Circular tube welding seam detecting and positioning mechanism

A welding seam detection and positioning mechanism technology, which is applied in the direction of positioning device, feeding device, storage device, etc., can solve the problems of large data and low efficiency of pipe welding seam detection, and achieve improved efficiency, convenient welding seam detection, and rotation smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

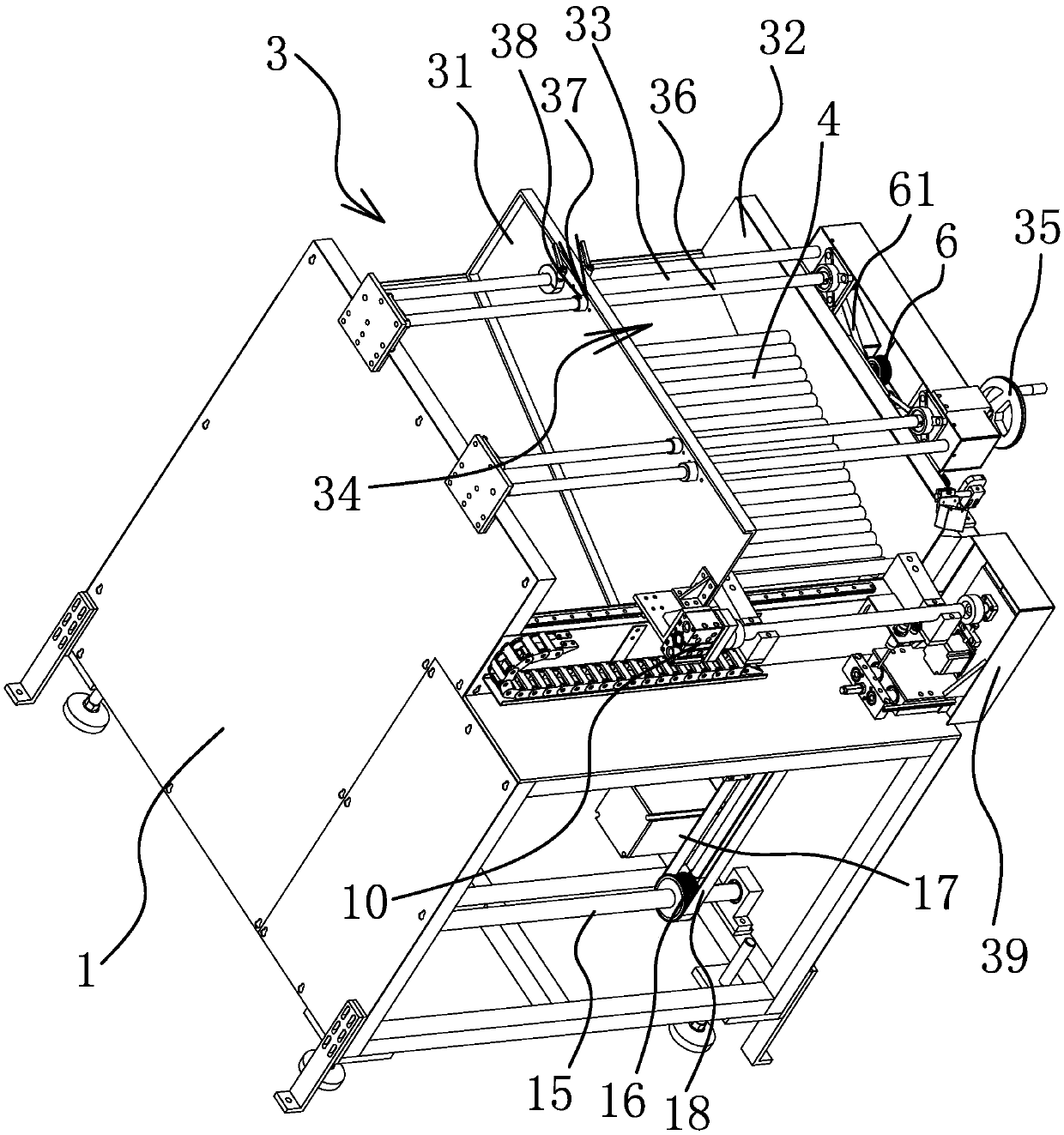

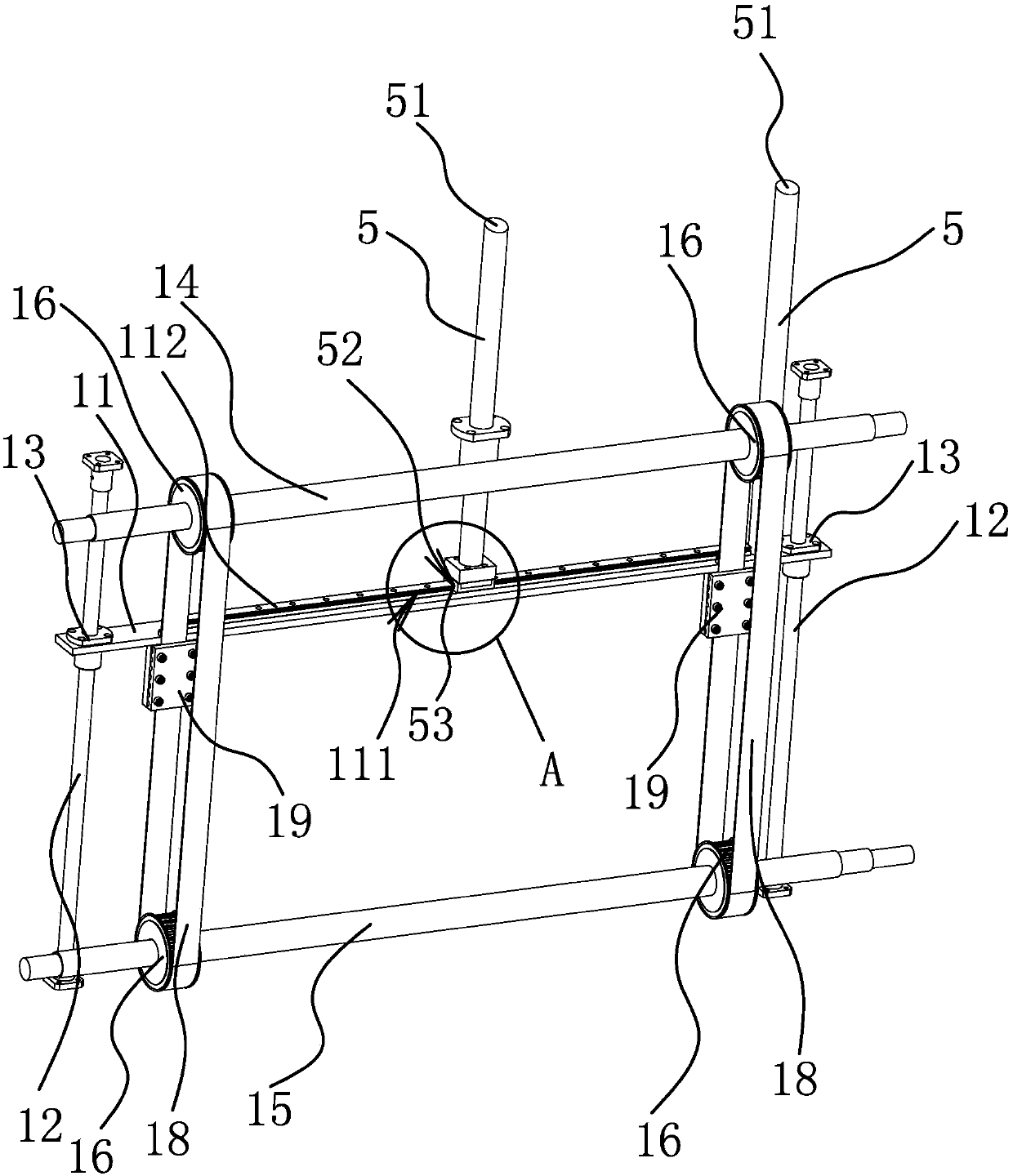

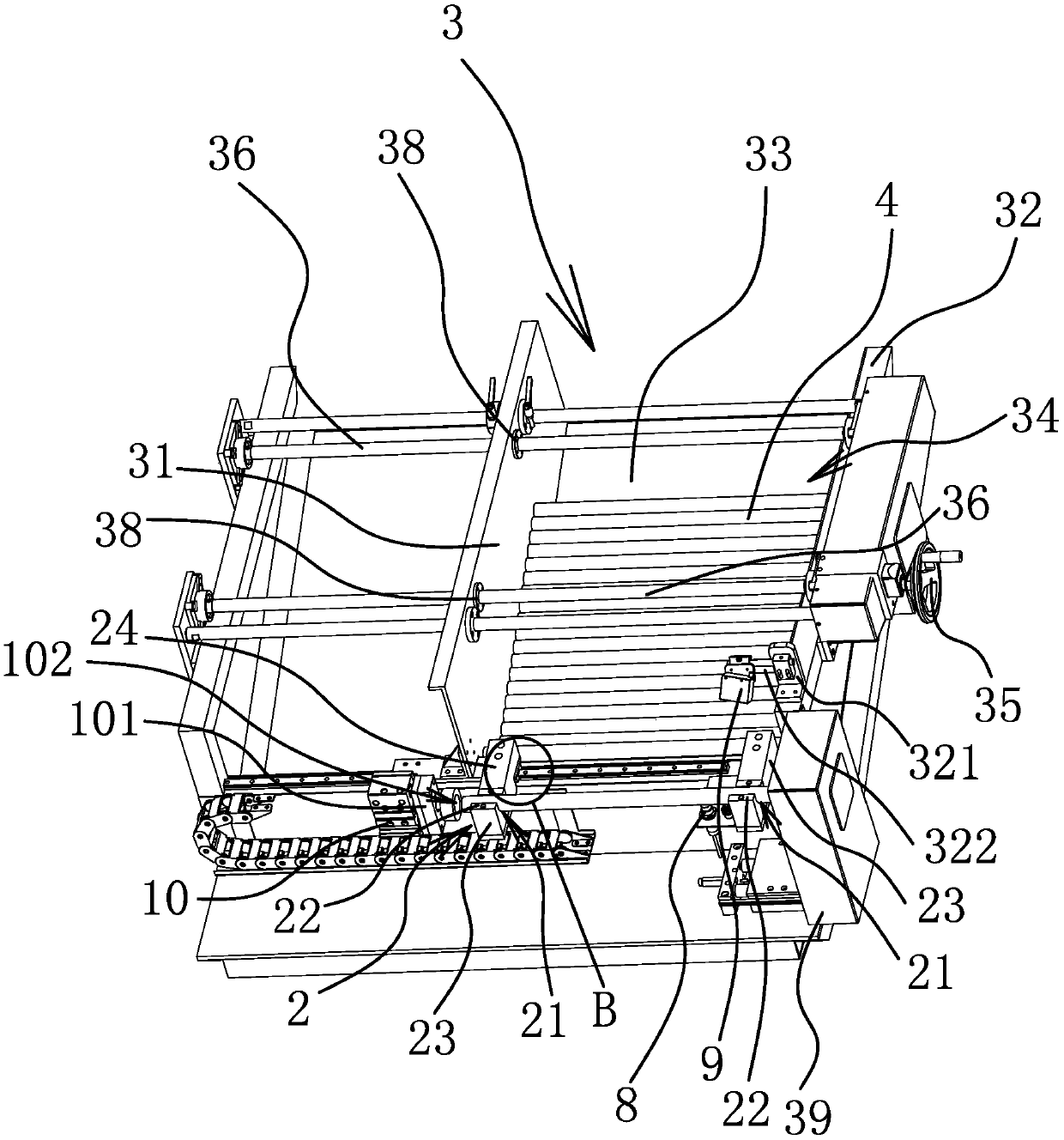

[0037] like figure 1 As shown, the circular pipe welding seam detection and positioning mechanism includes a base 1, on which a feeding bin 3 and a positioning seat 2 are arranged, and a bottom plate 33 capable of transmitting workpieces 4 is arranged on the feeding bin 3.

[0038] Specifically, if Figure 1-6 As shown, the positioning seat 2 is provided with a limiting groove 21 for placing the workpiece 4, and the workpiece 4 can rotate in the limiting groove 21, and the base 1 is provided with a rotating motor 7, a proximity switch 8 and a clamping cylinder 10, The rotating motor 7 is arranged on one side of the workpiece 4, and one end of the rotating motor 7 is provided with a rotating groove 71 that can be embedded in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com