Carbon-coated metal sulfide electrode material, preparation method and application thereof

A metal sulfide and electrode material technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of poor cycle performance and rate performance of sodium ion batteries, achieve good sodium ion intercalation and extraction capabilities, simple preparation methods, slow down The effect of volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The preparation method of the carbon-coated metal sulfide electrode material of the present invention comprises the following steps:

[0030] (1) Cover the metal sulfide precursor on the nanowire template to form uniform and neatly dispersed nanoscale products.

[0031] (2) A uniform and dense carbon material film is covered on the surface of the metal sulfide.

[0032] (3) The nanowire template is removed to obtain a carbon-coated metal sulfide electrode material.

[0033] Step (1) adopts electrospinning method, spray method, sol-gel method, hydrothermal method, solvothermal method, co-precipitation method or impregnation method.

[0034] Wherein, when the step (1) adopts the hydrothermal method to prepare the metal sulfide, it specifically includes the following steps:

[0035] (1-1) After mixing the organic solvent (ethanol or acetone) and water at a volume ratio of 1:0~1, then add 1-butyl-3-methylimidazolium tetrafluoroboric acid at a volume ratio of 40:1~3 Salt ...

Embodiment 1

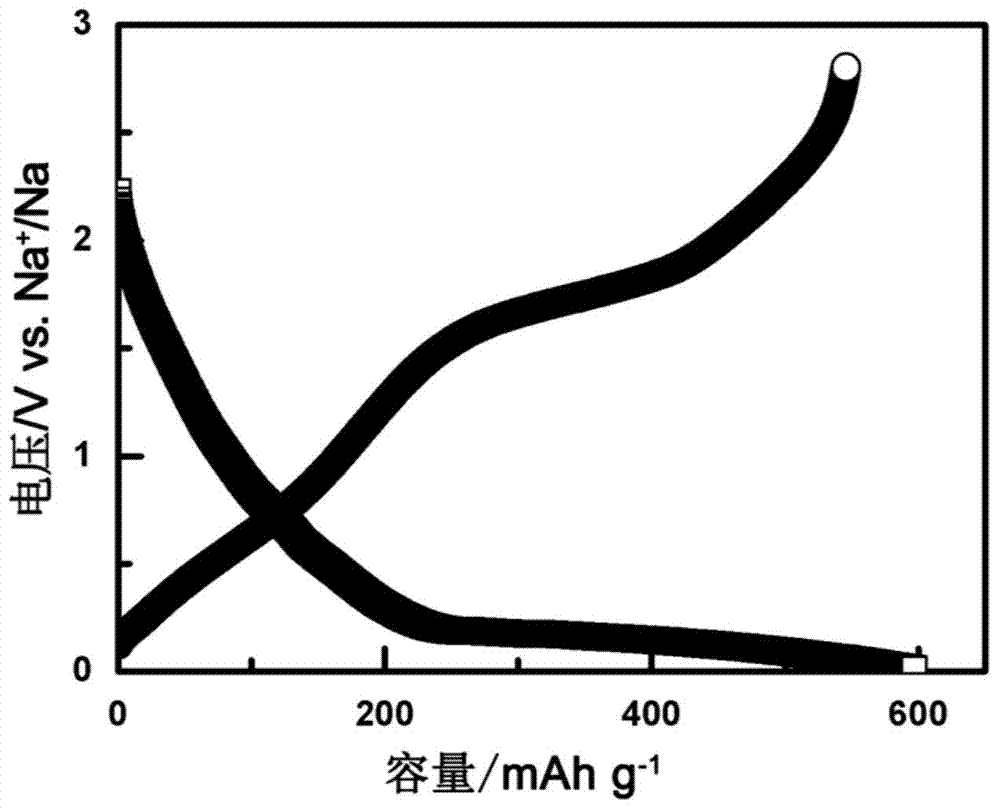

[0045] Preparation of carbon-coated MoS 2 (x=2) Electrode material, specifically including the following steps:

[0046] (1) MoS 2 The precursor covers the nanowire template to form uniform and neatly dispersed nanoscale products. Further include the following steps:

[0047] (1-1) After mixing water and ethanol at a volume ratio of 1:1, 1-butyl-3-methylimidazolium tetrafluoroborate and alumina nanowire templates are added at a volume ratio of 40:1 to obtain a mixed solvent.

