Heat-resistant polypropylene plastic pipe and preparation method thereof

A polypropylene and plastic pipe technology, applied in the field of plastics, can solve the problems of easy deformation of pipes due to heat, short service life, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

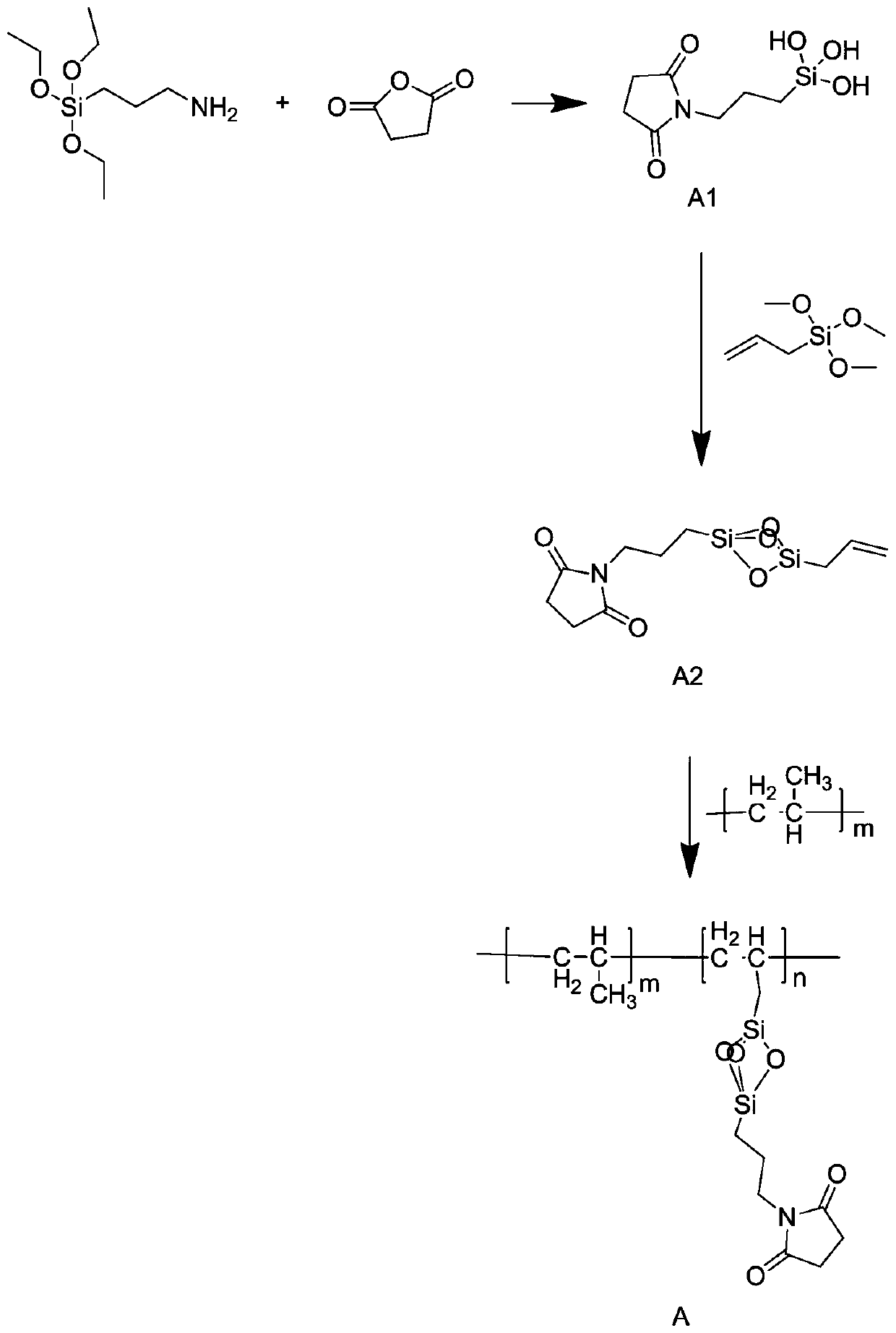

[0029] Such as figure 1 Shown, the preparation method of modified polypropylene is:

