Ballistic construction panel

a technology of construction panels and ballistics, applied in construction, building components, construction materials, etc., can solve the problems of increased danger to personnel stationed in the middle east, increased risk of shooting and/or fragmentation of shrapnel, and inability to resist high-velocity projectiles, etc., to achieve the effect of convenient transportation and light weigh

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

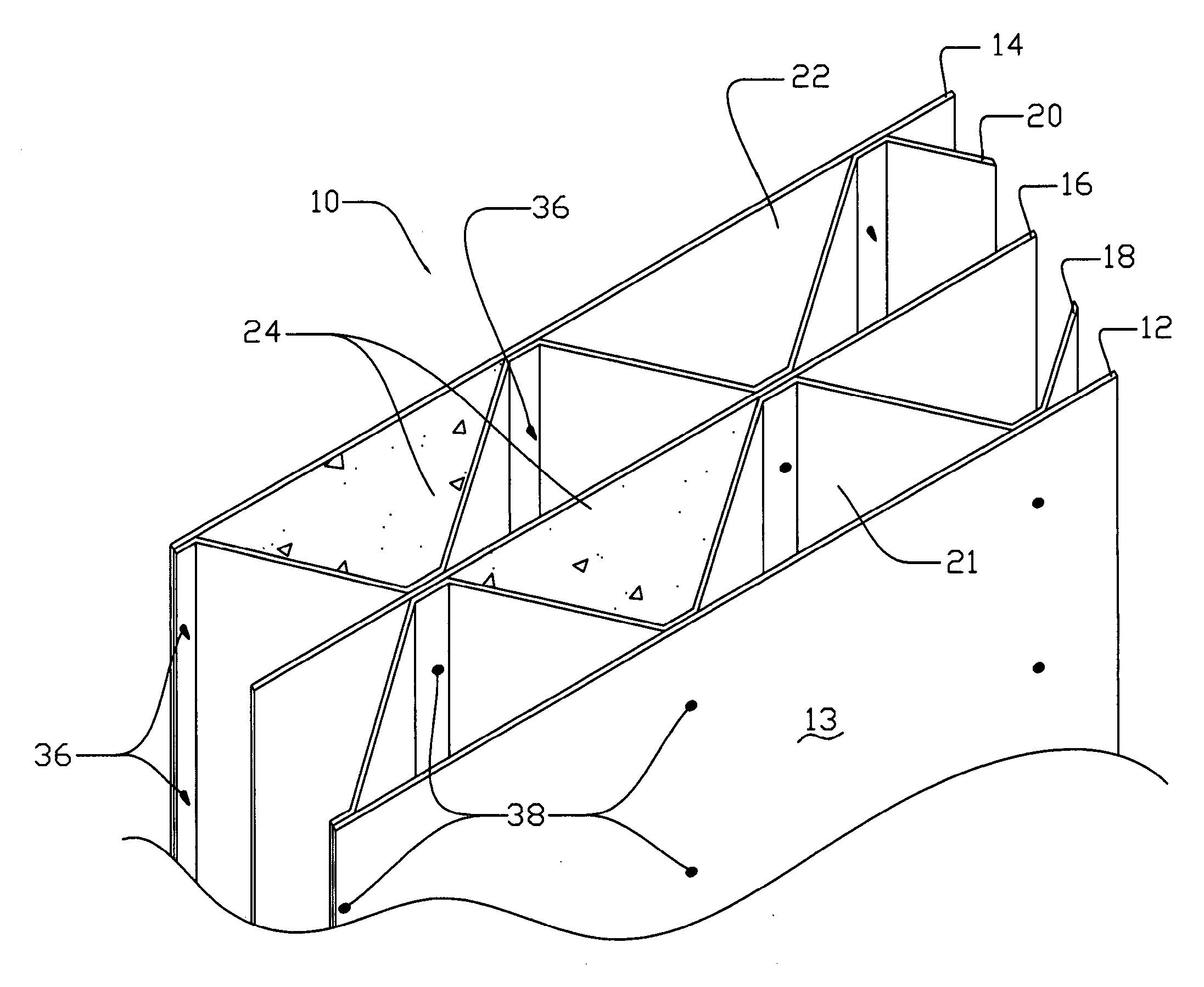

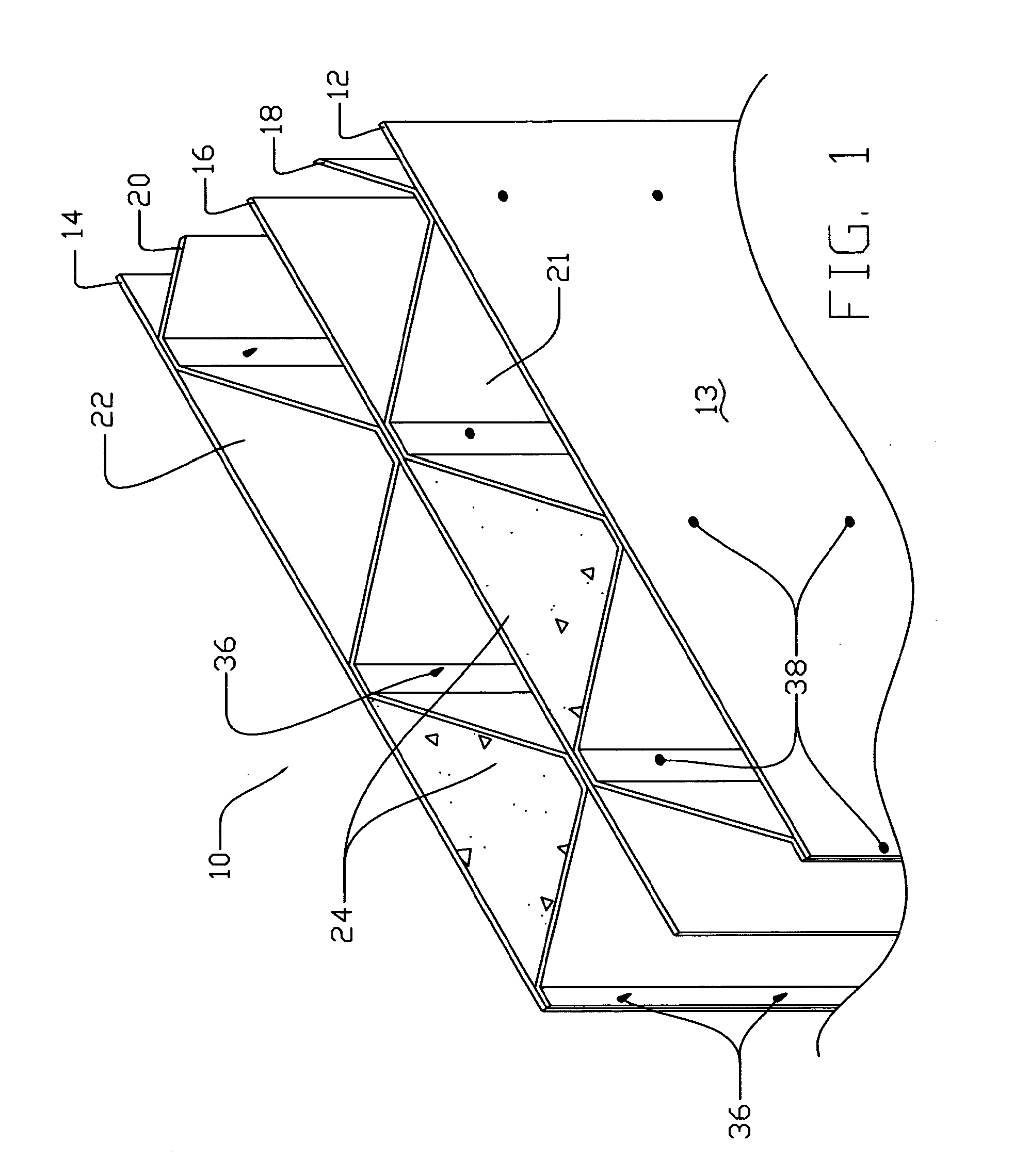

