Special double-spacing side hung mechanical protection device for injection machine

A technology of mechanical protection and double limit is applied in the field of double limit side suspension type mechanical protection device for injection molding machines, which can solve the problems of complex stress on the safety rod, affecting the working life of the structure, and short life of the mechanism, etc. The effect of mechanism maintenance cost, improving the reliability level of the whole machine, and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

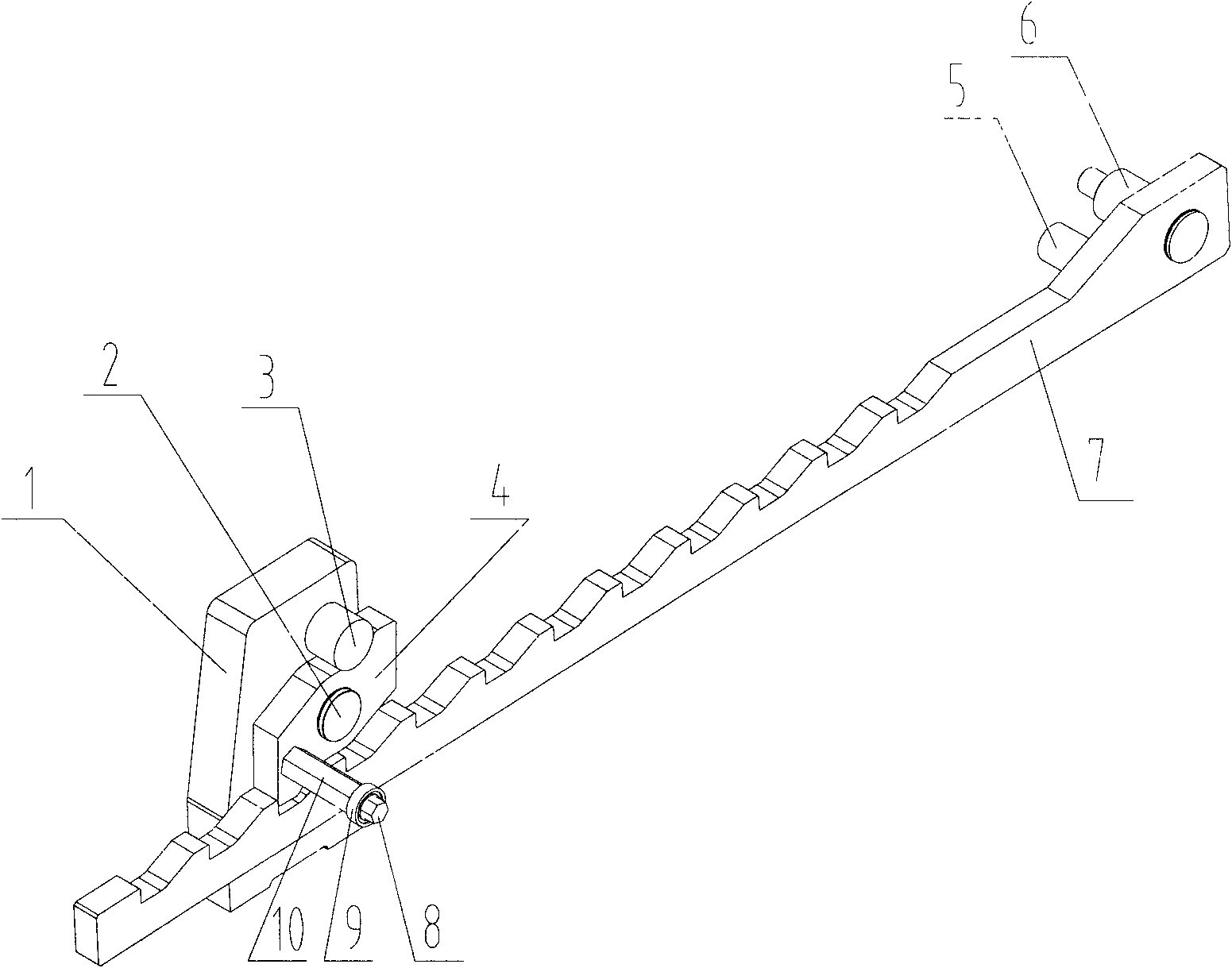

[0013] 1. If figure 1 As shown, a simple and high-efficiency mechanical protection device for injection molding machines, which includes an independent support (1), a gate shaft (2), a gate limit shaft (3), a gate (4), a safety rod limit Bit shaft (5), safety rod fixed shaft (6), safety rod (7), screw (8), bearing (9), gate support plate (10). A DU sleeve bearing is installed between the independent support (1) and the gate rotating shaft (2); the independent support (1), rotating shaft (2), gate limit shaft (3), gate Plate (4), screw (8), bearing (9), and gate support plate (10) are assembled to form a mechanical limit part; the safety rod limit shaft (5), safety rod fixed shaft (6), After the safety bar (7) is assembled, it forms a mould-closing linkage part. The safety rod (7) is hinged to the movable template through the safety rod limiting shaft (5) and the safety rod fixing shaft (6), and is suspended below the gate (3).

[0014] working principle:

[0015] The inven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com