Pipeline welding seam detection method

A welding seam detection and pipeline technology, which is applied in the fields of unstructured text data retrieval, instruments, image data processing, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention is further described below by means of a preferred embodiment, but the present invention is not limited to the scope of the described embodiment.

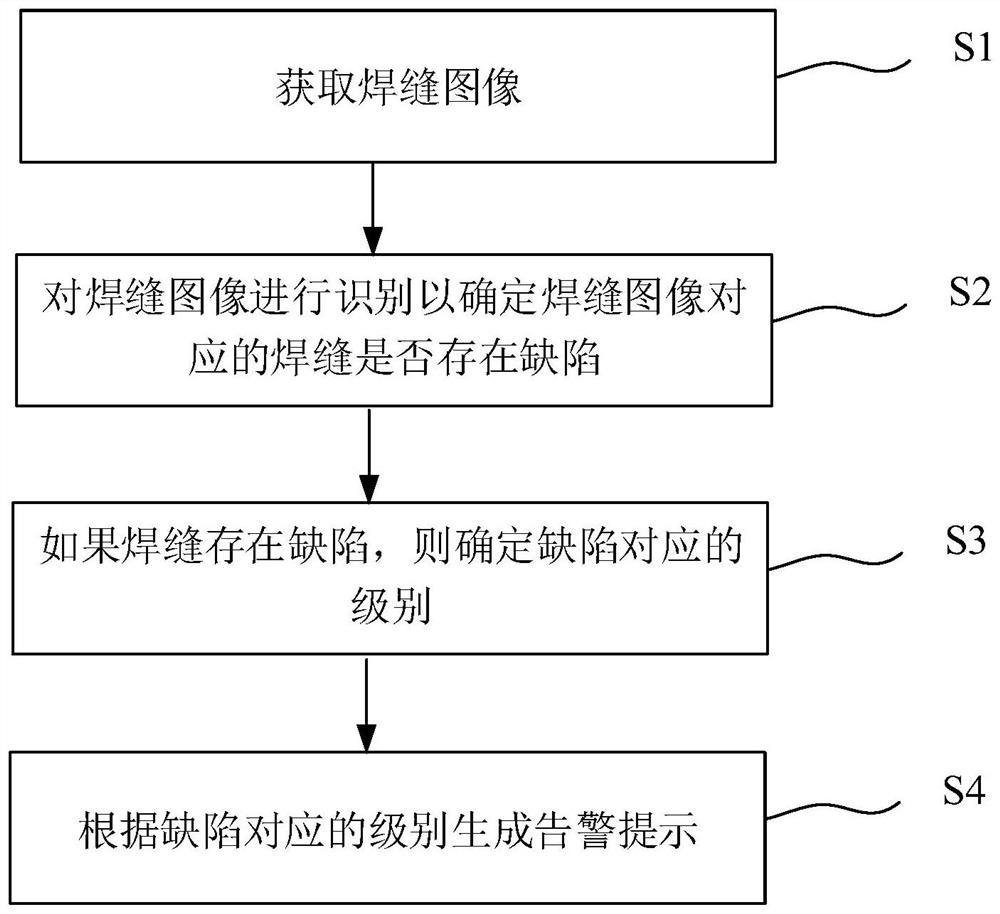

[0038] This embodiment provides a pipeline weld detection method. refer to figure 1 , the pipeline weld detection method includes the following steps:

[0039] Step S1, acquiring a weld image.

[0040] Step S2, identifying the weld image to determine whether the weld corresponding to the weld image has defects.

[0041] Step S3, if there is a defect in the weld, determine the level corresponding to the defect.

[0042] Step S4, generating an alarm prompt according to the level corresponding to the defect.

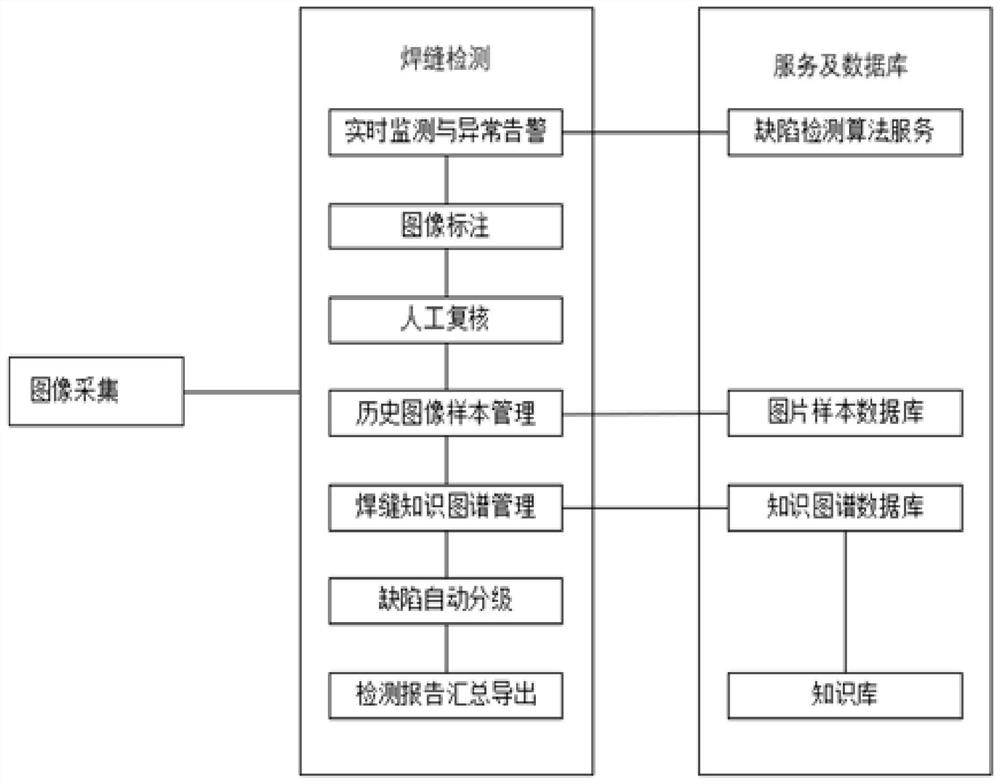

[0043] In some optional embodiments, the pipeline weld detection method is implemented in the form of weld detection software and runs on a computer platform. The structural reference of this weld inspection software figure 2 As shown, it includes three modules: image acquisition, weld inspect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com