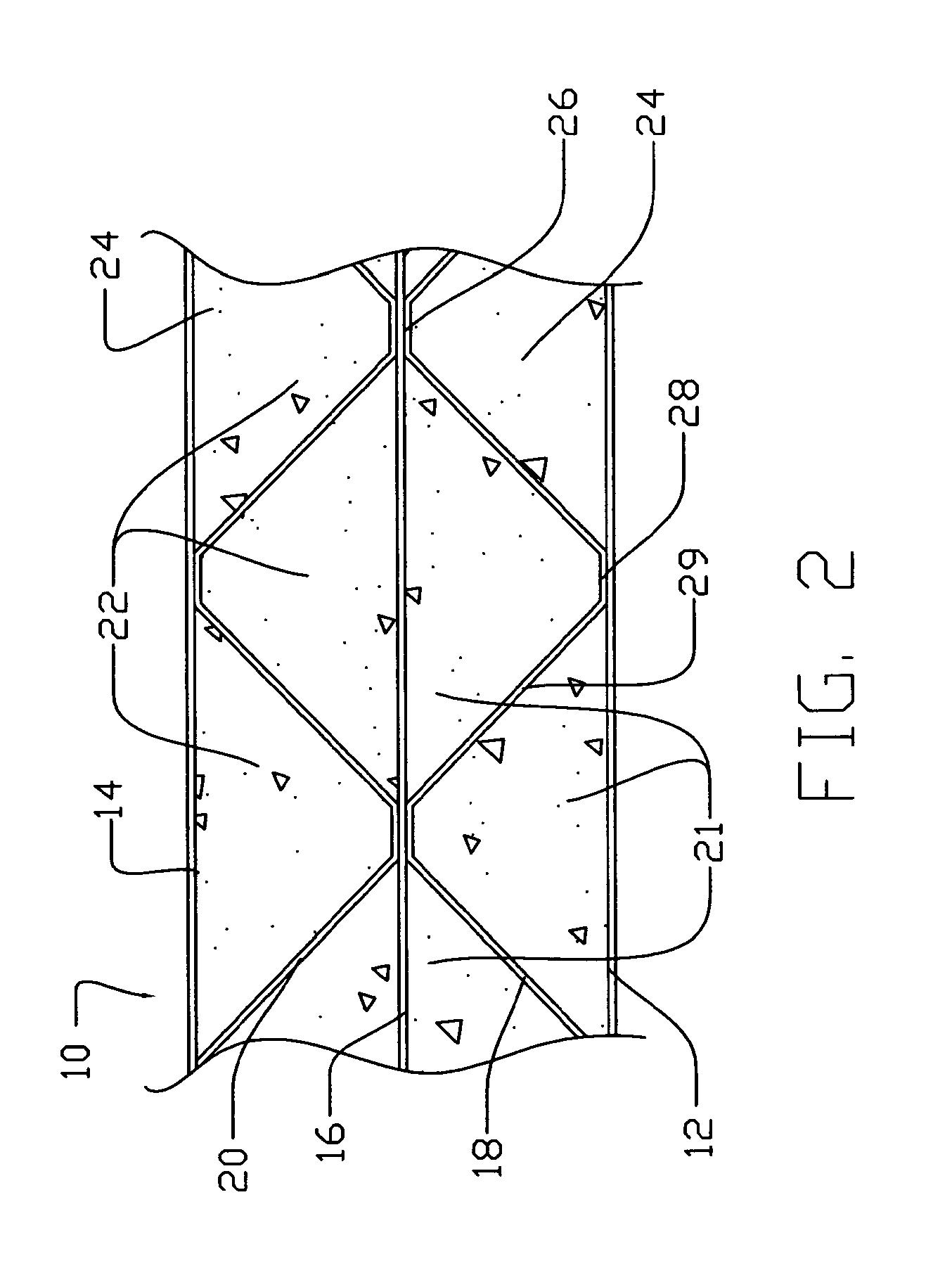

[0035]Referring now to FIGS. 1-3, there is shown a preferred embodiment of the present invention. As shown, a ballistic construction panel 10 includes an inner sheet member 12, an outer sheet member 14, and a middle sheet member 16. These sheets 12, 14, 16 are relatively thin, rigid, and planar and are disposed parallel to each other. A corrugated member is disposed between adjacent sheets. In the preferred embodiment, there are three sheets and therefore there are two corrugated members 18, 20. Corrugated member 18 is disposed between and abuts sheets 12 and 16 while corrugated member 20 is disposed between and abuts sheets 14 and 16. In this manner, a layered or sandwich arrangement is produced having alternating layers of a sheet, then a corrugated member, then a sheet, etc. By abutting the corrugated members 18, to the planar sheets 12-16 a plurality of enclosed cells or channels 21, 22 are formed within the panel 10. These cells 21, 22 are filled with a solid granular filler ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thick | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com