[0030] S1. Add 20mmol (3-aminopropyl) triethoxysilane, 20mmol succinic anhydride and 100-150ml solvent DMF into the reaction flask, feed nitrogen gas for 10-15min, replace the air in the reaction flask, and heat to 105 React at -110°C for 1.5-2h, then open the reaction bottle, add 0.1-0.2g of acid catalyst p-toluenesulfonic acid and zinc chloride, feed nitrogen again for 10-15min, raise the temperature to 150-160°C, and reflux for 2-3h , after the reaction, naturally cool to 75-80°C, add 50-70ml of deionized water, stir for 1.5-2h, naturally cool to room temperature, separate liquids, the organic phase is decompressed and the solvent is recovered to obtain intermediate A1; The rate is 92.7%;

[0031] S2, add 10-11mmol allyltrimethoxysilane and 100ml absolute ethanol in the reaction bottle, after stirring and dissolving, add the 10mmol intermediate A1 prepared in the first step, put the reac...

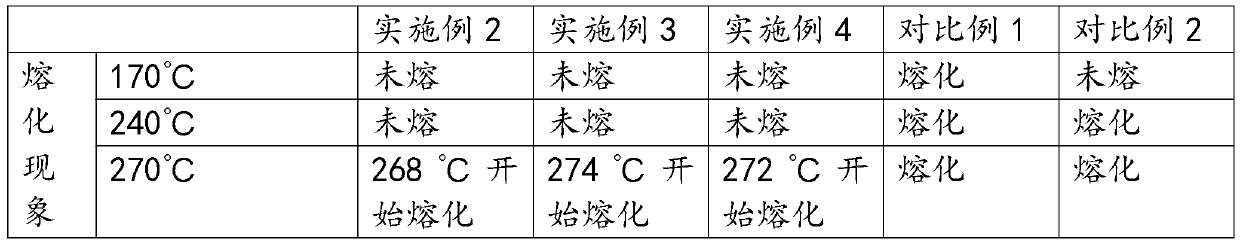

Embodiment 2

[0035] The invention is a heat-resistant polypropylene plastic pipe, comprising the following raw materials in parts by weight: 120g of modified polypropylene, 30g of filler, 2g of stabilizer, 3g of plasticizer, and 5g of antioxidant;

[0036] Described filler is carbon black;

[0037] Described stabilizer is sodium stearate;

[0038] Described plasticizer is dioctyl phthalate;

[0039] Described antioxidant is antioxidant 168;

[0040] The preparation method of the heat-resistant polypropylene plastic pipe specifically comprises the following steps:

[0041] The first step is to add modified polypropylene, fillers, stabilizers, plasticizers, and antioxidants into the high-speed mixer, and pre-mix at a temperature of 50°C for 25 minutes;

[0042] The second step is to put the pre-mixed raw materials into a screw extruder, melt and extrude them at a temperature of 190-250°C, and cut them after setting the shape to obtain heat-resistant polypropylene plastic pipes.

Embodiment 3

[0044] The invention is a heat-resistant polypropylene plastic pipe, which comprises the following raw materials in parts by weight: 140g of modified polypropylene, 40g of filler, 3g of stabilizer, 5g of plasticizer, and 2g of antioxidant;

[0045] Described filler is carbon black;

[0046] Described stabilizer is sodium stearate;

[0047] Described plasticizer is di-n-octyl phthalate;

[0048] Described antioxidant is antioxidant 168;

[0049] The preparation method of the heat-resistant polypropylene plastic pipe specifically comprises the following steps:

[0050] The first step is to add modified polypropylene, fillers, stabilizers, plasticizers, and antioxidants into the high-speed mixer, and pre-mix at a temperature of 50°C for 25 minutes;

[0051] The second step is to put the pre-mixed raw materials into a screw extruder, melt and extrude them at a temperature of 190-250°C, and cut them after setting the shape to obtain heat-resistant polypropylene plastic pipes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com