Lithium supplementing material and preparation method thereof, negative electrode and lithium ion battery

A lithium-ion battery and lithium-replenishing technology, applied in negative electrodes, battery electrodes, secondary batteries, etc., can solve problems such as reducing lithium-replenishing efficiency, forming dendrites, and potential safety hazards, and improving lithium-replenishing efficiency, increasing channels, The effect of avoiding safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] The preparation method of the negative electrode of the lithium ion battery of the present disclosure has no special requirements, and can be carried out with reference to the prior art. For example, the preparation method of the negative electrode of the lithium ion battery of the present disclosure may include coating the negative electrode slurry containing the negative active material and the binder And / or filled on the negative current collector, dry, calendered or not. The specific operation methods and conditions can be conventional in the art, and there is no special limitation here.

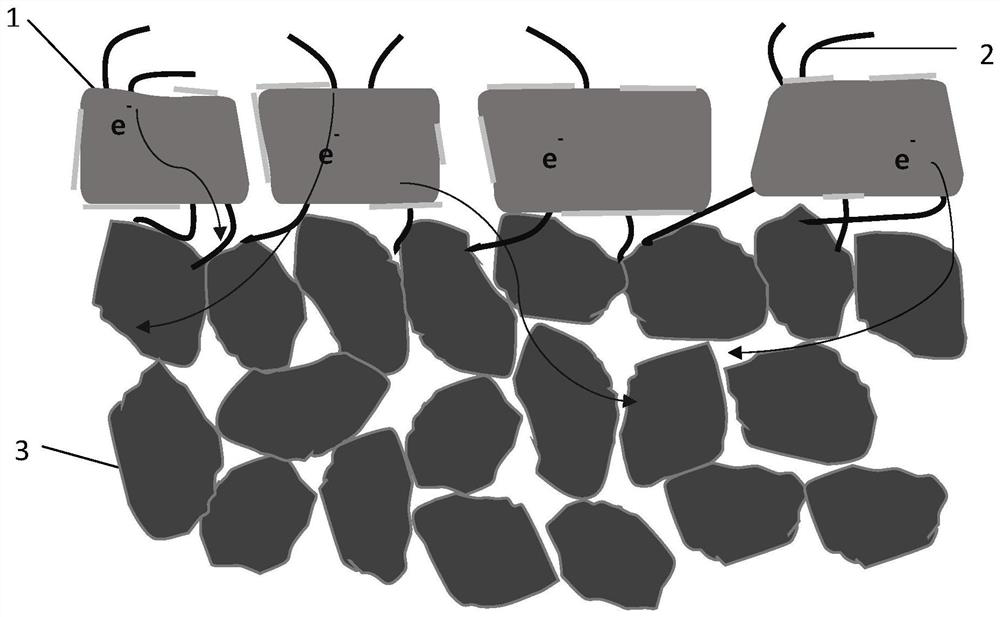

[0051] figure 1 It shows a schematic diagram of the principle of lithium supplementation when the lithium supplementation material of the present disclosure is applied to the negative electrode of a lithium ion battery. When the conductive material 2, such as carbon nanotubes, is partially embedded in the lithium metal particle 1, the conductive material 2 can be wound through the...

Embodiment 1

[0062] In a dry environment at -60°C, add 10g of metal lithium ingot to 25g of simethicone oil and raise the temperature to 200°C. After the metal lithium ingot is completely melted, add 0.1g of polyvinylpyrrolidone and stir until the metal lithium ingot is completely dissolved to obtain the first A dispersion liquid: take 0.05 g of multi-walled carbon nanotubes with a diameter of 10 nm and a length of 50 μm, add 25 g of silicone oil, and stir at 200 ° C until the multi-walled carbon nanotubes are fully dispersed to obtain a second dispersion; under high-speed stirring conditions, the first The second dispersion liquid was slowly added to the first dispersion liquid and mixed uniformly, carbon dioxide gas was introduced, stirring and heating were stopped, and after cooling to room temperature, the solid product was collected and dried to obtain the lithium supplement material A1. It was detected that the average particle diameter of the lithium metal particles was 27.8 μm, and ...

Embodiment 2

[0064] In a dry environment at -60°C, add 10g of metal lithium ingot to 25g of simethicone oil and raise the temperature to 200°C. After the metal lithium ingot is completely melted, add 0.1g of sodium dodecylbenzenesulfonate and stir until the metal lithium Dissolve the ingot completely to obtain the first dispersion; take 0.05 g of multi-walled carbon nanotubes with a diameter of 10 nm and a length of 50 μm, add 25 g of silicone oil, and stir at 200 ° C until the multi-walled carbon nanotubes are fully dispersed to obtain the second dispersion; Under certain conditions, the second dispersion liquid was slowly added to the first dispersion liquid and mixed uniformly, carbon dioxide gas was introduced, stirring and heating were stopped, and after cooling to room temperature, the solid product was collected and dried to obtain lithium-replenishing material A2. It was detected that the average particle diameter of the lithium metal particles was 42.2 μm, and the thickness of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com