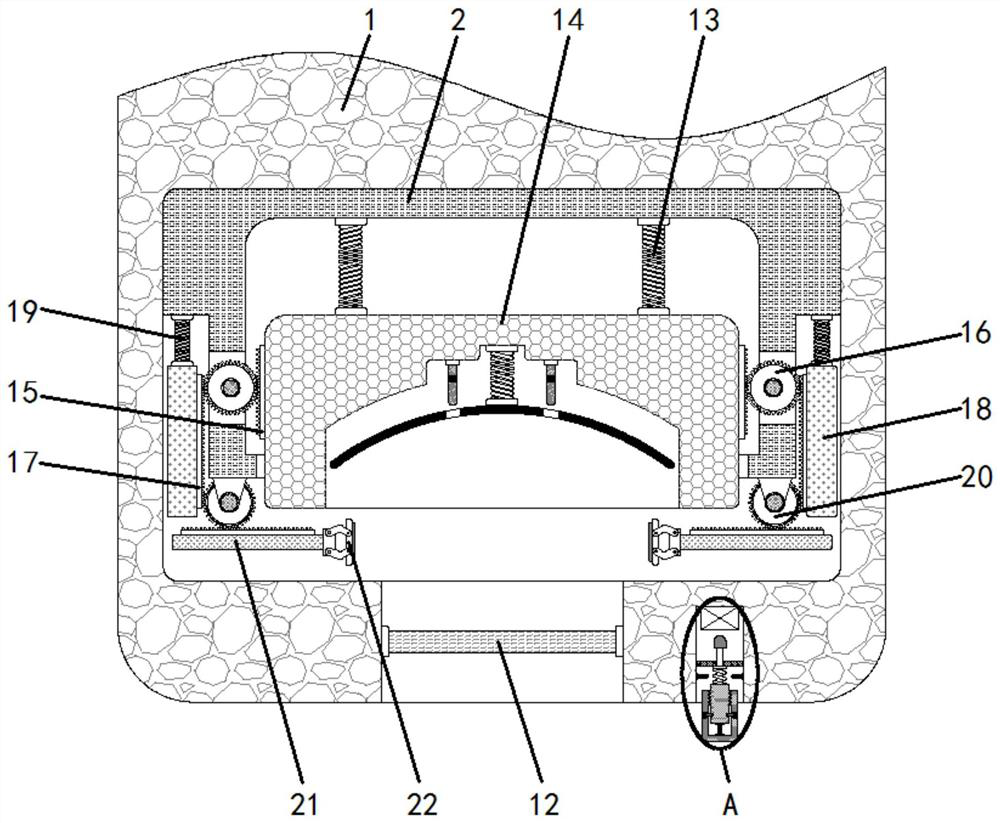

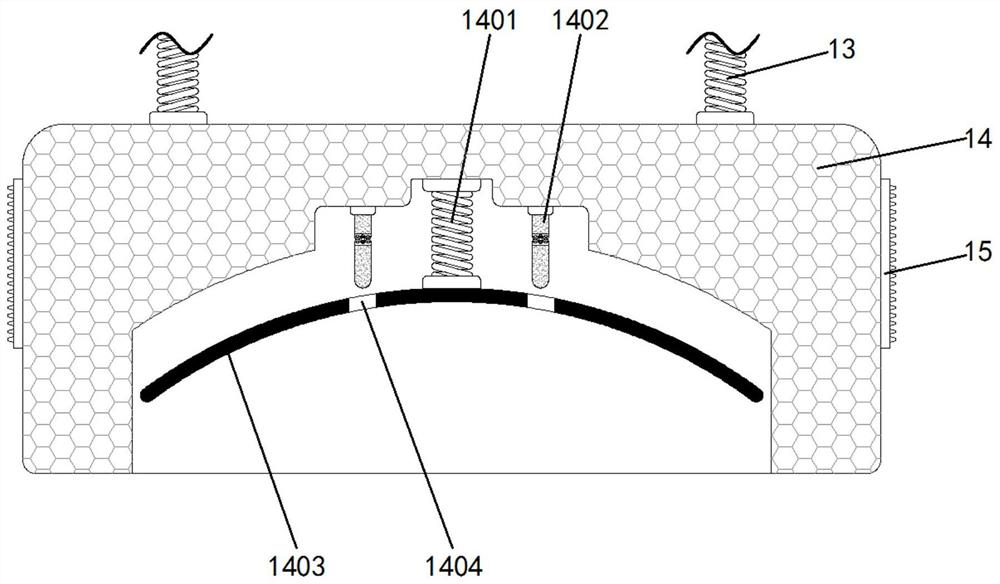

Test equipment for fabric fuzzing and pilling

InactiveCN111441163ASatisfy the pursuitImprove test efficiencyInspecting textilesStructural engineeringTest equipment

