Stuck eliminating structure of thermal printer with cutter

A technology of thermal printers and cutters, applied in printing devices, printing, etc., can solve problems such as knife jams, troublesome operation, and incomplete card removal by cutters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

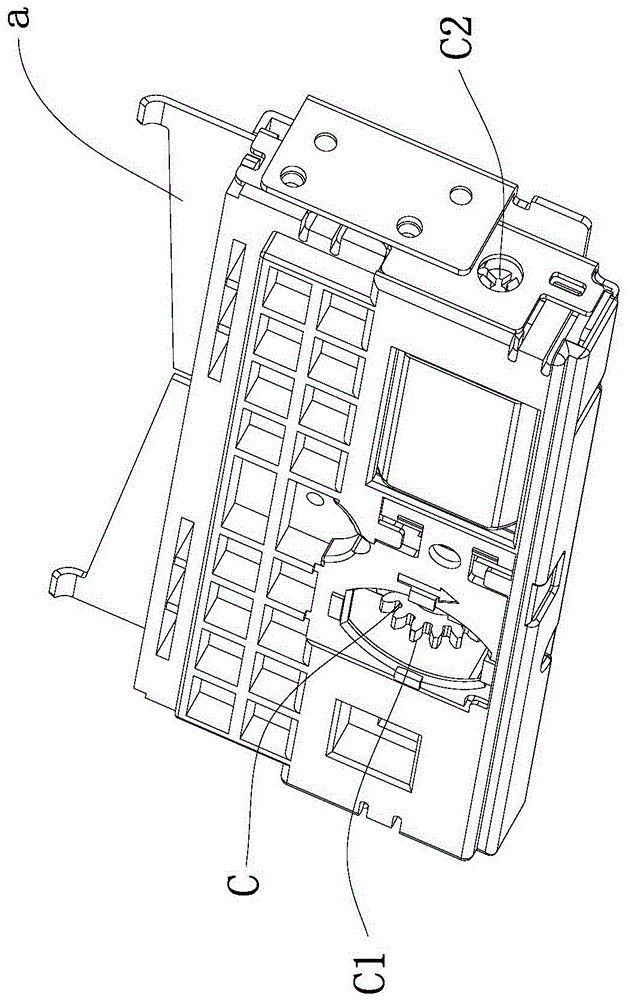

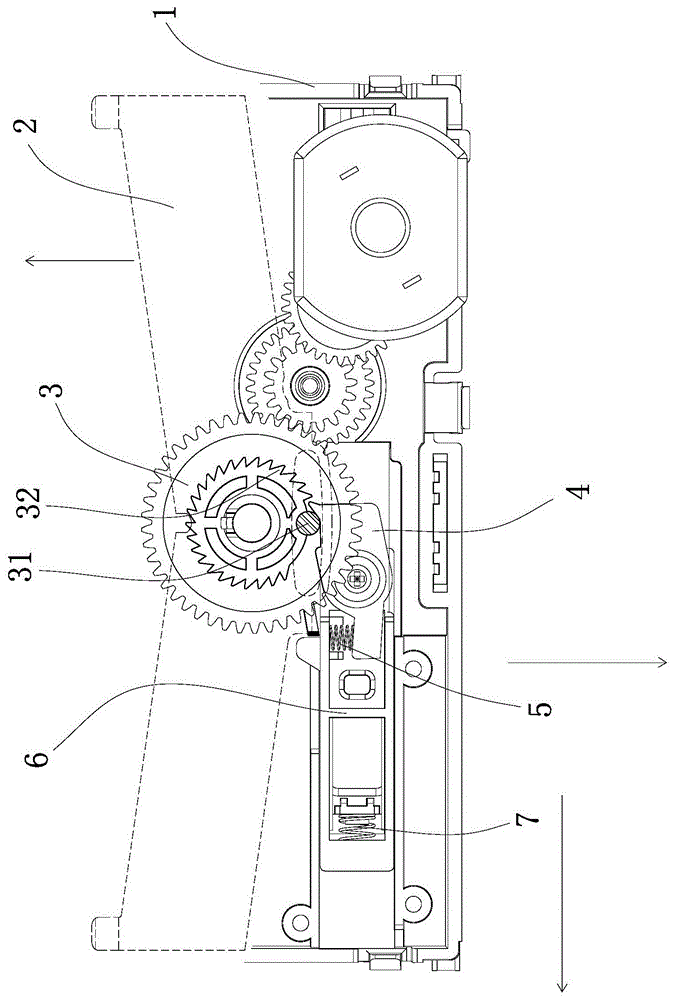

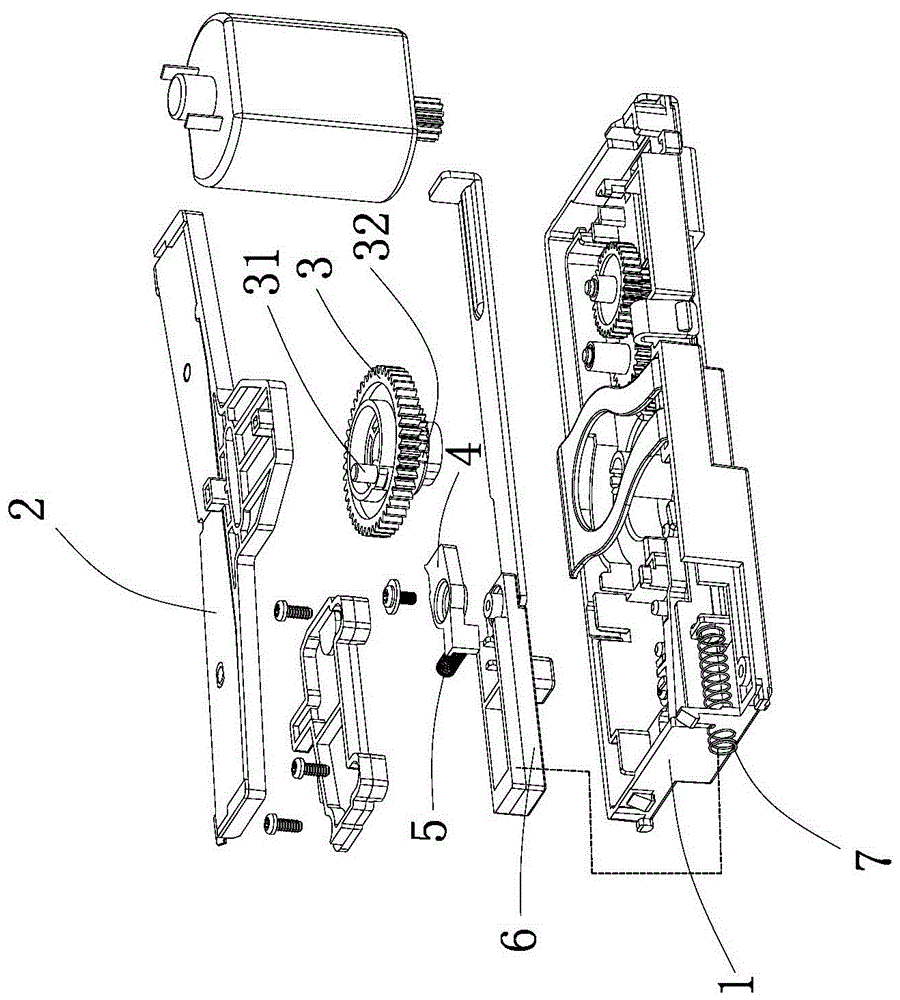

[0027] refer to figure 2 and image 3 As shown, the present invention discloses a card discharge structure for a thermal printer with a cutter, which includes a cutter gear 3, a cutter reset ratchet gear 32, a retracting pawl 4, and a retracting ratchet that can move relative to the cutter gear 3. Knife pull bar 6, cutter reset ratchet gear 32 is coaxially connected to cutter gear 3, knife retract pawl 4 is connected to retract knife pull bar 6, and both retract knife pull rod 6 and knife retract ratchet 4 are connected with a reset device. Under the effect of 6, the knife retraction pawl 4 engages 32 with the cutter reset ratchet gear.

[0028] refer to Figure 4 As shown, the above-mentioned card row structure is connected on the base 1 of the moving knife group, the cutter gear 3 is rotatably connected on the base 1, and the cutter gear 3 is connected with a driving shaft 31 matching the moving knife group 2, and the motor drives the cutter When the knife gear 3 rotates...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com