Swing type aggregate conveyor

A reloader and swing-type technology, which is applied to conveyors, loading/unloading, earthwork drilling and mining, etc., to achieve the effect of reducing labor intensity, reducing labor costs, and moving flexibly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

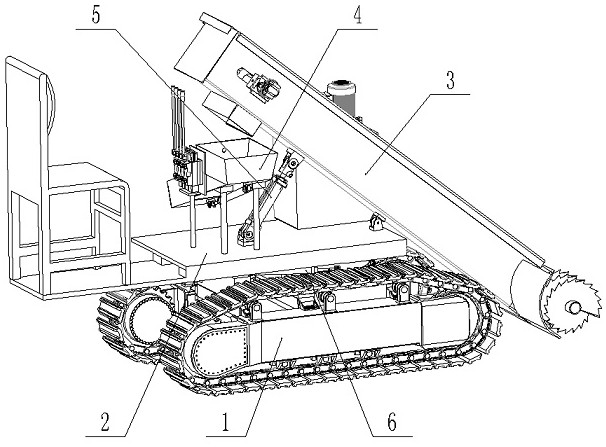

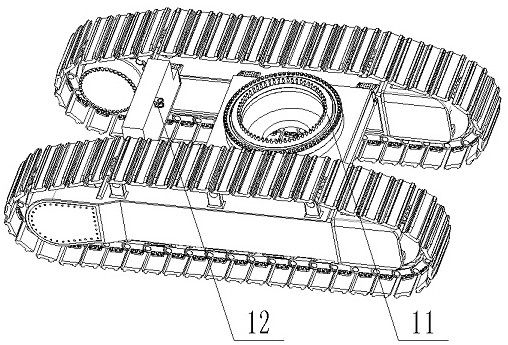

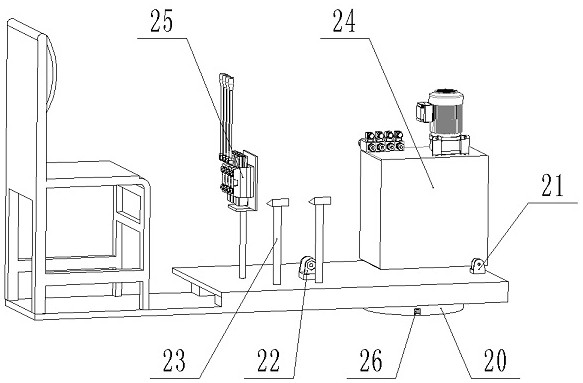

[0019] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 with Figure 8 As shown, a swing type aggregate reloading machine includes a crawler walking part 1, a rotary frame 2, a swing hydraulic cylinder 6, an aggregate transfer part 3, an inclination hydraulic cylinder 5 and a discharge part 4; wherein, the rotary Frame 2 is made up of revolving seat 20, front hinged ear seat 21, rear end hinged ear seat 22, swing hinged ear seat 26, pillar 23, oil tank 24 and console 25; On the revolving base 11 of the traveling part 1; the swing hinged lug 26 of the revolving frame 2 is hinged with the piston rod of the swing hydraulic cylinder 6, and the cylinder body of the swing hydraulic cylinder 6 is hinged with the crossbeam hinged lug 12 of the crawler walking part 1; The front-end hinged lug 31811 at the bottom of the transportation trough 318 of the material transfer part 3 is hinged with the front-end hinged lug 21 of the rotary frame 2,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com