Ultrasonic nondestructive testing device and method for welding seam of steel pipe

A technology of non-destructive testing and weld seam testing, which is applied to measuring devices, analyzing solids using sound waves/ultrasonic waves/infrasonic waves, and using sound waves/ultrasonic waves/infrasonic waves for material analysis. Complicated structures and other issues to achieve the effect of improving accuracy and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

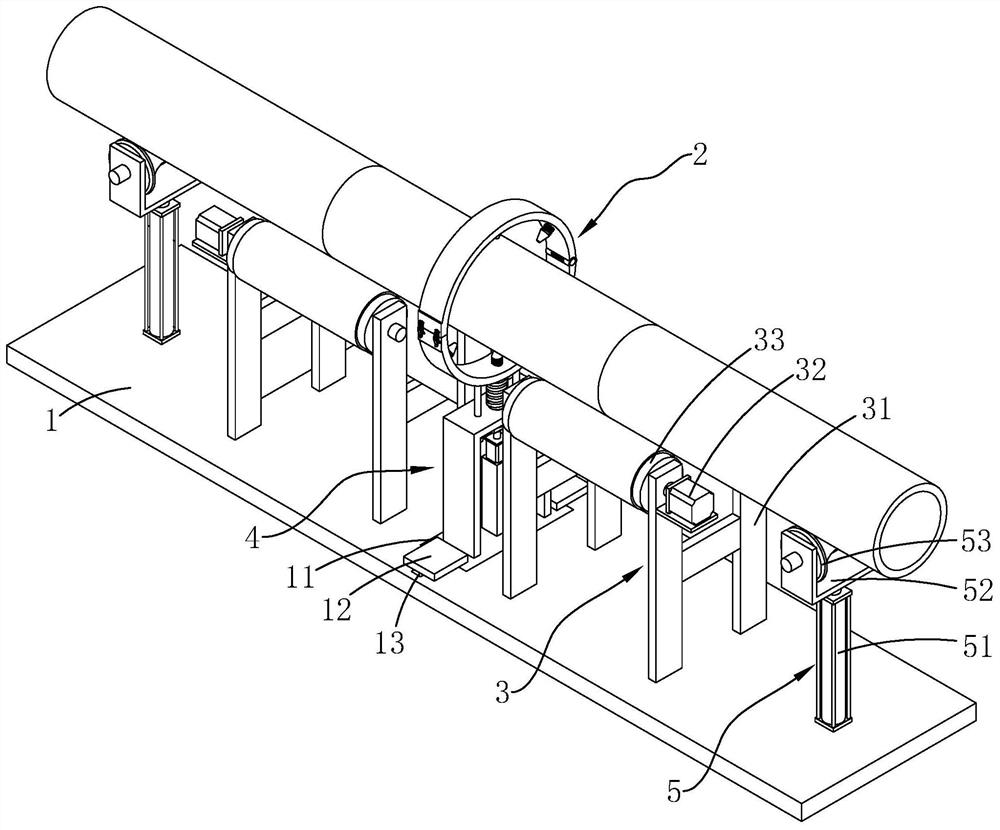

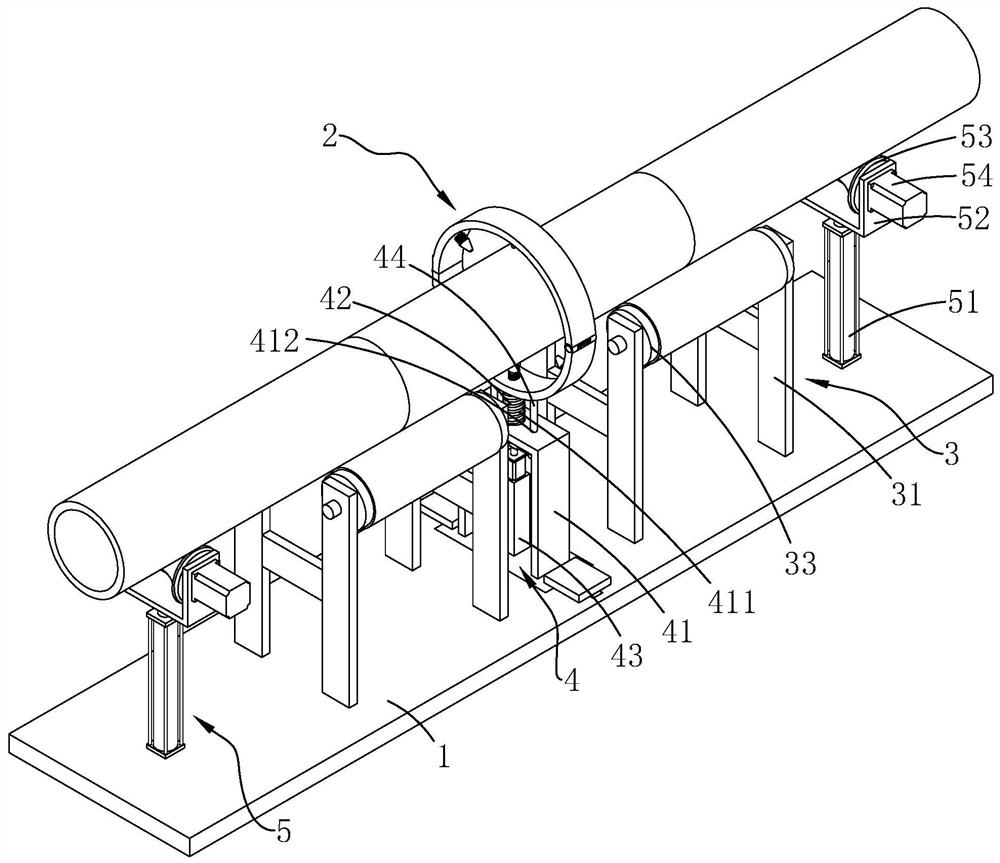

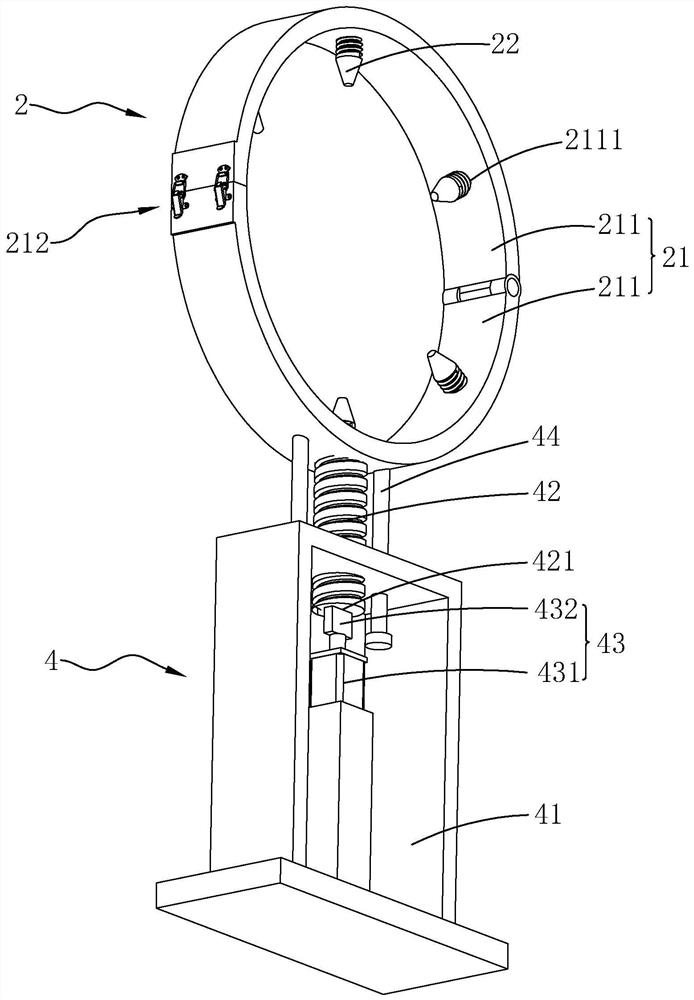

[0038] The following is attached Figure 1-3 The application is described in further detail.

[0039] The embodiment of the present application discloses an ultrasonic non-destructive testing device for a steel pipe weld seam.

[0040] refer to figure 1 and figure 2 , the ultrasonic nondestructive testing device for steel pipe welds includes a supporting base 1, a weld testing mechanism 2, a driving mechanism 3, a lifting mechanism 4 and a conveying mechanism 5, the welding seam testing mechanism 2 and the driving mechanism 3 are both arranged on the supporting base 1, and the driving mechanism 3. It is used to support the horizontally arranged pipeline and drive the pipeline to rotate around its center line. The weld seam on the outer peripheral wall of the pipeline is detected by the weld seam detection mechanism 2. The lifting mechanism 4 is arranged on the support base 1 and the weld seam detection mechanism 2 Between them, it is used to adjust the height of the weldin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com