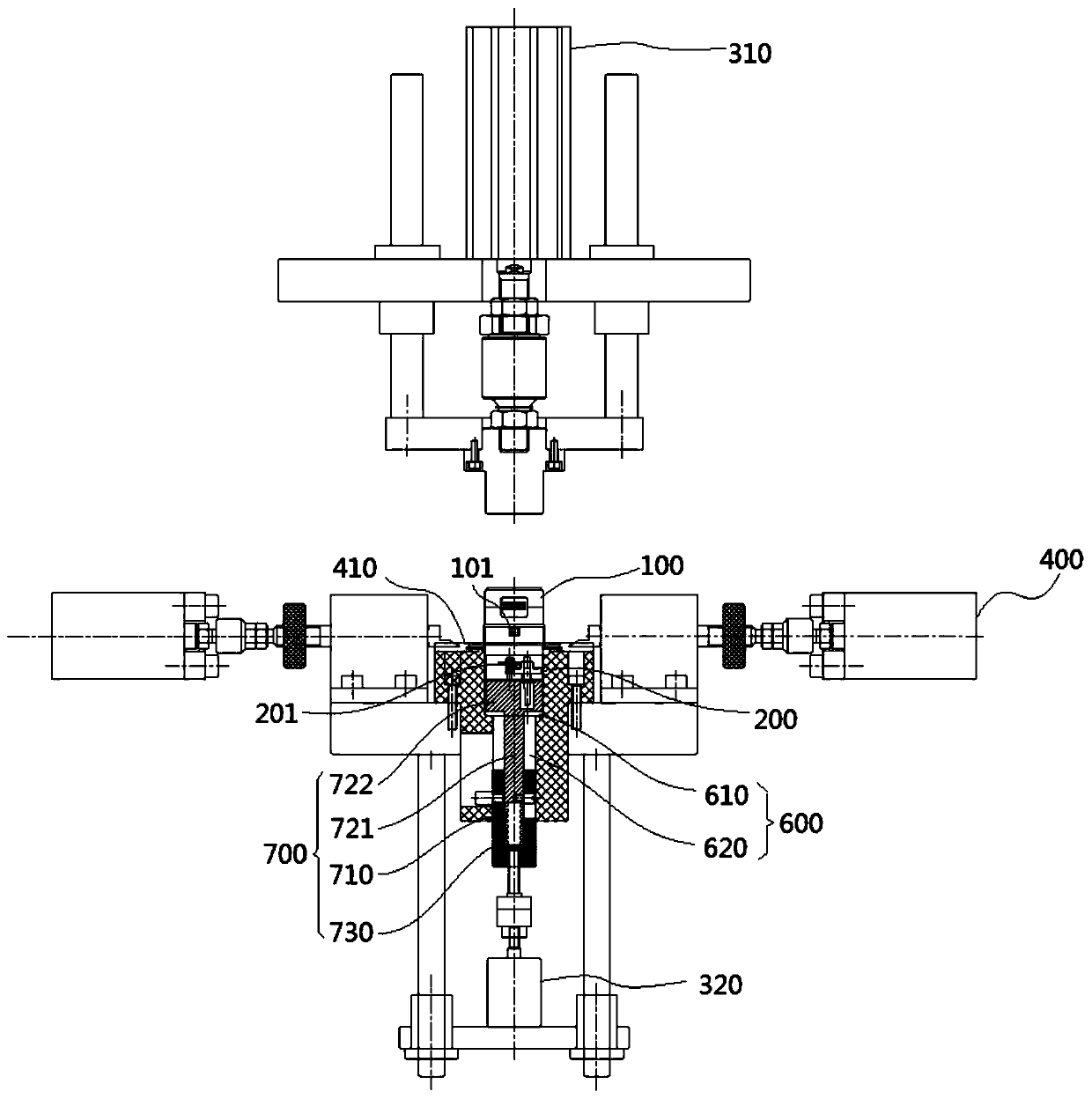

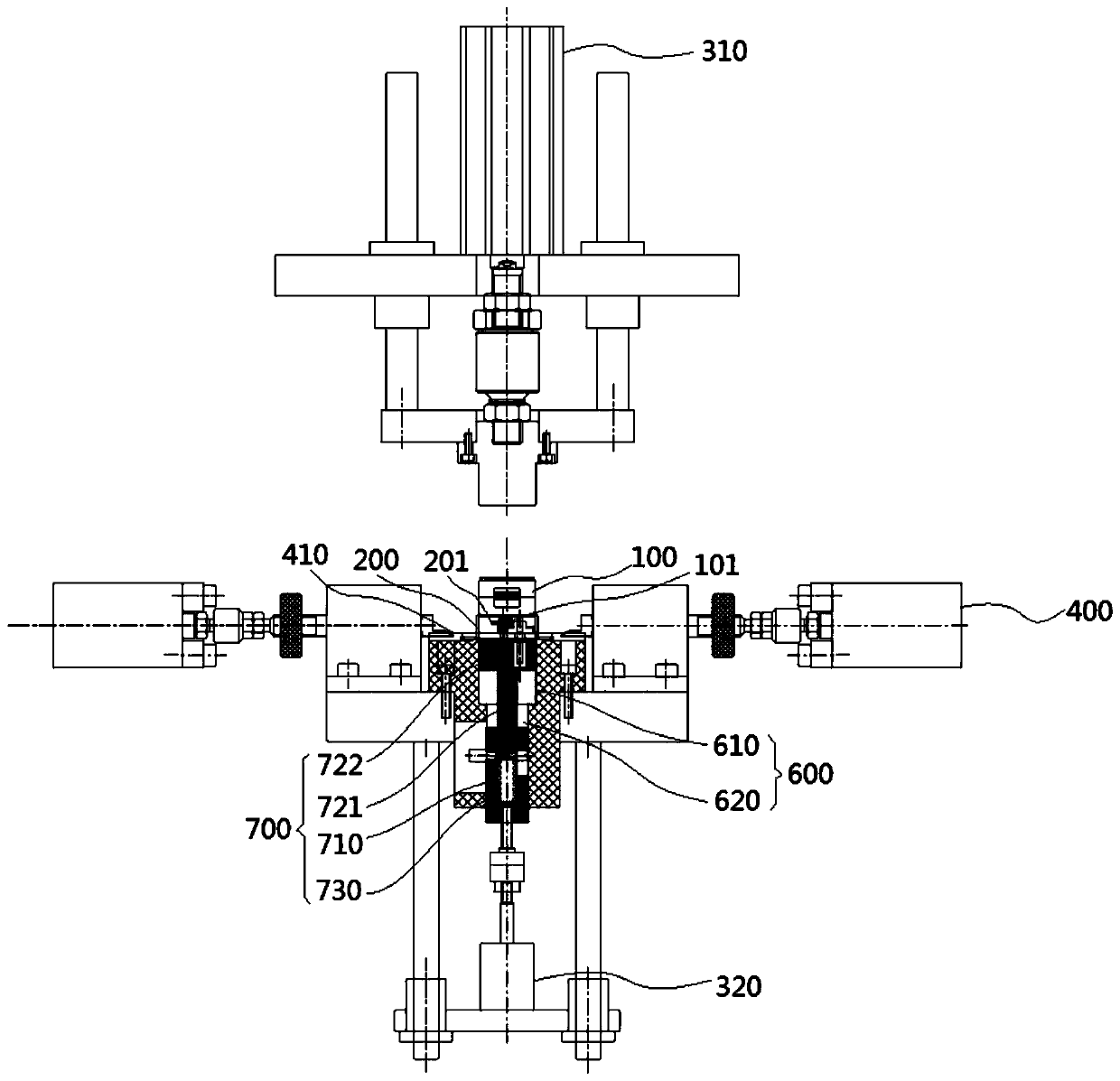

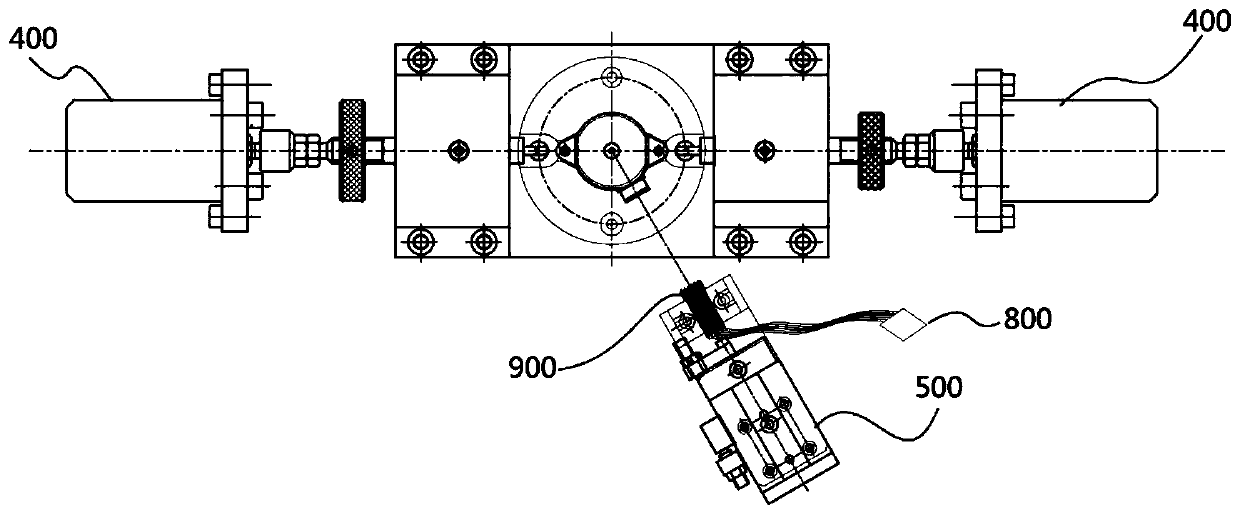

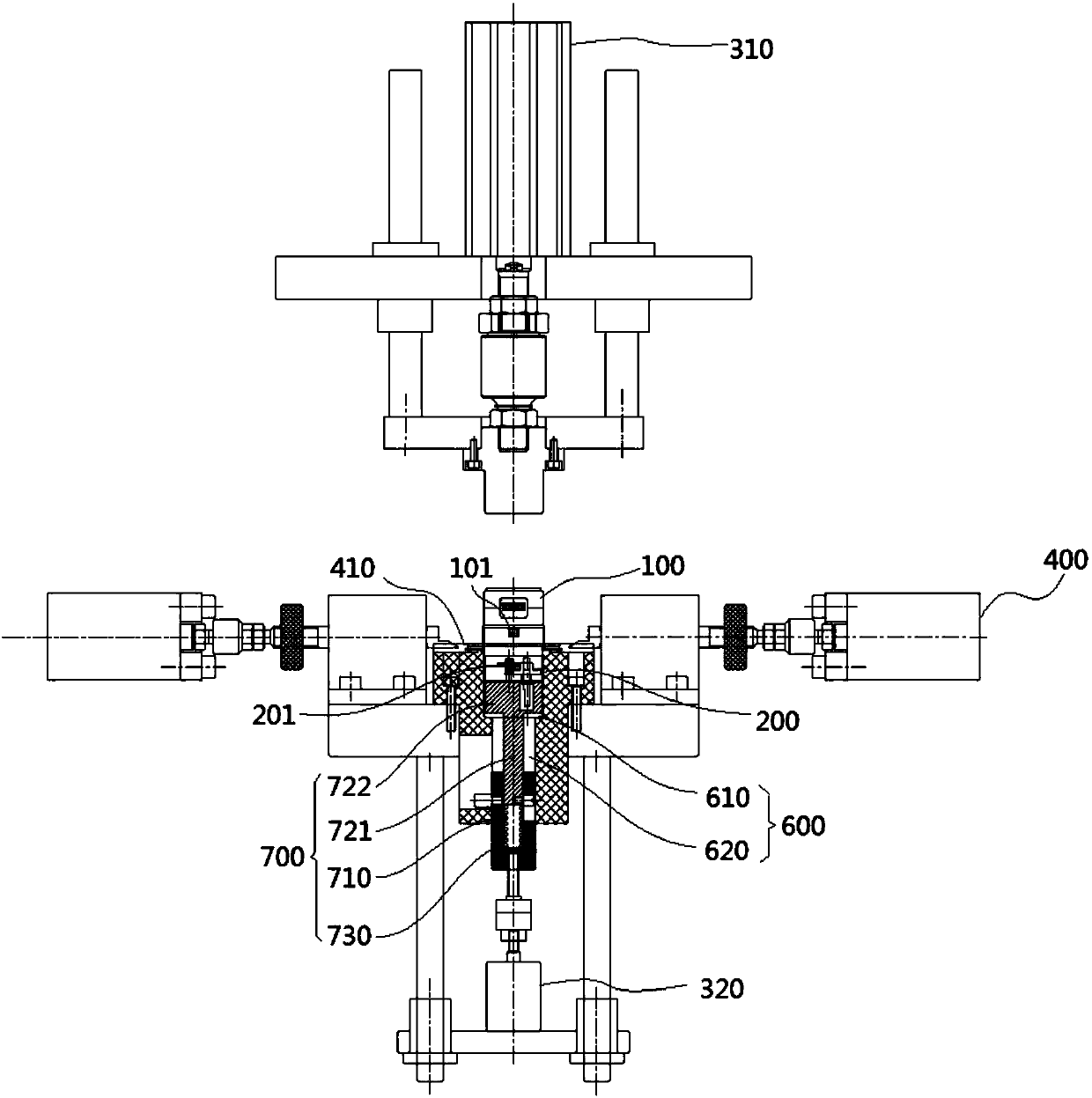

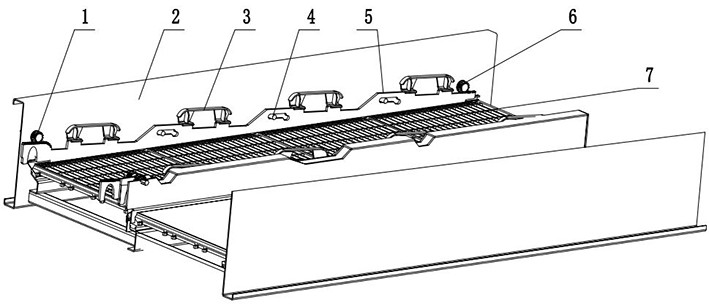

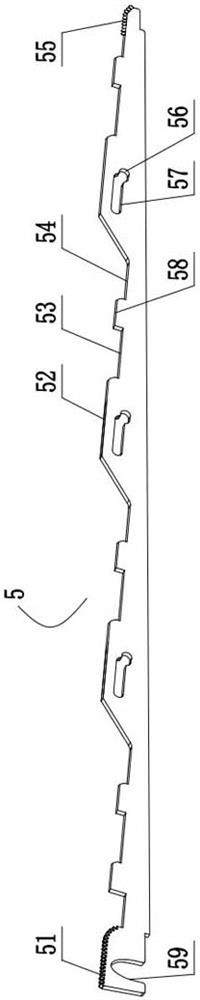

The invention provides test equipment for fabric fuzzing and pilling and belongs to the technical field of textile machinery. The test equipment comprises a rack device, a fabric unwinding device, a fabric winding device, a guide device, an electrostatic generator, a double-side fuzzing and pilling device, a perpendicularity adjusting device, a fuzz ball scraping device and a fuzz ball conveying and weighing device, wherein the double-side fuzzing and pilling device comprises a sliding double-side fuzzing and pilling mechanism and a double-side fuzzing and pilling drive mechanism; the fuzz ball scraping device comprises an upper fuzz ball scraping mechanism, a lower fuzz ball scraping mechanism and a fabric guide mechanism; and the fuzz ball conveying and weighing device comprises a firstfuzz ball conveying mechanism, a second fuzz ball conveying mechanism and a weighing mechanism. The test equipment can achieve synchronous fuzzing and pilling testing on double sides of a textile fabric, is high in testing efficiency, and achieves weighing of fuzz balls on the double sides of the textile fabric, so that quantitative evaluation is achieved, and the fabric fuzzing and pilling testing accuracy is greatly improved.

Owner:全彬强

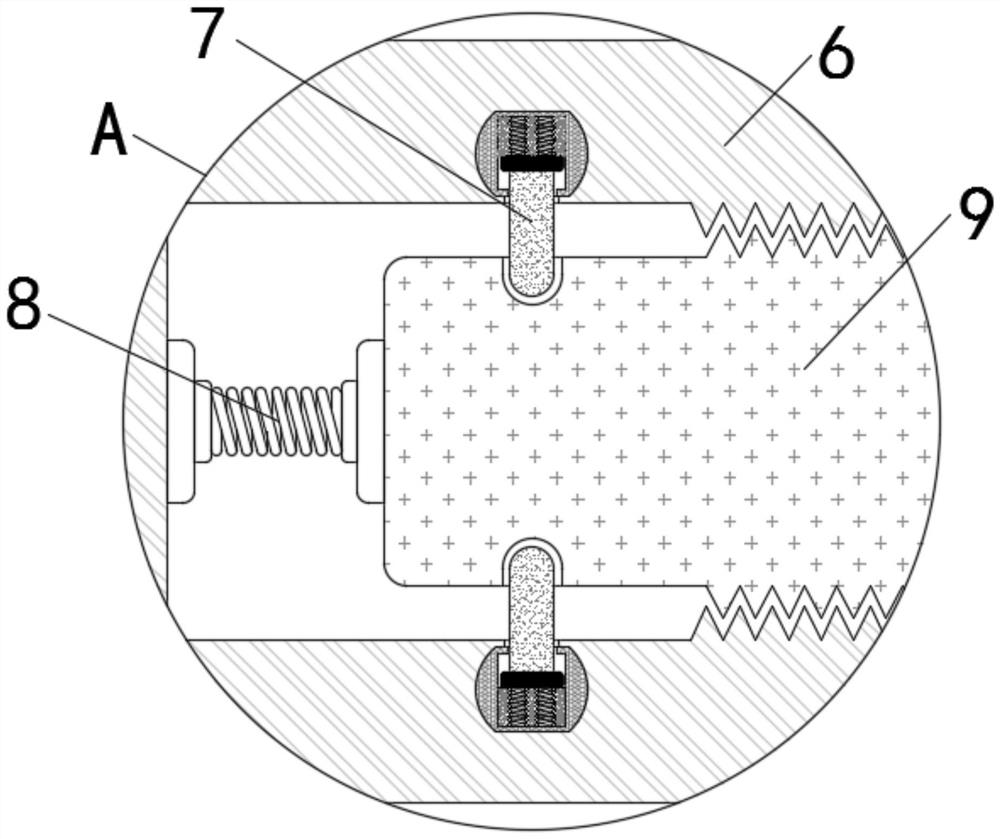

Efficient fixing mechanism for preventing network cable plug from falling off for computer

InactiveCN112234387AEffectively fixedAchieve interlinkageNetwork connectorsCouplings bases/casesSimulationNetwork data

The invention provides an efficient fixing mechanism for preventing a network cable plug from falling off for a computer. The mechanism comprises a main body, the interior of the main body is providedwith a fixed part, the lower side of the main body is movably provided with a control button, the bottom of the inner wall of the control button is movably provided with a pressure spring, and the upper end of the pressure spring is fixedly provided with a movable part. And an induction piece is fixedly installed at the upper end of the movable part, and an installation plate is fixedly installedon the inner wall of the main body. According to the efficient fixing mechanism for preventing the network cable plug from falling off for the computer, the computer network cable plug is inserted inwards, the computer network cable plug is promoted to make contact with the induction piece, meanwhile, the data piece penetrates through a positioning hole to make contact with the computer network cable plug, and therefore communication of network data is achieved; and the computer network cable plug is firmly clamped by the clamping mechanism and does not fall off so that the normal use of a computer network is ensured, setting is firmly fixed, use is convenient, and Internet surfing quality is ensured.

Owner:广州单凌舫科技有限公司

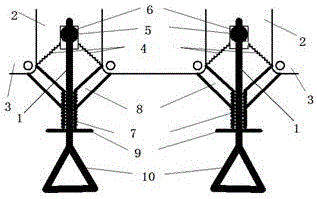

Device for driving ropes in tall building circulating escape device

ActiveCN105709343AReduce the kinetic energy of the ropeShort escape timeBuilding rescueDrive motorBlanket

The invention discloses a device for driving ropes in a tall building circulating escape device. The device is characterized in that rope rotating shafts are fixed inside the circulating escape device; ropes for escape are fixed to the rope rotating shafts of the circulating escape device; mounting grooves are formed in the circulating escape device right below the rope rotating shafts; spring type supporting pieces I are mounted in the mounting grooves and are fixed; the tops of the spring type supporting pieces I are fixed on the bottom sides of the rope rotating shafts; the rope rotating shafts are connected with a driving motor through speed reducers; rope guide openings are formed in the bottom of the circulating escape device; the ropes are guided out of the rope guide openings; spring type or hydraulic type support rods are symmetrically arranged on the two sides of each guide opening; the tail parts of the spring type support rods are hinged to the two sides of each guide opening respectively; rubber blankets are arranged at the end parts of the spring type support rods; the end parts of the spring type support rods tightly fit the side walls of the rubber blankets; the rubber blankets sleeve the ropes; and circular knots are arranged at the tail parts of the ropes at interval. The device is simple in structure, convenient to manufacture, and high in practicability.

