Compressor crankshaft, particularly refrigerant compressor crankshaft, and method for grinding such a crankshaft

A technology for compressor crankshafts and refrigeration compressors, applied in the field of compressor crankshafts, can solve problems such as long fixed cycle time, and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

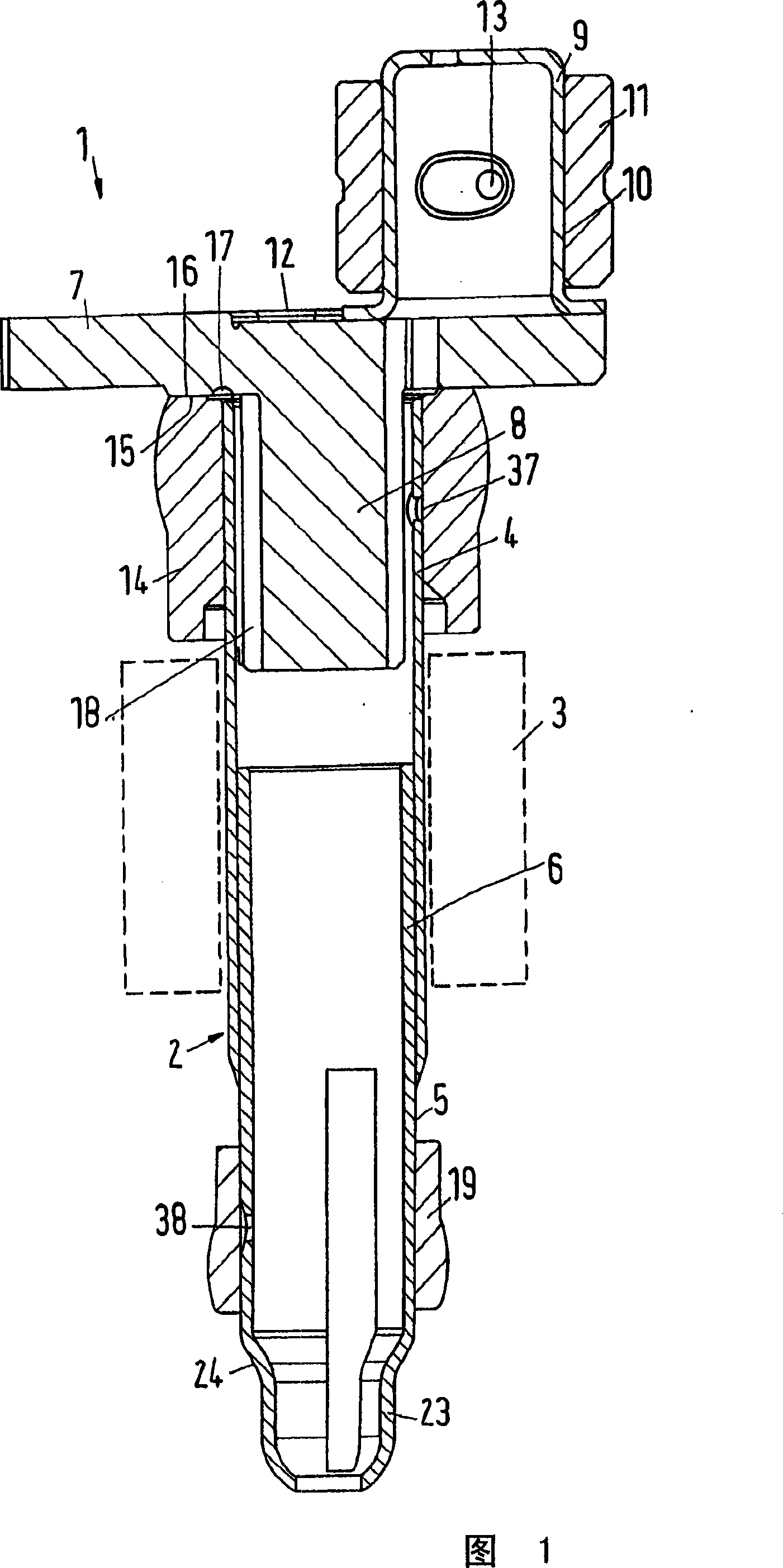

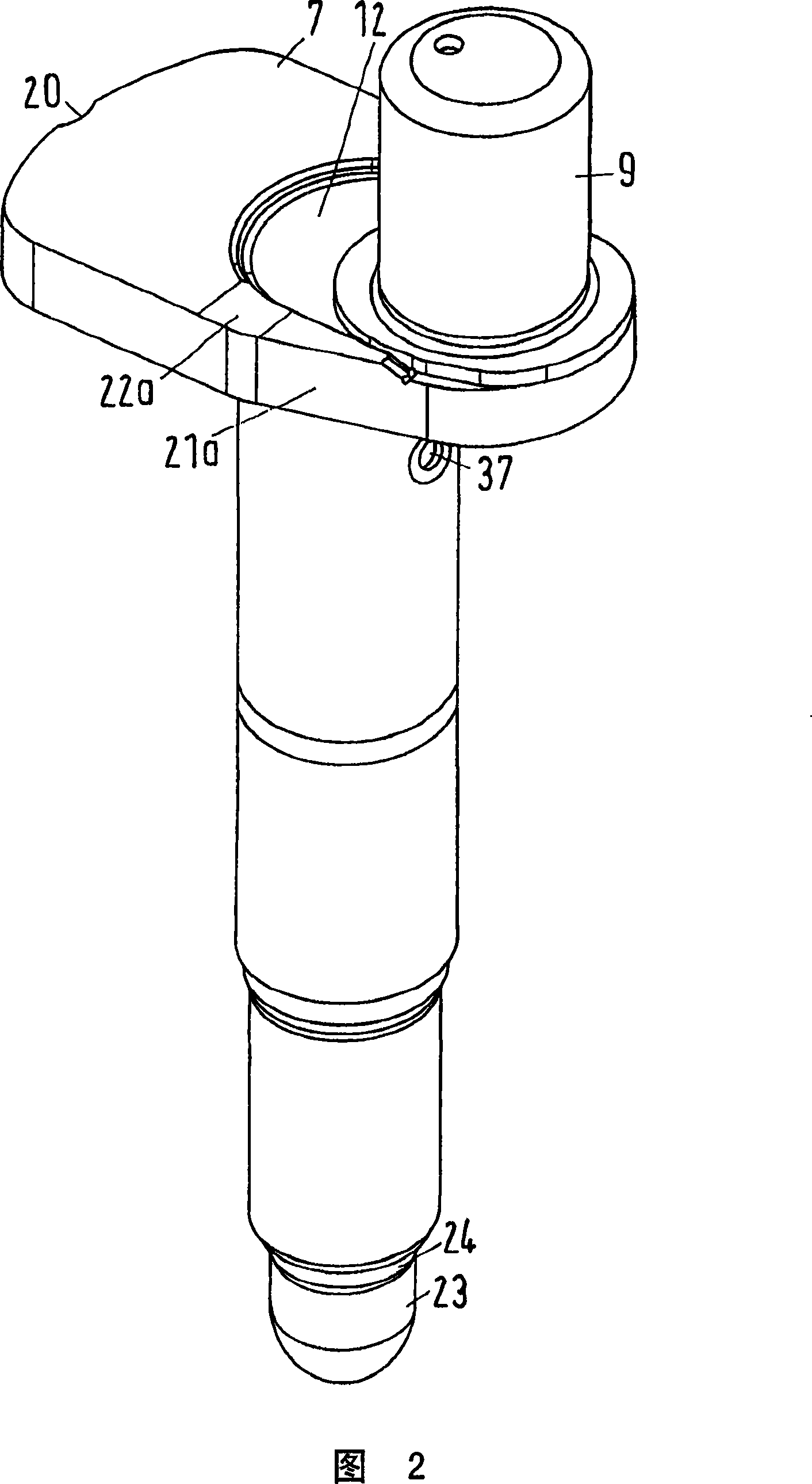

[0031] As shown in FIG. 1 , the crankshaft 1 of the refrigeration compressor has a shaft element 2 which is configured to be connected to a rotor 3 of an electric drive motor, which is only shown schematically. The shaft element 2 is made of two telescopically connecting parts 4, 5 which are connected to each other at overlapping portions 6 by means of welding, for example.

[0032] Such a crankshaft 1 is generally driven in the position shown in which the shaft elements are oriented substantially vertically. For reasons of clarity, directions will be referred to in the following as "upper" or "lower" or similar terms, the terms referring to the views of FIGS. 1 , 2 and 4 . However, no definite point of spatial orientation of the crankshaft 1 is given.