[0048] (1-2) Dissolve 3.0g of ammonium heptamolybdate in 40mL of mixed solvent and stir for 30min to obtain solution ①. Add 2.8g of thiourea to 40mL of mixed solvent and stir for 1h to obtain solution ②.

[0049] (1-3) Mix solution ① and solution ②, stir for 30 minutes, transfer to a 100mL hydrothermal reaction kettle with a stainless steel shell and a polytetrafluoroethylene lining, blow nitrogen into it for 1 hour, seal the reaction kettle, and put the reaction The kettle was heated to 200°C, and ...

Embodiment 2

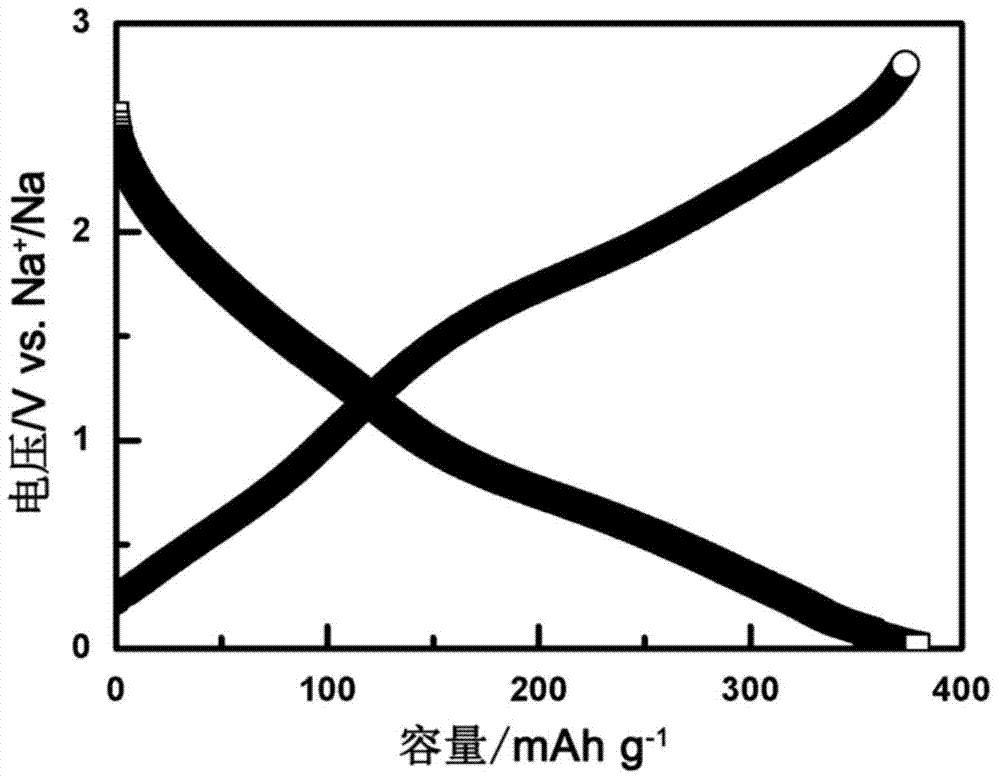

[0056] Preparation of carbon-wrapped MoS 3 (x=3) Electrode materials, specifically including the following steps:

[0057] (1) MoS 3 The precursor covers the nanowire template to form uniform and neatly dispersed nanoscale products. Further include the following steps:

[0058] (1-1) After mixing water and acetone at a volume ratio of 1:3, 1-butyl-3-methylimidazolium tetrafluoroborate and alumina nanowire templates are added at a volume ratio of 20:1 to obtain a mixed solvent.

[0059] (1-2) Dissolve 2.8g of ammonium heptamolybdate in 40mL of mixed solvent and stir for 30min to obtain solution ①. Add 4.2g of thiourea to 40mL of mixed solvent and stir for 1h to obtain solution ②.

[0060] (1-3) Mix solution ① and solution ②, stir for 30 minutes, transfer to a 100mL hydrothermal reaction kettle with a stainless steel shell and a polytetrafluoroethylene lining, blow nitrogen into it for 1 hour, seal the reaction kettle, and put the reaction The kettle was heated to 200°C, ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com