Owner:GUIZHOU UNIV

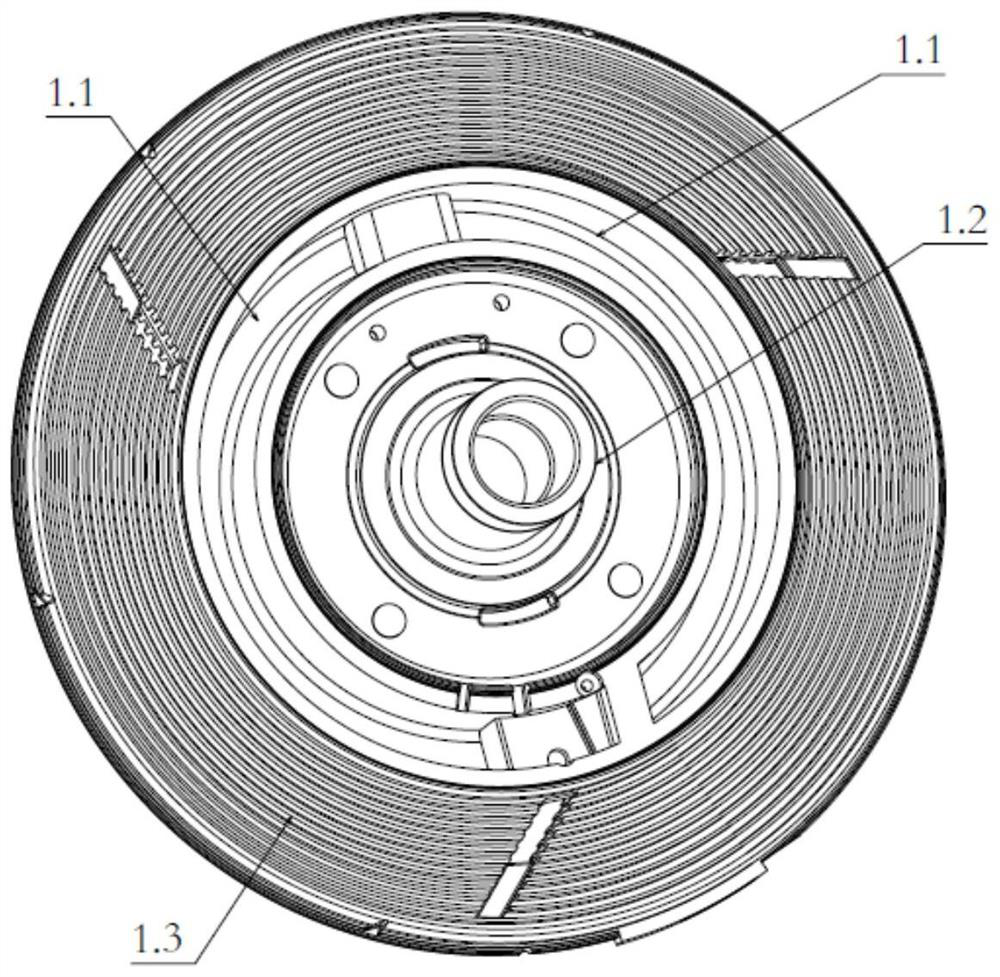

Electronic control silicone oil clutch driving disc and clutch

PendingCN113958625AAvoid stress concentrationAvoid failureCoolant flow controlMachines/enginesEngineeringCentrifugal force

The invention relates to an electronic control silicone oil clutch driving disc and a clutch. An oil storage cavity, a working cavity, oil outlet holes and an oil return hole are formed in the driving disc, a two-way slope oil guide groove is formed between the oil storage cavity and the working cavity, and an oil guide groove opening in one end of the two-way slope oil guide groove is formed in the top of the oil storage cavity and communicates with the oil storage cavity; the other end of the two-way slope oil guide groove is arranged at an oil outlet hole and communicates with the oil outlet hole; and the two-way slope oil guide groove close to one end of the oil guide groove opening is narrow and deep, the two-way slope oil guide groove close to one end of the oil outlet hole is wide and shallow, and the whole two-way slope oil guide groove is in slope shape. According to the electronic control silicone oil clutch driving disc and the clutch, when the whole vehicle is static, no centrifugal force exists in the clutch, silicone oil is difficult to flow from a terminal of a low horizontal plane to the oil outlet hole of a high horizontal plane, and the amount of the silicone oil flowing into the working cavity is effectively reduced through the slope type design; and when the whole vehicle is in a working state, the slope type design plays a flow guide role due to the centrifugal force, the silicone oil is accelerated to flow out of the oil outlet holes, and the meshing time is shortened.

