Stamp

A technology of seals and blocks, applied in the field of seals, can solve the problems of lack, inconvenience, and easy contamination of ink.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

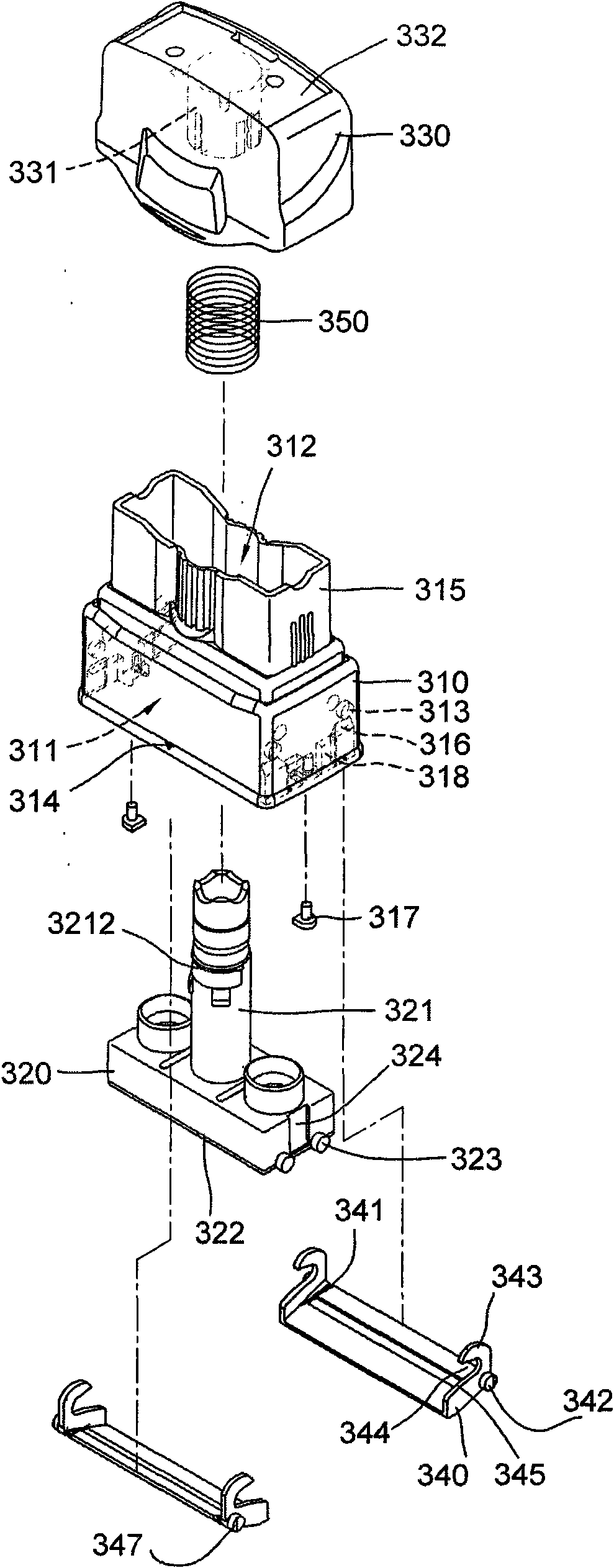

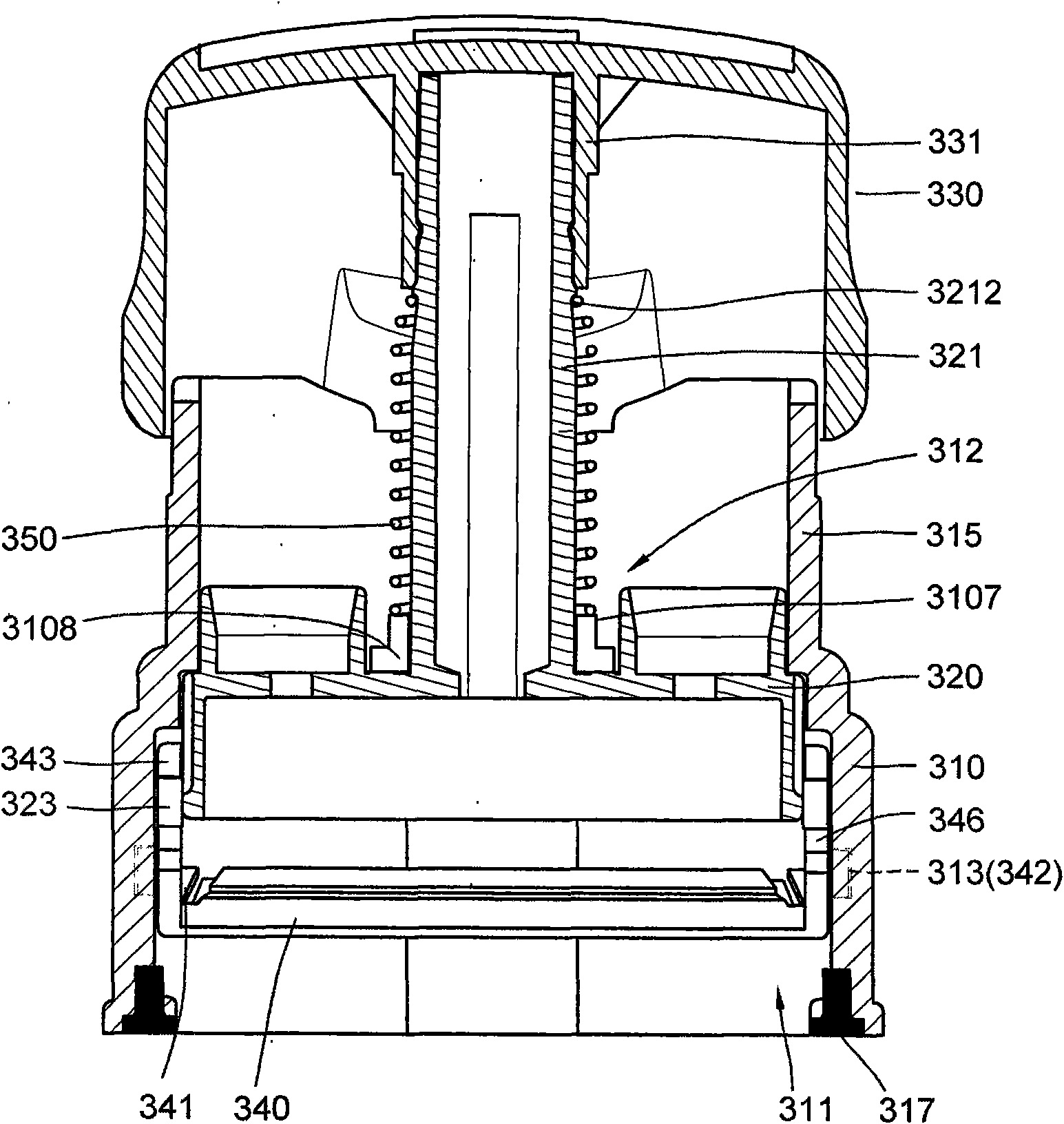

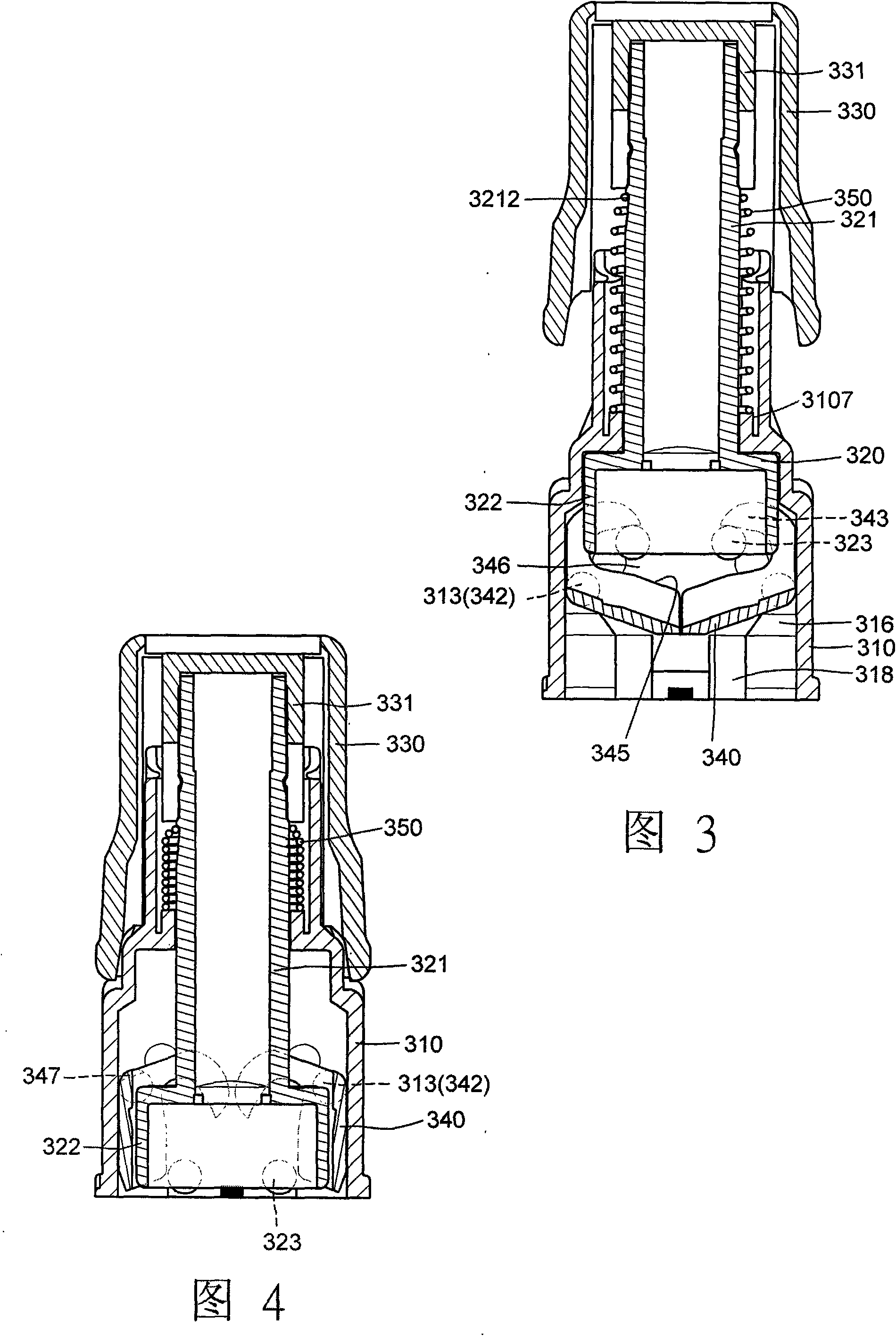

[0160] At first, a kind of seal of the present invention, as Figure 1-4 As shown, it mainly includes a main body 310, a printed body 320, a top cover 330 and two covers 340. The lower half of the main body 310 has a storage space 311, and the top surface of the storage space 311 is provided with a perforation 312. The two sides of the storage space 311 It is a wall, and the two side walls are directly provided with two circular shaft holes 313. The circular shaft holes 313 can be closed or through holes, and the circular shaft holes 313 can provide the largest bearing area on the entire circumference of the protruding shaft 342 of the cover 340. , to disperse the friction force and reduce the damage during operation (the conventional concave arc design will make the friction force concentrate on the concave arc edge and cause relatively rapid damage), thus prolonging the service life of the seal. The wall of the circular shaft hole 313 is set in a sheet shape The shape makes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com