Screen cloth pressing device of vibrating screen

A technology of compaction device and sieve mesh, which is applied in the fields of filtration, solid separation, chemical instruments and methods, etc., can solve the problems of difficult to confirm the installation position, small use space, high material price, etc., and achieve the expansion of application places, Small footprint, long-lasting corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

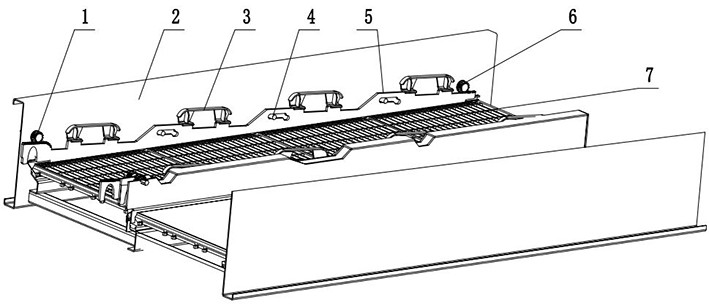

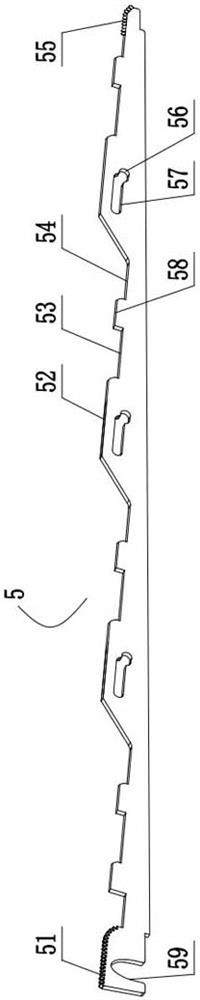

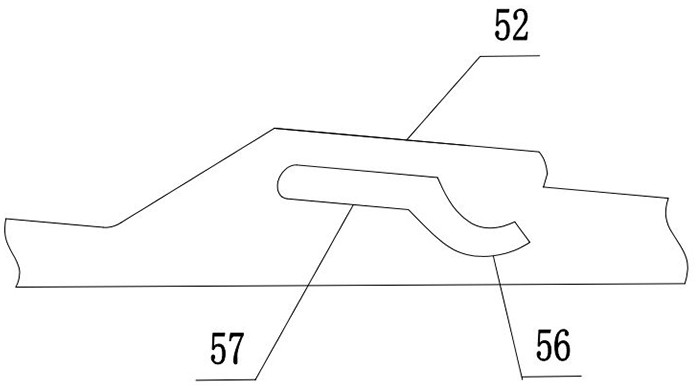

[0030] like figure 1 , figure 2 and Figure 5 As shown, a vibrating screen screen pressing device includes a driving wheel 1, a guide wheel 6, an integral wedge 5 and a pressing member 3 fixed on the side plate 2 of the screen box. The driving wheel 1 is installed at the front end of the side plate 2 of the screen box, and the guide wheel 6 is installed at the rear end of the side plate 2 of the screen box. The top of the front end of the wedge block 5 is provided with a first rack portion 51 that is matched with the driving wheel 1 , and the top of its rear end is provided with a second rack portion 55 that is matched with the guide wheel 6 . The wedge block 5 is provided with at least two guide grooves, three in this embodiment, and they are evenly distributed along the length direction of the wedge block 5; one end of the guide grooves close to the first rack portion 51 is higher than the other end, that is, the guide grooves The front end is higher than the back end. ...

Embodiment 2

[0037] A vibrating screen mesh pressing device, the difference between this embodiment and the first embodiment is that there is no downward protrusion near the front of the rearmost end of the arc positioning section 57 . That is to say, the rearmost end of the arc positioning section 57 is the lowest point. The side plate 2 of the screen box is provided with at least two first positioning holes for fixing the wedge block 5 when the screen mesh 7 is disassembled, and the wedge block 5 is provided with second positioning holes corresponding to the positions of the first positioning holes and equal in number, The pins pass through the first positioning hole and the second positioning hole respectively to fix the wedge block 5 on the side plate 2 of the screen box. Through the above structural design, compared with the first embodiment, the wedge block 5 is more firmly and reliably fixed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com