Owner:DONGFENG BEHR THERMAL SYST

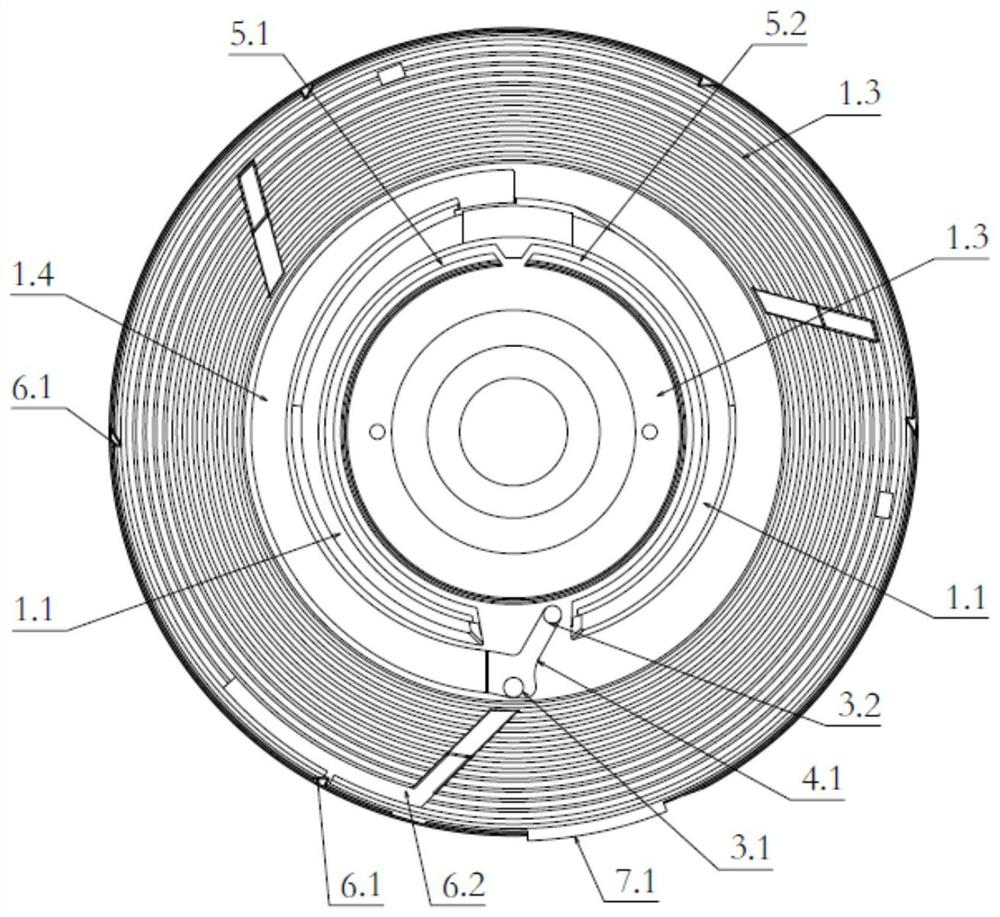

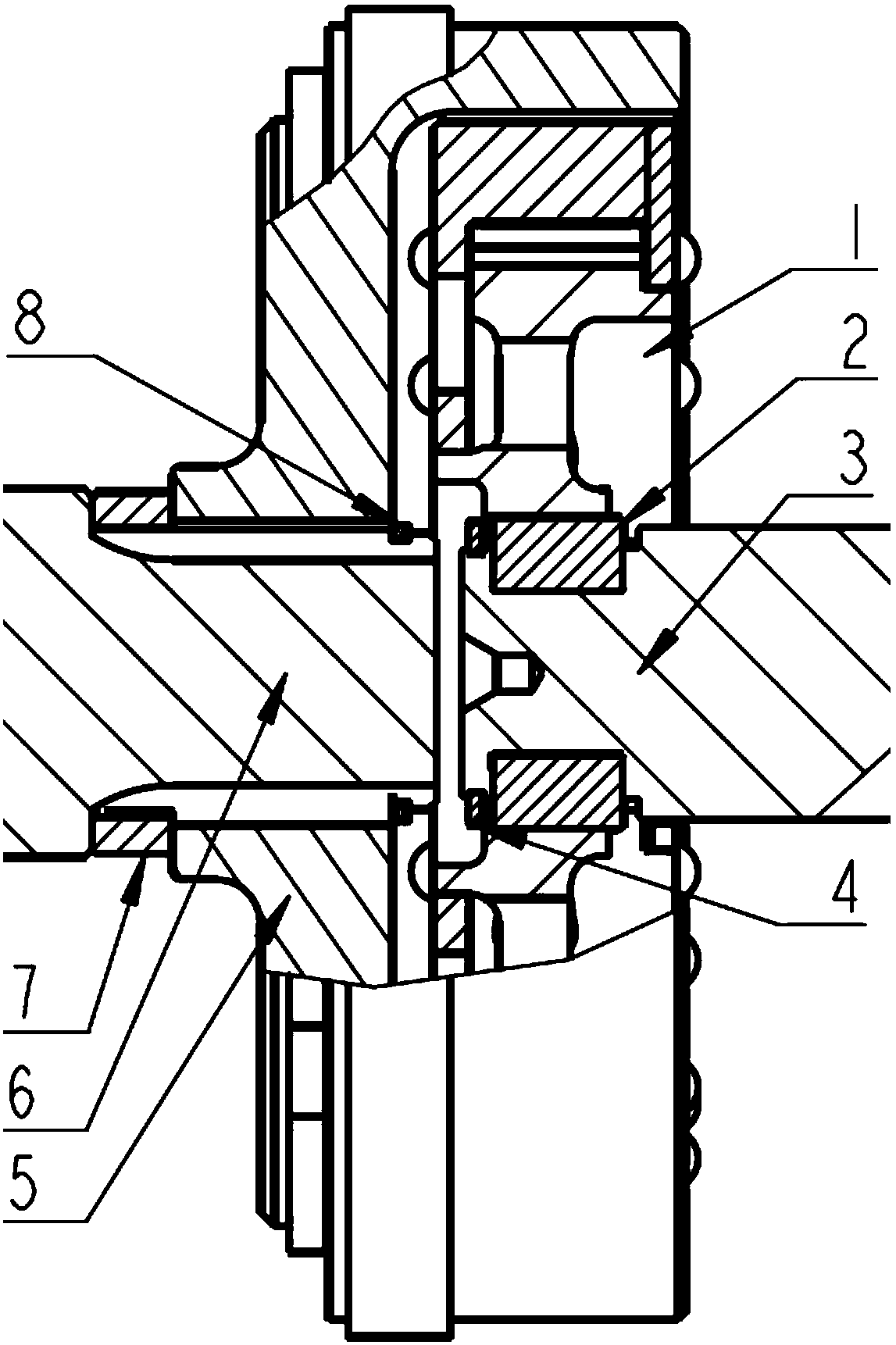

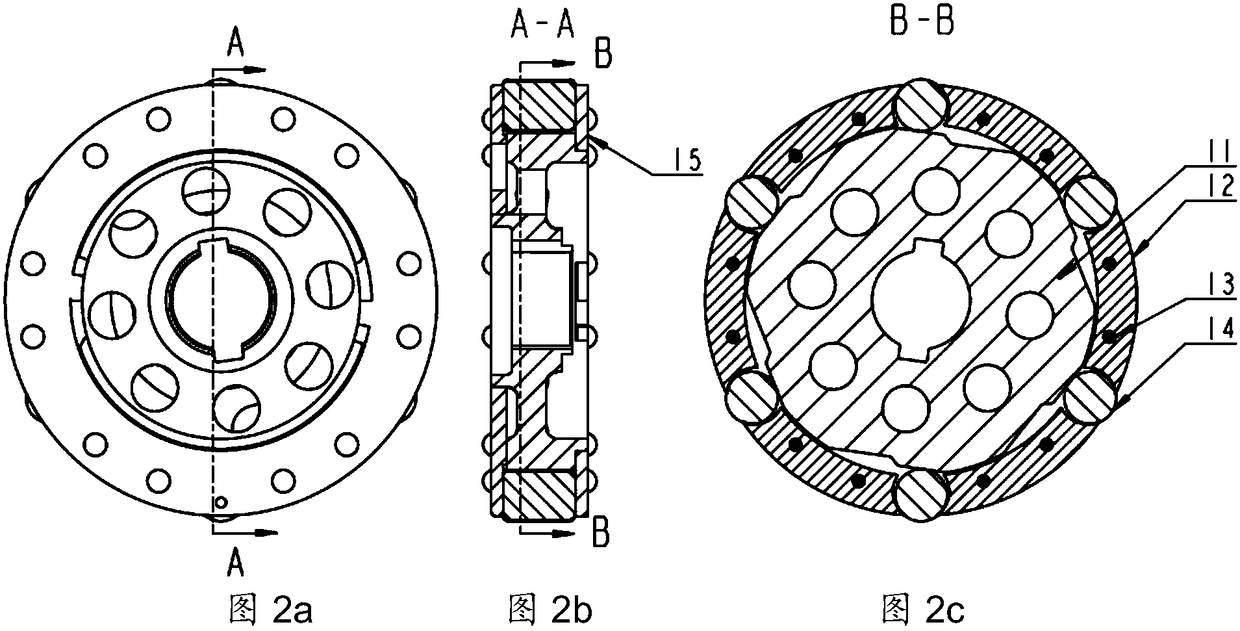

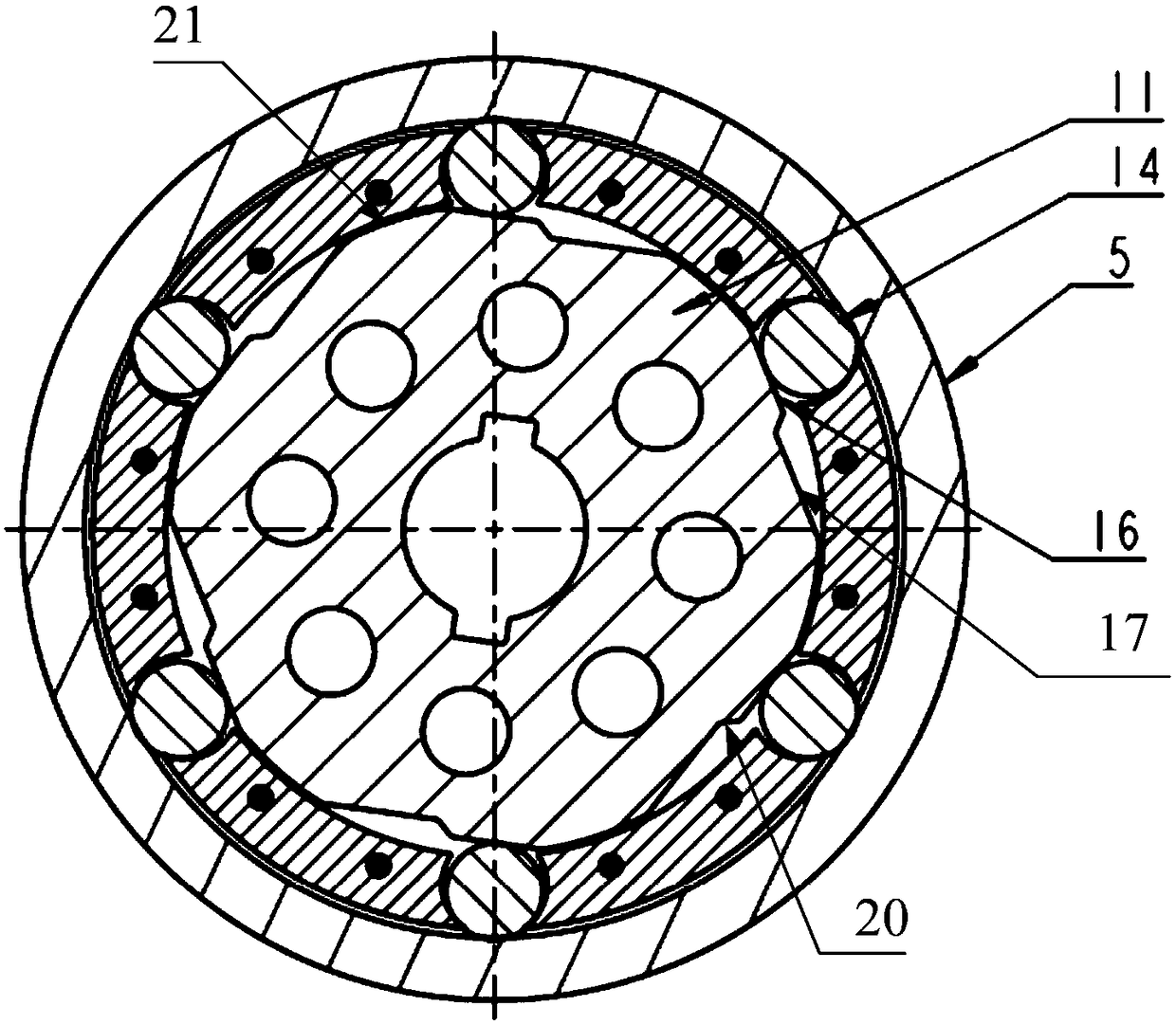

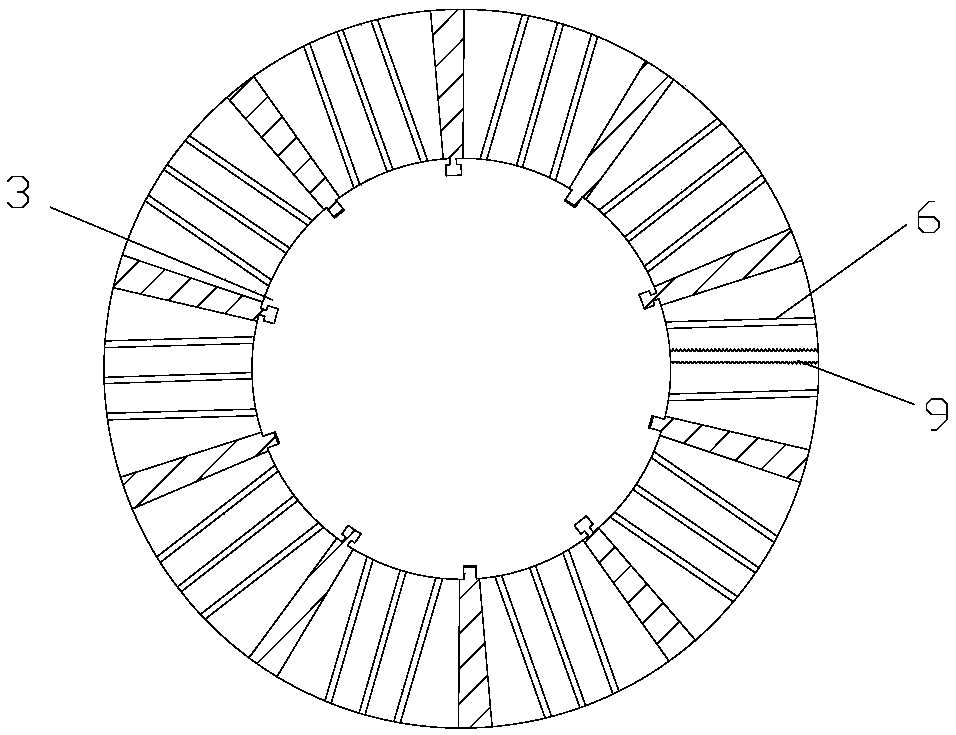

A Split Type Springless Overrunning Clutch

The invention provides a split type springless overrunning clutch which comprises a clutch body and a clutch cap, wherein the clutch body is mounted on a hydraulic motor shaft, and rotates synchronously along with the hydraulic motor shaft; the clutch cap is mounted on an electric motor shaft, and rotates synchronously along with the electric motor shaft; the cutch body comprises a cam, a backing ring and N rolling rods; the cam is located in the middle of the backing ring; the N rolling rods are located at the outer part of the cam, and are uniformly distributed along the edge of the backing ring; the cam adopts a circular structure; N working areas and N non-working areas are alternately distributed on the outer surface of the cam; the outer surface of each non-working area is matched with the inner surface of the edge of the backing ring; each working area comprises a meshing area and a separating area; the meshing areas are connected with the separating areas through transition slopes; the rolling rods are in contact with the meshing areas to realize meshing between the clutch body and the clutch cap; and the rolling rods are in contact with the separating areas to realize separation. Meshing and separating are realized by means of the inertia of the rolling rods and relative movement between the cam and the rolling rods, and the split type springless overrunning clutch is simple in structure, high in reliability, and convenient to disassemble, assemble and use.

Owner:BEIJING RES INST OF PRECISE MECHATRONICS CONTROLS +1

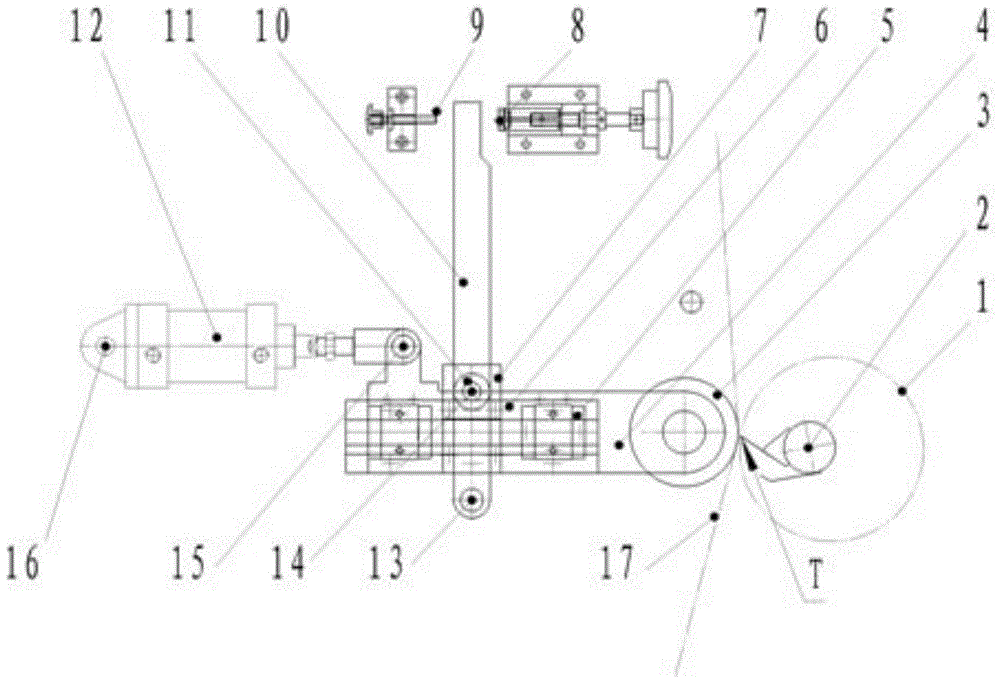

Method and device for assembling gear motor, and gear motor

ActiveCN108054881BGuaranteed assembly qualityReduce collision timeManufacturing dynamo-electric machinesGear wheelEngineering

The invention discloses a method and device for assembling a gear motor and a gear motor. The method and the device are used for assembling the driving gear and the driven gear of the gear motor. Themethod comprises the following steps that: the driving gear is made to rotate; and the driven gear and the driving gear are made to approach to each other along an axial direction, so that the gear teeth of the driven gear are plugged into the tooth slots of the rotating driving gear, and therefore, the full engagement of the driving gear with the driven gear can be realized. With the method and device of the present invention adopted, damage caused collision between the driving gear and the driven gear can be alleviated, gear damage caused during the assembly process of the gear motor, especially the assembly process of the driving gear and the driven gear can be greatly reduced, and the assembly quality of the gear motor can be ensured.

Owner:NIDEC COPAL ELECTRONICS (ZHEJIANG) CO LTD

Method and apparatus for assembling gear motor and gear motor

ActiveCN108054881AGuaranteed assembly qualityReduce collision timeManufacturing dynamo-electric machinesGear wheelGear tooth

The invention discloses a method and device for assembling a gear motor and a gear motor. The method and the device are used for assembling the driving gear and the driven gear of the gear motor. Themethod comprises the following steps that: the driving gear is made to rotate; and the driven gear and the driving gear are made to approach to each other along an axial direction, so that the gear teeth of the driven gear are plugged into the tooth slots of the rotating driving gear, and therefore, the full engagement of the driving gear with the driven gear can be realized. With the method and device of the present invention adopted, damage caused collision between the driving gear and the driven gear can be alleviated, gear damage caused during the assembly process of the gear motor, especially the assembly process of the driving gear and the driven gear can be greatly reduced, and the assembly quality of the gear motor can be ensured.

