Electronic control silicone oil clutch driving disc and clutch

A silicon oil clutch, active disc technology, applied in clutches, fluid clutches, machines/engines, etc., can solve the problems of slow separation speed, high fan idle speed, fan fault misjudgment, etc., and achieve time and speed control of accelerated engagement and separation High precision, accelerated meshing and separation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

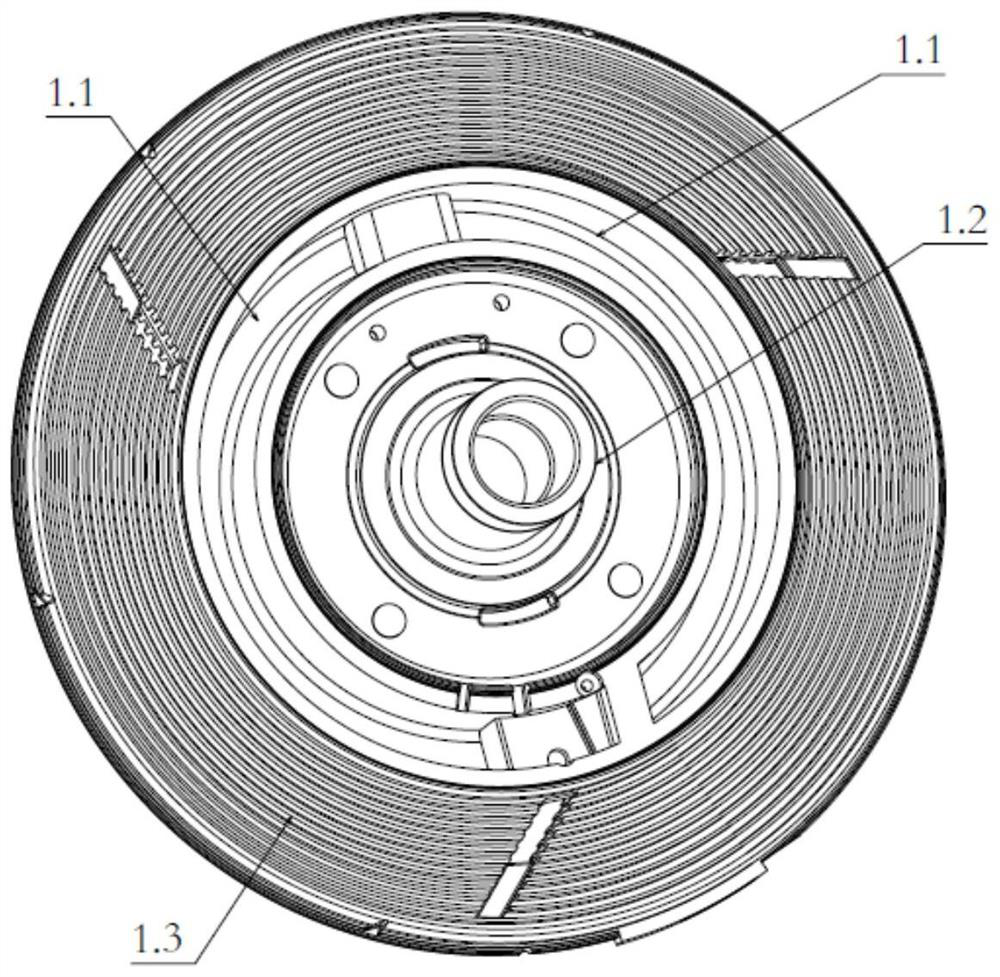

[0042] Such as figure 1 As shown, the existing clutch has a working cavity 1.3 arranged in the center of the driving disc and the edge of the driving disc, an oil storage chamber 1.1 is arranged between the working cavity 1.3 in the center of the driving disc and the edge of the driving disc, and an oil storage chamber 1.1 is arranged in the center of the driving disc. Drive disc central axis 1.2.

