A Split Type Springless Overrunning Clutch

An overrunning clutch, no spring technology, used in clutches, one-way clutches, mechanical equipment, etc., can solve the problems of inconvenient application, low reliability, complex structure, etc., and achieve simple structure, high reliability, quick engagement and quick separation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

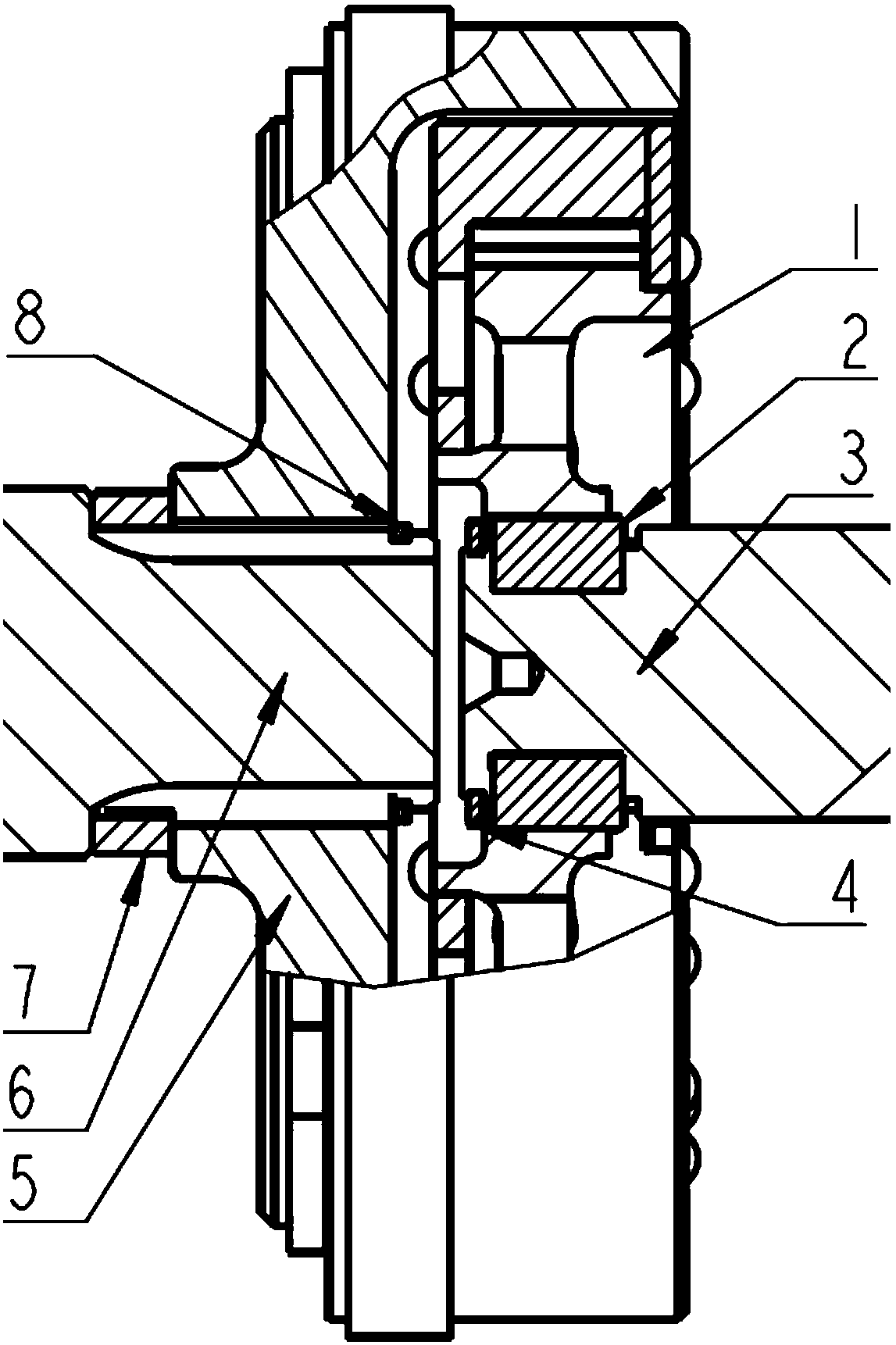

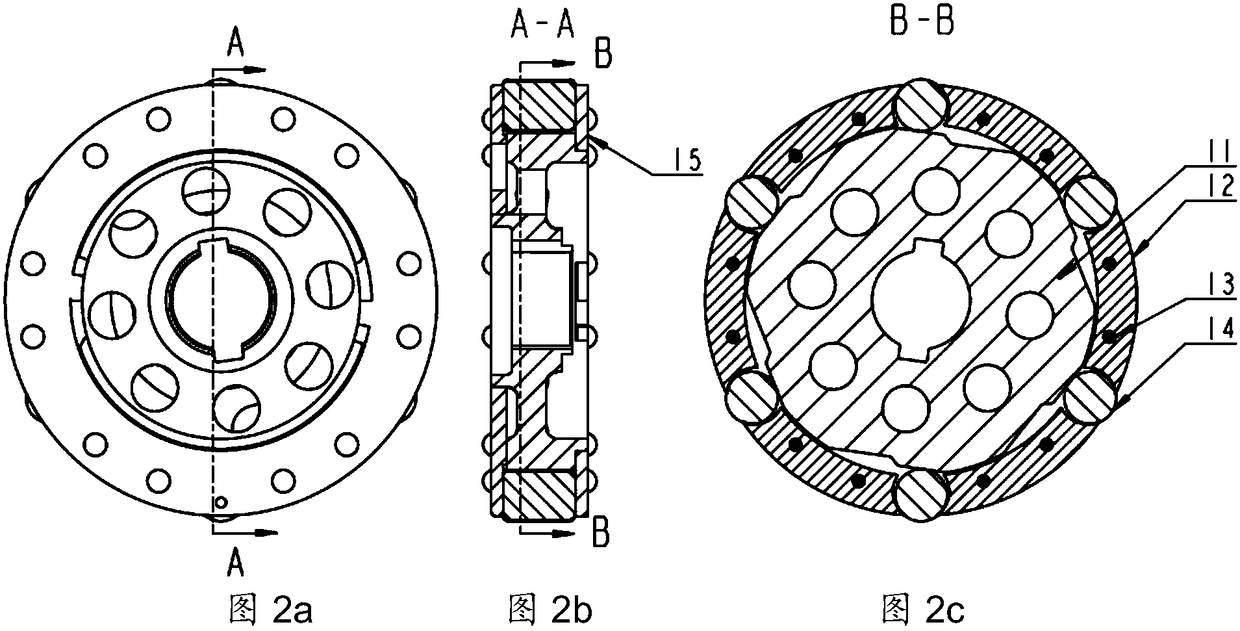

[0045] Such as figure 2 As shown, the support ring 12 in this embodiment includes a central stepped hole and six blind holes, the cam 11 is located in the central stepped hole of the support ring 12, and is supported by the steps, and the six rolling rods 14 are respectively located on the six corners of the support ring 12. In a blind hole; then the cam 11 and the rolling rod 14 are packaged inside the support ring 12 through the cover plate 15, and the cover plate 15 and the support ring 12 are linked by rivets 13, the cam 11, the support ring 12, the rivets 13, The rolling rod 14 and the cover plate 15 together form the clutch main body 1 .