Owner:NIDEC COPAL ELECTRONICS (ZHEJIANG) CO LTD

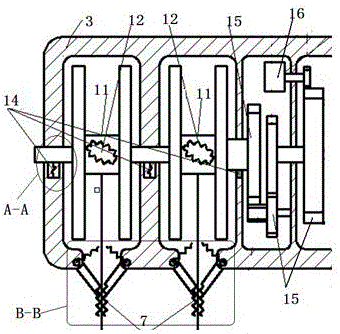

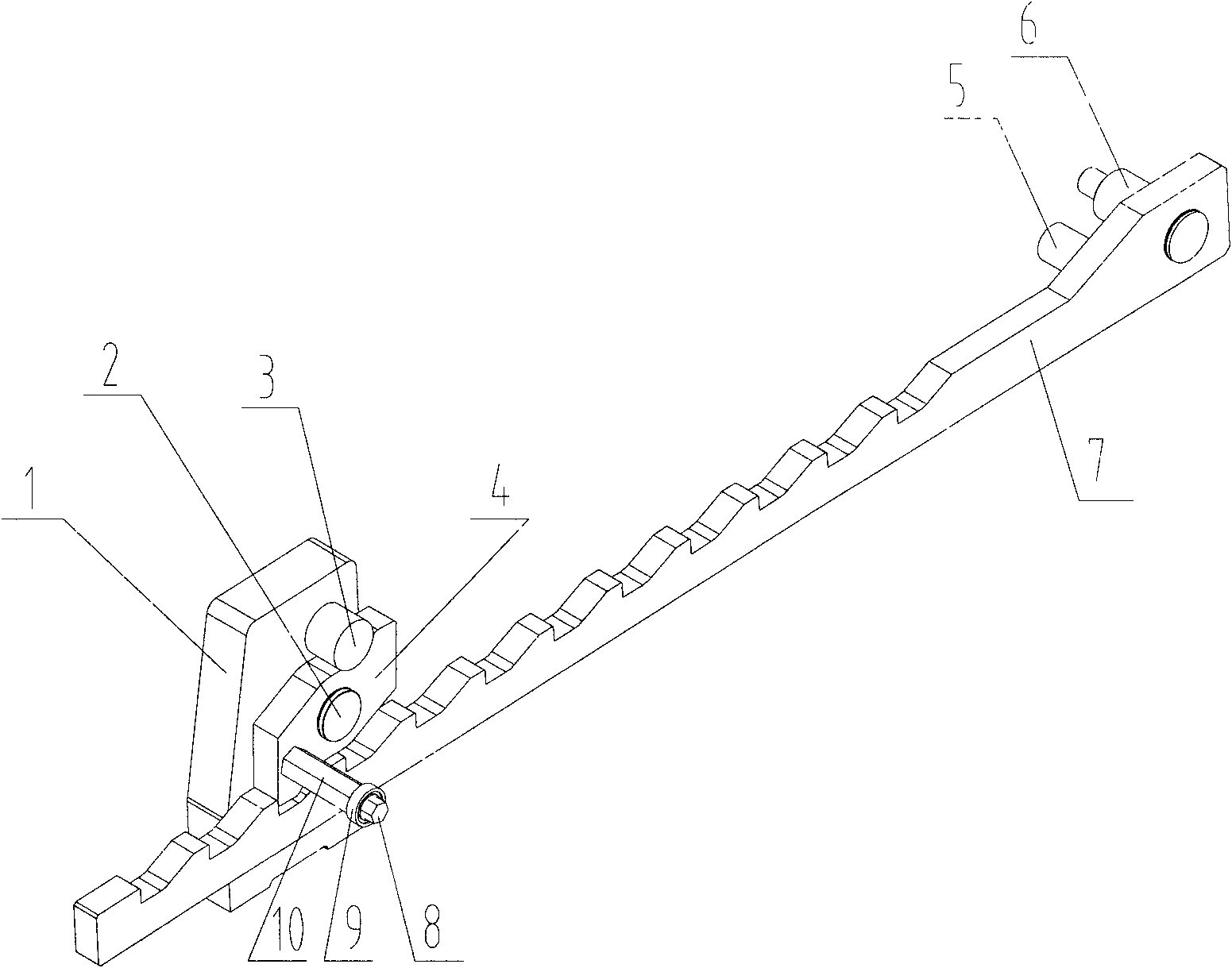

Special double-spacing side hung mechanical protection device for injection machine

The invention provides a special simple and efficient mechanical device for an injection machine, and concretely provides a special double-spacing side hung mechanical protection device for the injection machine. The safety rod of the device is hinged to a moving platen through a safety rod fixing shaft and a safety rod spacing shaft, is hung on the side surface of the moving platen, and is separated from other parts of the machine. The flashboard of the device is hinged to a flashboard seat through a flashboard fixing shaft, and is spaced through a flashboard spacing shaft to restrict the force application direction of the flashboard to the safety rod. By adopting the paw principle of a ratchet, the on-off direction of the flashboard and the movement direction of a mechanical lock rod are in a same plane, and the flashboard cannot bear lateral pull force. The spacing structure of a flashboard rotating shaft and the flashboard spacing shaft allows a case that the safety rod only bears stopping power along the safety rod direction in the working process to be guaranteed, and other contacts of the safety rod within the working period to be eliminated. The device allows the mechanical safety factor to be improved and the service life of the whole machine to be prolonged through simplifying bearing cases of various assemblies, so simplicity and high efficiency requirements of mechanical safety devices are realized.

Owner:浙江博创机械有限公司

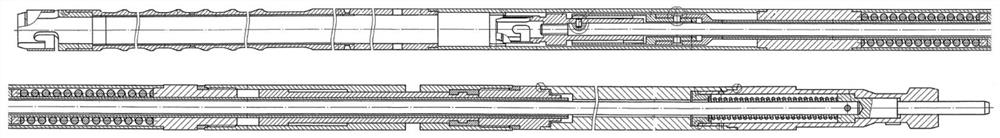

Reinstallation wrench for reactor driving rod

The invention belongs to the technical field of reactor maintenance, and particularly relates to a reactor driving rod reinstallation wrench. Comprising an inner-layer wrench and an outer-layer wrench, and the inner-layer wrench is sleeved with the outer-layer wrench which is used for connecting and disconnecting the inner-layer wrench and the driving rod. The inner-layer wrench comprises an inner-layer wrench sleeve, the upper portion of a connecting column is connected with the bottom of the inner-layer wrench sleeve in a socket welding mode, the lower portion of the connecting column is connected with a cross universal joint, the lower portion of the cross universal joint is connected with a connecting rod, an external thread section is arranged on the connecting rod, and a locking nut is meshed with the external thread section and installed on the connecting rod. The pin shaft is installed in a through hole in the lower end of the connecting rod, matched with a J-shaped key groove in the head of the driving rod and used for connecting the wrench with the driving rod. The outer-layer wrench comprises an outer-layer wrench sleeve, an outer-layer wrench handle and a fan-shaped key. According to the invention, the efficiency of driving rod reassembling work is improved, and industrial safety and human error events in the operation process are avoided.

Owner:JIANGSU NUCLEAR POWER CORP

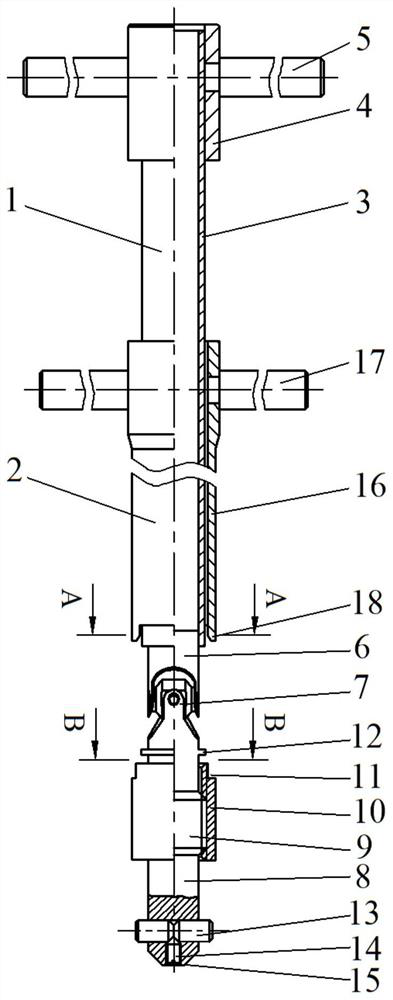

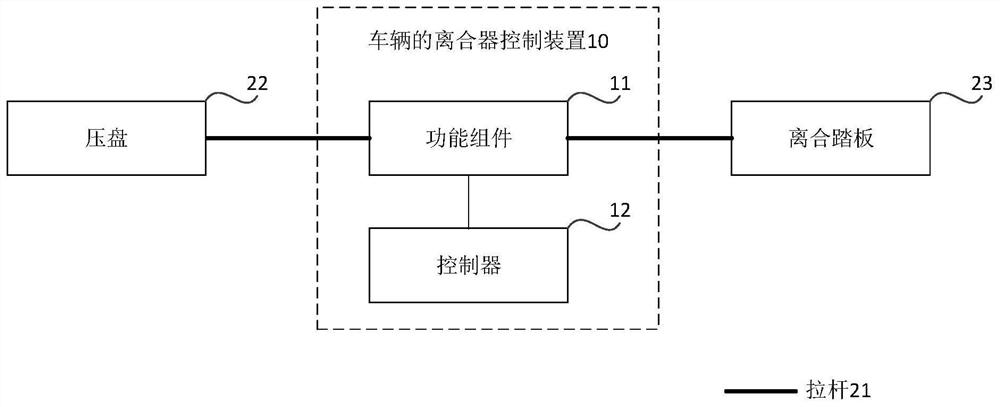

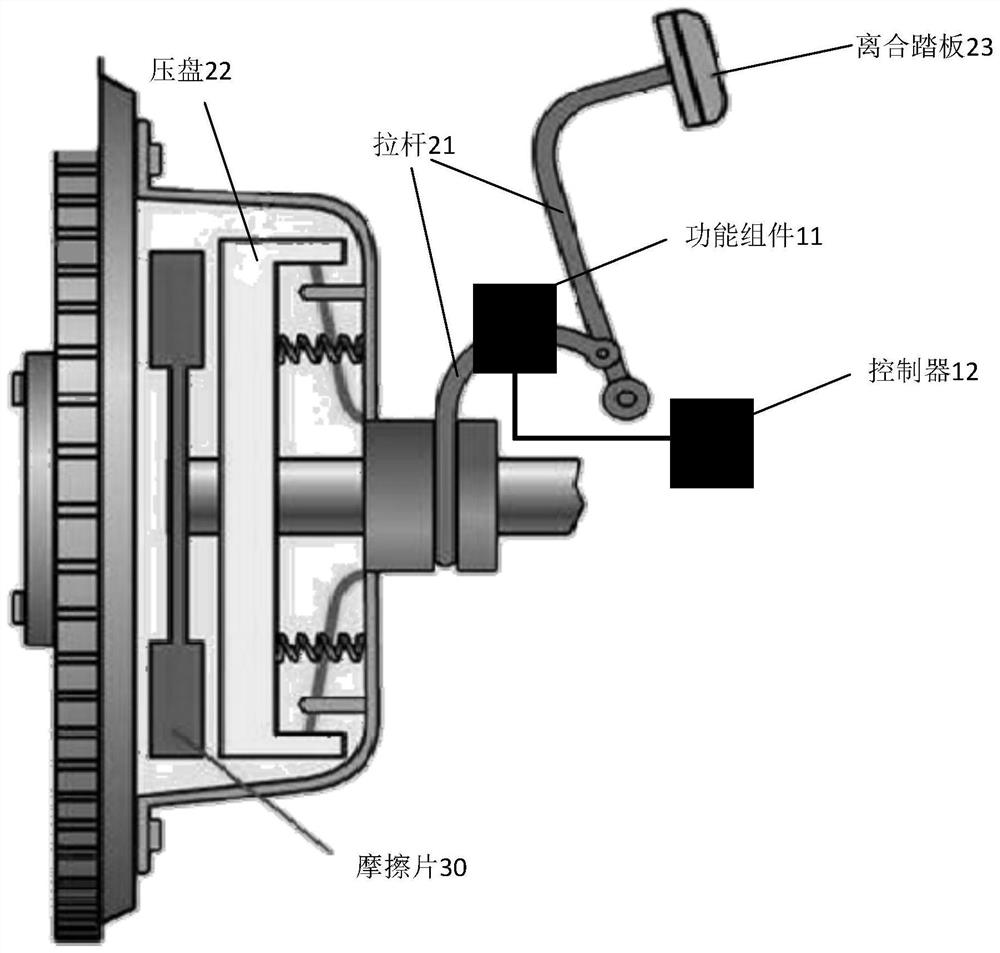

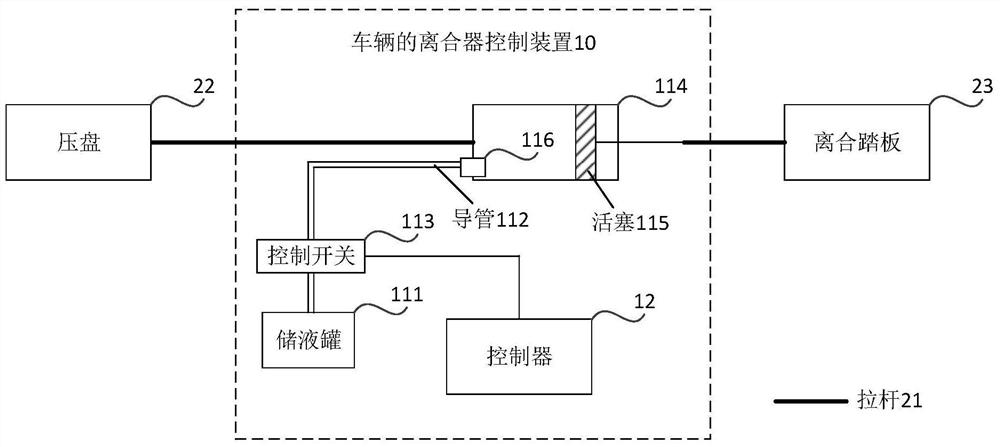

Clutch control device of vehicle, method and device for controlling clutch, and vehicle