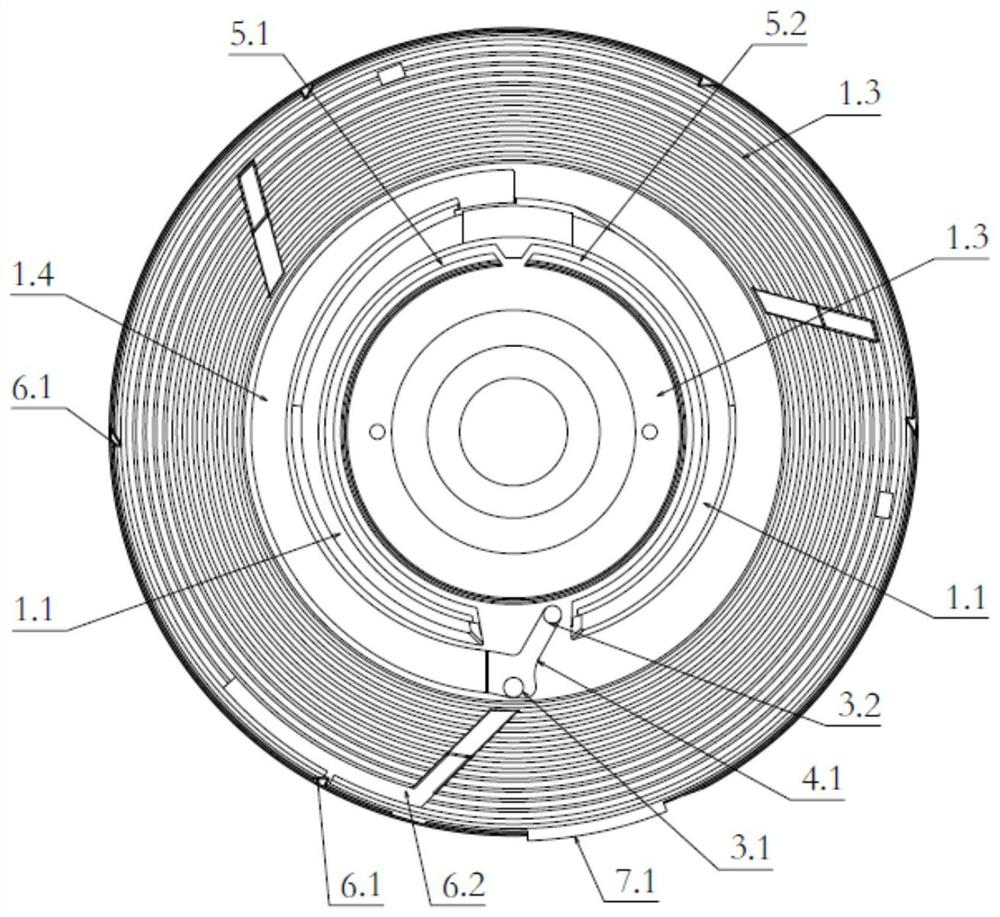

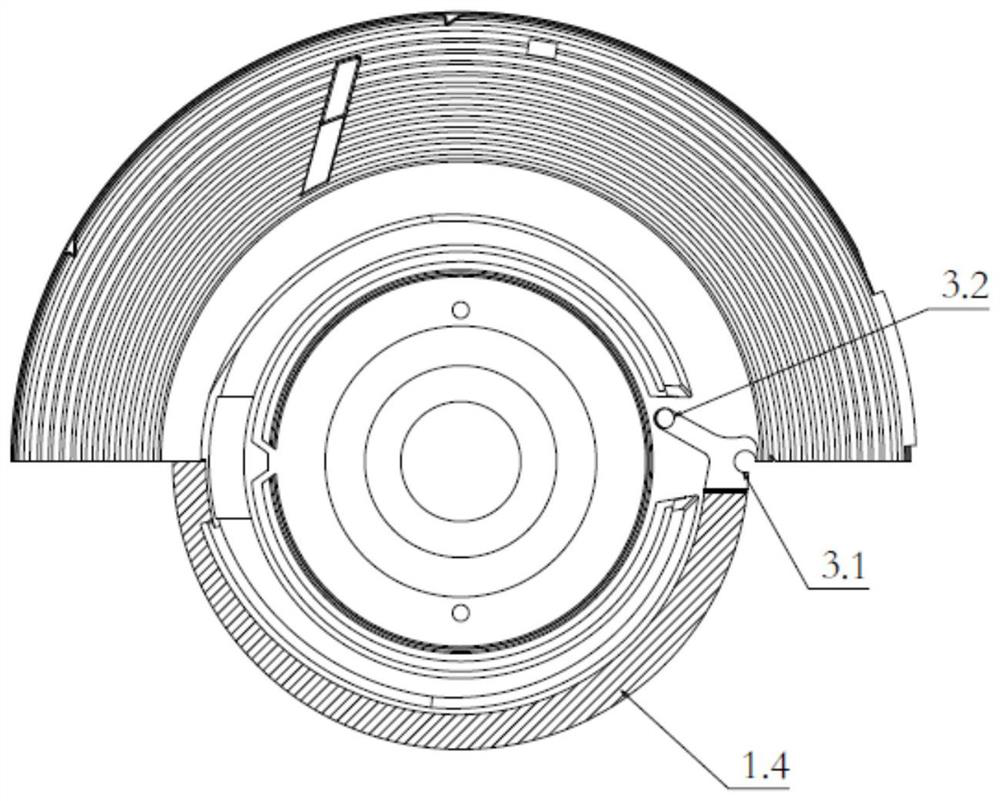

[0043] Such as Figure 2-6 As shown, the driving disc of an electronically controlled silicon oil clutch of the present invention is provided with an oil storage chamber 1.1, a working chamber 1.3, an oil outlet hole 3.1 and an oil return hole 3.2, and the oil storage chamber 1.1 and the working chamber 1.3 are closed According to the design, the silicone oil can only flow through the oil outlet hole 3.1 and the oil return hole 3.2; the oil storag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com