Clutch assembly of food processer

The technology of a clutch assembly and a cooking machine, which is applied in the field of cooking machines, can solve the problems of easy wear, inconvenient use, high noise, etc., and achieves the effects of convenient use, convenient alignment and small wear and tear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

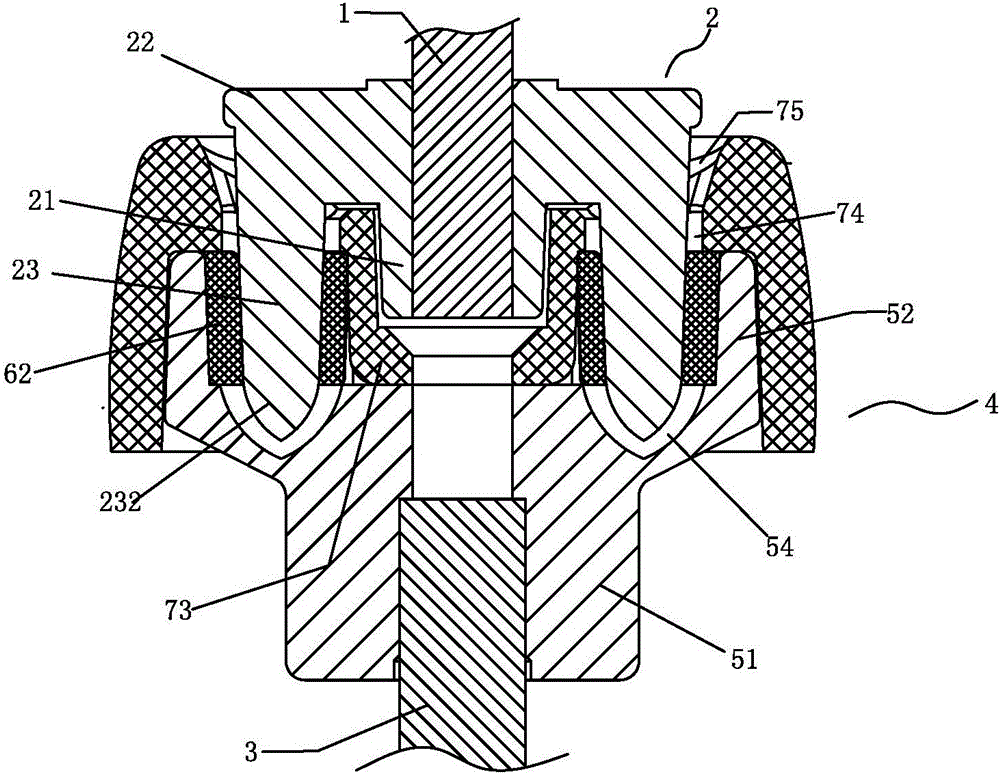

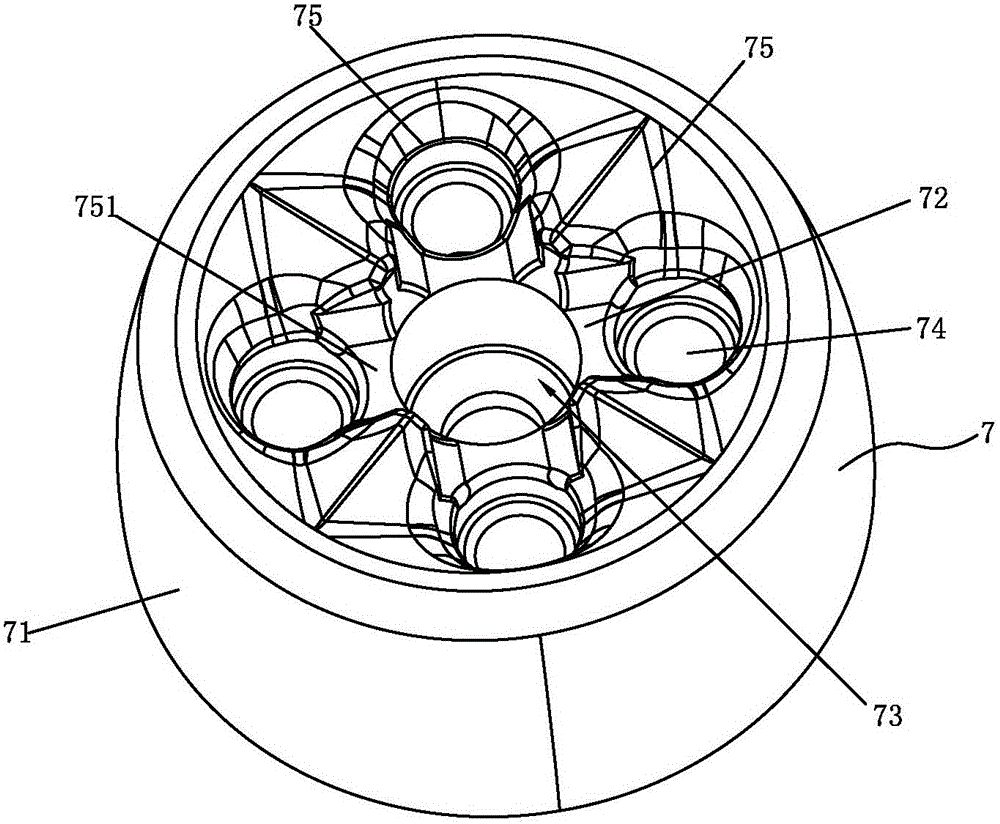

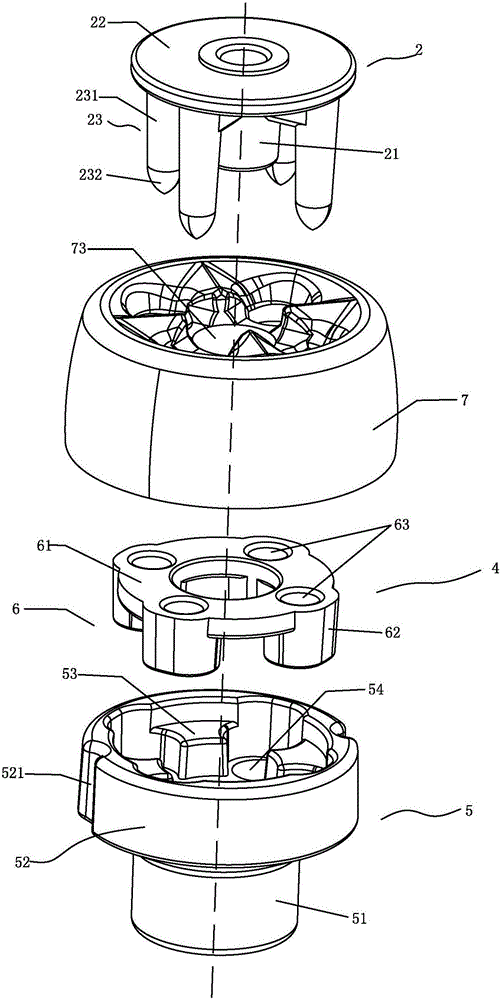

[0024] Such as figure 1 , image 3 , Figure 4 As shown, a cooking machine clutch assembly includes a sub-clutch 2 arranged at the lower end of the cutter shaft 1 and a female clutch assembly 4 arranged at the upper end of the motor shaft 3, and the sub-clutch 2 and the female clutch assembly 4 cooperate.

[0025] The sub-clutch 2 includes a cutter shaft seat 21, an annular disk 22 surrounding the upper part of the cutter shaft seat, and four clutch teeth 23 evenly distributed on the lower surface of the annular disk 22. The body 231 of the clutch tooth 23 is in the form of a column Shape, head 232 are spherical curved surface;

[0026] The female clutch assembly 4 includes a base 5, a buffer member 6 and a top guide sleeve 7,

[0027] The base 5 includes a motor shaft seat 51 and an upper opening seat body 52 positioned at the top of the motor shaft seat. Four sto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com