The invention relates to a clutch control device of a vehicle, a method and device for controlling a clutch, and the vehicle, and relates to the technical field of vehicle control. The device comprises a controller a function assembly in a variable shape, and the first end of the function assembly is connected with a pressure plate of the clutch through a pull rod of the clutch of the vehicle, the second end of the function assembly is connected with a clutch pedal of the clutch through a pull rod, and the control end of the function assembly is connected with the controller. The controller is used for adjusting the speed at which the function assembly recovers to the shape in which the function assembly is not compressed according to the speed, the rotating speed of an engine and the gear, flameout of the engine is avoided, and the safety of the vehicle is improved.

Owner:BEIJING BORGWARD AUTOMOBILE CO LTD

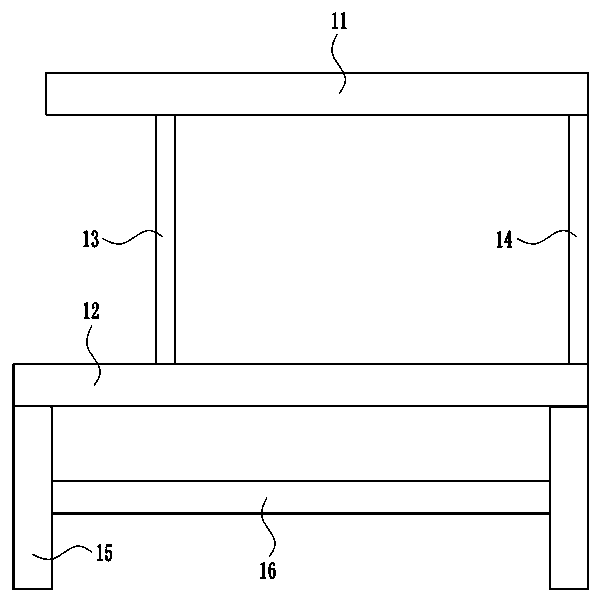

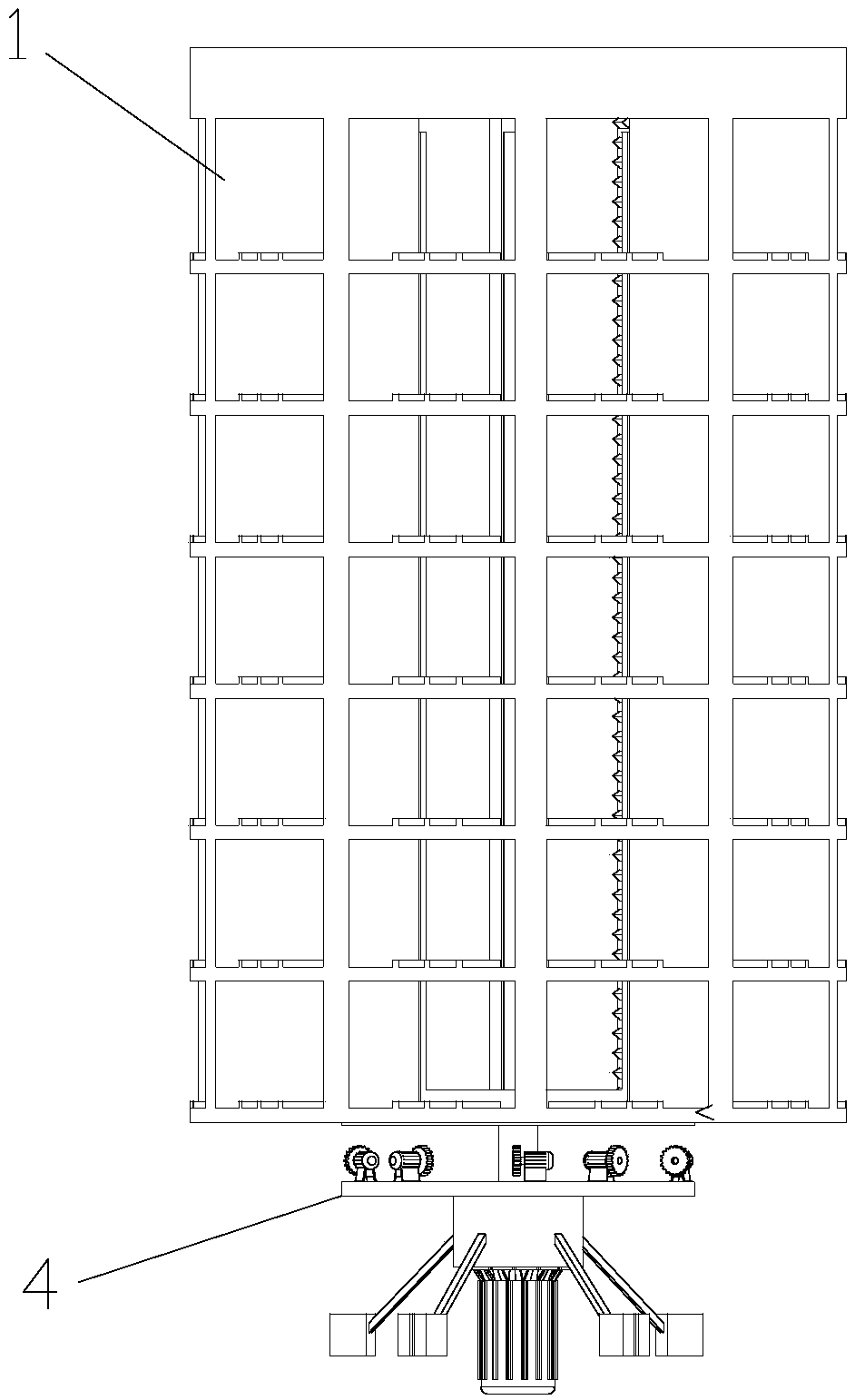

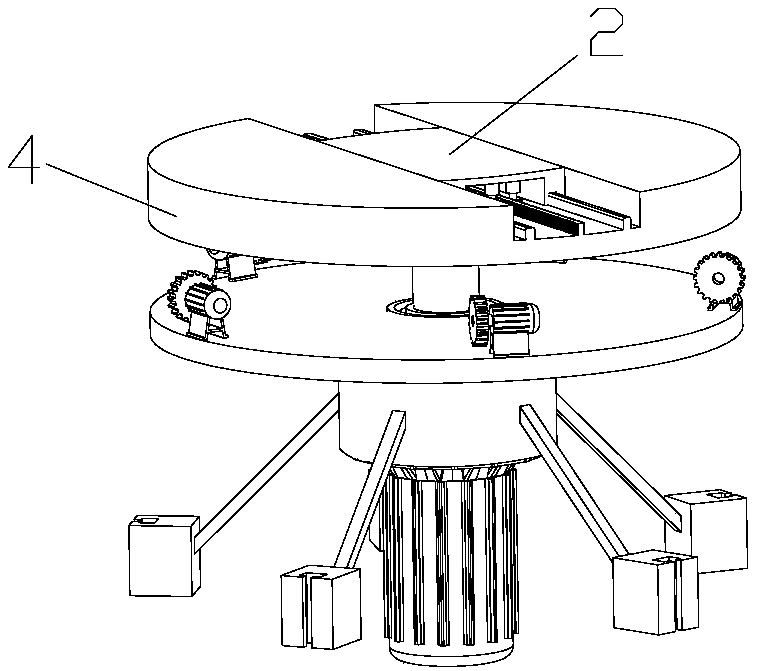

Garage vehicle-moving device

InactiveCN107558779ASmall space requirementImprove space utilizationParkingsBlock and tackleDrive motor

The invention discloses a car moving device in a garage, which belongs to the technical field of parking devices, and includes a car-carrying plate arranged in the center of the garage, a horizontal movement guide mechanism and a horizontal movement drive mechanism. The horizontal movement guide mechanism includes two A slideway or a pulley block on a thickness side of the vehicle-carrying board and a slide rail corresponding to the slideway or pulley set are arranged in the garage, and the horizontal movement drive mechanism includes two slideways or two The driving motor inside the pulley block, the driving gear arranged at the end of the main shaft of the driving motor, and the tooth rack arranged in the garage for meshing transmission with the driving gear. In the present invention, the car-carrying plate is arranged in the center of the garage, and the car is sent to the circumference of the circular garage for parking through the horizontally moving guide mechanism and the horizontally moving driving mechanism, without the need for an external conveying channel, thereby reducing the demand for space , improve space utilization.

Owner:重庆檀科科技有限公司

Shuttle-shaped gear engagement sleeve for gearbox

InactiveCN106812910AEasy to operateQuick meshPortable liftingGearing controlTangential forceMechanical engineering

The invention discloses a shuttle-shaped gear engagement sleeve for a gearbox. The shuttle-shaped gear engagement sleeve comprises an engagement sleeve body. A center through hole is formed in the center of the engagement sleeve body. An inner spline is arranged in the center through hole. Shifting fork grooves used in cooperation with shifting forks are formed in the peripheral wall of the engagement sleeve body. One ends of all spline teeth of the inner spline are correspondingly provided with tapered ends, and the other ends of all the spline teeth of the inner spline are correspondingly provided with circular arc enveloping surfaces formed by circular arc chamfers. The widths of the tapered ends are gradually increased in the direction from the side where the tapered ends are located to the middle of the engagement sleeve body. The tapered end and the circular arc enveloping surface are correspondingly arranged at the two ends of each spline tooth of the inner spline. In this way, during gear engagement, the tapered ends can extend into tooth grooves of other engagement teeth, so that fast and stable engagement is achieved, and fast gear engagement of a synchronizer is guaranteed; and the circular arc enveloping surfaces are in contact with an engagement tooth seat, a tangential force effect is generated, the engagement tooth seat is made to smoothly slide along the circular arc enveloping surfaces, and the stable gear engagement operation is guaranteed.