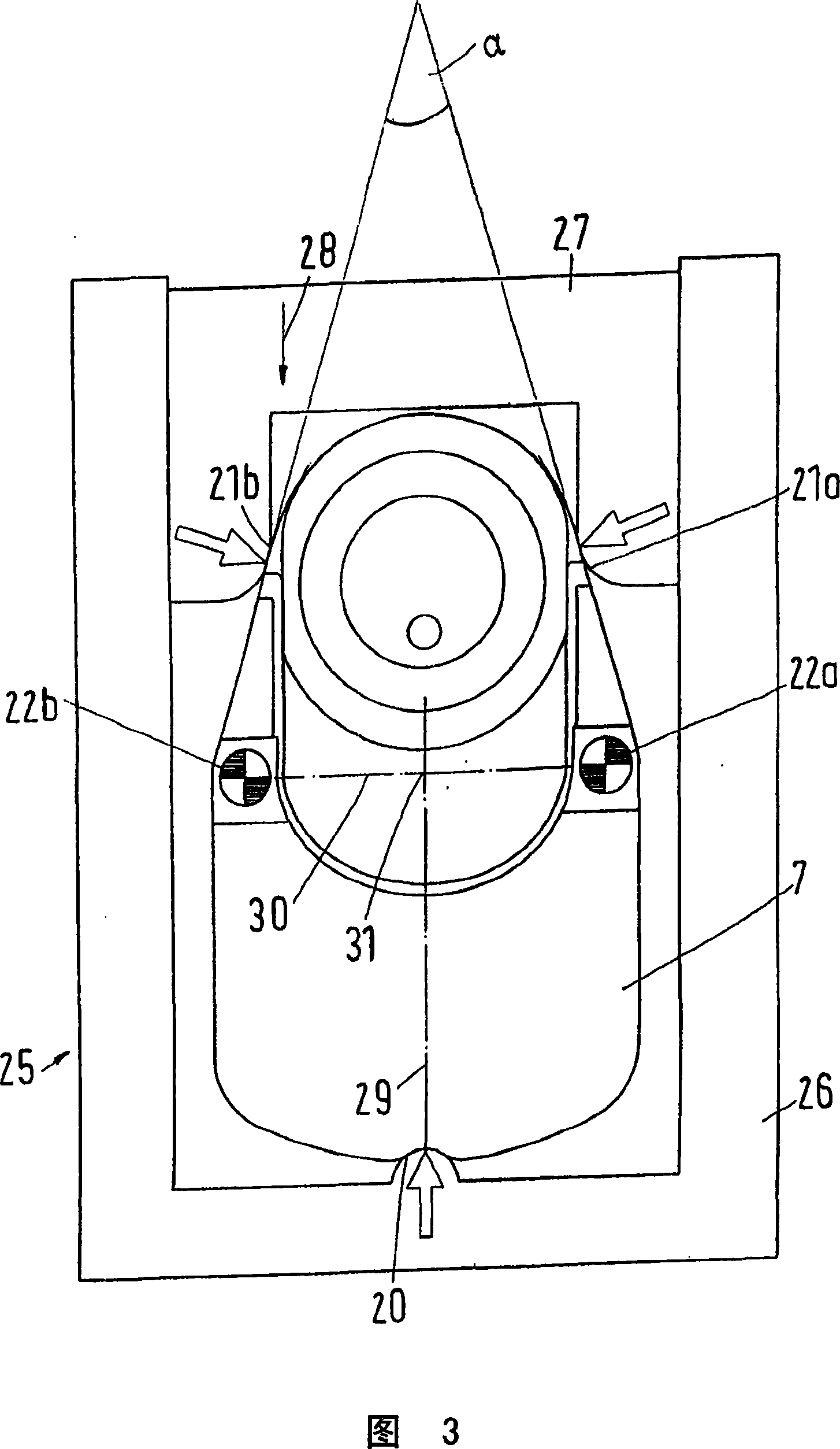

[0033] The conversion element 7 is located at the upper end of the part 4 of the shaft element 2 . The conversion element 7 is produced as a sintered or extruded molded part, in particular a cold-formed part. It can thus be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com