Reinstallation wrench for reactor driving rod

A technology for driving rods and reactors, which is applied in the field of reactor maintenance, can solve problems such as potential safety hazards, and achieve the effects of preventing pinching, reducing overall weight, and improving efficiency and qualification rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

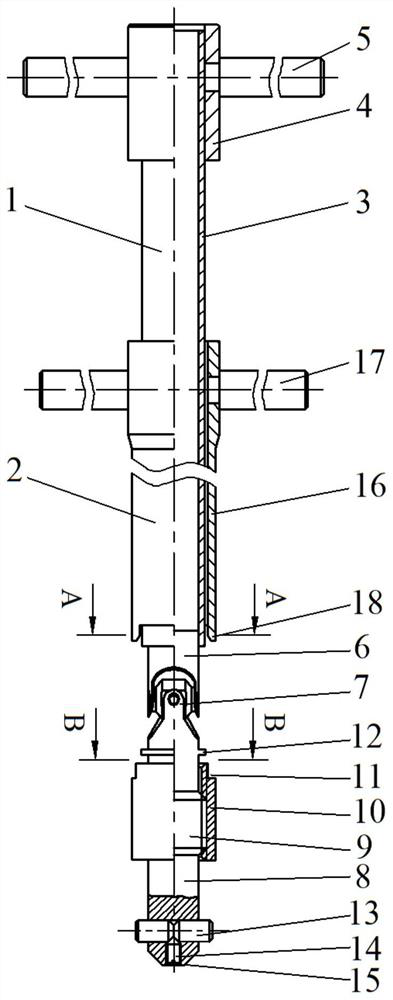

[0032] The following is a further detailed description of a reactor drive rod return wrench provided by the present invention with reference to the accompanying drawings and specific embodiments.

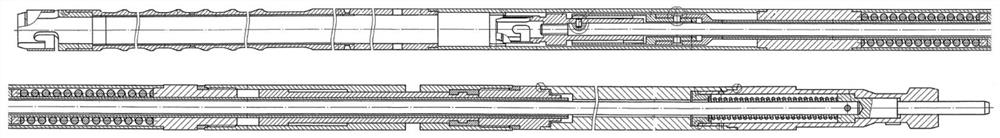

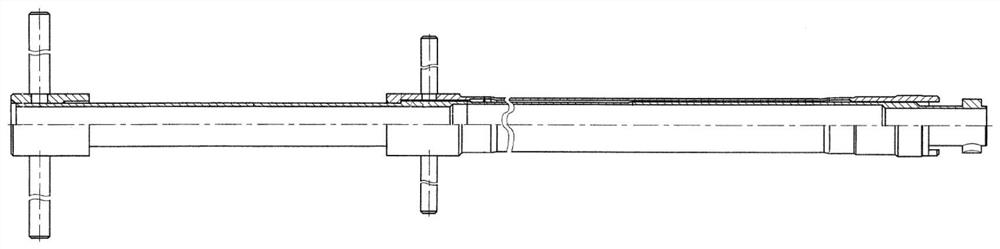

[0033] like image 3 As shown in the figure, the present invention provides a return wrench for a reactor drive rod, including an inner wrench 1 and an outer wrench 2. The inner and outer wrenches cooperate to realize reliable connection with the driving rod, lowering of the driving rod, and remote connection between the special wrench and the driving rod. separation, etc.

[0034] The overall appearance of the inner wrench 1 is a long rod, which is used to connect and lock the head of the driving rod.

[0035] The upper part of the inner wrench 1 is the inner wrench sleeve 3, and its length occupies most of the total length of the inner wrench 1. It is a hollow pipe fitting structure, which greatly reduces the overall weight of the special wrench on the basis of ensuring the mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com