Owner:CHONGQING KANGTIAN GEAR

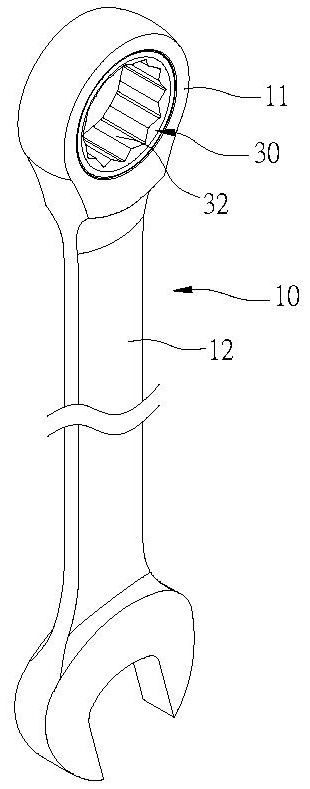

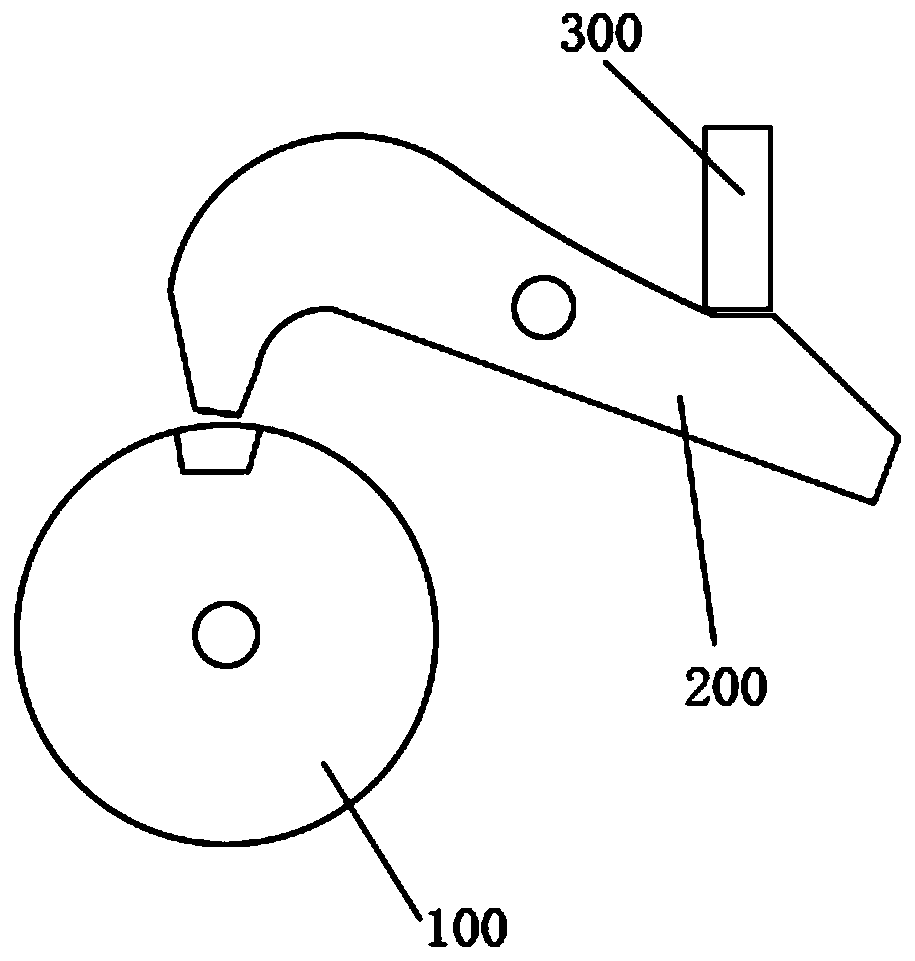

One-way ratchet wrench structure

The invention discloses a one-way ratchet wrench structure. The one-way ratchet wrench structure comprises a wrench body, a tooth manufacturing piece and a ratchet wheel. The wrench body is provided with containing space and a containing groove, the ratchet wheel is installed in the containing space, the tooth manufacturing piece is installed in the containing groove, a tooth section of the tooth manufacturing piece is provided with multiple equal-angle teeth and a different-angle tooth, and due to the fact that the angle of the different-angle tooth is different from the angles of the equal-angle teeth, and the different-angle tooth sinks to be lower than the equal-angle teeth, when the wrench body is twisted anticlockwise, the wrench body can be rapidly separated from the equal-angle teeth of the ratchet wheel through the different-angle tooth. A cambered surface section and the tooth section of the tooth manufacturing piece are cambered surfaces which are not concentric and abut against the periphery of the ratchet wheel at different times, through abutting of a fulcrum of the tooth manufacturing piece and center-of-gravity shift during wrench twisting, the tooth manufacturing piece can generate deflection action similar to a seesaw, and the effects that the tooth section is quickly engaged with the periphery of the ratchet wheel and slipping happens indeed are achieved.

Owner:ZHEJIANG MAXTOP TOOLS MFG CO LTD

Screen cloth pressing device of vibrating screen

The invention aims to provide a screen cloth pressing device of a vibrating screen, and belongs to the technical field of material vibrating screening equipment. The device comprises a wedge block and a pressing piece fixed to a screen box side plate, a driving wheel and a guide wheel are arranged at the two ends of the screen box side plate respectively, and rack parts meshed with the driving wheel and the guide wheel are arranged at the two ends of the wedge block respectively. At least two guide grooves are formed in the wedge block, a positioning pin shaft is fixed on the screen box side plate, and the free end of the positioning pin shaft extends into the guide grooves; and a handheld part for pushing and pulling the wedge block is arranged at the front end of the wedge block. The wedge block is driven to move back and forth through rotation of the driving wheel, the screen is pressed or loosened, operation is convenient, the structure is firm, the occupied space is small, good abrasion resistance and corrosion resistance are achieved, the service life of the device is prolonged, the device is not limited by a well site air source, and the application place of a product is expanded.

Owner:濮阳市中原锐实达石油设备有限公司

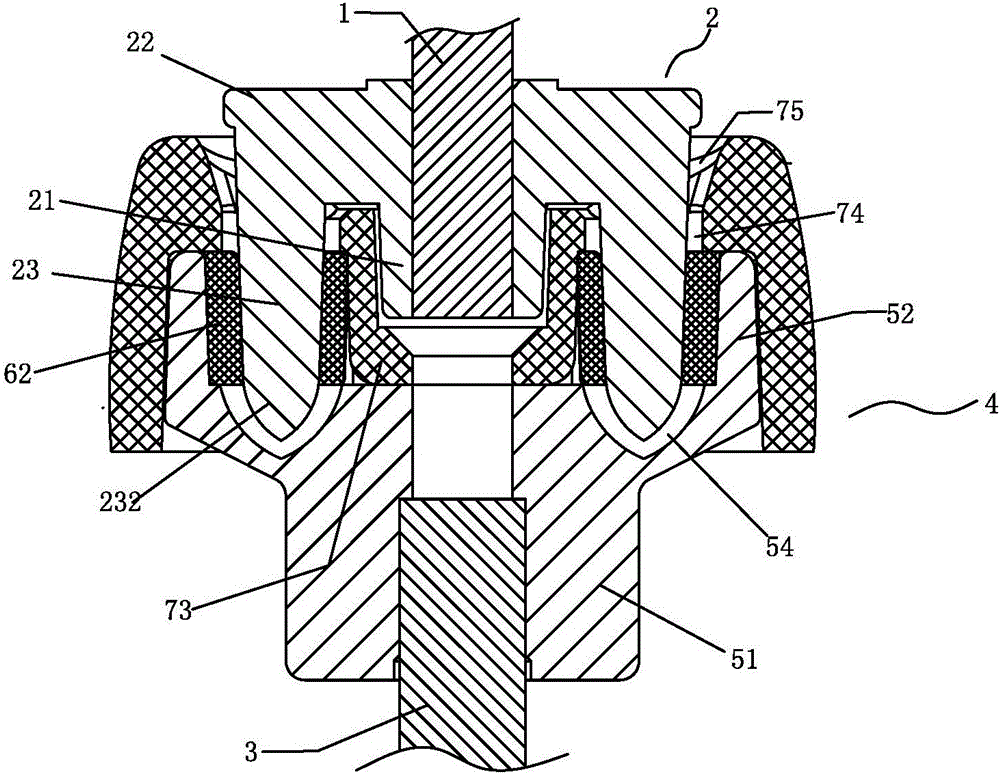

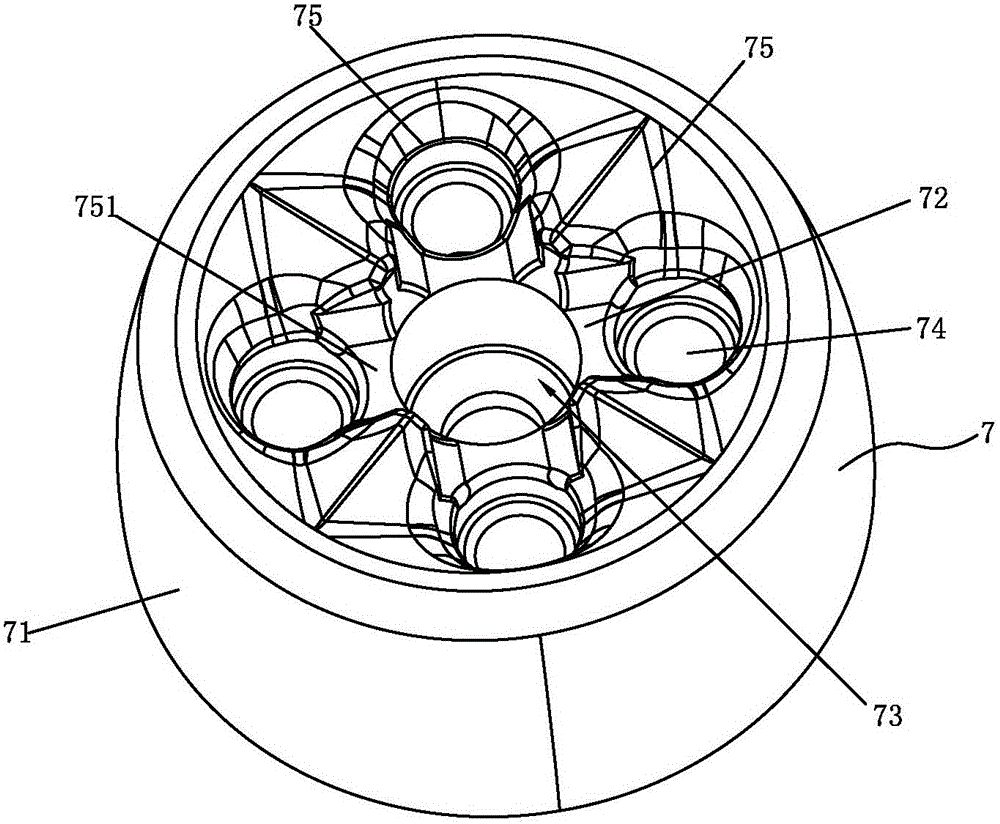

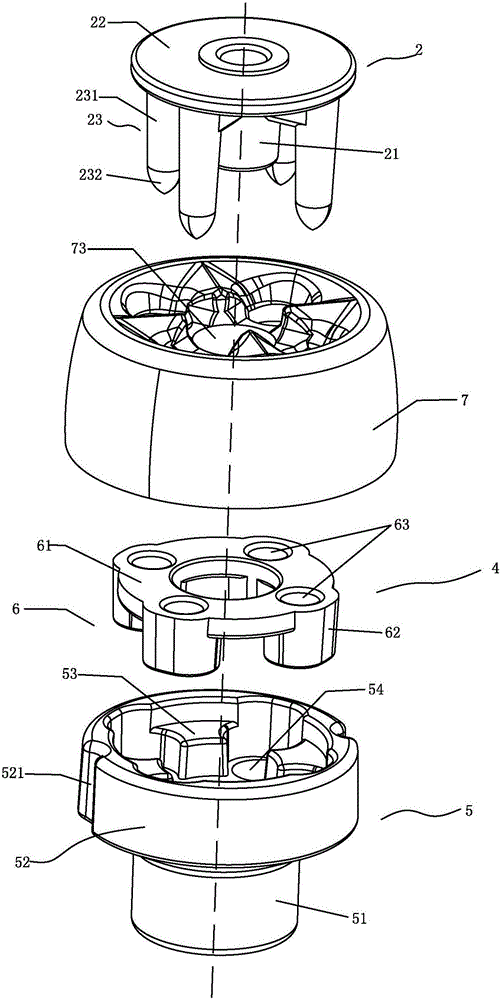

Clutch assembly of food processer

The invention discloses a clutch assembly of a food processer. The clutch assembly comprises an auxiliary clutch piece and a main clutch component which are matched with each other; the auxiliary clutch piece comprises a knife shaft holder, a ring disc surrounding the upper part of the knife shaft holder, and at least three clutch teeth arranged on the lower surface of the ring disk and distributed uniformly, wherein the body of each clutch tooth is columnar, and the head of each clutch tooth is of a spherical curved surface; the main clutch component comprises a base; by adopting the structure, the lower end of each clutch tooth is in sliding fit with a guiding mouth, then the head of the clutch tooth is engaged with a clutch hole, and the body of the clutch tooth is matched with a buffering clutch hole of a buffer, so that the purposes of low friction degree, quick engagement and collision prevention are fulfilled. The lower end of each clutch tooth is intersected with the two adjacent guiding holes of a guiding sleeve linearly, so that the clutch assembly is convenient to align, has the effect of automatic alignment and is convenient to use.