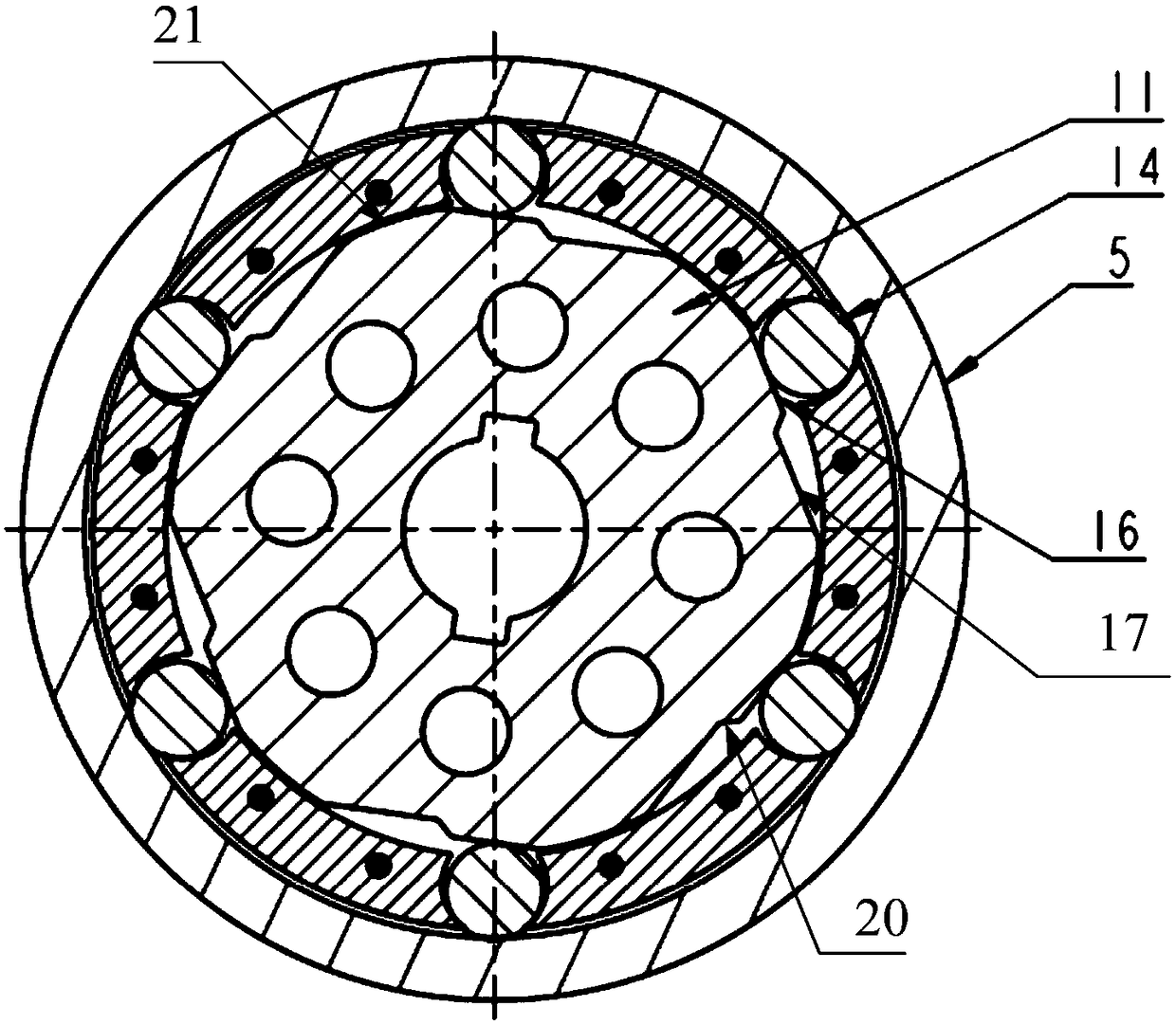

[0046] Such as Figure 6 As shown, in this embodiment, there are six working areas and non-working areas, which are evenly distributed on the circumference of the cam 11. The six working areas have the same structural shape, and the six non-working areas 21 are also six sections with the same structural shape. arc. The wrap angle δ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com