Owner:ZHONGSHAN KONLON ELECTRICAL TECH CO LTD

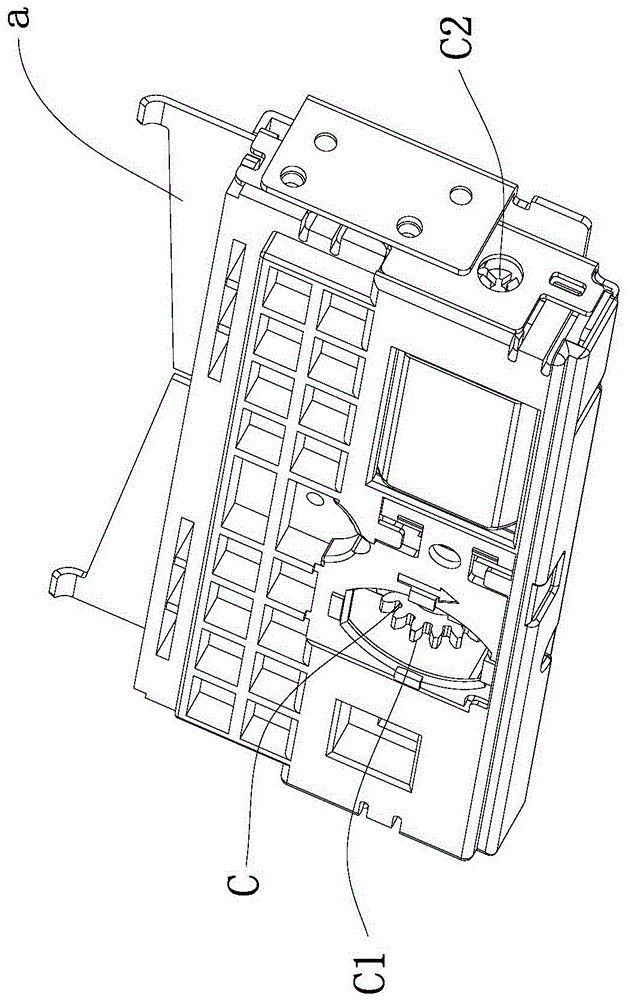

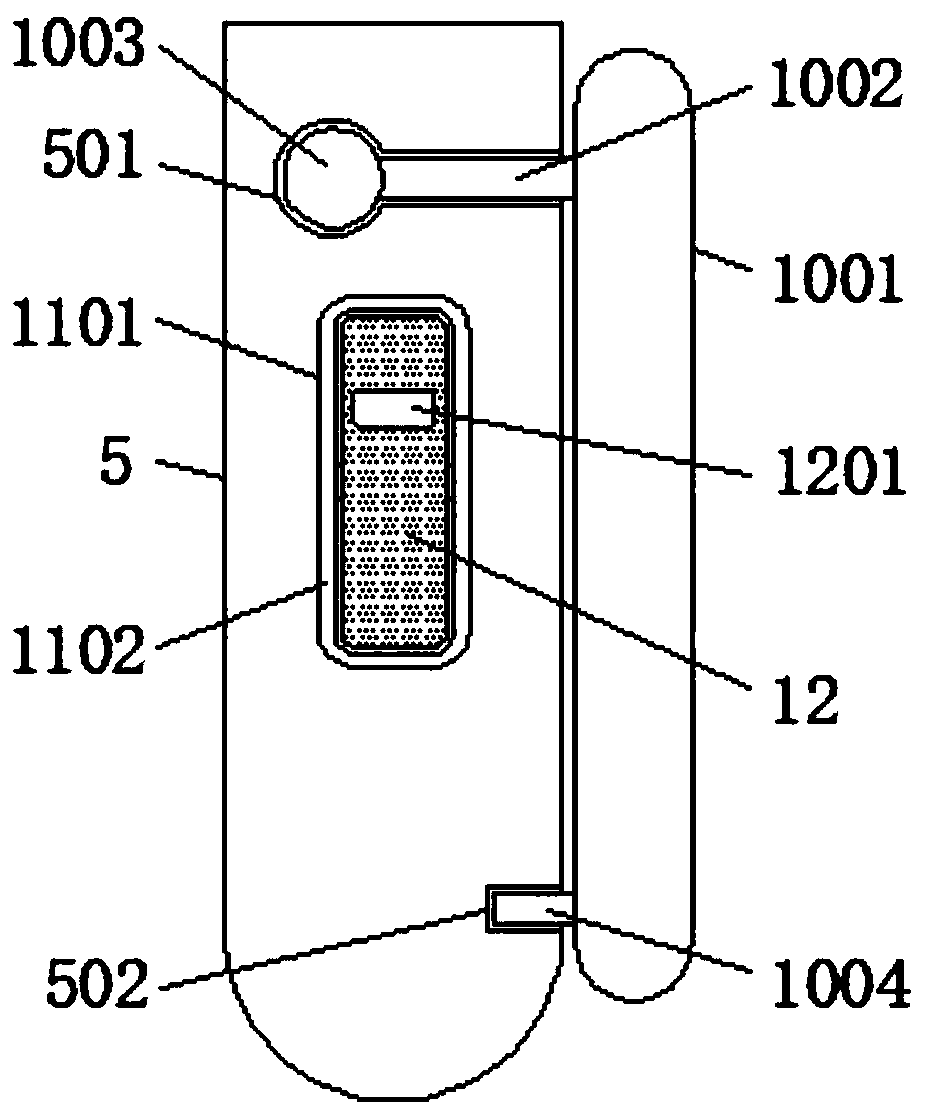

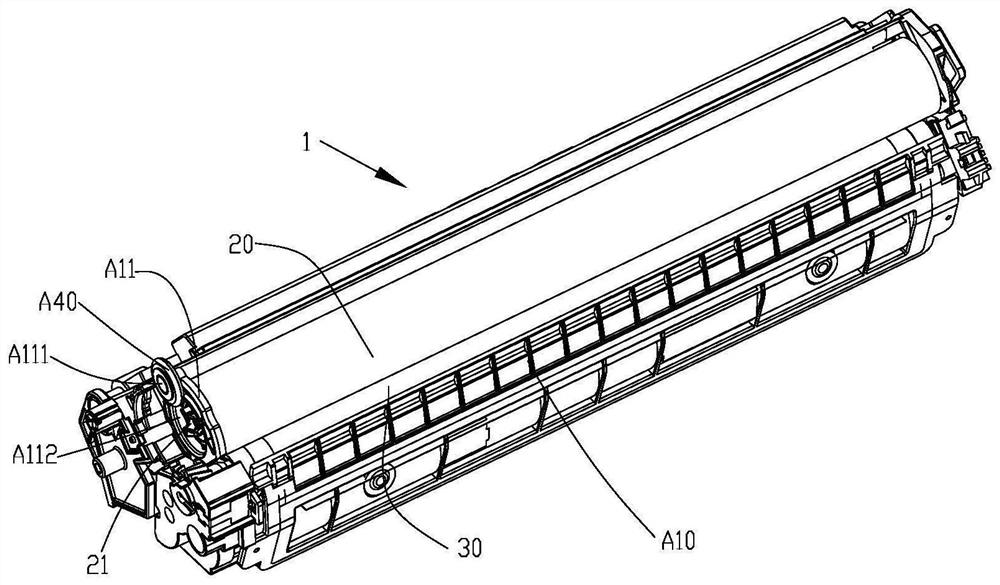

Processing box

PendingCN114488745AImprove work efficiencyQuick meshElectrographic process apparatusMechanical engineeringElectronic imaging

The invention provides a processing box. The processing box is detachably installed in an electronic imaging device. The processing box comprises a box body; the photosensitive drum is rotatably arranged on the box body; the power receiving unit is arranged at one end of the photosensitive drum, and the power receiving unit is used for being matched with the driving unit; the force applying unit is arranged on the box body, the force applying unit and the power receiving unit are located at the same end, and the force applying unit is used for applying acting force to the driving unit pushing piece, so that the driving unit is adjusted to be in a straightening state from an inclined state after losing the support of the driving unit pushing piece. And the transmission unit is meshed with or separated from the power receiving unit. According to the processing box and the electronic imaging device provided by the invention, the driving unit loses the support of the driving unit pushing piece to be engaged with or separated from the power receiving unit through the force application unit, so that rapid engagement is facilitated.

Owner:NINESTAR CORP

Transmission parking system and method of using the transmission parking system

The invention provides a transmission parking system and a transmission parking system use method and relates to the technical field of automobile braking systems. The transmission parking system comprises a parking ratchet, a parking pawl and a time-delay mechanism. The parking ratchet meshes with the parking pawl. The time-delay mechanism is connected to the end, away from the parking ratchet, of the parking pawl and is used for pressing the parking pawl, or the time-delay mechanism is connected to the end, close to the parking ratchet, of the parking pawl and is used for lifting the parkingpawl, so that the parking pawl is arranged in the direction away from the parking ratchet under the action of the time-delay mechanism. The technical problems that in the prior art, when an automobile is operated from a D gear or an R gear to a P gear, a parking pawl and a parking ratchet are completely attached to bear force due to overturning of a power assembly, and the driving feeling of a driver is influenced are solved. The time-delay mechanism of the transmission parking system can provide certain acting force for the parking pawl, and the time need by meshing of the parking pawl and the parking ratchet is prolonged.

Owner:SHENGRUI TRANSMISSION

A fast high torque clutch system

ActiveCN106090087BEasy to separateAvoid damageFluid actuated clutchesCoupling-brake combinationRolling-element bearingCoupling

The invention discloses a quick large-torque clutch system which comprises a clutch device, a hydraulic oil pump, a motor, a disengagement oil way, an engagement oil way and an oil storage tank. The clutch device comprises an input shaft, a first coupling, a first snap spring, a second snap spring, a rolling bearing, a bearing bush, a cylinder wall sleeve, a second coupling, a sliding bearing, a third snap spring and an output shaft. Compared with existing clutch devices, the clutch device arranged in this way overcomes shortcomings by learning strong points and has the characteristics of large transmission torque, rapid action response, simple structure and easy operation. The quick large-torque clutch system further comprises the disengagement oil way and the engagement oil way, the first coupling and the second coupling are quickly disengaged in a high speed state through the disengagement oil way, the first coupling rotating at high speed is slowly and gradually engaged with the second coupling stopping rotating through the engagement oil way, and thus the operation stability of equipment is improved, and the service life of the equipment is prolonged.

Owner:中色正锐(山东)铜业有限公司

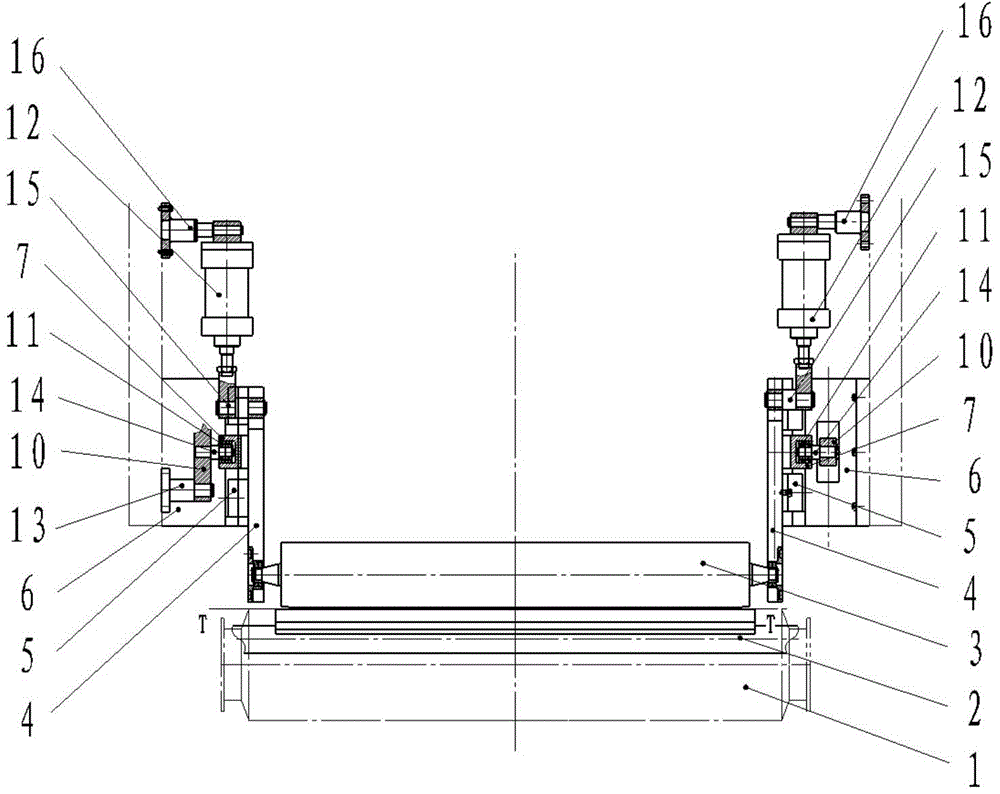

A wallpaper rotary screen direct pressure roller device

InactiveCN103434266BSolve precision problemsQuality improvementScreen printersEngineeringMechanical engineering

Owner:XIAN AEROSPACE HUAYANG PRINTING & PACKAGING MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com